Patents

Literature

124results about How to "Solve the demoulding problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

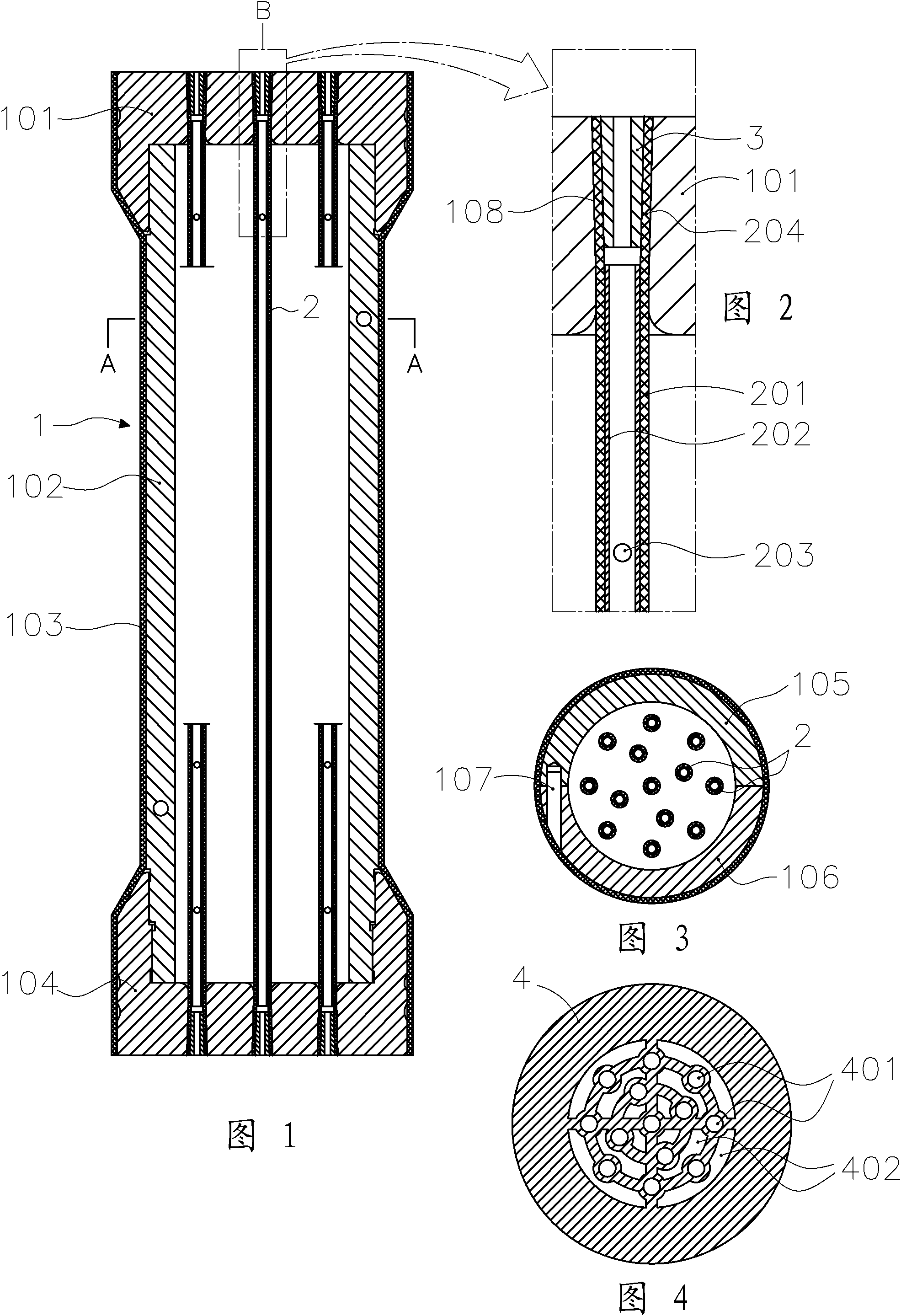

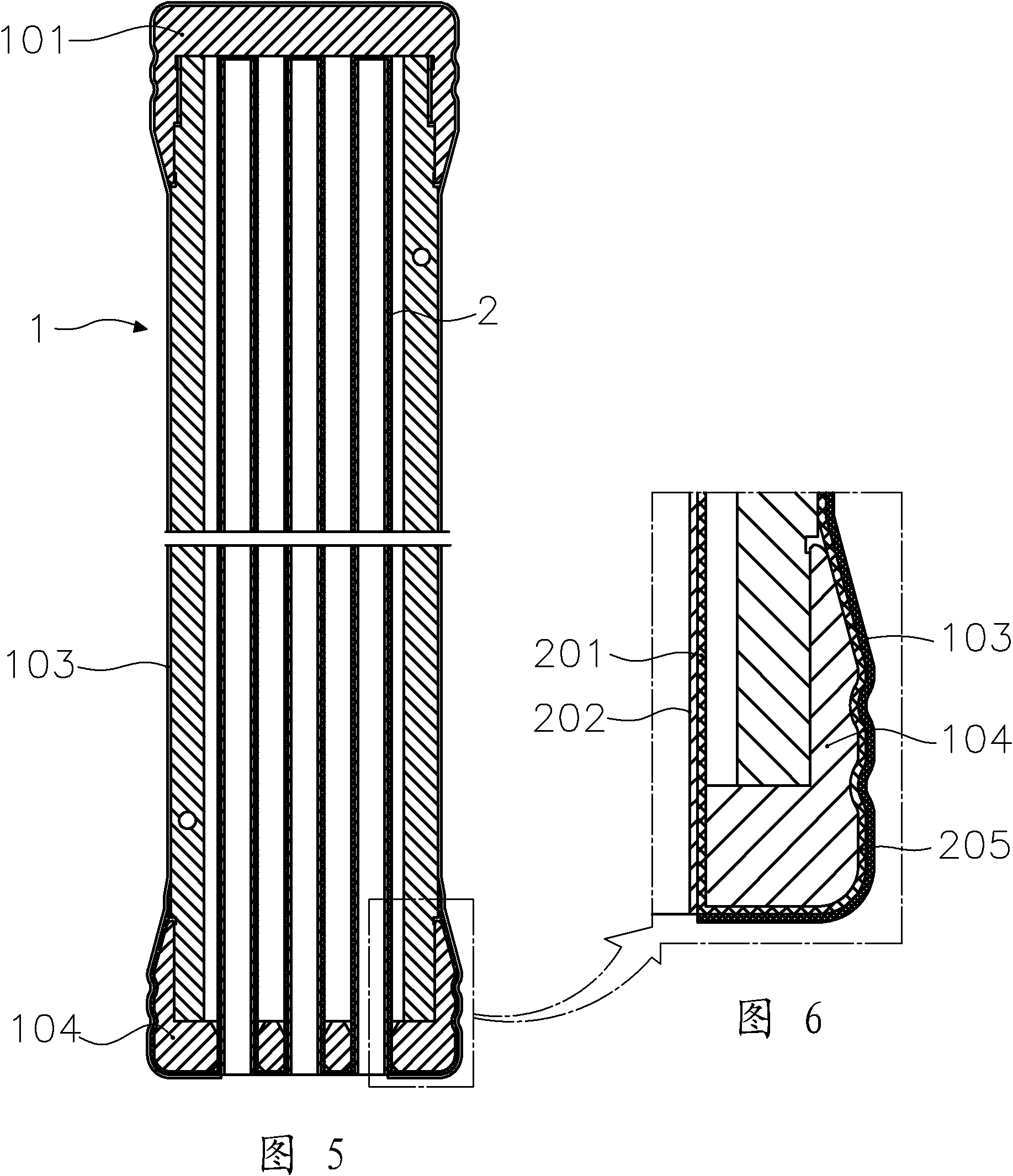

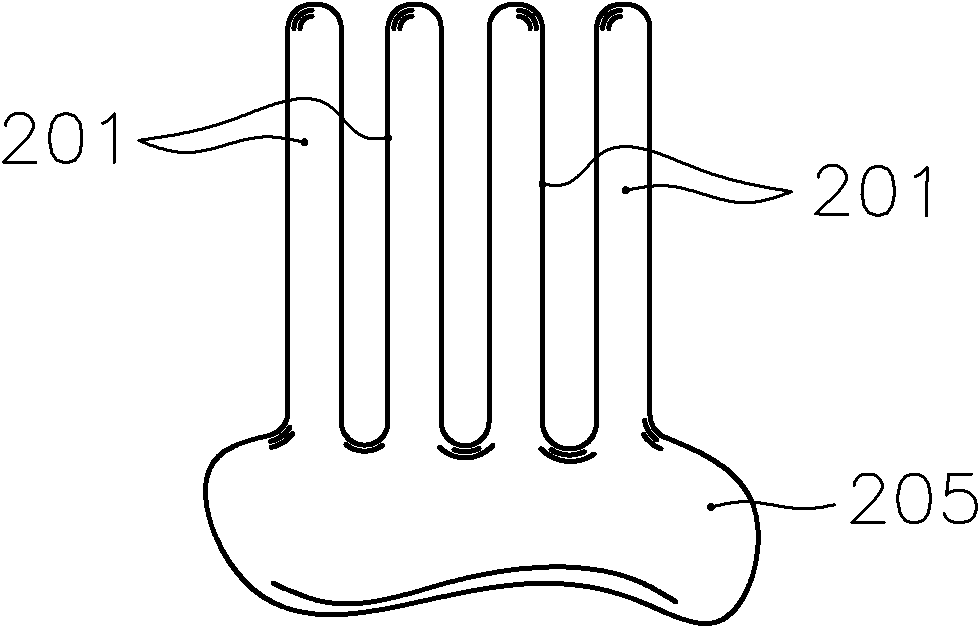

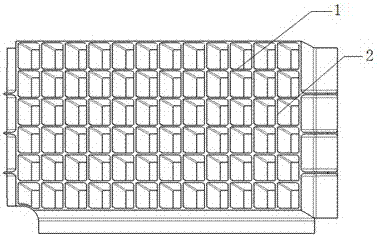

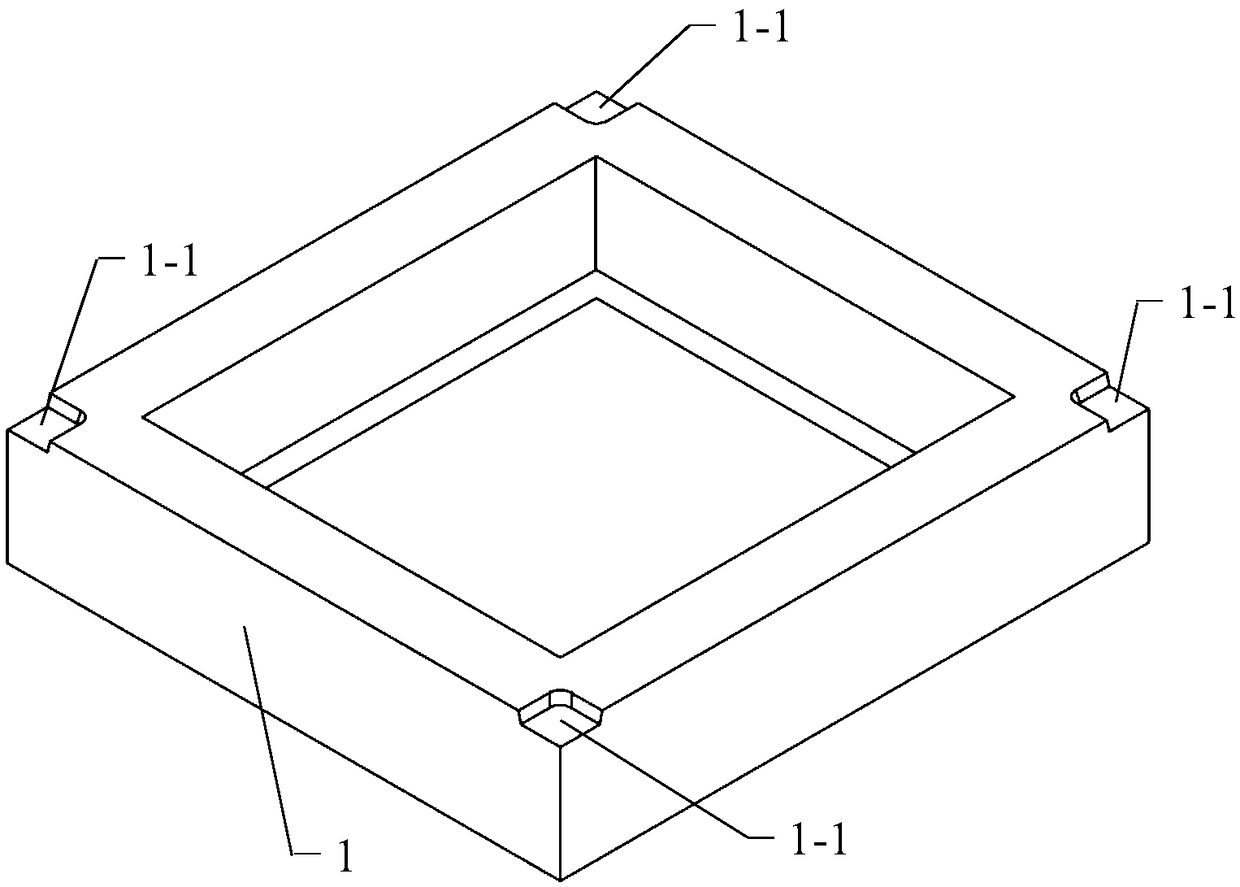

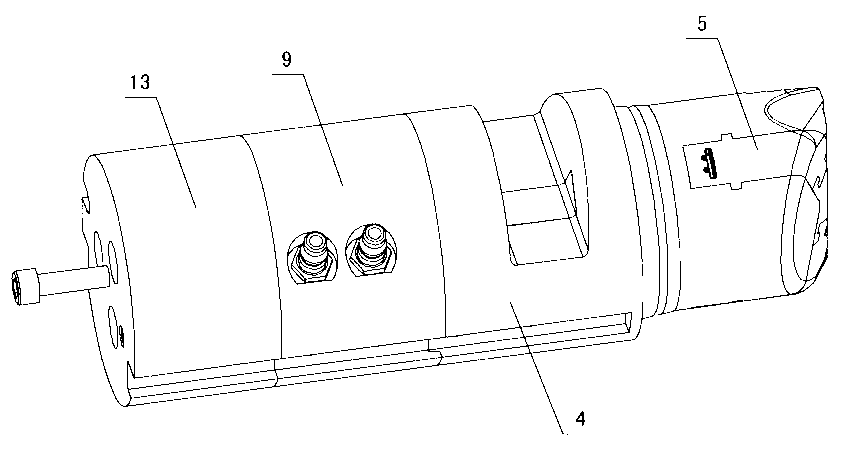

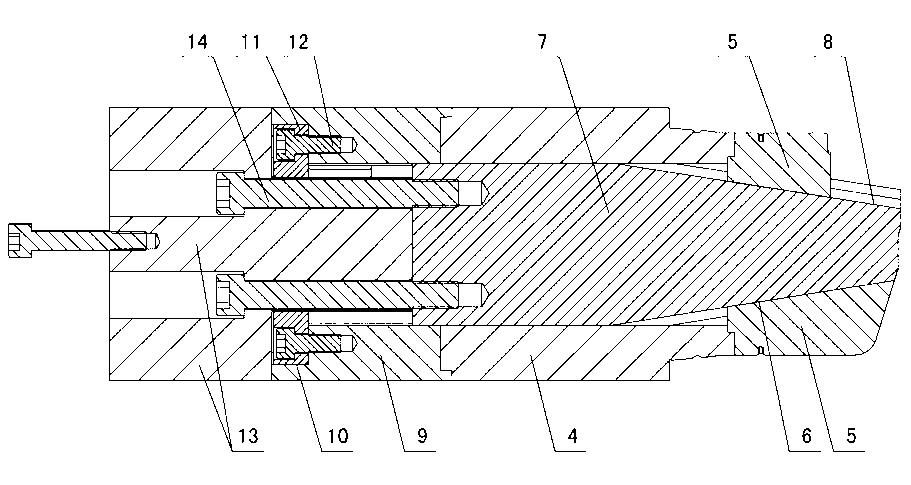

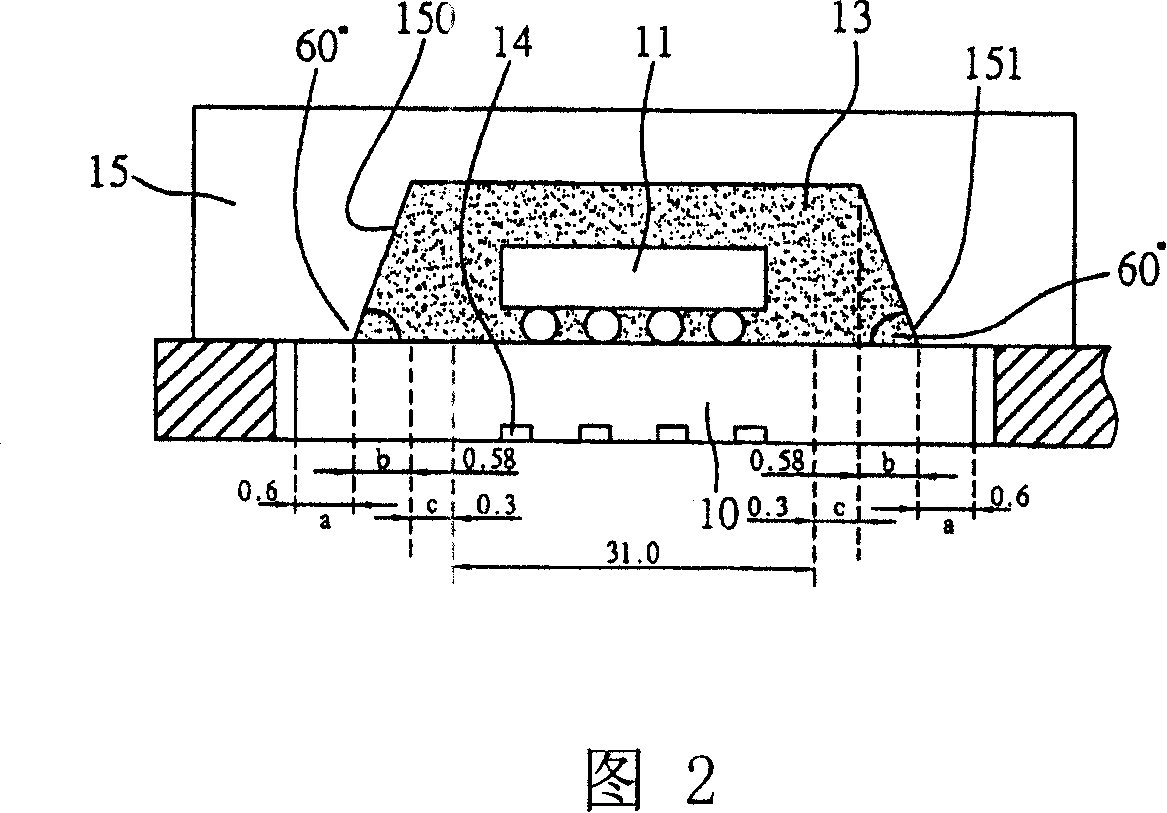

Mould for forming multi-channel filter element and method for forming intermetallic compound multi-channel filter element

The invention discloses a mould which is easy to demould a core rod and used for forming a multi-channel filter element. The mould comprises an outer mould and multiple core rods mounted in the outer mould, wherein each core rod is composed of a support tube and an elastic sleeve sleeved on the support tube; multiple through holes are formed on the wall, on which the elastic sleeve is sleeved, ofeach support tube; and at least one end of each core rod is an open end communicated with the exterior of the mould. The support tubes can support the core rods so as to accurately position the core rods in the outer mould, thereby basically ensuring the true position after inner bores of a filter element are formed and improving the entire quality of the filter element; when the elastic sleeve is formed, the elastic sleeve extrudes powder filled between the outer mould and the core rods from inside to outside so as to carry out compression moulding on the powder; and during demoulding, the elastic sleeve retracts so as to demould the core rods. The invention also discloses a method for forming an intermetallic compound multi-channel filter element, wherein an intermetallic compound material filled in the cavity of the mould is pressed into the multi-channel filter element by use of an isostatic pressing technology. By utilizing the method, the cold isostatic pressing manufacturing ofthe intermetallic compound multi-channel filter element is achieved.

