One-mold two-part injection mold

A technique for injection molds and fixed molds, which is applied in the field of one-piece two-piece injection molds, can solve problems such as difficulty in maintaining consistency, and achieve the effect of consistent color and texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further described in conjunction with the following examples.

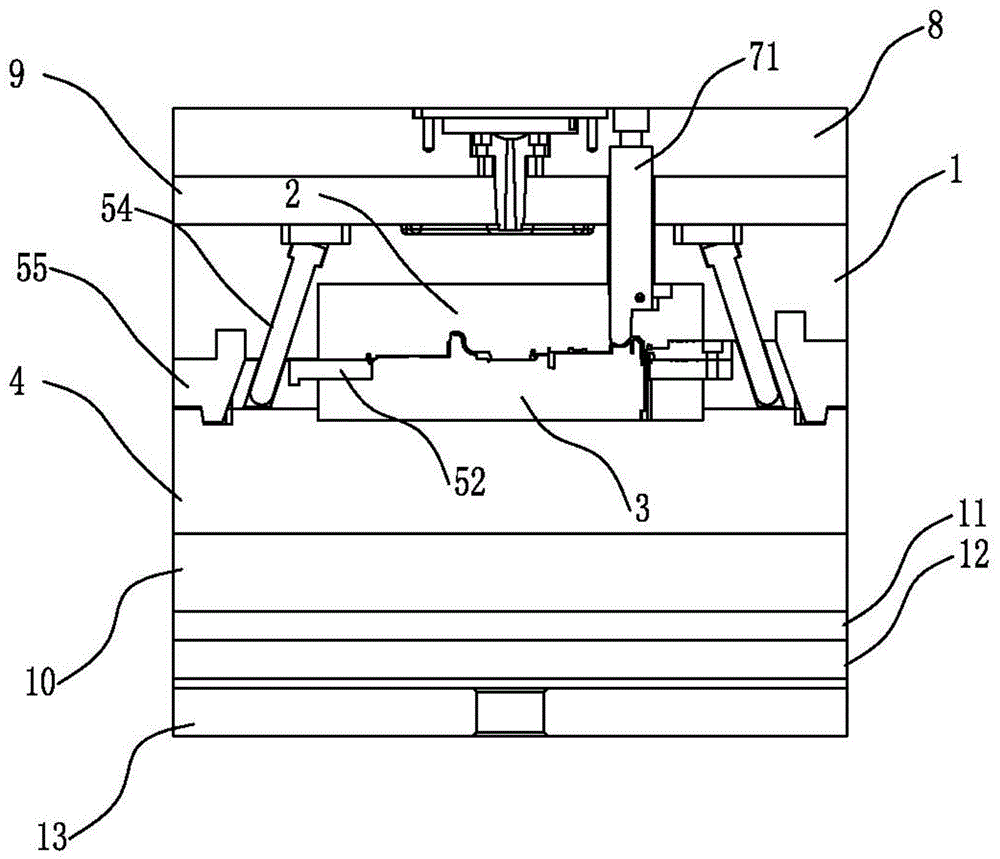

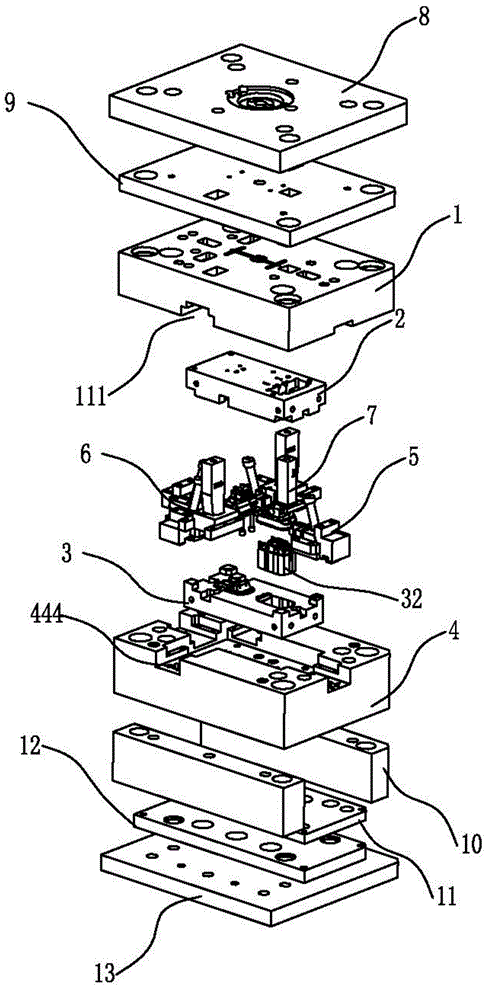

[0037] The one-die two-piece injection mold that the present invention creates, as figure 1 with figure 2 As shown, it includes fixed mold bottom plate 8, stripper plate 9, fixed mold plate 1, fixed mold core 2, movable mold core 3, movable mold plate 