Flexible demolding device

A flexible and demolding technology, applied in the field of injection mold equipment, can solve the problems of cumbersome demolding process, long molding cycle, low production efficiency, etc., to reduce demolding time, reduce friction and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

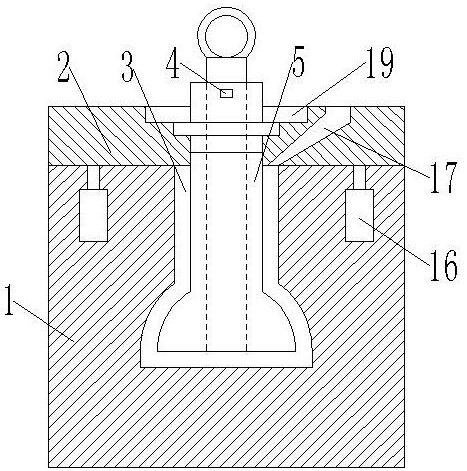

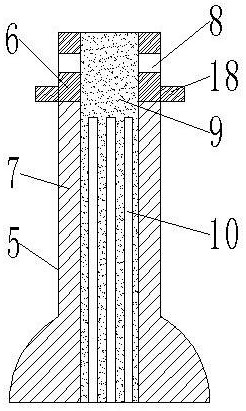

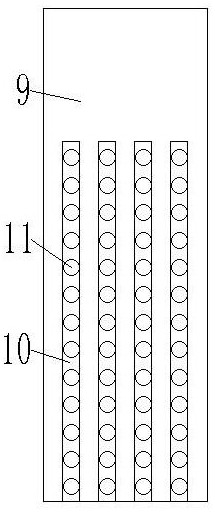

[0045] like Figure 1-5 As shown, a flexible demoulding device includes a concave mold 1 and a convex mold 2, the concave mold 1 is arranged corresponding to the convex mold 2, the convex mold 2 is provided with an injection port 17, and the concave mold 1 is provided with a The cavity 3, the injection port 17 communicates with the inner side of the cavity 3, the punch 2 is provided with a core 5, the core 5 is located inside the cavity 3, and the core 5 is used with the cavity 3 In order to form plastic products, the core 5 is provided with a through hole, and a metal core 9 is arranged in the through hole. During the injection molding process, the metal core 9 is used to provide a supporting force to make the core 5 . Keeping a certain shape and not easily deformed, a gap is set between the metal core 9 and the inner wall of the core 5, and a plurality of miniature steel balls 11 are arranged in the gap. The filling and pressure holding stages can ensure the dimensional acc...

Embodiment 2

[0051] Combined with Example 1 and Figure 5 As shown, the trajectory cosine function curve of the channel 10, the channel 10 is uniformly arranged on the surface of the metal core 9, and the trajectory of the channel 10 is set as a cosine function curve, which extends the movement distance of the miniature steel ball 11 during core pulling, The interference friction between the adjacent miniature steel balls 11 is avoided, and the metal core 9 can be pulled out smoothly. The cosine function of the channel trajectory is y=a·cosα, where a is the correlation coefficient. The diameter of the core 5 is R, and the diameter of the through hole on the core 5 is r, then a=β·r / R, where β is the correction coefficient, the value range is 0.89-0.93, when the value of β When the range is less than 0.89, the curvature of the channel track is small. When the metal core 9 is drawn out, the micro steel balls 11 are prone to sliding, and friction occurs between the micro steel balls 11, which...

Embodiment 3

[0054] In combination with the second embodiment, the cosine function of the channel trajectory is y=a·cosα, which can be further described as y=β·r / R·cosα, where β is a correction coefficient, and the value range is 0.89-0.97, and R is taken as 20mm, r is 10mm, carry out the insertion and extraction experiment of the metal core 9, and test the smoothness of the insertion and extraction process. In order to simplify the experiment, measure the change curve of the force used in the process of inserting and pulling out the metal core 9, and the change curve of the force fluctuates. When it is larger, it means that when the metal core is pulled out, there is interference between the internal micro steel balls, which affects the movement of the micro steel balls. Collect the data of the force change curve, collect 10 groups of its smaller values, take the average a1, collect 10 groups of its larger values, take the average value a2, and use k=a1 / a2 to represent the change of force,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com