Owner:CHENGDU INTERMENT TECH

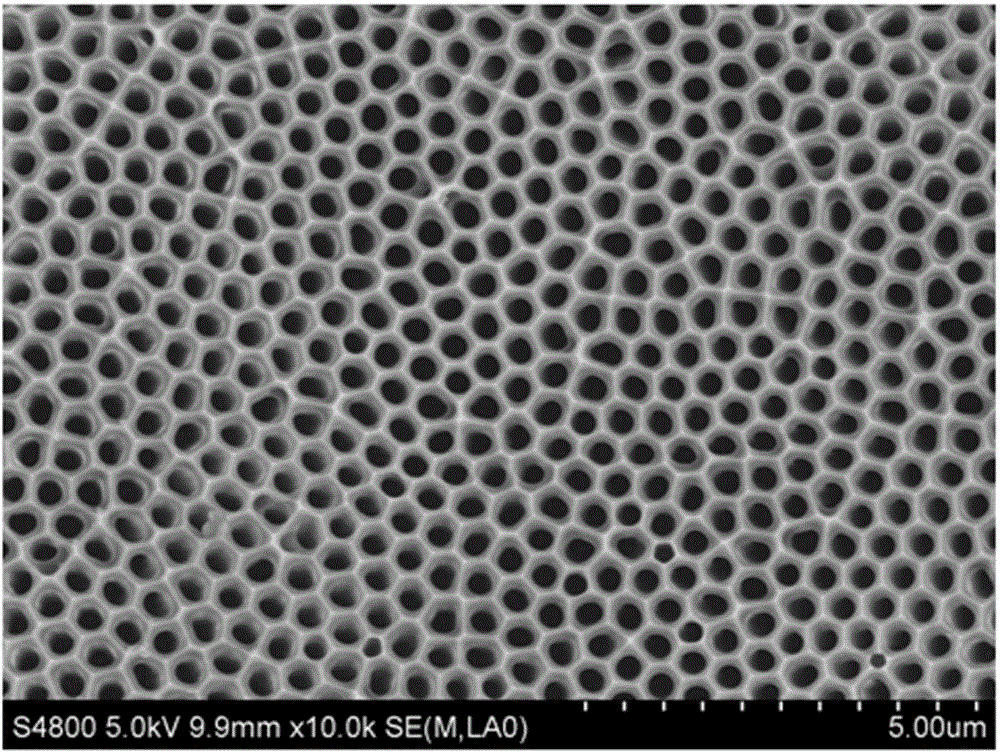

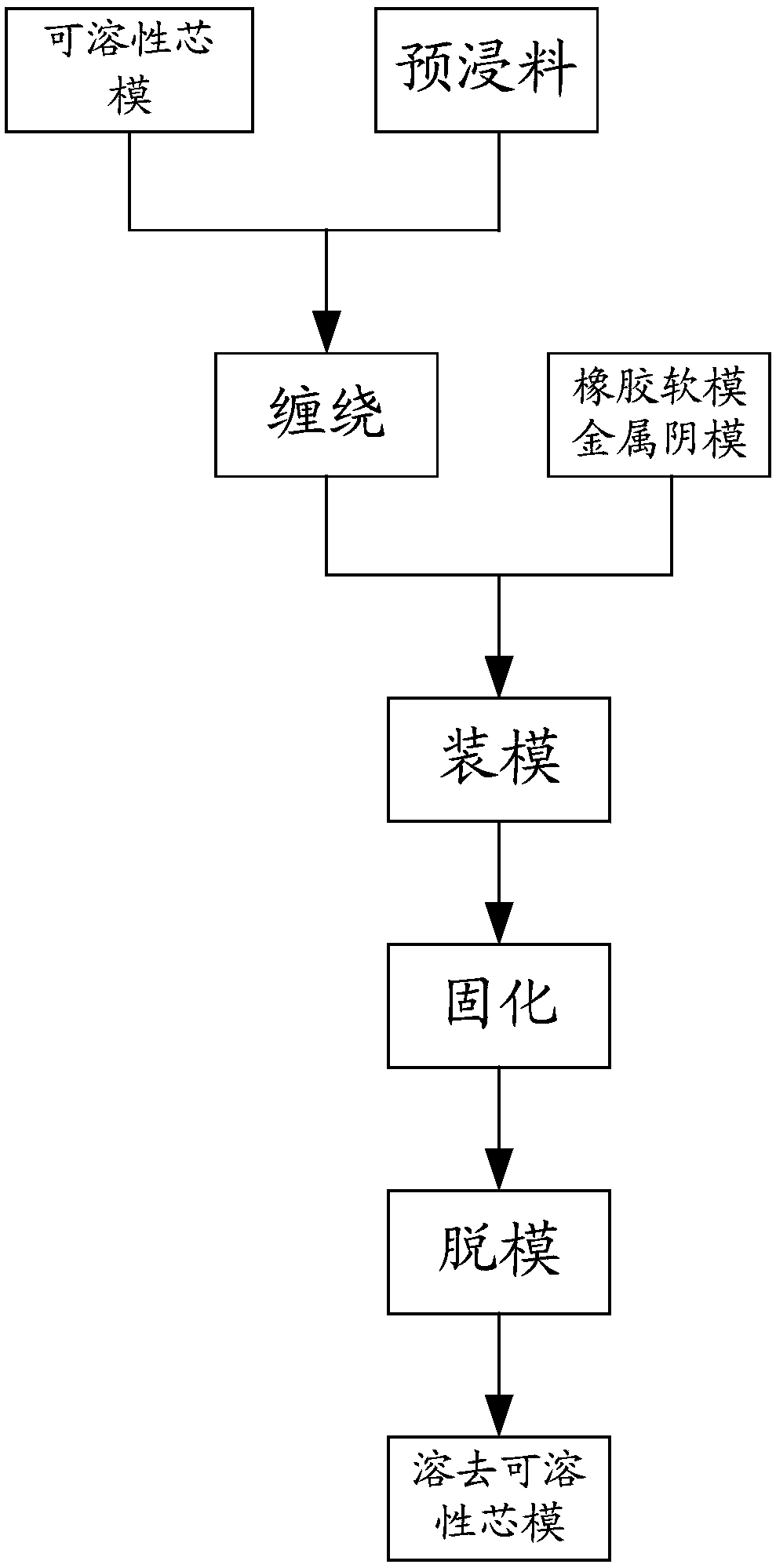

Preparation method of SQRTM forming process carbon fiber grating based on water-soluble core

InactiveCN106853694ASolve the demoulding problemReduce manufacturing costDomestic articlesAviationFiber

The invention relates to a method for preparing a carbon fiber grid based on the SQRTM molding process of a water-soluble core. The method first prepares a grid core with a soluble material, and lays carbon fiber prepreg on it, and adopts SQRTM molding The process is to solidify the part, and in the later stage, the water-soluble mandrel is dissolved by tap water under a certain pressure, and the grille part is obtained by demoulding. This method solves the demoulding problem of complex parts with high curvature of the grid. The SQRTM process adopted, combined with the prepreg process and liquid RTM molding technology, effectively reduces the manufacturing cost and guarantees The high performance requirements of the parts are met. This invention can provide a feasible solution for composite aviation complex curvature parts.

