Buckle type connection structure of contactor

A connection structure and snap-on technology, applied in relays, electromagnetic relays, electromagnetic relay details and other directions, can solve the problems of increasing the cost of screws, difficult to automate assembly, and high costs, achieving simple mold structure design, saving mold costs, Easy core pulling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

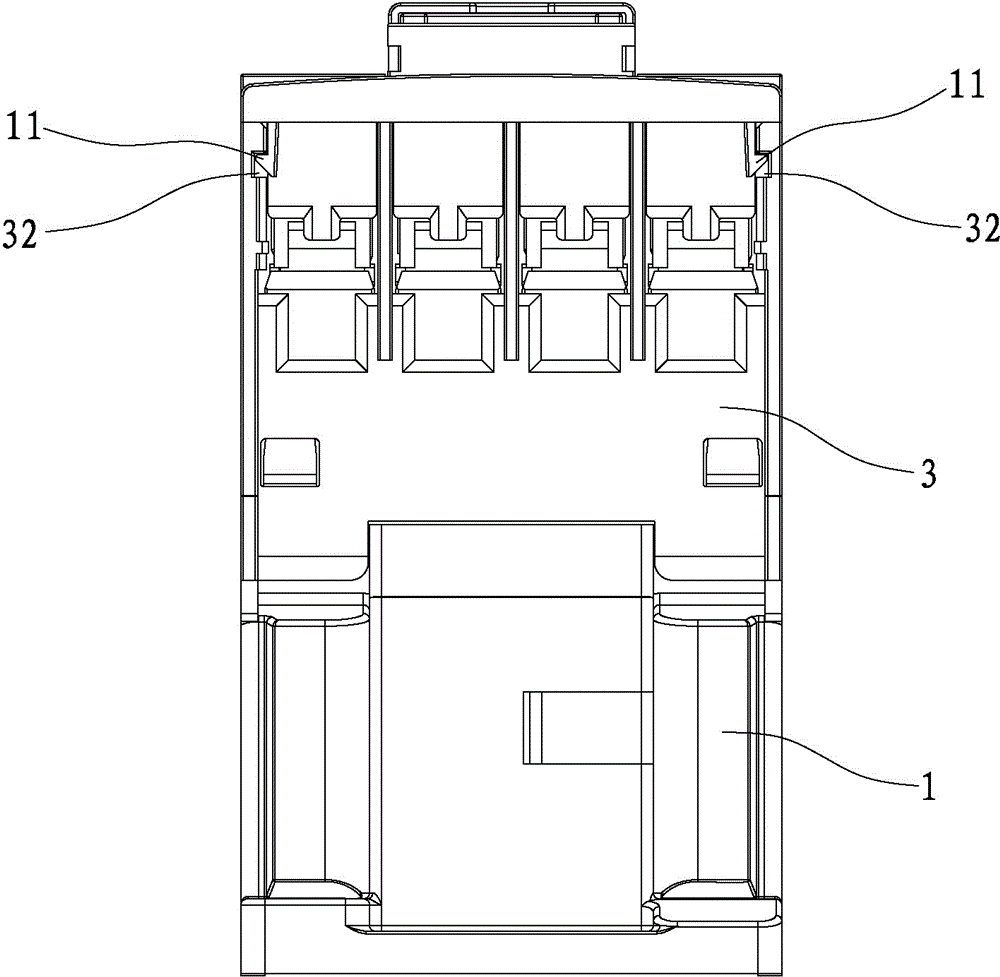

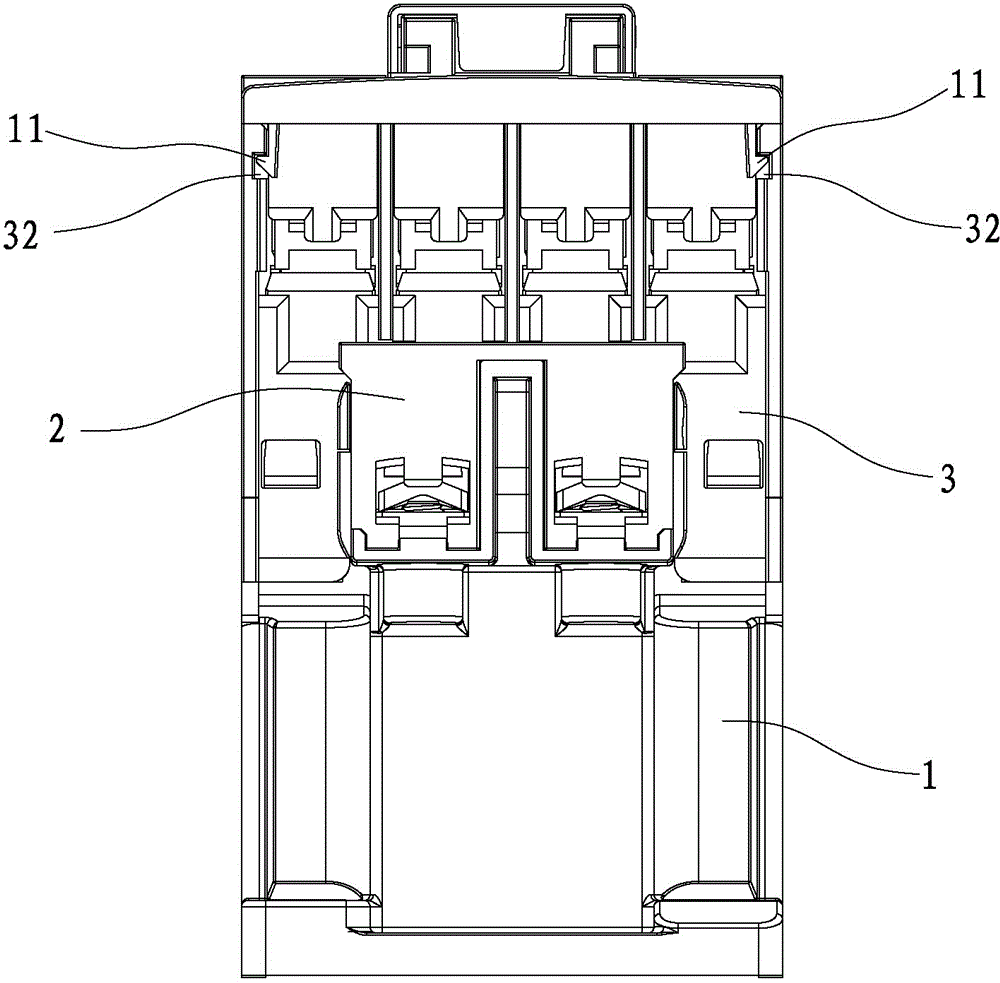

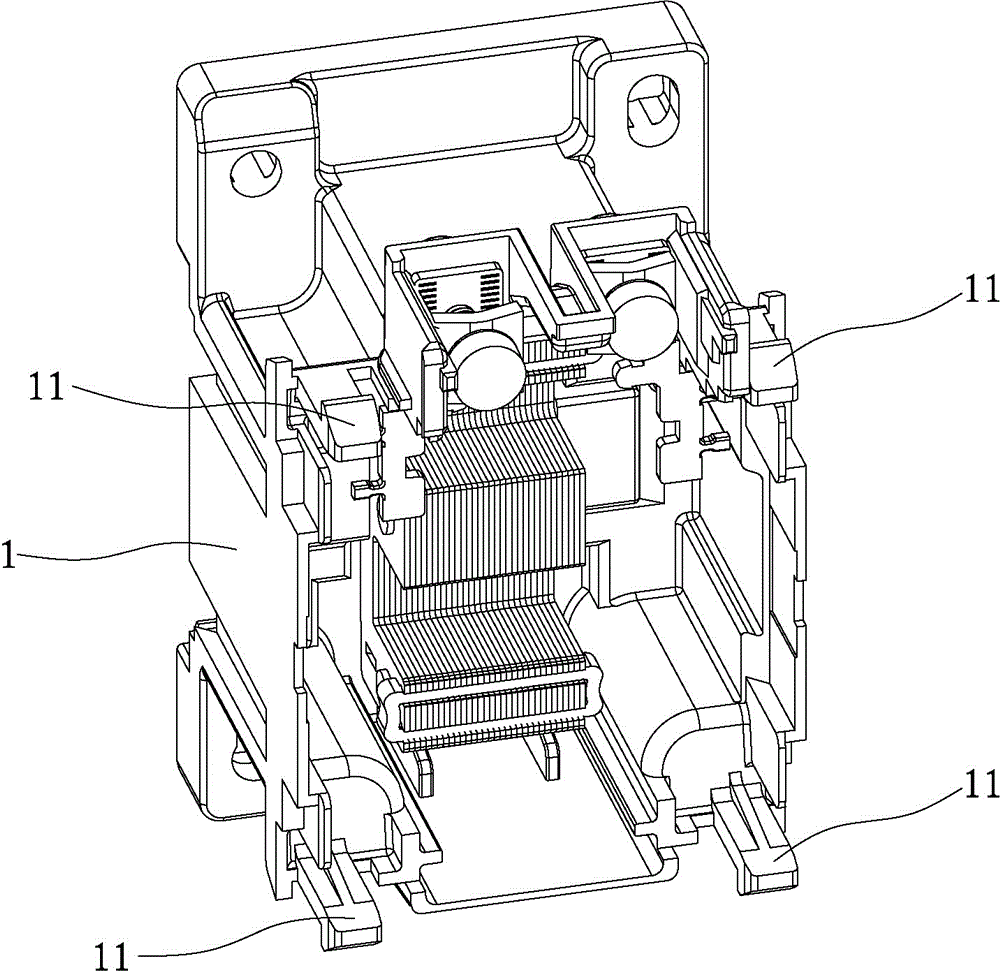

[0033] refer to Figure 1 to Figure 8 As shown, a snap-fit connection structure of a contactor disclosed by the present invention includes a base 1, a coil frame 2 and a body 3; an accommodation cavity 30 for installing contacts is formed on the body 3, and the accommodation cavity 30 The room is separated by side panels 31, such as Figure 3c shown.

[0034] like Figure 7 and Figure 8 As shown, the coil bobbin 2 and the body shell 3 are connected through the first buckle 4, as Figure 4 and Figure 5 shown, combined with Figure 3b and Figure 3c As shown, the first buckle 4 is connected to protrude and extend on the central side plate 31 of the body shell 3 to form a buckle 311, the central side plate 31 is located on the axial center line of the body shell 3, and at the end The part forms a buckle 311, correspondingly, as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com