4, square iron 10, face needle plate 11, bottom needle plate 12 and movable mold plate arranged in sequence. A first row assembly 5 , a second row assembly 6 and a third row assembly 7 are arranged between the mold bottom plate 13 , the fixed template 1 and the movable template 4 .

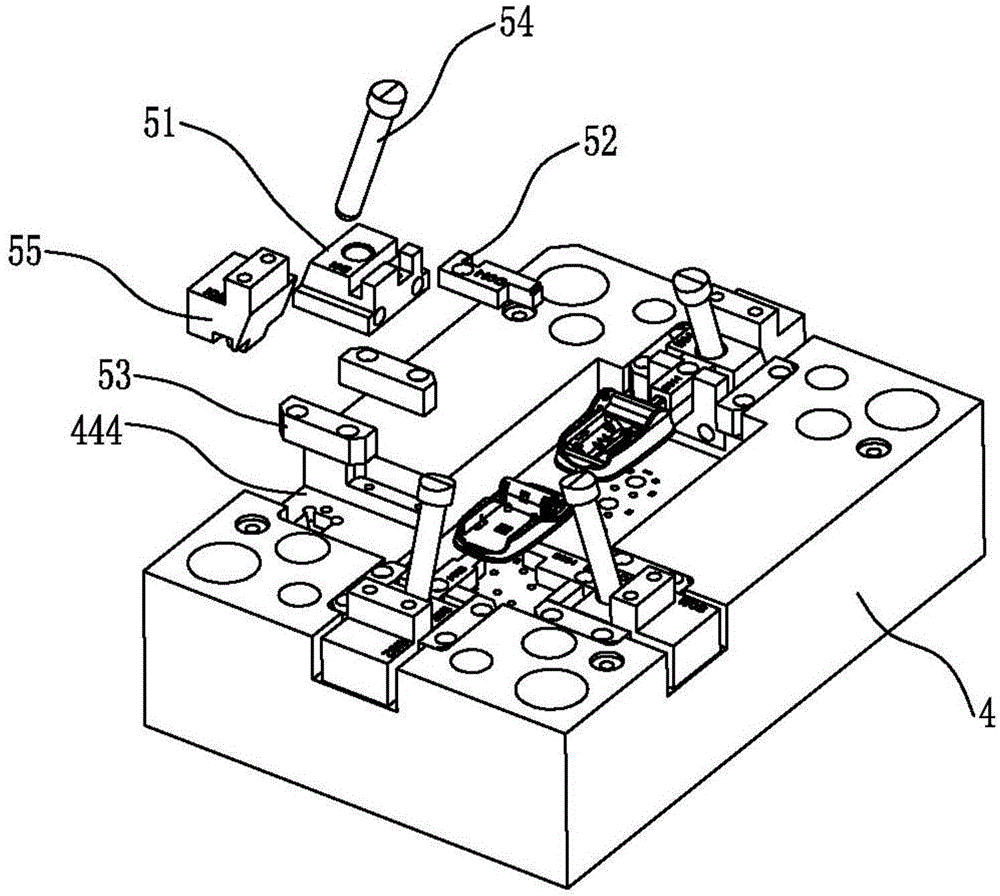

[0038] Such as Figure 7 As shown, a first cavity 21 and a second cavity 22 are arranged side by side on the fixed mold core 2, as Image 6 As shown, the first core 31 and the second core 32 respectively corresponding to the first cavity 21 and the second cavity 22 are arranged side by side on the movable mold core 3, preferably, the second core 32 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com