Owner:HENGSHEN

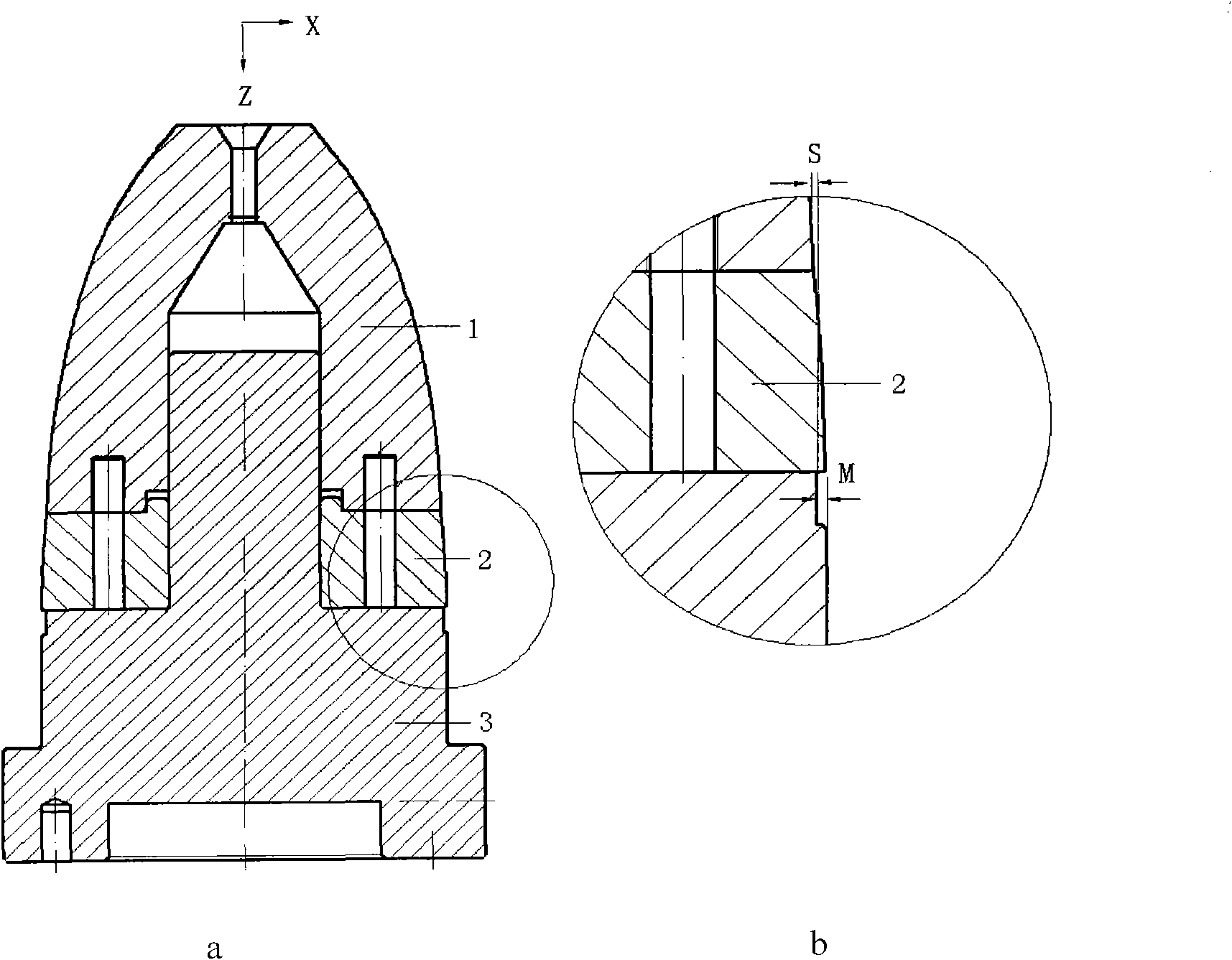

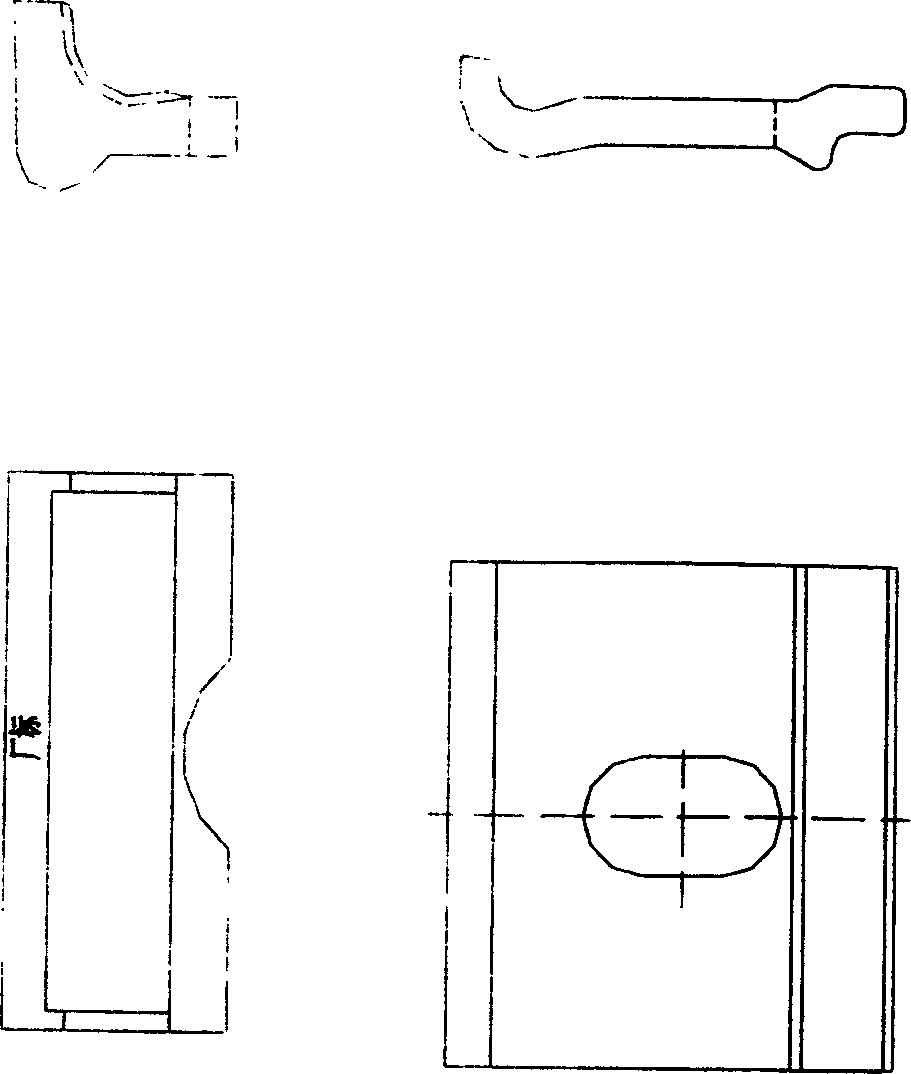

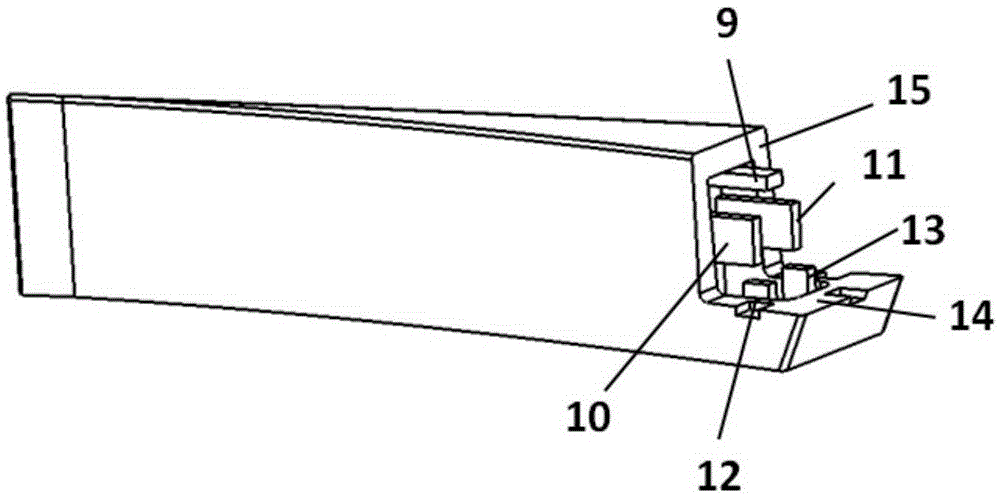

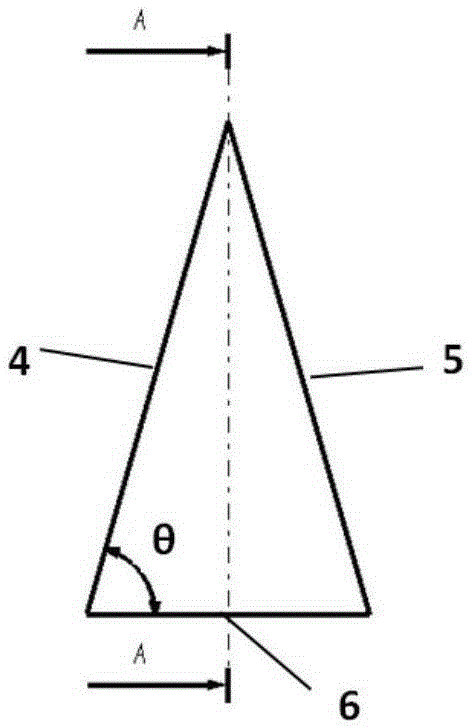

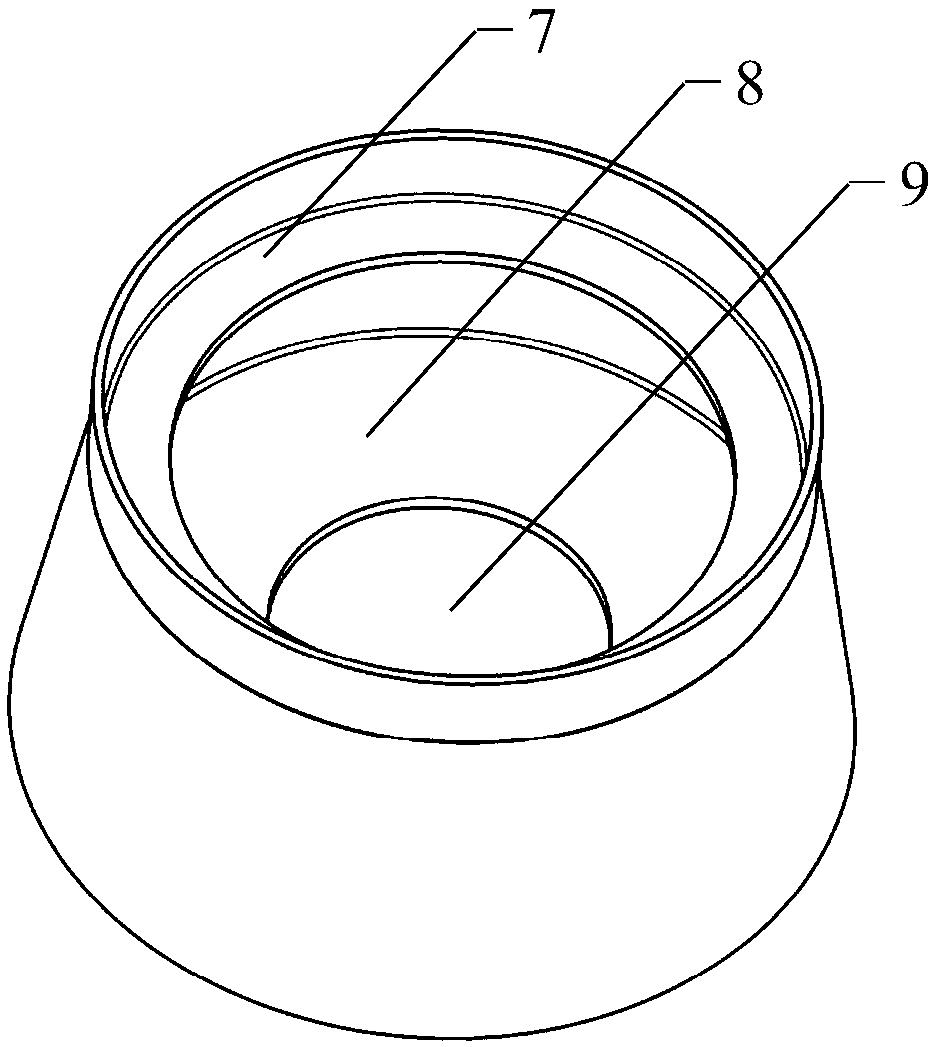

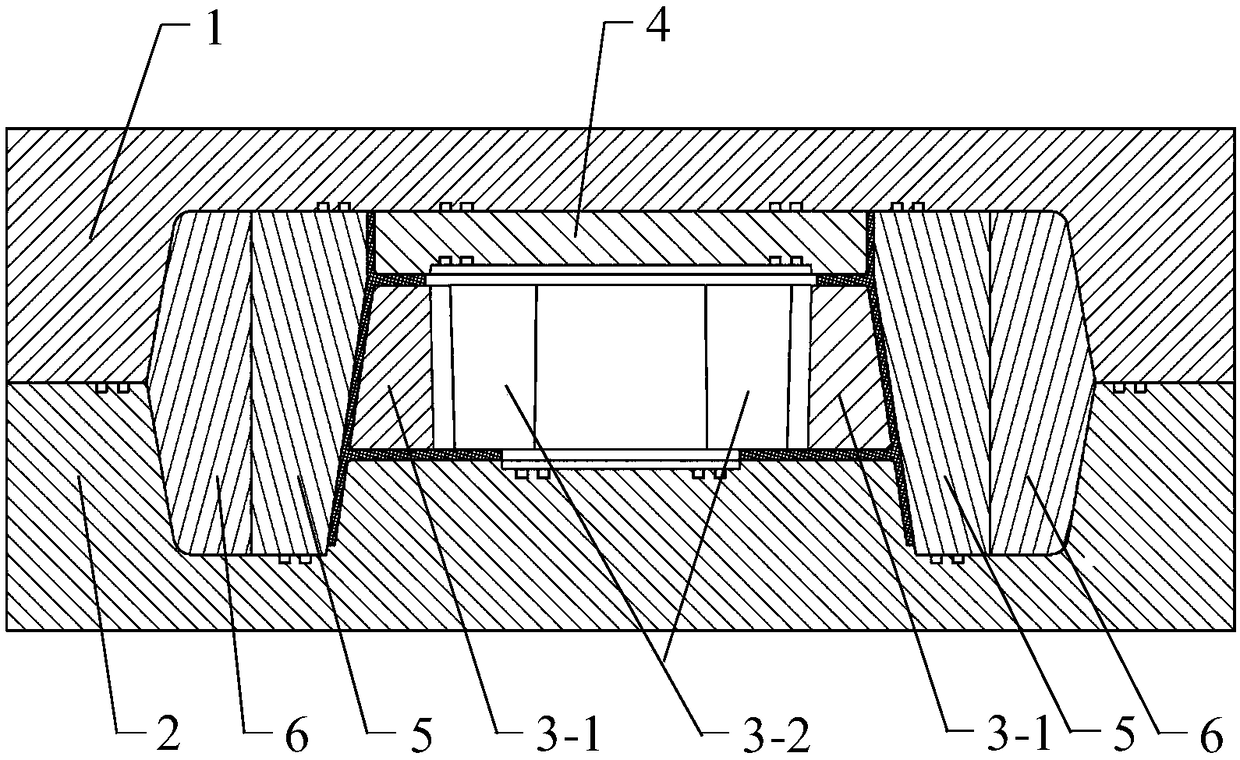

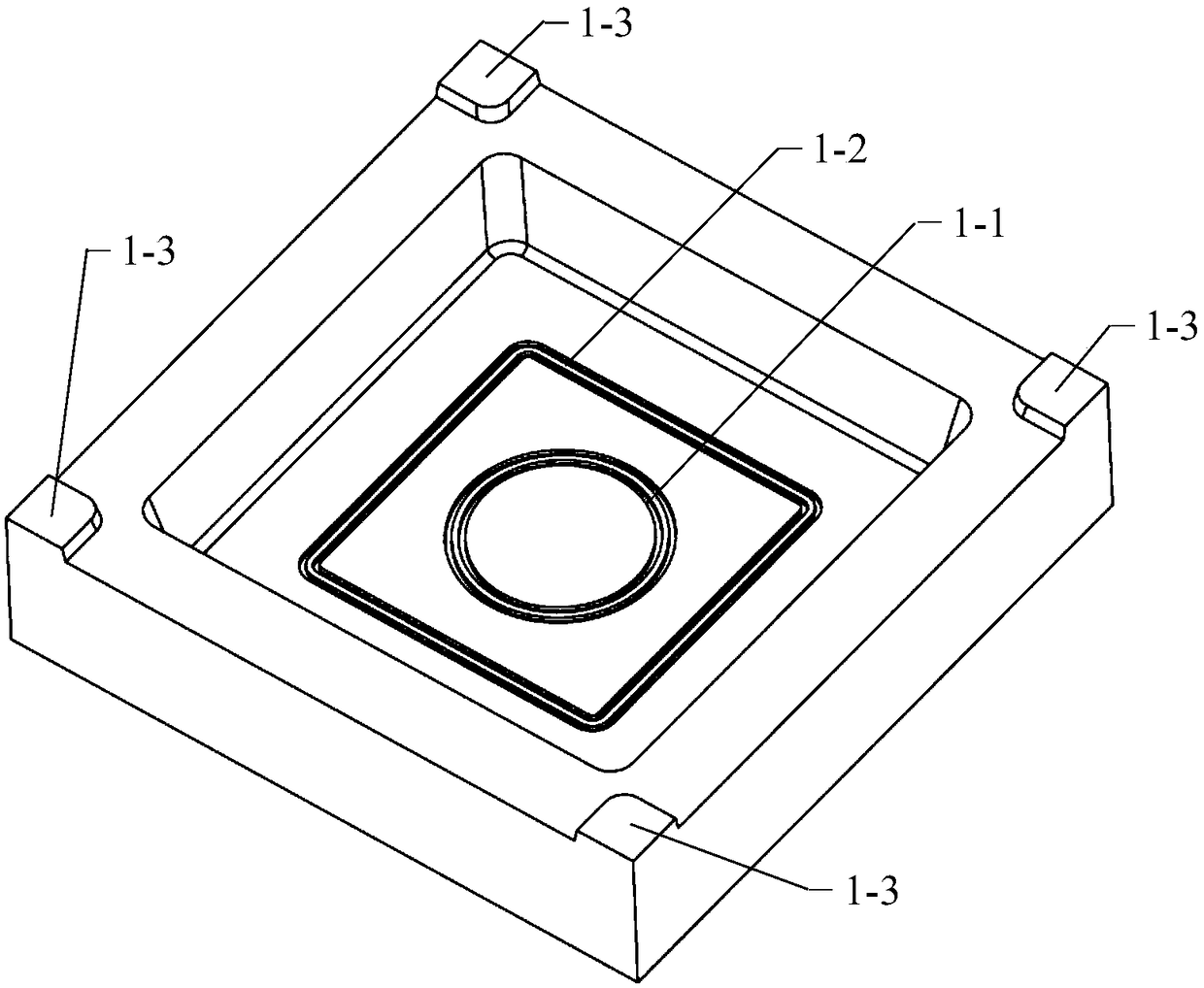

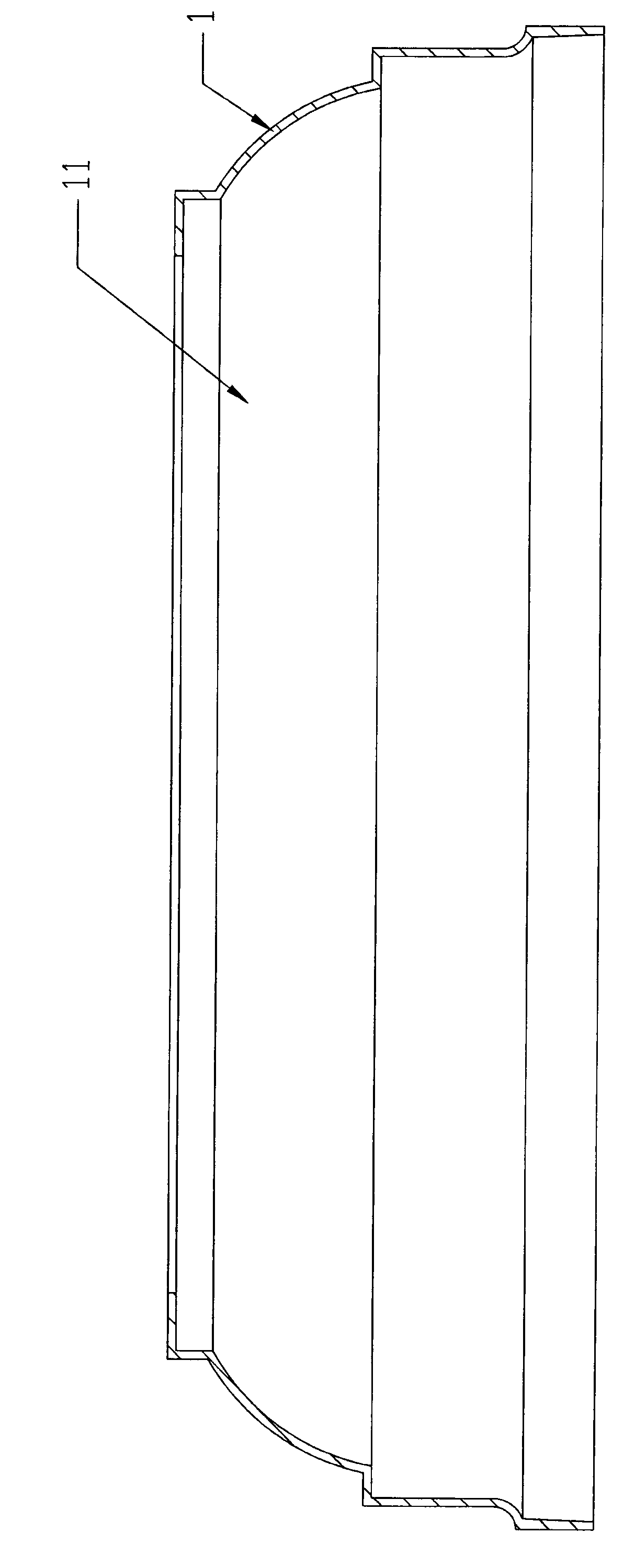

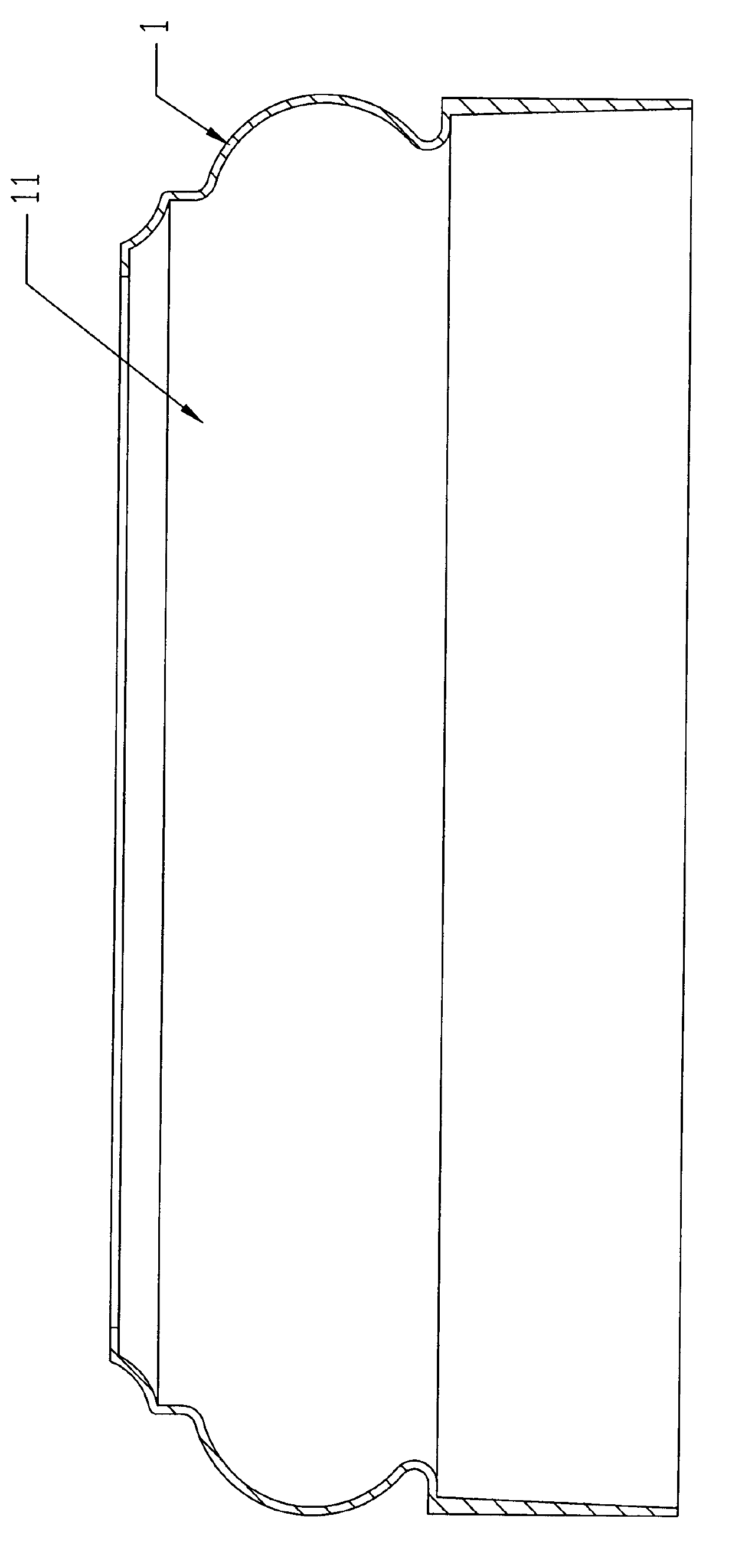

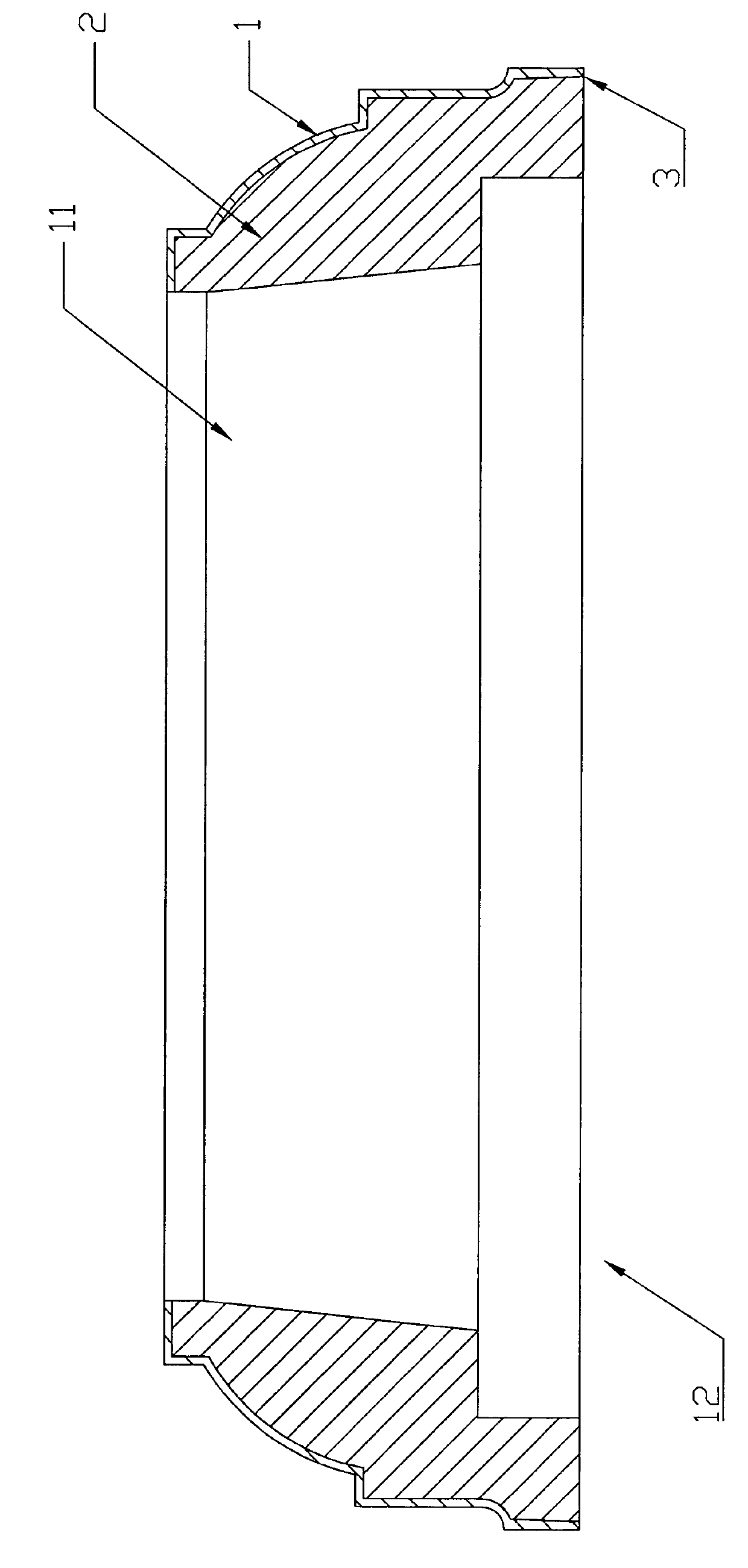

Core mold for spinning and forming large-size complex curved generatrix thin-wall member with transverse inner ribs

The invention relates to a core mold for spinning and forming a large-size complex curved generatrix thin-wall member with transverse inner ribs, wherein a clamping plate is positioned between the head part and tail part of the core mold and sheathed on a positioning shaft at the tail part of the core mold; the clamping plate and the head part of the core mold are hollow shells, and the clamping plate and the head part of the core mold take the shape of a curved generatrix; an aperture of an inner hole at one end of the head part of the core mold is an assembling hole of the positioning shaftat the tail part of the core mold; on the end surface of the core mold, a circle of groove is arranged around the assembling hole at the tail part of the core mold, and used for positioning the clamping plate; a screw hole for hanging the core mold is arranged at the other end of the core mold; and the assembling hole, at the head part of the core mold, of the positioning shaft at the tail part of the core mold, and a hanging hole at the other end of the head part of the core mold are in tapered transition. All the parts of the core mold are rotary parts, and the combined horizontal and longitudinal split technology is adopted for the core mold, therefore, the large-size complex curved generatrix thin-wall members with the transverse inner ribs can be demolded smoothly after spinning and forming. The core mold has the characteristics of easiness of processing and assembly, and low manufacturing cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

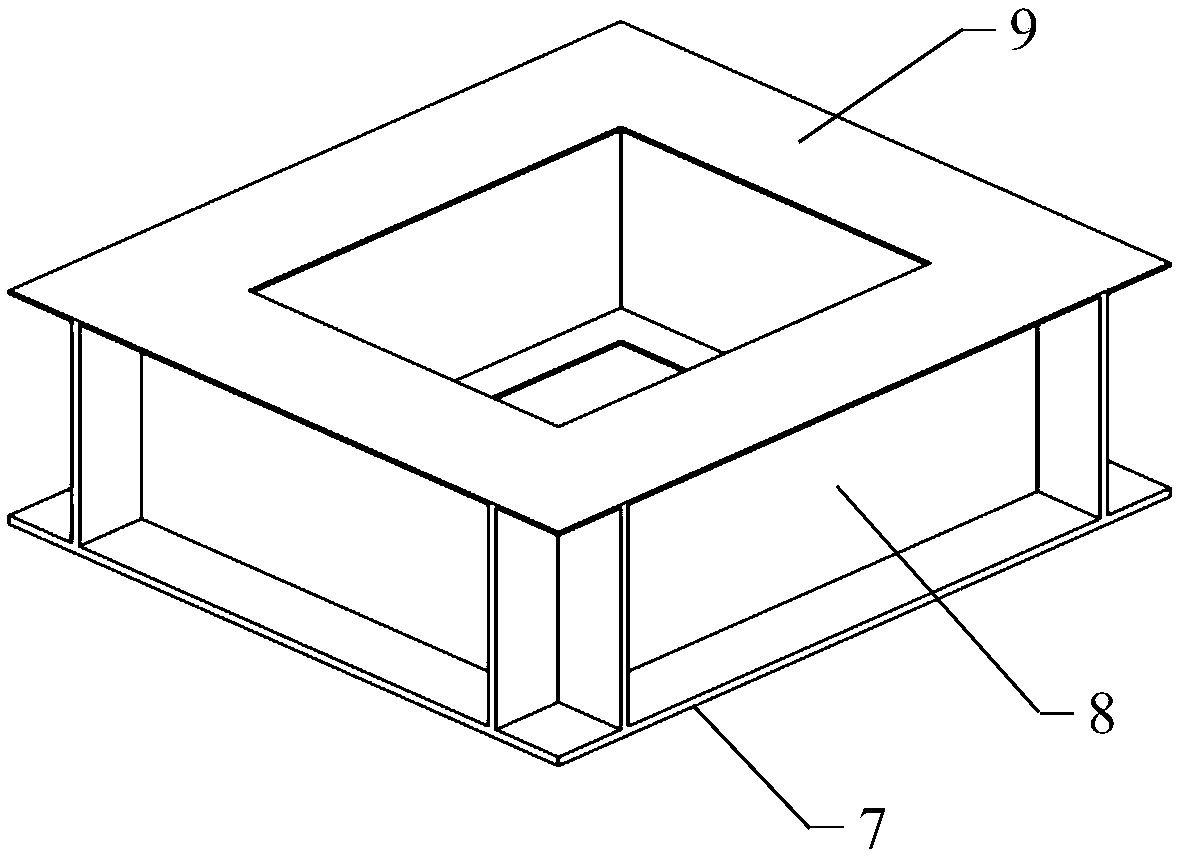

Testing device for resin matrix composite material heat mold pressing curing deformation and manufacturing and using method thereof

ActiveCN104315990AReduce difficultyAvoid damageUsing optical meansSpecial purpose recording/indication apparatusTemperature resistanceStrain sensor

The invention relates to a testing device for resin matrix composite material hot mold pressing curing deformation and a manufacturing and using method thereof. The testing device comprises resin matrix composite material prepreg and FBG sensors arranged in the prepreg. The method comprises the steps that the FBG sensors are laid on the nth layer in the fiber axial direction to be used as strain sensors, reference sensors for temperature compensation are laid on the nth layer or the (n+1)th layer or the (n-1)th layer, lead grooves are formed in a mold side wall frame board, the mold side wall frame board is coated with a high temperature resistance polymer film, leads of the sensors are led out of the lead grooves and connected with a signal receiver, a mold is closed, hot press molding is carried out, and curing forming on-line real-time monitoring is achieved. The problems that during composite material heat mold pressing curing deformation monitoring, grid regions are fragile and prone to breakage, and monitoring signals cannot be effectively transmitted if leading is inappropriate in a closed full-rigid hot mold pressing mold are solved, and meanwhile the problem that a composite material structure part with built-in FBG sensors is hard to break away from the full-rigid mold is solved.

Owner:SHANDONG UNIV

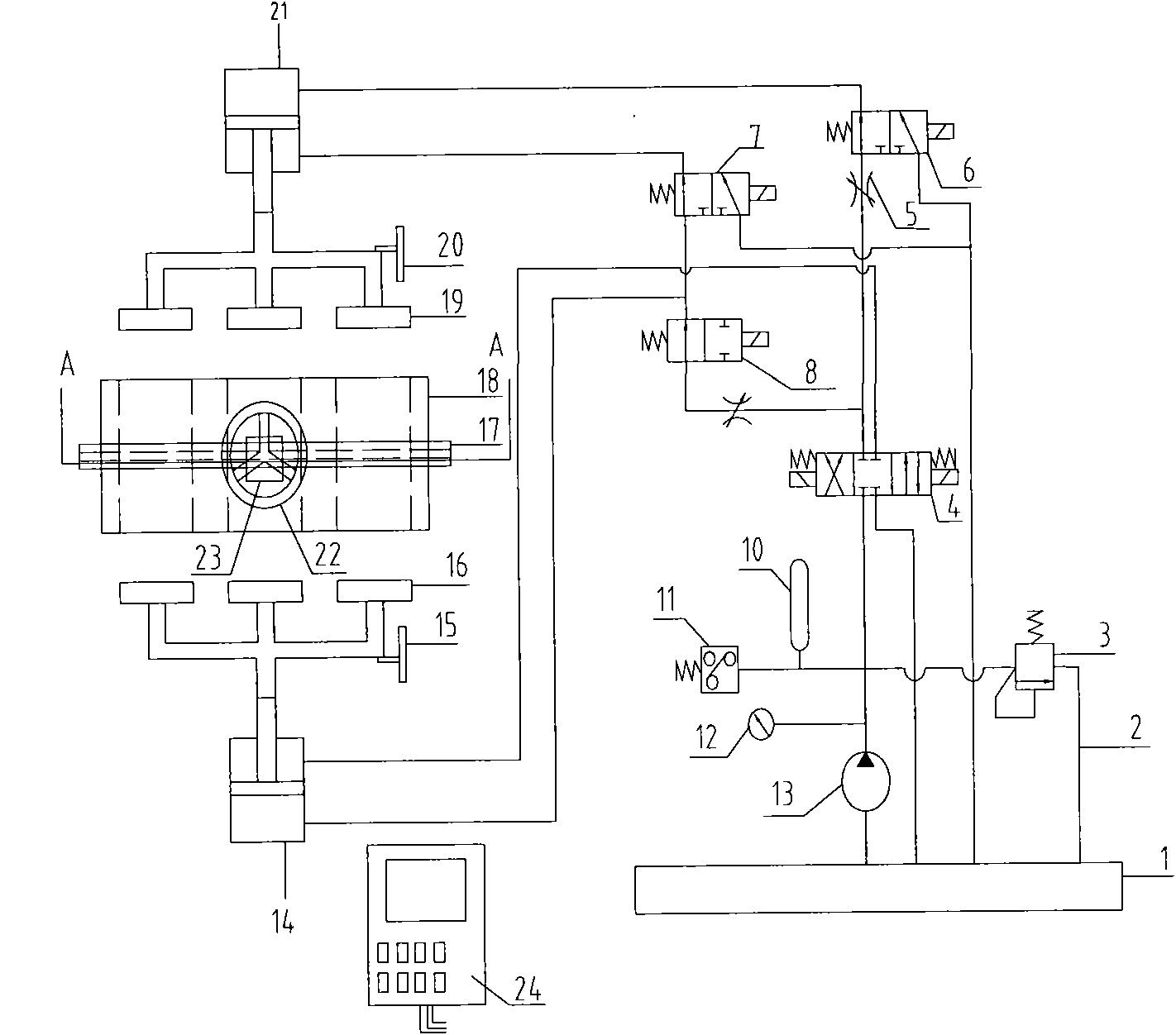

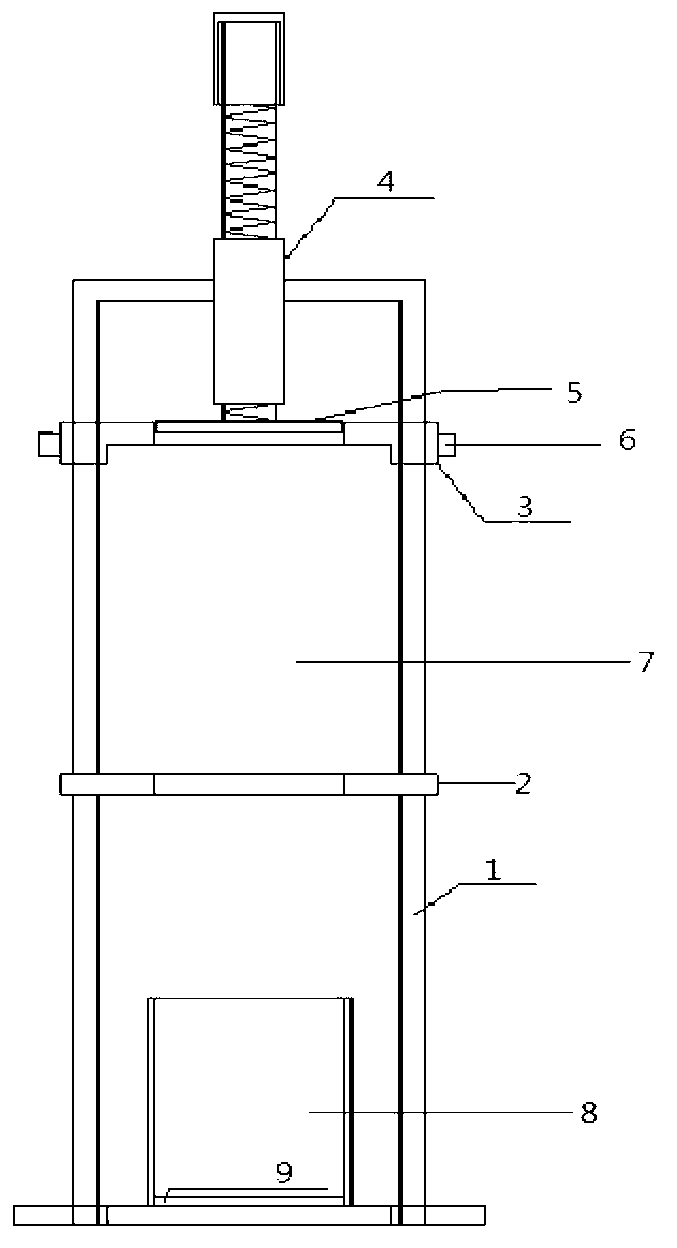

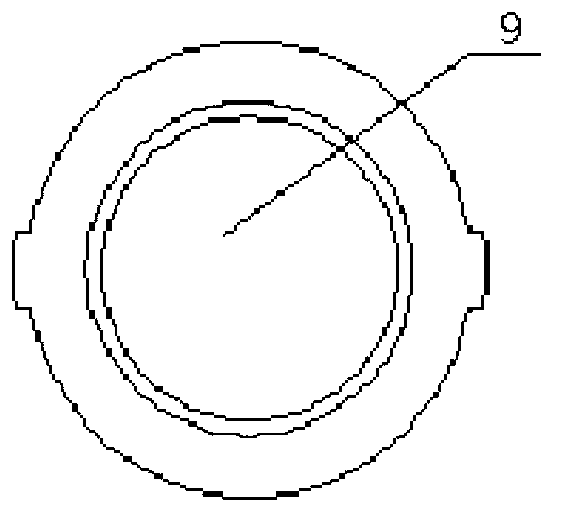

Sample preparing and demoulding integrated instrument

InactiveCN101863075AControl automatic demouldingAddressing inhomogeneityDischarging arrangementHigh densityEngineering

The invention discloses a sample preparing and demoulding integrated instrument. The integrated instrument at least comprises a driving mechanism, a transmission mechanism, a base and a material loading die which is arranged on the base, wherein an upper pressure plate is arranged above the material loading die; a lower pressure plate is arranged below the material loading die; and both the upper pressure plate and the lower pressure plate are connected with the transmission mechanism. The integrated instrument has the advantages of capability of preparing a plurality of test pieces at the same time, and realizing a mode of bidirectional vertical pressurization, simple operation and using, certain automation degree, convenient maintaining, capability of preparing geotechnical samples with higher density and uniform water content, and high efficiency of sample preparation.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

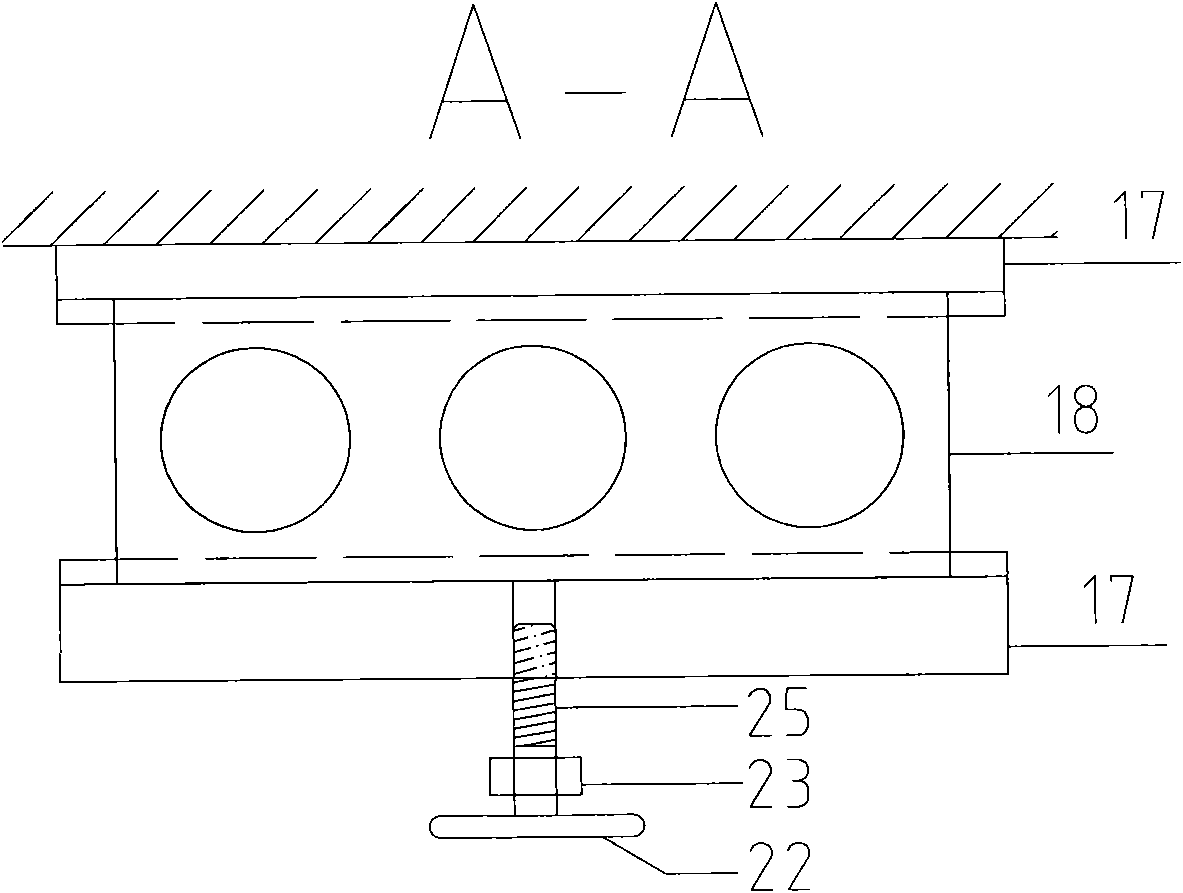

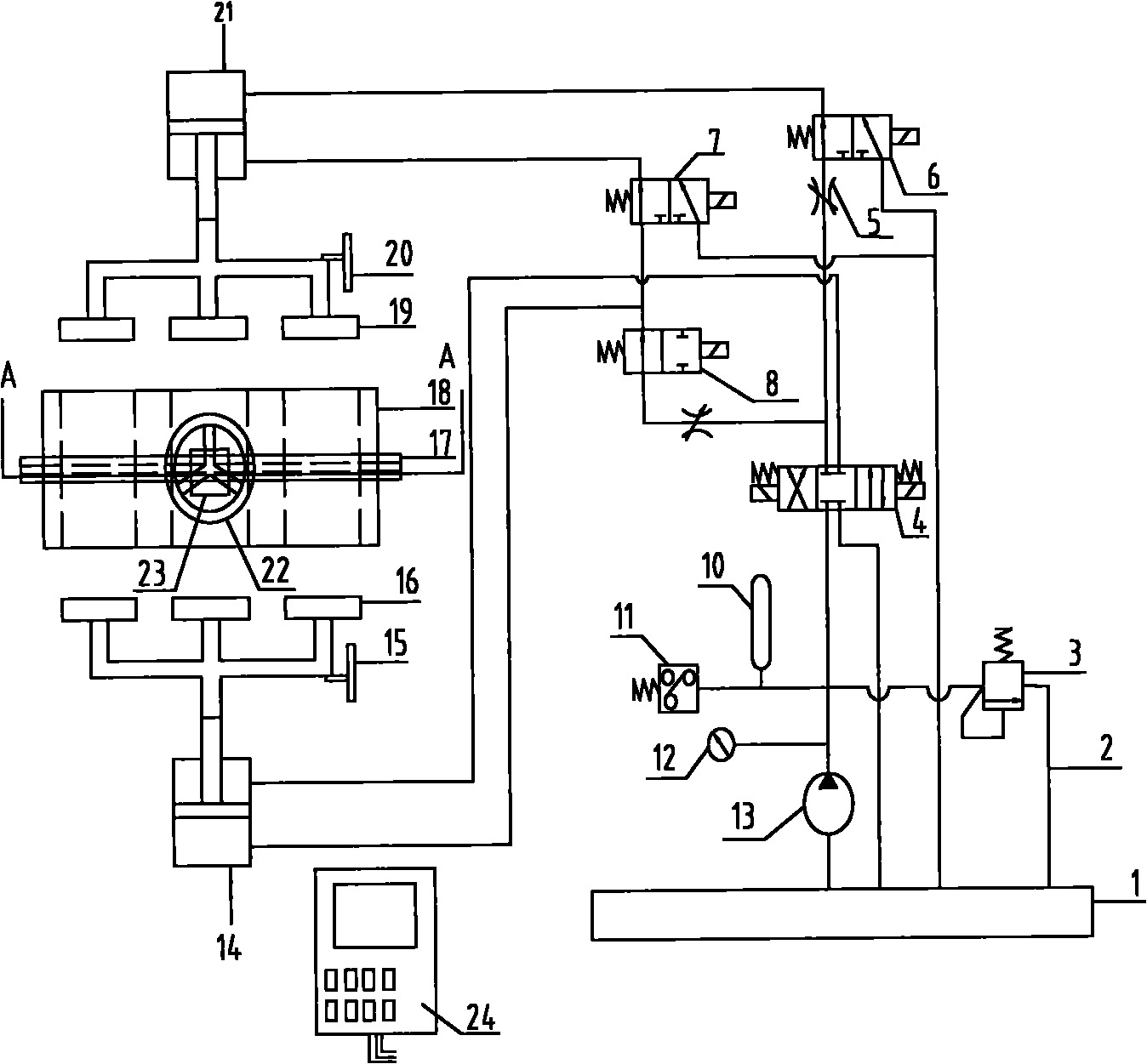

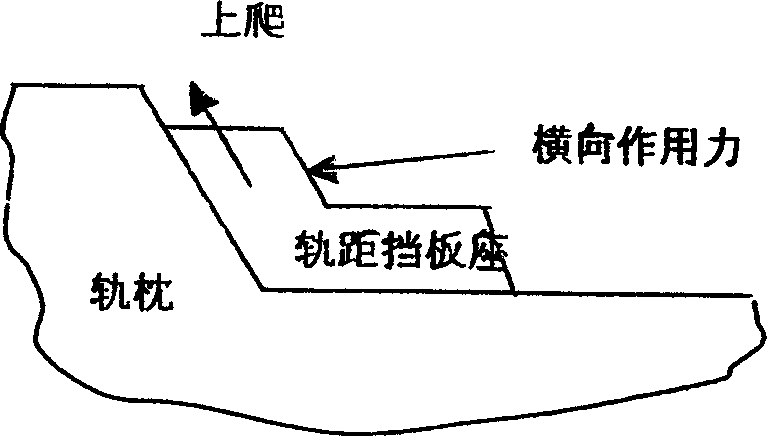

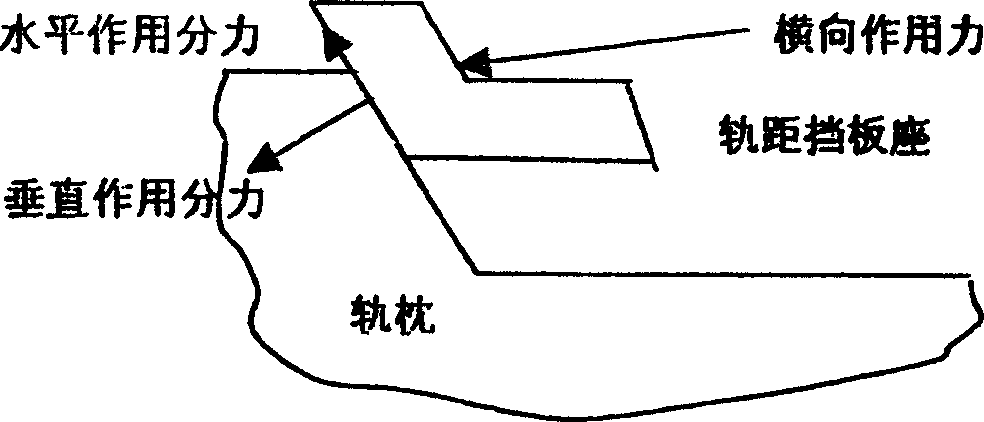

Concrete sleepers and their making process

This invention discloses one kind of concrete tie and its production method, after this sleeper suits the heavy load and raises the fast railroad standard line to use sleeper, as well as the radius 500m - 1200m curve and the straight line mountainous area track line use, this invention sleeper keeps off the shoulder structure, it keeps off the shoulder concrete to raise, the gauge back plate adds thick, the rubber backing strip adds thick, sleeper in according to vertical staggers the arrangement way arrangement to have the spiral rib steel bar, is keeping off the shoulder nose minute position disposition shearing force muscle. The beneficial effect is: Enhances keeps off the shoulder intensity, the change crosswise action in keeps off on the shoulder the transmission direction, increased the area of thrust surface, the theory and the experiment had proven might enhance keeps off above a shoulder limit bearing capacity time, effectively solved the concrete to keep off the shoulder to be easy to damage the question; Simultaneously solved the gauge apron block along to keep off on the shoulder to crawl, gets down the string question; Enhances under in the axle and the pillow the section dead load strength, prevented produces along the steel bar vertical crack, effectively strengthens sleeper anti- weary ability and later period intensity.

Owner:成铁德阳轨道有限责任公司

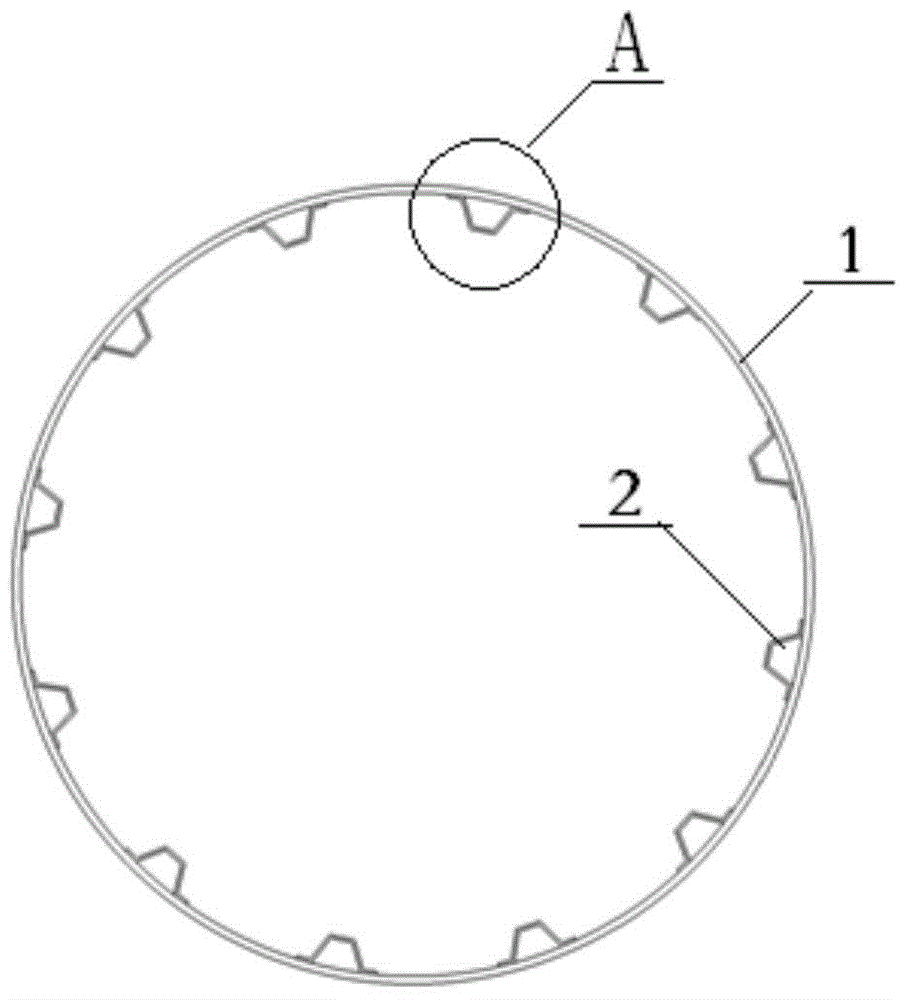

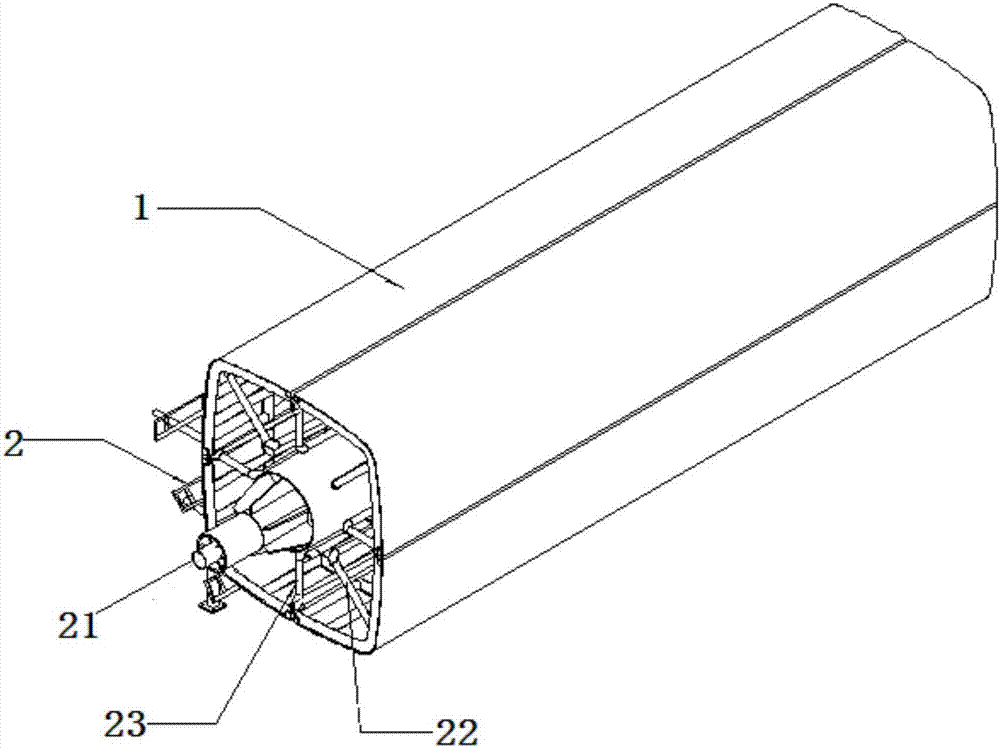

Molding method of integral composite material reinforced cylinder, laying tool, curing mold and stringer positioning device

The invention belongs to a composite material molding technology, and relates to a molding method of an integral composite material reinforced cylinder, a laying tool, a curing mold and a stringer positioning device. The method comprises the molding steps of: assembly of a laying mold; adjustment of a movable mold (6a); sealing of the laying mold; laying of a skin (1); installation of the curing mold; extraction of the laying mold; curing of the skin; adjustment of the stringer positioning device (7); bonding of an adhesive film on a stringer; positioning of the stringer; and curing. The invention proposes the molding method of the integral composite material reinforced cylinder, the laying tool, the curing mold and the stringer positioning device; the appearance surface precision of the cap-shaped stringer and the cylinder is greatly improved; the stringer positioning method is simplified; the demolding difficulty is solved; and the product pass percent is improved.

Owner:AVIC COMPOSITES

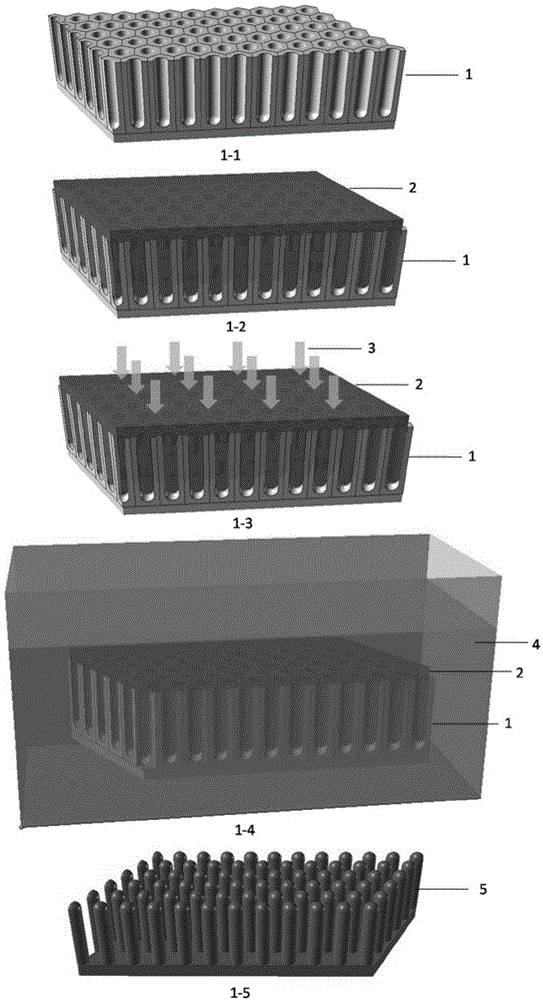

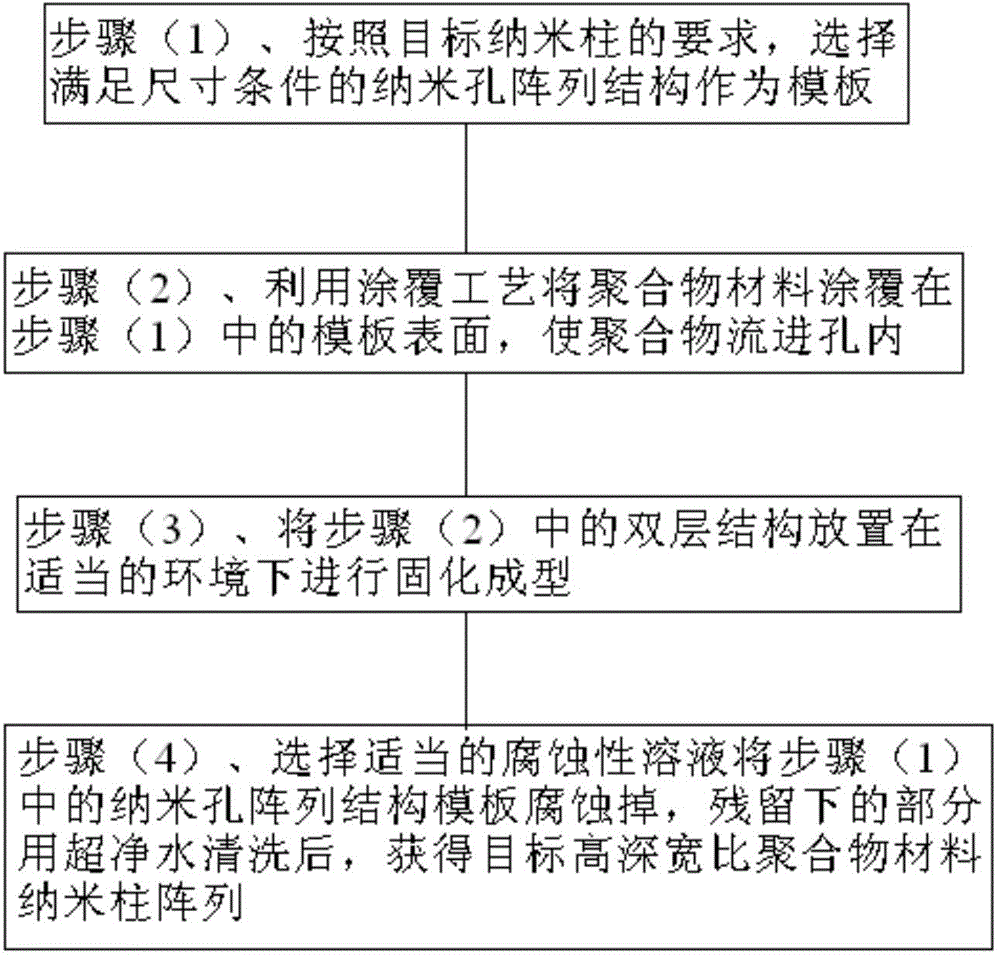

Method for preparing high depth-width ratio polymer nanorod array by sacrificing template

InactiveCN104803348ASolve the demoulding problemImprove reliabilityMicrostructural devicesMicro nanoNanopillar

The invention relates to a method for preparing a high depth-width ratio polymer nanorod array by sacrificing a template, and belongs to the field of micro-nano structure processing. The preparation method comprises the following steps: taking a corrodible nanopore array structure as the template; coating a polymer material on the surface of the template by utilizing a coating process, and adjusting the viscosity and Young modulus of the polymer material, wherein not only is the defect that surface tension of nanopores flows into the holes overcome, but also the resolution and the depth-width ratio of nanorods can be effectively improved; placing the template coated with the polymer material under proper environment to be cured and formed; corroding the template by utilizing a corrosive solution so as to leave over the cured polymer material nanorod structure. The size and the depth-width ratio of the nanorods are controlled by the template and the polymer, the nanorods with small size and high depth-width ratio can be prepared, and meanwhile the same template can be prepared into the nanorods with different depths. The operation in the preparation process is simple, the cost is low, the depth-width ratio is controllable, and wide application prospects are realized in the field of biochemical sensing, biochemical analysis and the like.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Forming mould for composite material part of box type closed-angle structure

The invention belongs to the technical field of aeronautical manufacturing and particularly relates to a forming mould for a composite material part of a box type closed-angle structure. In the present, composite material forming moulds include metal moulds, composite material moulds, rubber moulds, foam moulds, plaster moulds and soluble polymer moulds. Traditional composite material parts of irregular-shaped structures can be manufactured and formed by rubber shrinkage moulds, foam and plaster, and then the moulds are broken to obtain the parts. However, the moulds can only be used for once or several time and is not suitable for batch production, and the surface accuracy and the quality of the composite material parts manufactured by the moulds are not as good as the surface accuracy and the quality of the composite material parts manufactured by metal moulds totally. The forming mould for the composite material part of the box type closed-angle structure is reasonable in design and simple to manufacture and also solves the problem of demoulding of the composite material part of the box type closed-angle structure.

Owner:AVIC BASIC TECH RES INST

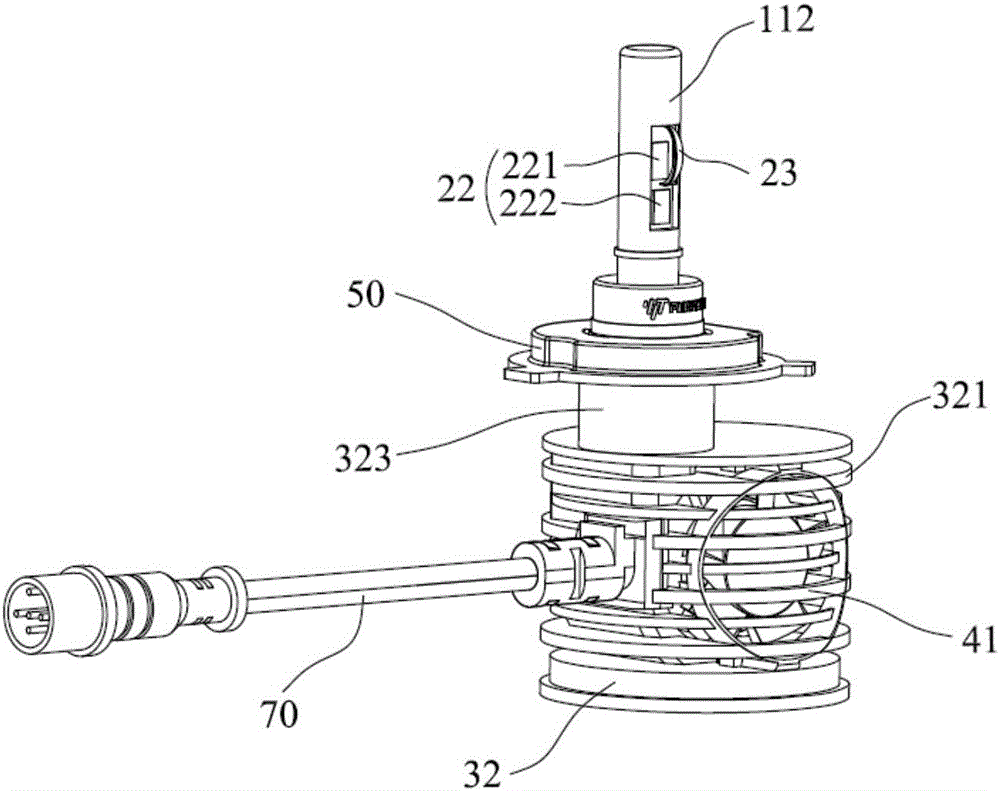

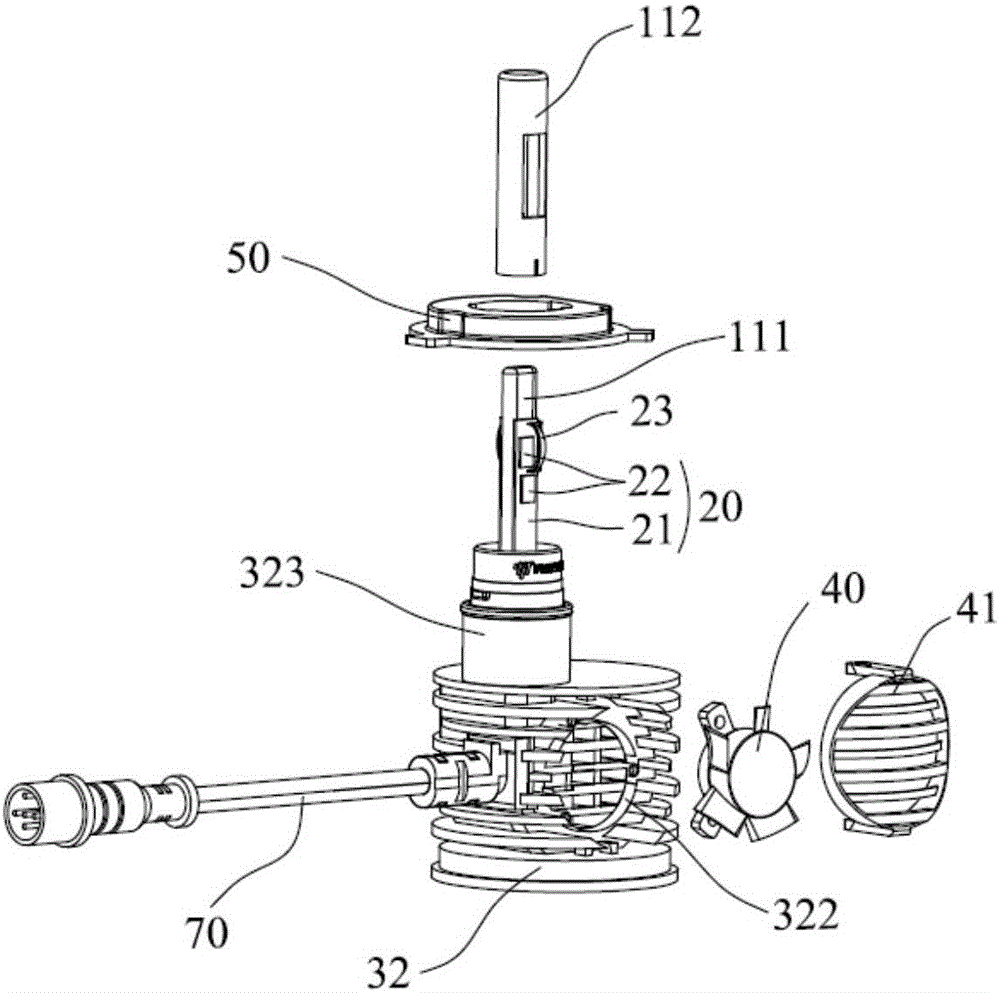

LED (Light-emitting Diode) automobile light and preparation method thereof

InactiveCN106594627APrevent or reduce oxidationImproved thermal connectionLighting support devicesElectric circuit arrangementsEngineeringLight-emitting diode

The invention provides an LED (Light-emitting Diode) automobile light and a preparation method thereof. The automobile light comprises a metal heat pipe with a light source installation section and a heat conduction section, LED light sources arranged on the light source installation section, and a heat radiator comprising a metal radiator and a thermal conductive plastic isolator, wherein the metal radiator and the heat conduction section form thermal connection; and the thermal conductive plastic isolator covers the heat conduction section so as to separate the heat conduction section from outside air. The LED automobile light provided by the invention has the advantages of excellent heat radiation performance and long service life.

Owner:RAYBEN TECH ZHUHAI

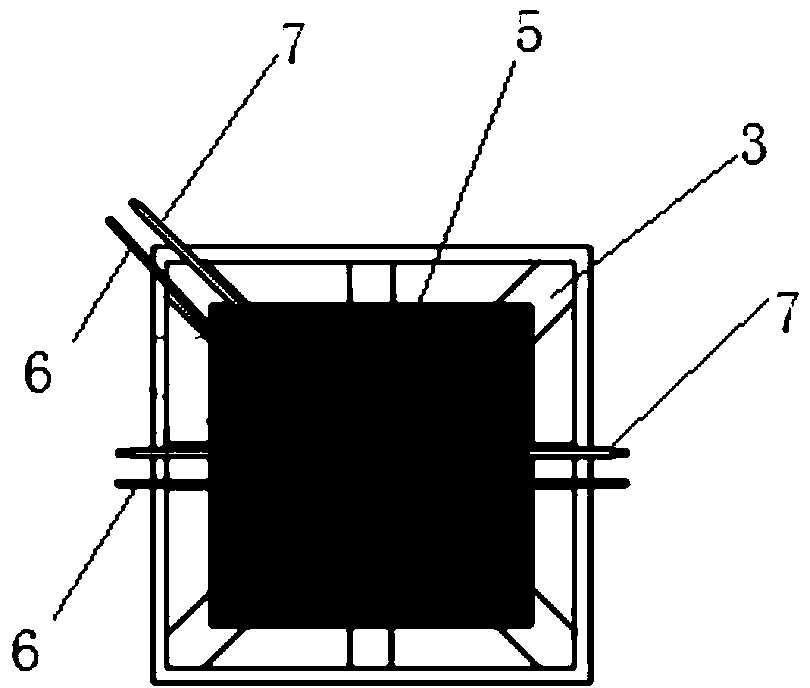

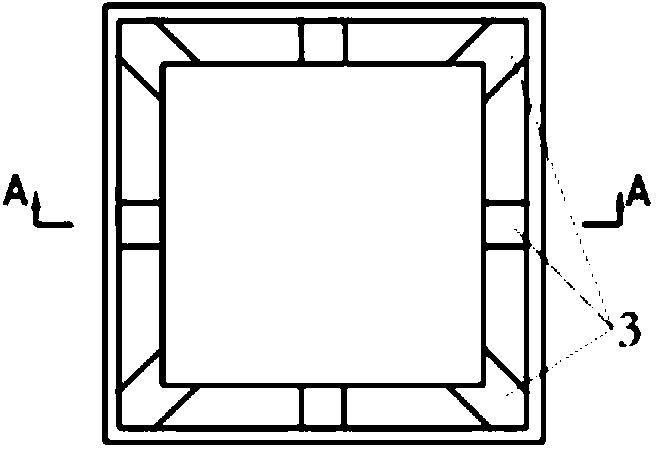

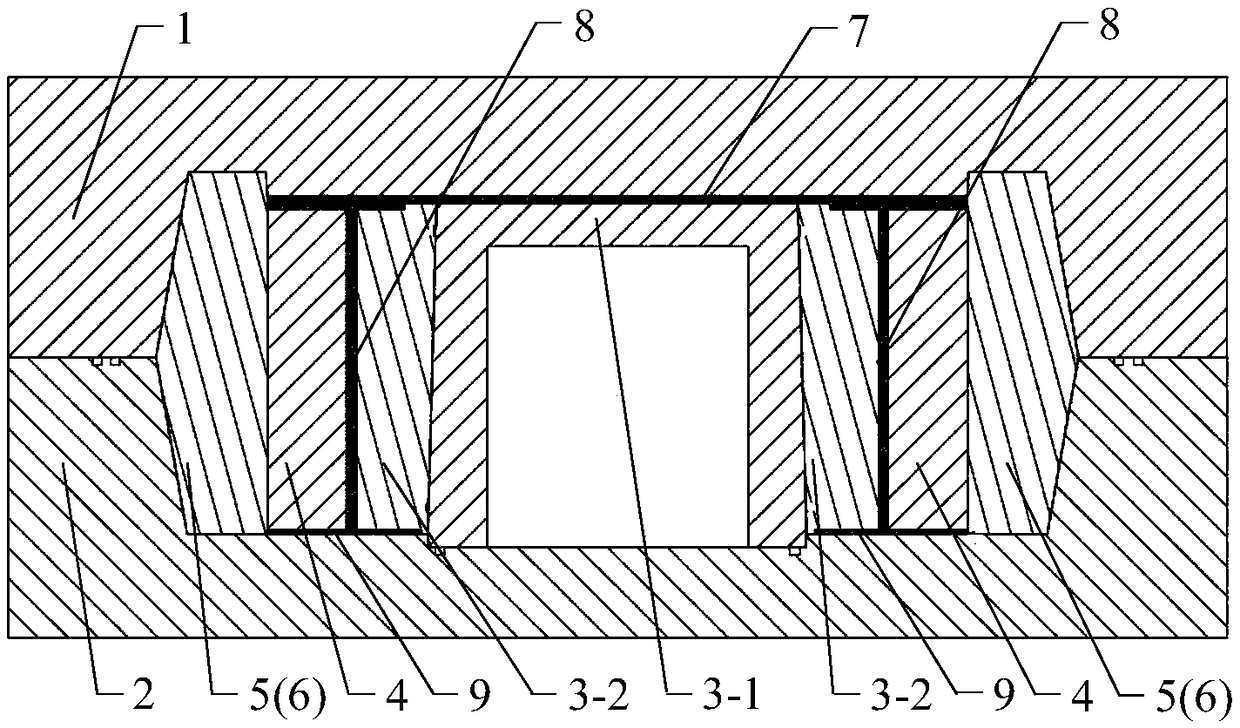

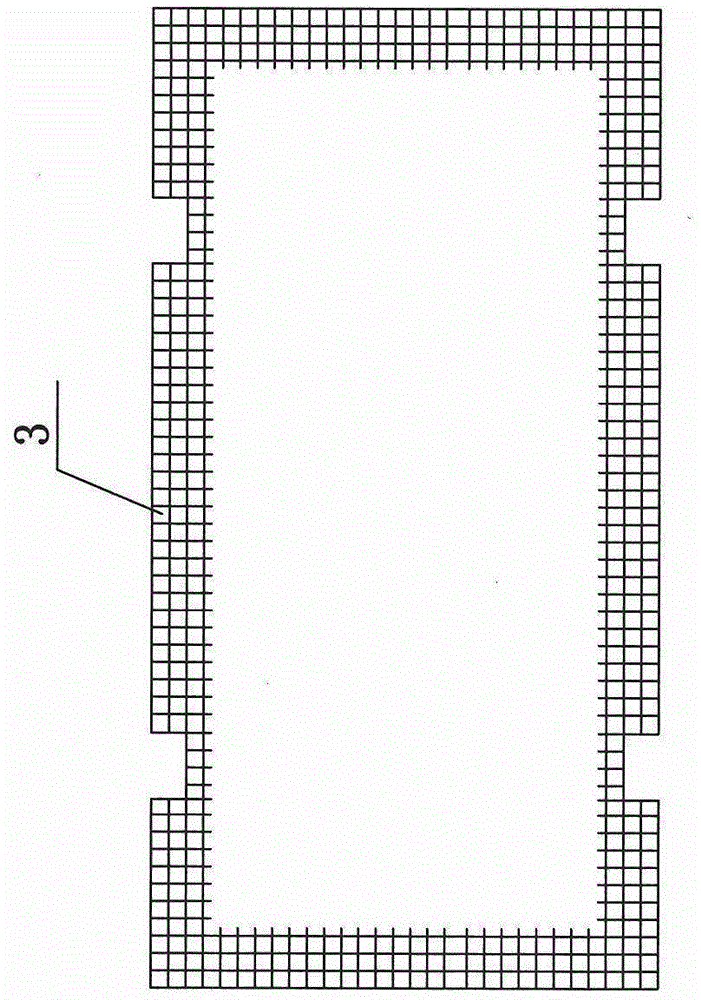

Mold for integrally preparing I-shaped longitudinally-horizontally-stiffened composite panel

ActiveCN108943775AHigh dimensional accuracyImprove internal and external surface qualityDomestic articlesResin-Based CompositeMaterials science

The invention belongs to the technical field of resin matrix composite forming, and relates to a mold for integrally preparing an I-shaped longitudinally-horizontally-stiffened composite panel. According to the mold for integrally preparing the I-shaped longitudinally-horizontally-stiffened composite panel provided by the invention, a design idea adopting a combined type inner core mold is provided, an uncovered part of an I-shaped flange is designed to be a U-shaped core mold capable of being demolded freely, and then a C-shaped forming mold formed through a block design is connected to the outer surface of the U-shaped core mold through a bolt; and when the longitudinally-horizontally-stiffened panel prepared by adopting the core mold is demolded, the U-shaped core mold can be firstly demolded, and then the C-shaped forming mold is sequentially taken out according to the design sequence along the direction perpendicular to an I-shaped stiffener web member. Meanwhile, based on an RTMforming process requirement, a whole set of design idea of the forming mold suitable for the I-shaped longitudinally-horizontally-stiffened panel is provided.

Owner:AVIC BASIC TECH RES INST

Agriculture straw regeneration fire-proof heat preservation plate material and preparation method thereof

InactiveCN107186855ASolve long-term accumulation problemsLow costCeramic shaping apparatusDomestic articlesFire retardantRapid prototyping

The invention discloses an agriculture straw regeneration fire-proof heat preservation plate material. The agriculture straw regeneration fire-proof heatpreservation plate material comprises raw materials, by weight, 60-80 parts of agriculture straw, 10-15 parts of binder, 3-6 parts of metal oxide, 3-7 parts of water-proof agent, 3-5 parts of fire retardant, 15-20 parts of modified kaolin, 12-18 parts of white cement and 20-26 parts water. The agriculture straw regeneration fire-proof heat preservation plate material has the excellent properties of rapid prototyping, heat insulation and heat preservation, inflaming retarding, mould proof, deliquescence resistance, high strength and the like, the plate material is divided into a pressed inner core and an outer surface coating layer, the problems of being prone to breaking billet, sticking plate and demoulding are solved, continuous production is achieved, and the production efficiency is improved greatly; and meanwhile, the source of the main raw materials of the agriculture straw regeneration fire-proof heat insulation plate material is wide, the cost is low, the technology is simple and clear, and the high practical value and the good application prospect are achieved.

Owner:合肥市风达农业有限责任公司

Rubber product demolding agent and preparation method thereof

The invention discloses a rubber product demolding agent and a preparation method thereof. The rubber product demoldinng agent comprises the following ingredients by weight percent: 0.3 to 0.8 percent of polytetrafluoroethylene, 0.2 to 0.8 percent of stearic acid, 0.1 to 0.2 percent of carbon black, 0.5 to 1 percent of sodium sulfate and the balance being distilled water. The preparation method of the rubber product demolding agent comprises the following steps of (1) mixing polytetrafluoreothylene, stearic acid, carbon black, sodium sulfate and the distilled water according to the mass proportion; (2) stirring the mixture for 20 to 60 minutes by utilizing a stirring device to form uniform emulsion to obtain the emulsion demolding agent. The demoldinng agent is simple in ingredients and reliable in ingredient source; the preparation method is simple; the demolding agent is convenient to use, easy to paint and good in attachment performance and has the advantages of high temperature resistance, environmental friendliness, long service life and the like; moreover, the application range is wide, and the purpose of demolding a great amount of rubber and workpiece can be achieved.

Owner:LIUZHOU YINGHANG AUTO PARTS

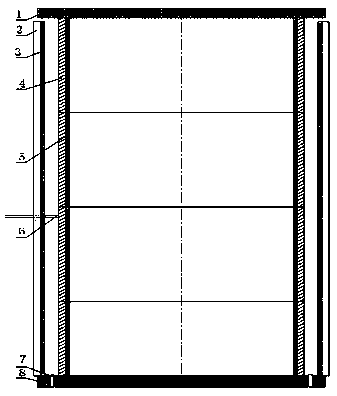

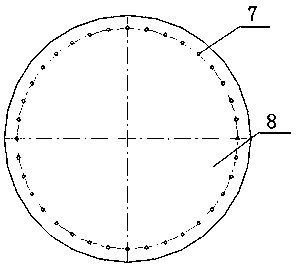

RTM (resin transfer molding) mold for partition type rotating structure composite parts

ActiveCN108995250AHigh dimensional accuracyGood internal and external surface qualityDomestic articlesIn planeFlange

The invention belongs to the technical field of molding of resin-based composites and relates to an RTM (resin transfer molding) mold for partition type rotating structure composite parts. The mold comprises an upper mold, a lower mold, a middle partition combined type inner mandrel, an upper partition inner mandrel, an outer mold and moving sliders. During mold assembly, the middle partition combined type inner mandrel is placed into a positioning groove of the lower mold firstly, then the upper partition inner mandrel is placed on the middle partition combined type inner mandrel, the outer mold is placed on the bottom surface of the lower mold, the moving sliders are placed on the periphery of the outer mold, the upper and the lower mold are assembled oppositely, the gap between the upper mold and the lower mold is reduced gradually under the fastening effect of bolts, and the moving sliders move in plane to enable the outer mold to be placed in a theoretical position under the action of lateral inner mold surfaces of the upper mold and the lower mold. By design of the combined steel inner mandrels, the mandrels can be prevented from falling out of the inner cavities of the semi-closed partitions, and dimensional accuracy of the inner mold surfaces and flanges of the rotating structure is guaranteed.

Owner:AVIC BASIC TECH RES INST +1

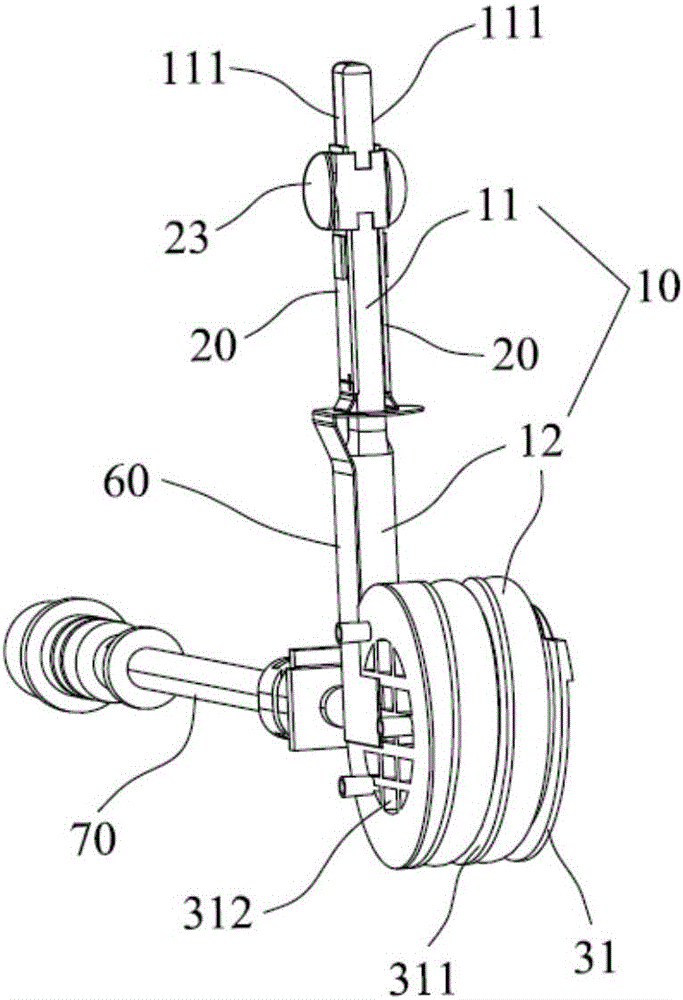

Reducing coupling injection mold core-pulling mechanism

The invention discloses a reducing coupling injection mold core-pulling mechanism which comprises a movable mold base plate and a movable template, wherein a movable mold insert is arranged on the movable template; a secondary internal core-pulling mechanism is arranged on the movable template; floating core-pulling mechanisms are arranged on the movable mold base plate, the movable template and the movable mold insert; according to the secondary internal core-pulling mechanism, an inner inclined sliding surface is formed in a core-pulling small slide block connected in front of a main mold core; an outer inclined sliding surface formed on a sliding rod arranged in the main mold core is matched with the inner inclined sliding surface; a fixing plate is arranged in a mounting groove formed in the rear end of a connecting seat behind the main mold core and is fixed together with the connecting seat through a screw; the sliding seat and the sliding rod are fixed through a bolt; according to the floating core-pulling mechanism, one end of a spring arranged in the movable template is contacted with the movable template, and the other end of the spring is contacted with the movable mold base plate; a core-pulling slide block arranged in the movable mold insert is matched with an external fastener; the core-pulling slide block is provided with a T-shaped clamping block; inclined guide slots formed in an I-shaped locking module are formed in the movable template and the movable mold insert; the upper part of the I-shaped locking module is matched with the T-shaped clamping block through the inclined guide slots; and the lower part of the I-shaped locking module and the movable mold base plate are fixed together.

Owner:TAIZHOU HUANGYAN WEIDA PLASTIC MACHINERY

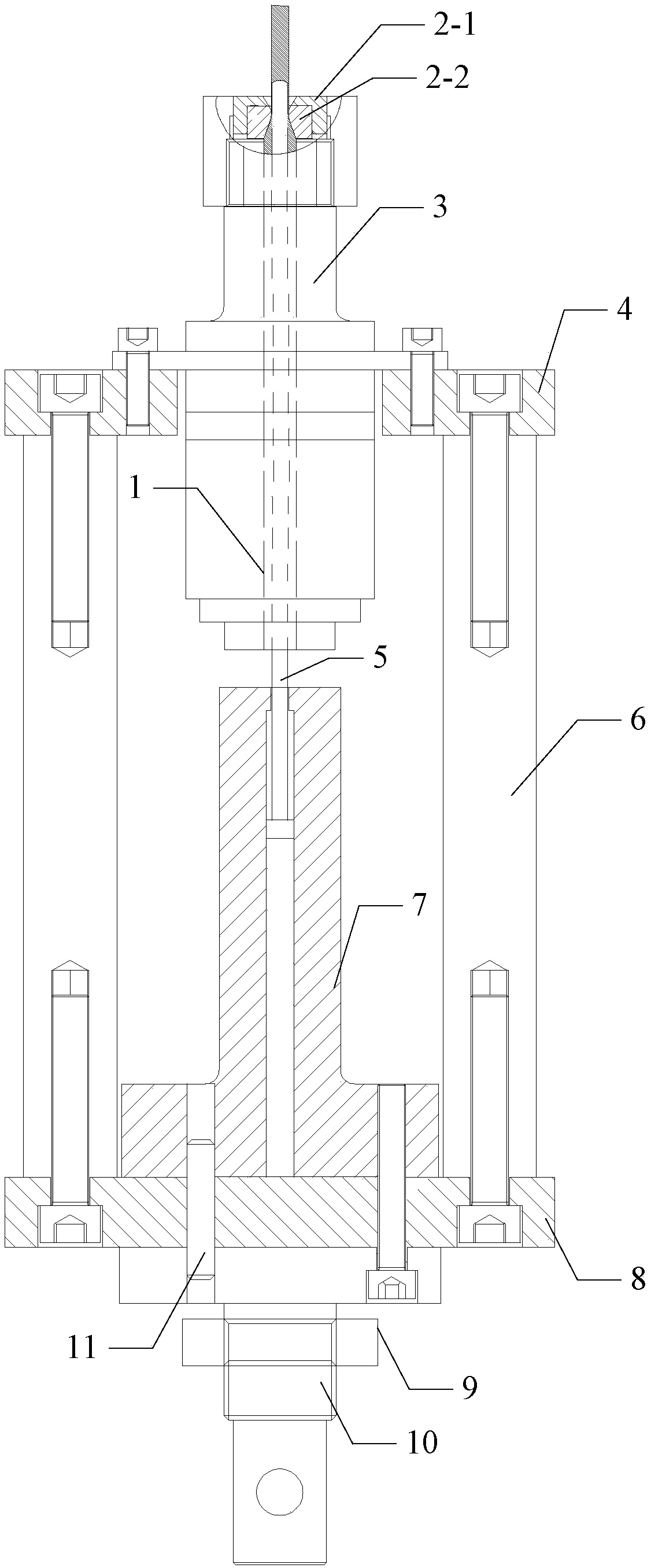

Manual demoulding device

ActiveCN103308364ASolve the demoulding problemOvercoming the disadvantages of oil leakageDischarging arrangementPreparing sample for investigationFixed frameEngineering

The invention belongs to the technical field of demoulding equipment in building construction, and relates to a manual demoulding device aiming at a sample with diameter of 39.1mm and height of 80mm. The main body of the manual demoulding device structurally comprises a support fixed frame, a fixed plate, an upper roof plate, an actmix threaded rod, a pressuring plate, a fixed bolt, a mould placing room, a detachable mould receiving box and a rubber cushion. A test mould is placed into the mould placing room, a glass sheet with diameter of 39.1mm is paved on the surface of the sample, the upper roof plate downwards moves to enable the circle hole center of the upper roof plate to be aligned and in tight contact with the center of the mould, then the fixed bolt is screwed down, the upper end of the support fixed frame is pressed by one hand, and the actmix threaded rod is rotated by the other hand to enable the pressuring plate to downwards move, and the sample is gradually separated from the mould and can fall into the detachable mould receiving box along the downward movement of the pressuring plate. The manual demoulding device provided by the invention is simple in preparation technology, low in cost, small in shape, convenient to place, convenient to use and high in reliability, substantive features are outstanding, and improvement is prominent.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

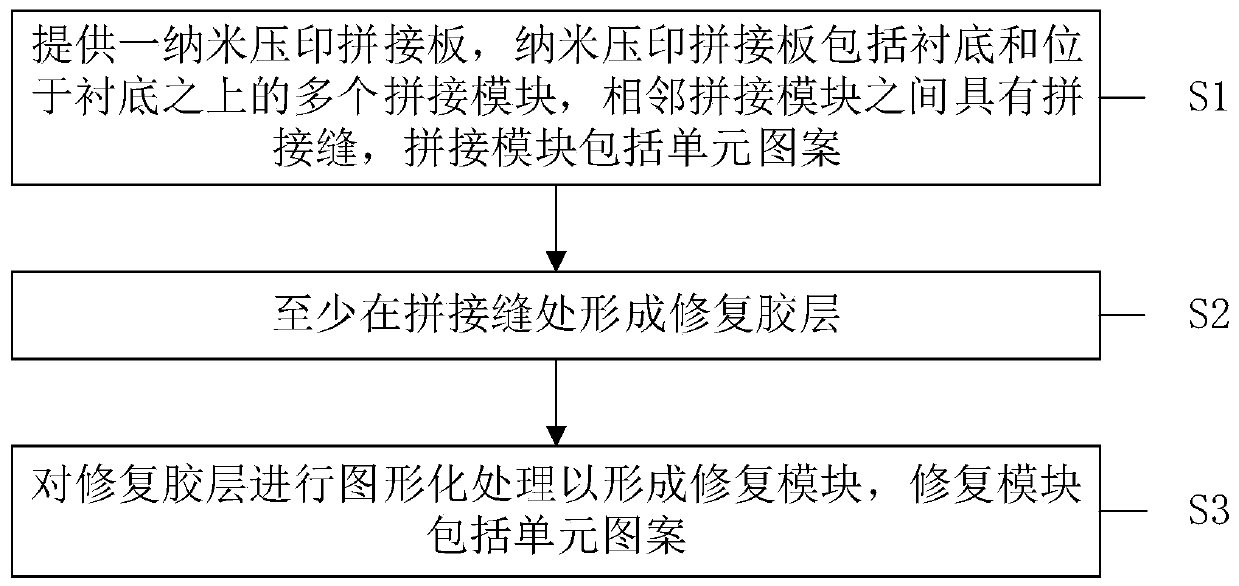

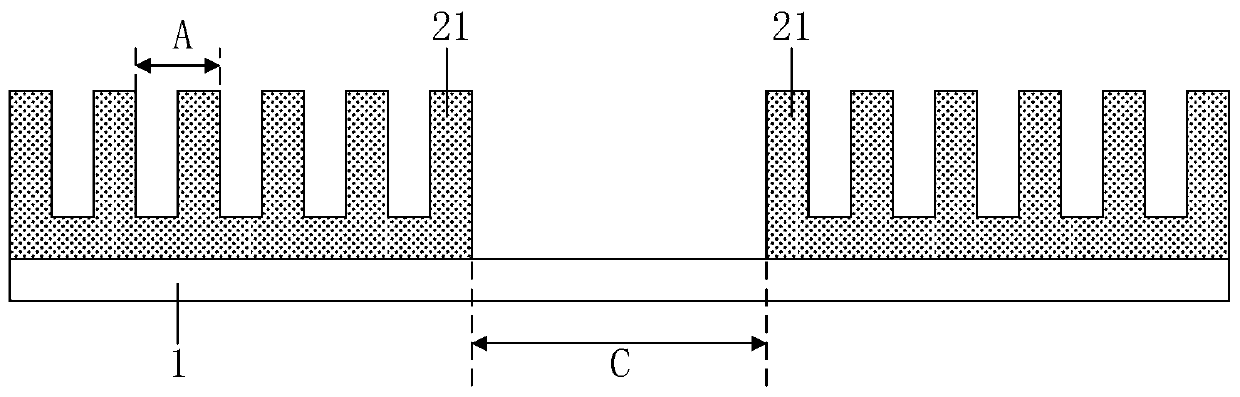

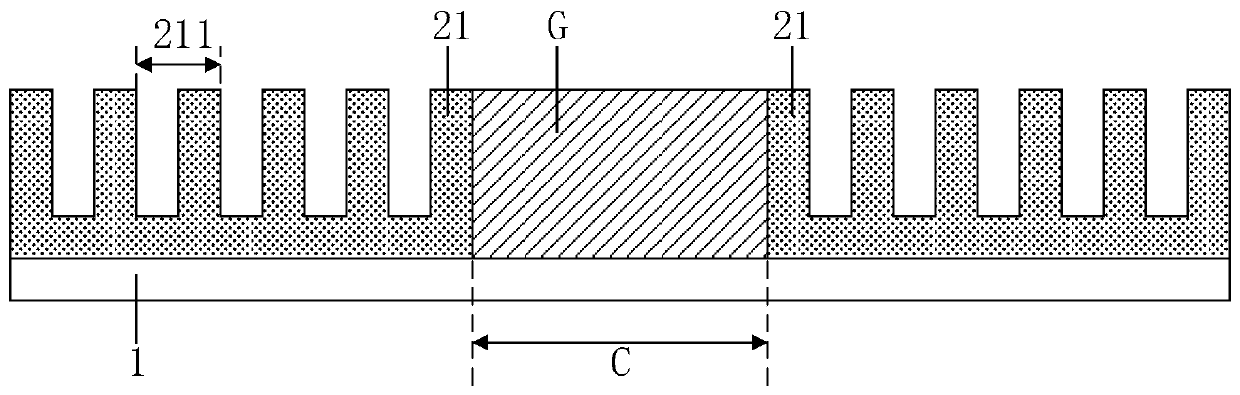

Spliced nanoimprint template and repairing method of splicing seam thereof, and manufacturing method of spliced nanoimprint template

ActiveCN110824835AAchieve fixQuality improvementPhotomechanical apparatusSemiconductor/solid-state device manufacturingStructural engineeringMechanical engineering

The embodiment of the invention provides a spliced nanoimprint template and a repairing method of a splicing seam thereof, and a manufacturing method of a spliced nanoimprint template. The repairing method of the splicing seam of the spliced nanoimprint template comprises the steps of: providing a nanoimprint splicing plate, wherein the nanoimprint splicing plate comprises a substrate and a plurality of splicing modules located on the substrate, a splicing seam is formed between every two adjacent splicing modules, and each splicing module comprises a unit pattern; forming a repairing adhesivelayer at least at each splicing seam; and performing graphical processing on the repair adhesive layers to form a repair module, wherein the repair module comprises a unit pattern. According to the embodiment of the invention, the repairing of the splicing seam of the spliced nanoimprint template can be achieved, so that the seamless spliced nanoimprint template is manufactured; and moreover, theseamless spliced nanoimprint template is beneficial to improving the quality of a photoelectric device, and solves the demoulding problem caused by splicing seams.

Owner:BOE TECH GRP CO LTD

Demolding method for artificial MDI glue board

InactiveCN1672887ASolve the demoulding problemEasy to operateWood working apparatusFlat articlesEngineeringHot pressing

The demolding method for artificial MDI glue board with Kangbai demolding agent Nos. 2, 3 and 4 includes the following steps: 1) painting Kangbai demolding agent No. 2 homogeneously onto the lining board and hot pressing board and stoving at 170-185 deg.c for 25-40 min; 2) painting Kangbai demolding agent No. 3 homogeneously onto the lining board and hot pressing board through processing in the step 1) and stoving at 170-185 deg.c for 3-4.5 hr; 3) spraying Kangbai demolding agent No. 4 to lining board before spreading material; and 4) spraying Kangbai demolding agent No. 4 to the surface of spread material. The said method makes demolding complete.

Owner:SHANGHAI COMPAK ENVIRONMENTAL PROTECTION EQUIP CO LTD

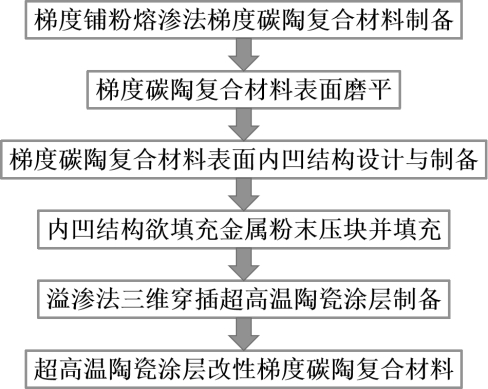

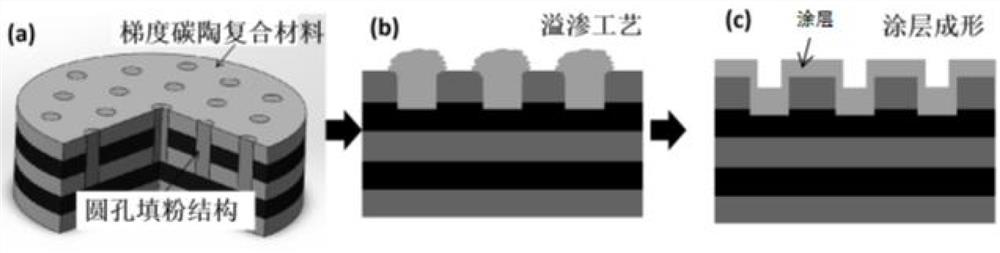

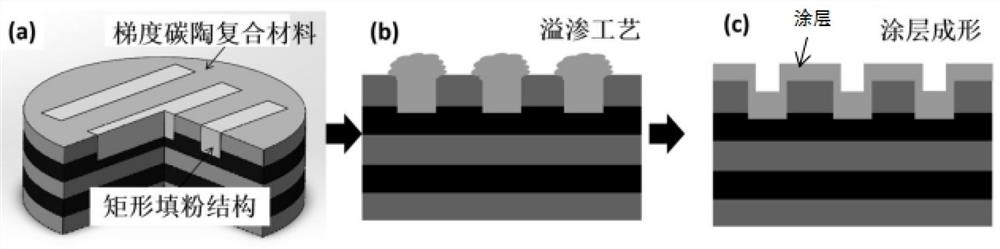

Ceramic coating protection gradient carbon-ceramic composite material and preparation method thereof

ActiveCN113582713AStable high temperature mechanical propertiesImprove high temperature mechanical propertiesCeramic compositeCarbide coating

The invention discloses a ceramic coating protection gradient carbon-ceramic composite material and a preparation method thereof. The ceramic coating protection gradient carbon-ceramic composite material comprises: a gradient carbon-ceramic composite material which is provided with a concave structure on the surface thereof and is a gradient C / C-ZrC-SiC composite material; and an ultrahigh-temperature ceramic coating which is continuously arranged along the surface of the gradient carbon-ceramic composite material and the inner wall surface of the concave structure. The ultrahigh-temperature ceramic coating is an indissolvable metal carbide coating formed by diffusing and infiltrating indissolvable metal along the surface of the gradient carbon-ceramic composite material and reacting the indissolvable metal with the surface of the gradient carbon-ceramic composite material. Therefore, the formed ceramic coating is a three-dimensional jack structure coating, the interfacial strength of the ceramic coating is far higher than that of a two-dimensional plane coating, the surface area of the coating is greatly increased due to the arrangement of the concave structure, meanwhile, the flow resistance of melt on the surface of the composite material can be improved, then the overall temperature resistance of the composite material can be improved, and the risk of coating stripping is reduced.

Owner:CENT SOUTH UNIV

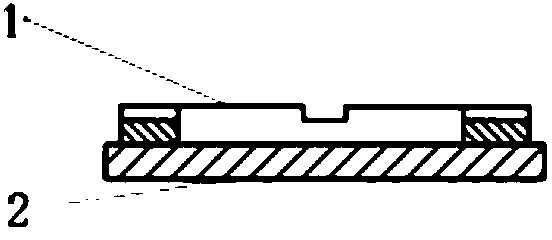

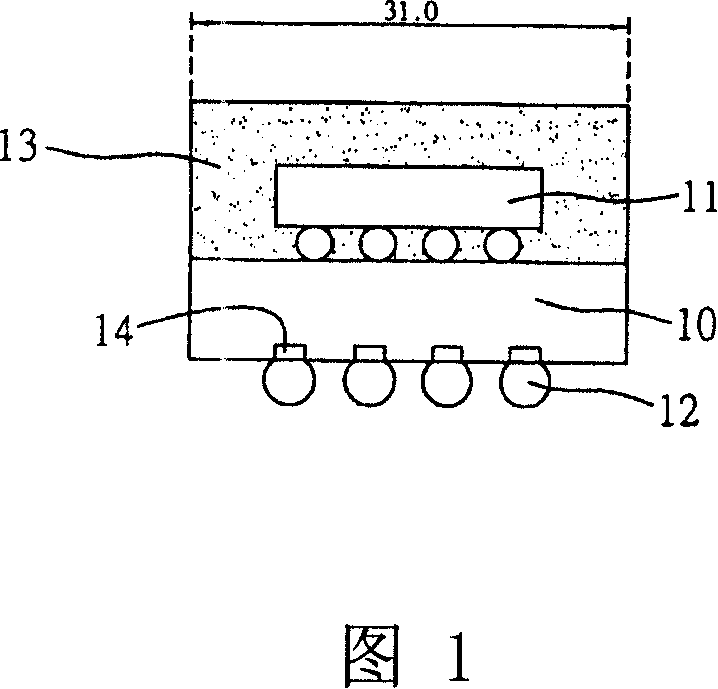

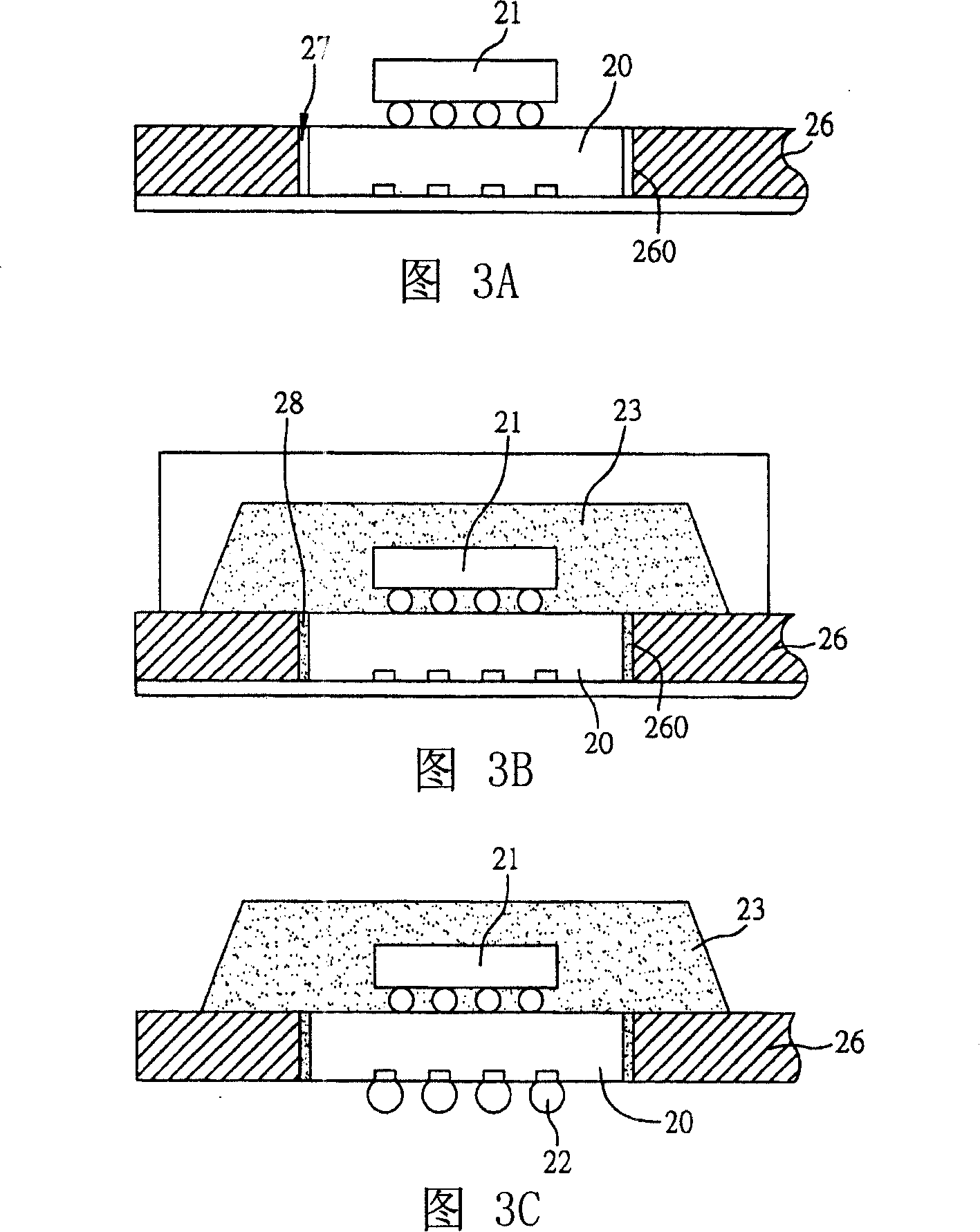

Making method for semiconductor encapsulation component and semiconductor part location structure and method

InactiveCN101150076AAvoid elevationAvoid wastingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageColloid

This invention relates to a manufacturing method for semiconductor package pieces and a locating structure and a method for semiconductor elements, which provides a base board and a loader for locating said board, in which, the length and width of the board approach to the pre-desinged size of the package piece, a chip is set on the board, an aperture is set on the loader and the size of which is greater than that of the board and at least one storage hole is set around the aperture to hold the board in the aperture, at the same time, glue is filled into the storage hole then to fill the gap between the board and the loader by capillarity and form a package colloid covering said chip then to demold and cut along the edge of the base board according to the pre-designed size of the package piece after the covering area of the colloid is greater than that of the aperture so as to manufacture a semiconductor package piece.

Owner:SILICONWARE PRECISION IND CO LTD

Ultrasonic vibration assisted drawing forming device and method for thin-walled micro fine pipe

InactiveCN107931341AImprove plasticityImprove surface qualityDrawing profiling toolsUltrasonic vibrationTensile testing

The invention discloses an ultrasonic vibration assisted drawing forming device and method for a thin-walled micro fine pipe and relates to a thin-walled micro fine pipe ultrasonic vibration assisteddrawing forming technology in order to solve the problems that during drawing forming of the thin-walled micro fine pipe, the surface quality is low, and breakage is easily caused. According to the ultrasonic vibration assisted drawing forming device and method for the thin-walled micro fine pipe, a connector is fixedly connected with a stretching testing machine; the connector is fixed to a lowermold base; a mandrel guiding base is arranged on the lower mold base; an ultrasonic vibrator is fixed to an upper mold base; a drawing female mold is in close rigidity connection with the ultrasonicvibrator; a supporting column is supported between the upper mold base and the lower mold base; a drawing mandrel is fixed to the mandrel guiding base, and sequentially penetrates the ultrasonic vibrator and the drawing female mold, and the drawing mandrel is higher than the drawing female mold; and drawing forming on a pipe blank is completed under the joint effect of the drawing female mold andthe drawing mandrel. The beneficial effects are that the surface quality of the thin-walled fine pipe formed in a drawing manner is better, and the ultrasonic vibration assisted drawing forming deviceand method for the thin-walled micro fine pipe is applicable to drawing forming of the metal thin-walled micro fine pipe.

Owner:HARBIN INST OF TECH

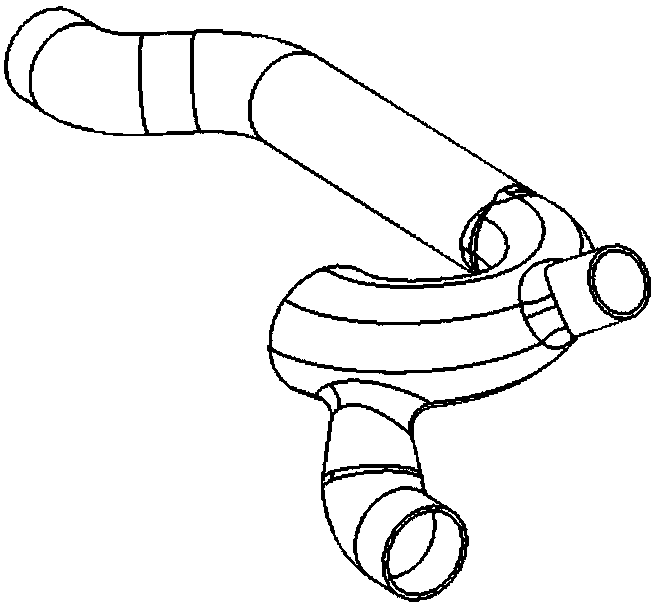

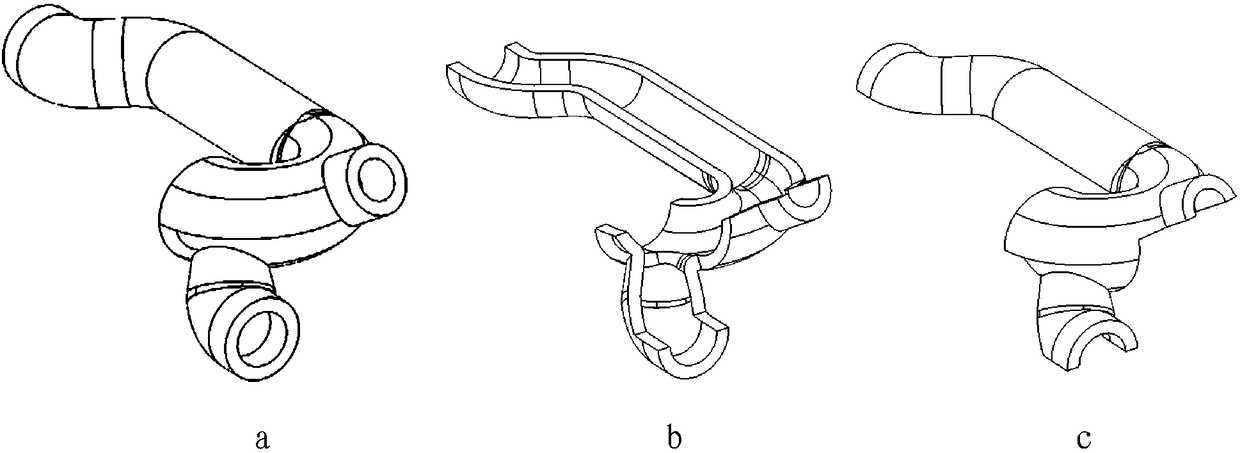

Multi-axial direction composite material bent pipe and preparation method thereof

ActiveCN108864995ALow melting pointReduce forceNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberQuartz

The invention provides a multi-axial direction composite material bent pipe and a preparation method thereof. The multi-axial direction composite material bent pipe is integrally formed by using a soluble core mold and using a heat expansion pressure process; the soluble core mold is heated to be molten through soluble bonding agents in the core mold resin mixture; after the cooling shaping, a solid-state core mold is obtained; the core mold resin mixture comprises quartz sand, soluble bonding agents and short cut fiber. The process characteristics of the soluble core mold and a heat expansionpressurization method are combined; the problem of demolding and peripheral pressurization difficult point problem in the bent pipe structure shaping of the special-shaped composite material is solved; the whole preparation of the special-shaped bent pipe is realized.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

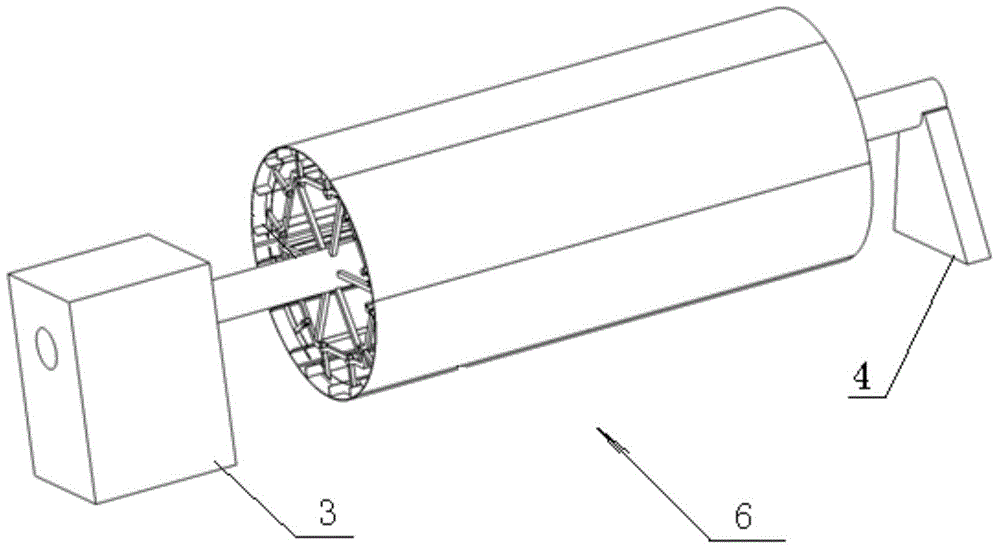

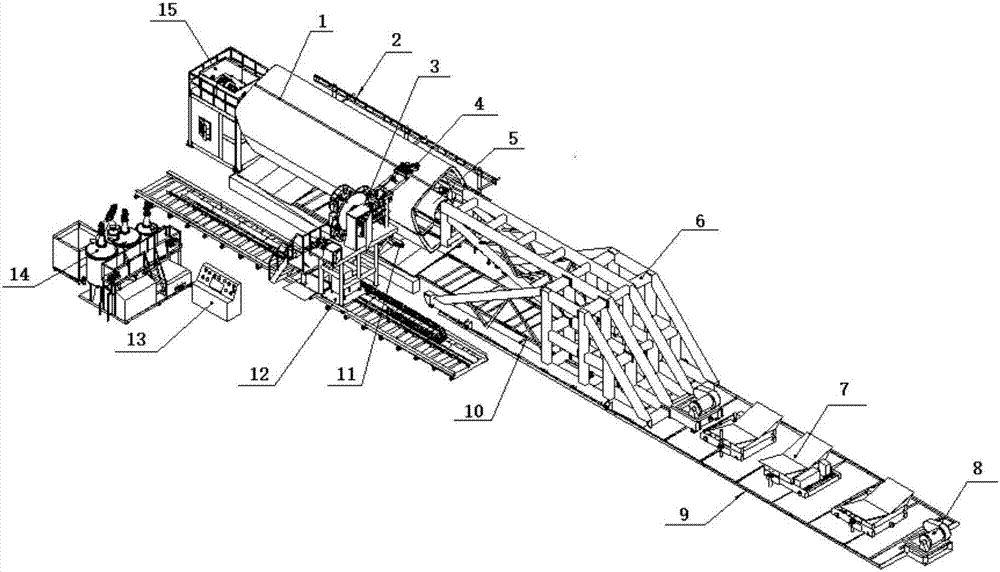

Automatic bamboo winding vehicle production line and production method

PendingCN107150450AWeight increaseReduce weightDomestic articlesBio-packagingPipe supportAbnormal shaped

The invention belongs to the technical field of vehicle manufacturing, and particularly relates to an automatic bamboo winding vehicle body production line. The automatic bamboo winding vehicle body production line comprises a vehicle body preparing device, a vehicle body forming device, a vehicle body cutting device and a demoulding device. The vehicle body preparing device comprises a special-shaped opening and closing die and a winding workbench. The vehicle body forming device comprises a following press roller and curing devices. The curing devices are arranged inside and outside the special-shaped opening and closing die. The vehicle body cutting device is a profiling cutting tool rest. The demoulding device comprises a cantilever support, a first pipe supporting trolley and a second pipe supporting trolley. The invention further discloses a method for producing a bamboo winding vehicle body through the automatic production line. By means of the automatic bamboo winding vehicle body production line and the method, the problems that during bamboo winding vehicle body production, the section rotation radius change is hard to form, the curing time is long, curing is not uniform, and a vehicle body large in mass is hard to demould can be effectively solved; and meanwhile, the beneficial effects that the production process is short, the equipment structure is simple, the occupied area is small, and operation is convenient, and therefore the automatic bamboo winding vehicle body production line and the method are particularly suitable for automatic bamboo winding vehicle body production.

Owner:中林鑫宙竹缠绕发展有限公司

Nano stamping photoresist surface modifier

ActiveCN102604454ASolve the demoulding problemExtend your lifeCoatingsPhotosensitive materials for photomechanical apparatusPolymer scienceManufacturing technology

The invention relates to a nano stamping photoresist surface modifier and belongs to the technical field of photoresist materials of a semiconductor manufacturing technology. The surface modifier comprises the following components in percentage by weight: 65-85% of organic micromolecule solvent, 10-30% of full fluorine UV (ultraviolet) curing resin, 0.5-5% of surfactant, 0.1-0.5% of photo-initiator and 0.1-0.5% of stabilizer. According to the proportion, the components are placed into a container in turn, the components are heated and uniformly stirred, the mixture is stabilized for half a hour at 30-40 DEG C, and the stabilized mixture is filtered by a filter with the aperture of 0.2Mum, so as to obtain a surface treating agent. The surface treating agent is sprayed on a stamping photoresist surface so as to be used as the surface treating agent. The surface treating agent can be used for effectively reducing the surface energy of a photoresist, so as to smoothly demould, reduce the defects and protect a template.

Owner:SHANGHAI UNIV

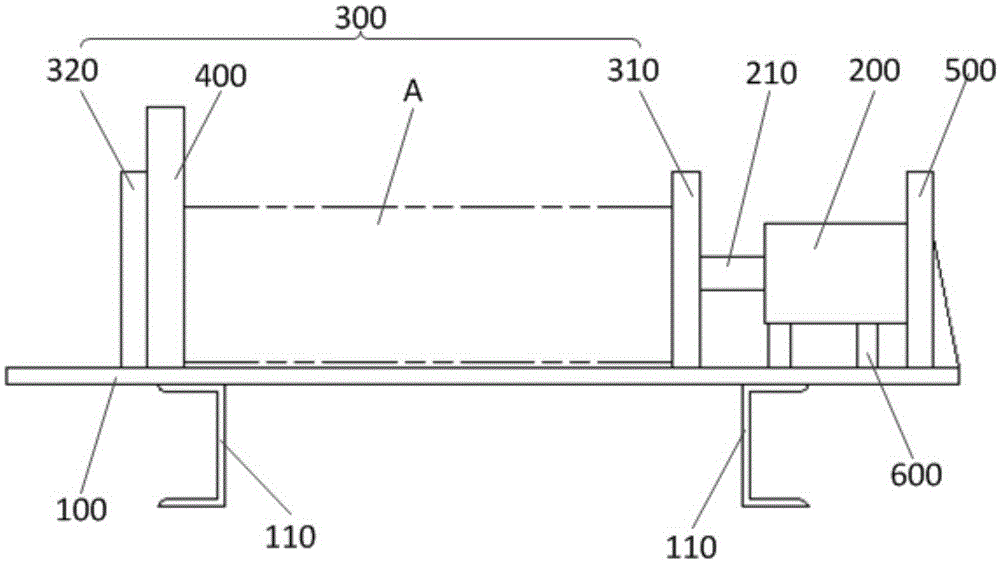

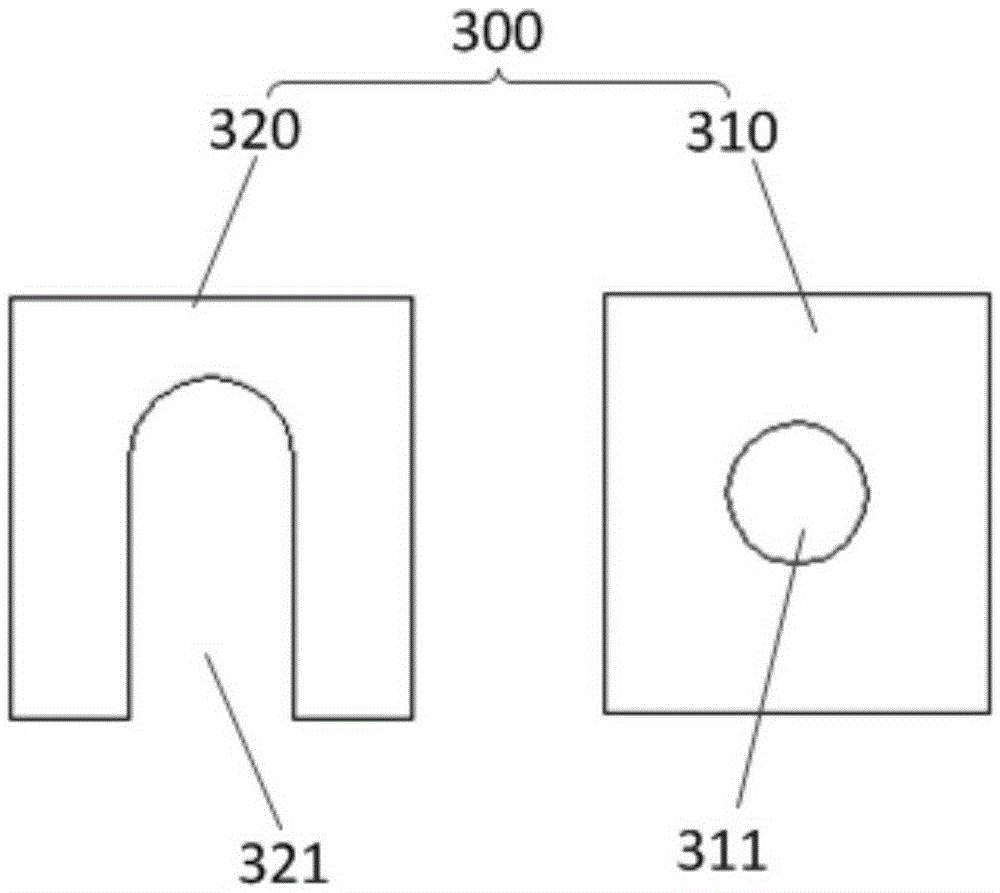

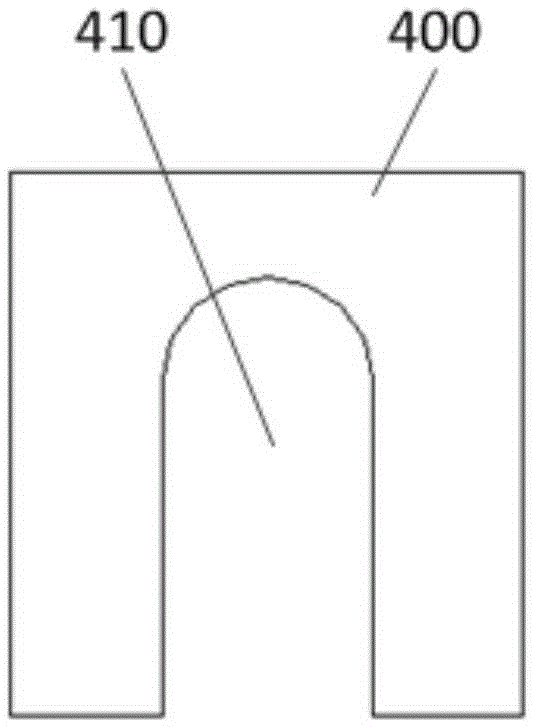

Demoulding tool for epoxy resin dry transformer coil pouring inner mould

InactiveCN105405637AEasy to operateReduce labor intensityCoils manufactureEngineeringMechanical engineering

The invention discloses a demoulding tool for an epoxy resin dry transformer coil pouring inner mould, and belongs to the technical field of transformers. The demoulding tool comprises a base, a hydraulic jack and a pair of fixing plates, wherein the hydraulic jack is arranged at one end of the base, and a push rod points to the other end of the base; the pair of the fixing plates are welded to the base in parallel at interval of a certain distance; a to-be-demoulded coil is arranged between the pair of the fixing plates; a through hole for the push rod of the hydraulic jack to penetrate through is formed in one fixing plate; an outer hole for the stripped coil inner mould to penetrate through is formed in the other fixing plate; the outer hole is an n-shaped hole communicated with the bottom of the fixing plate; and the push rod of the hydraulic jack penetrates through the through hole and pushes against the end surface of the coil inner mould to push the coil inner mould out of the outer hole. The demoulding tool is free of potential safety hazards and low in labor intensity, and can be used anywhere.

Owner:重庆吉能变压器有限公司

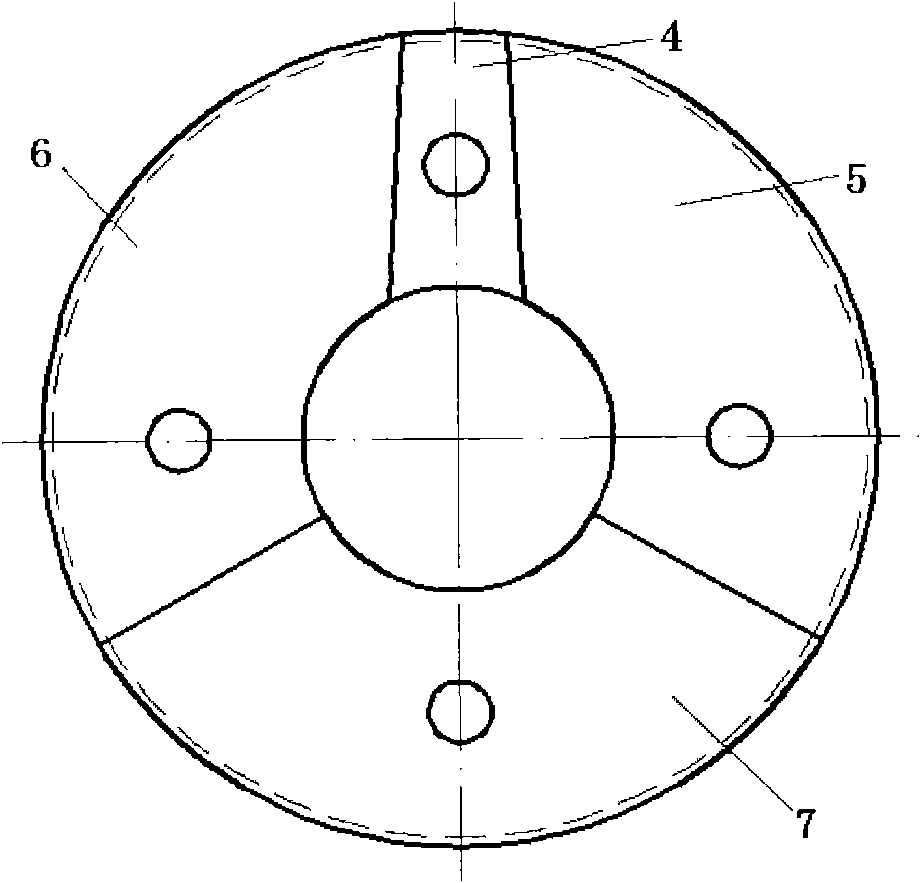

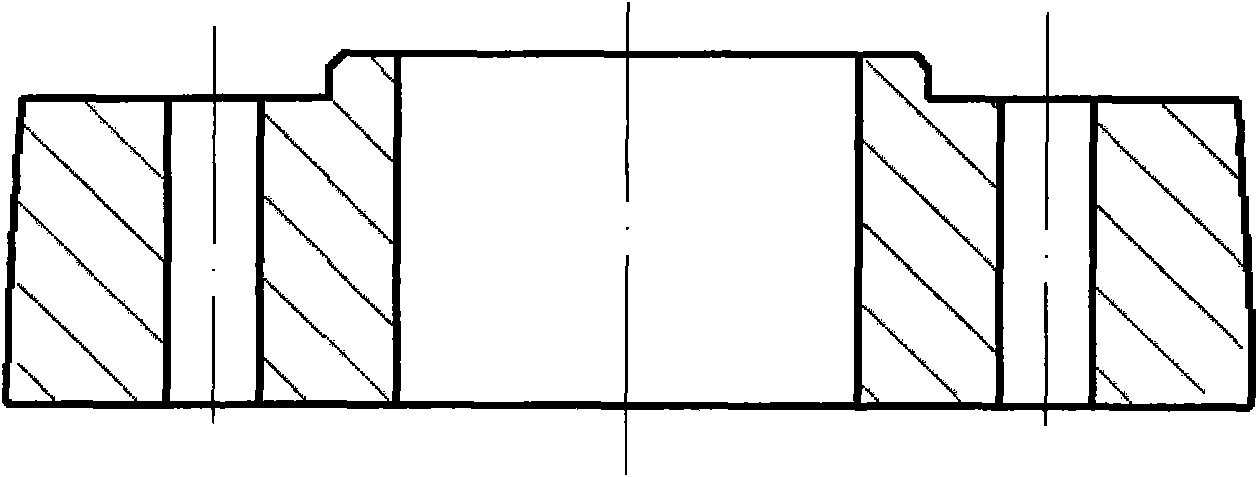

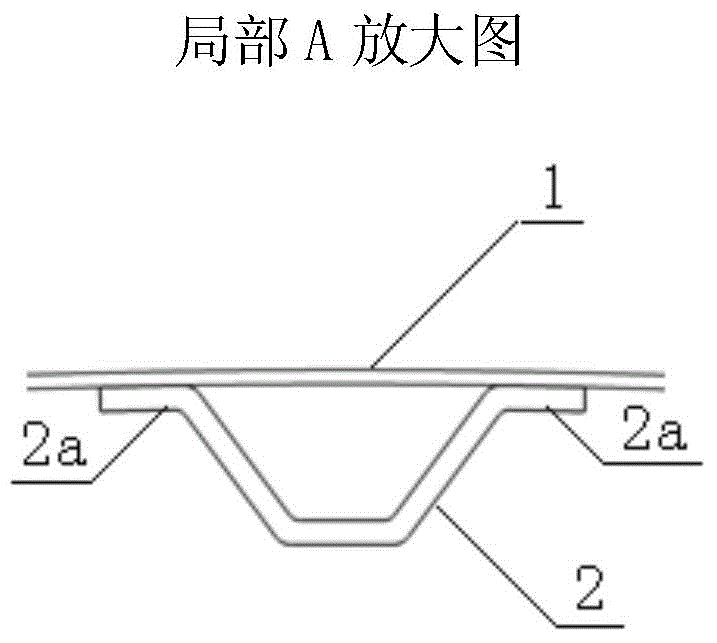

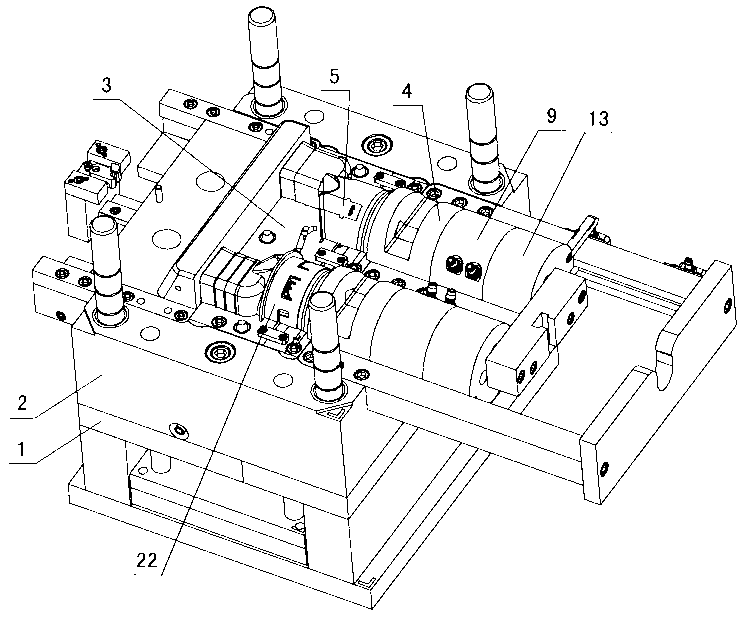

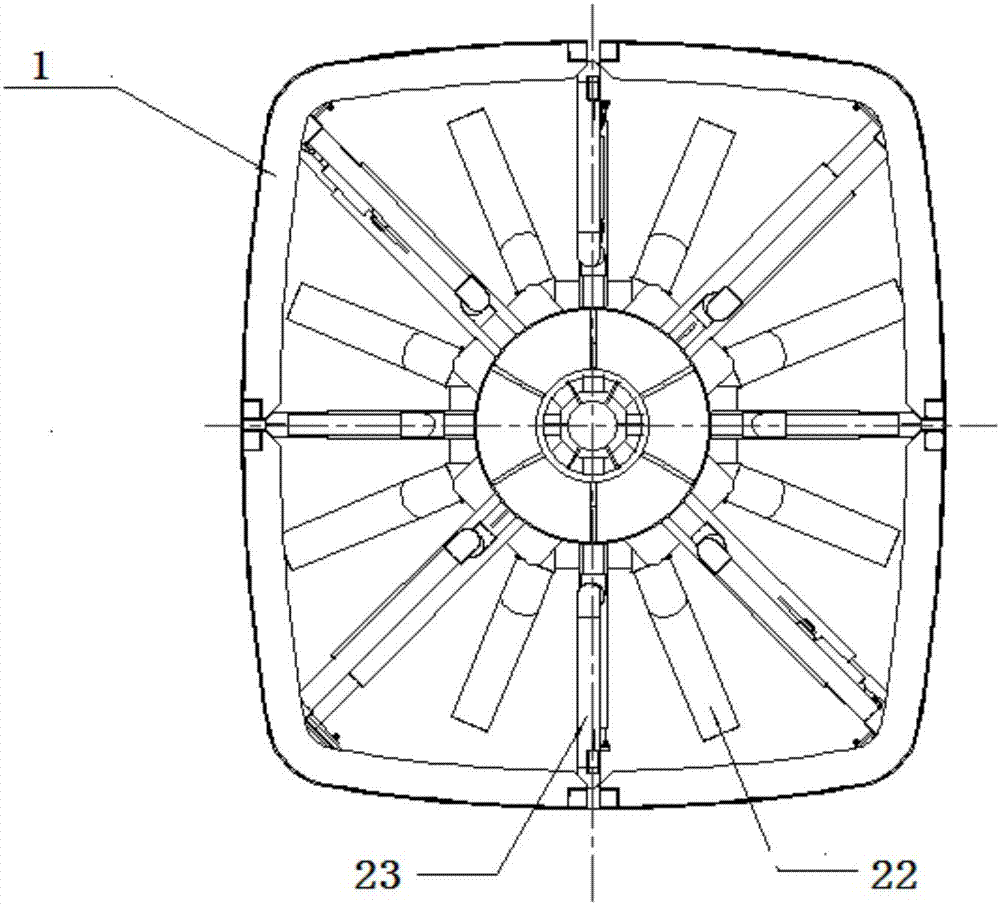

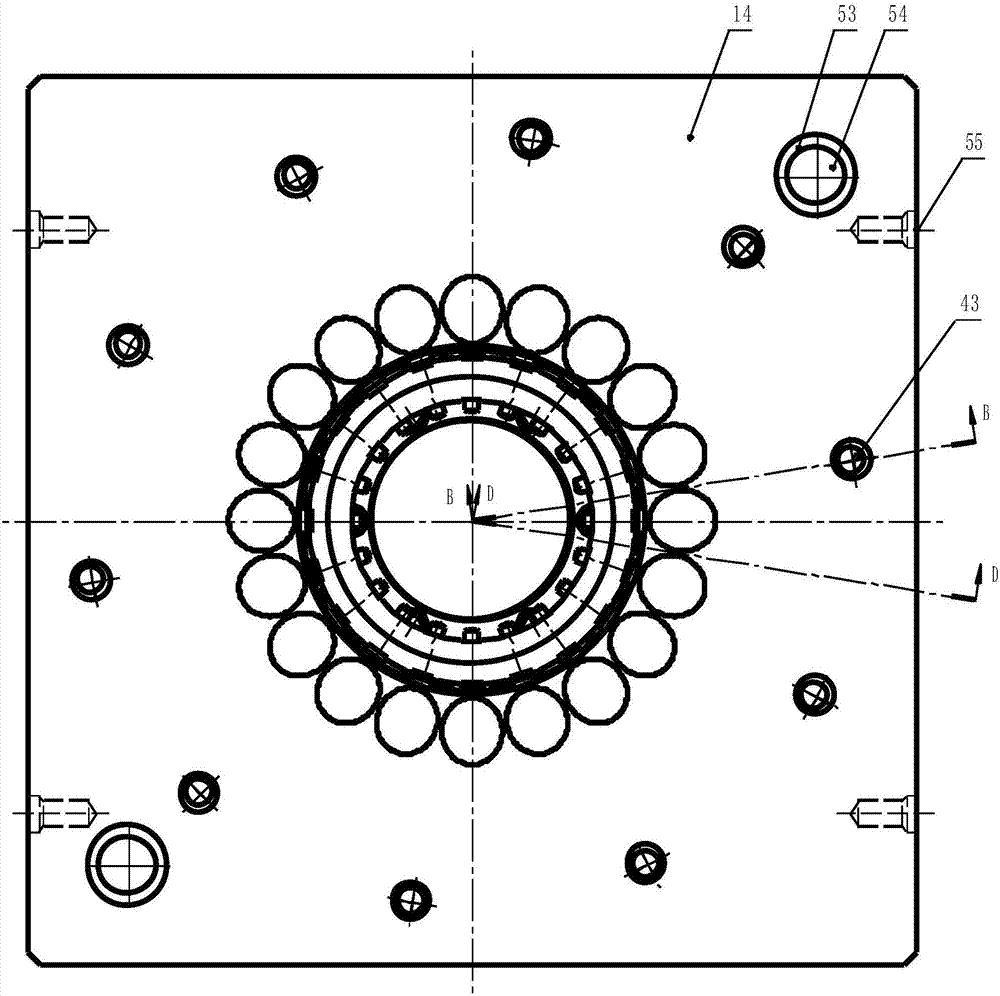

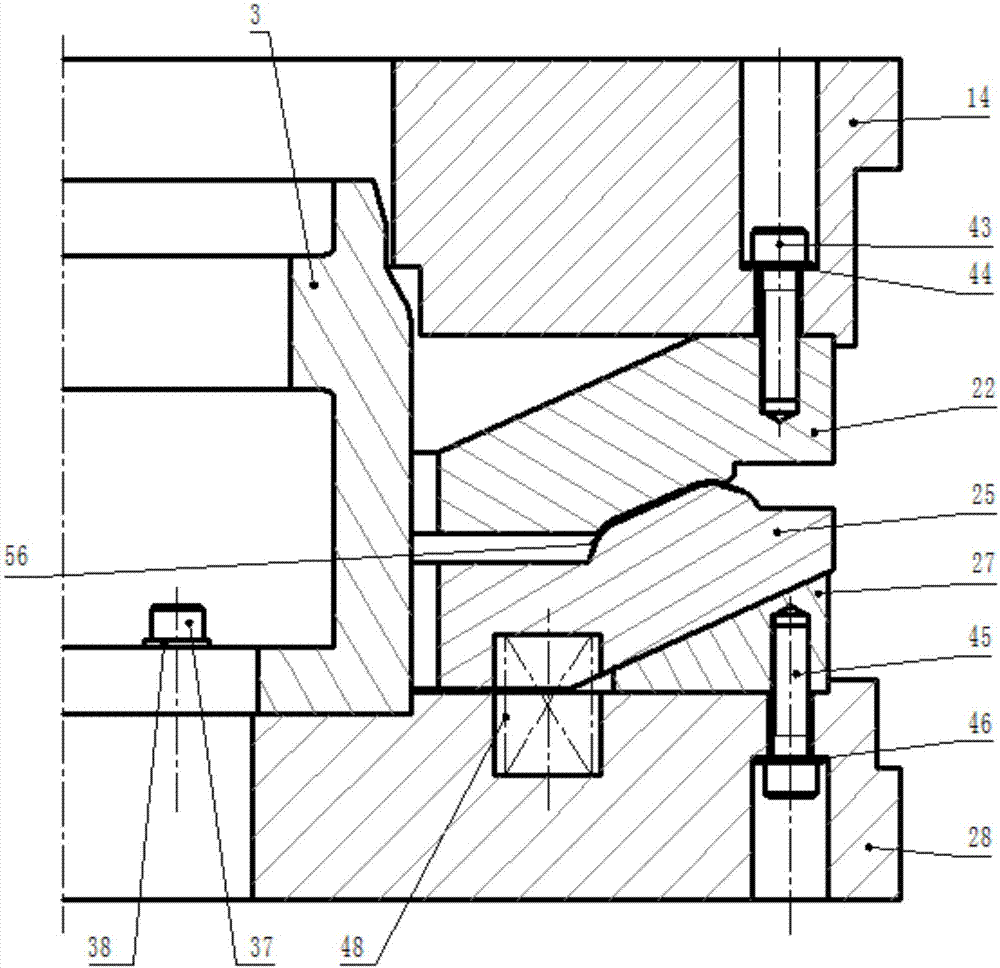

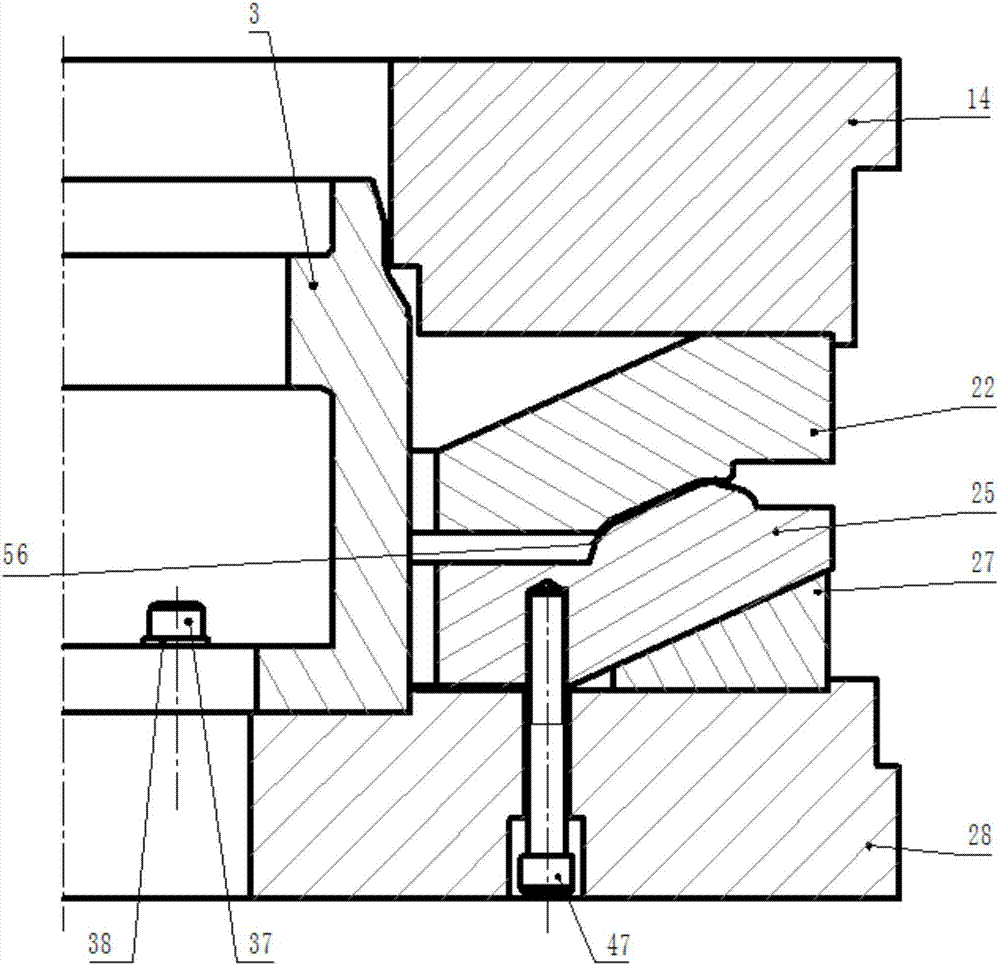

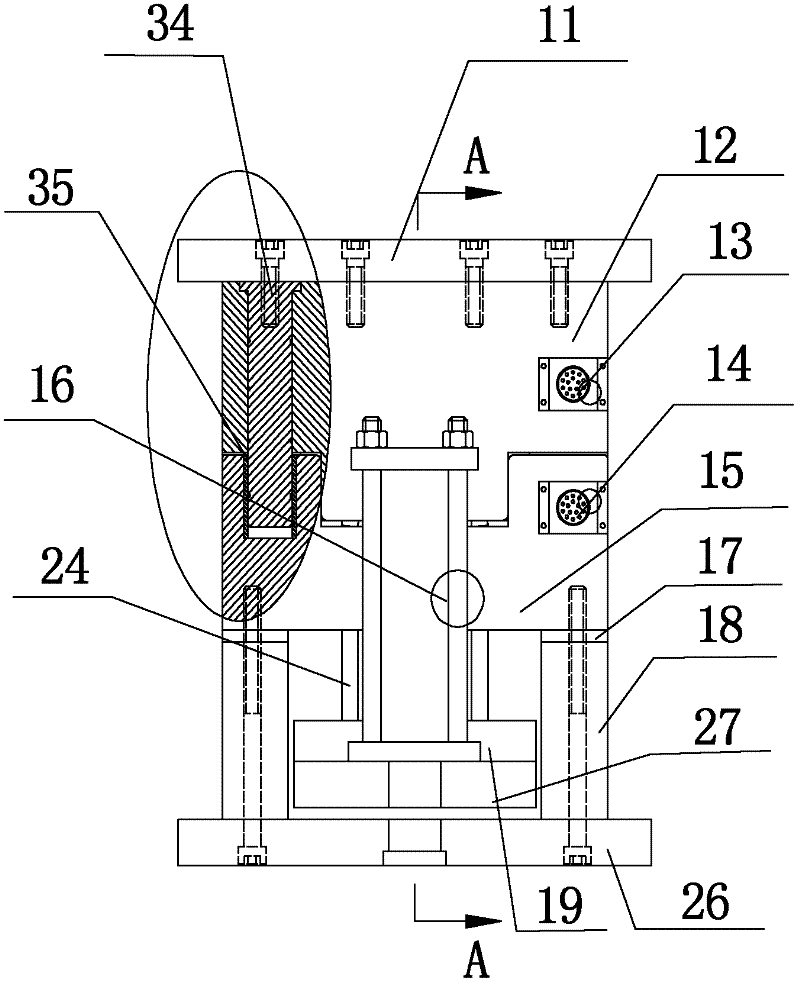

Aero-engine annular flame barrel array inclined hole flanging die and using method thereof

The invention discloses an aero-engine annular flame barrel array inclined hole flanging die and a using method thereof. The aero-engine annular flame barrel array inclined hole flanging die comprisesan upper die base and a lower die base which are matched, an upper die and a lower die are arranged between the upper die base and the lower die base, and a plurality of die sets matched with array inclined holes are arranged between the upper die and the lower die in the circumferential direction; a die assembly is characterized in that a workpiece is placed between the upper die and the lower die, a male die ejection device is arranged between the lower die and the lower die base, and a wedge and a second spring which are connected are arranged between the upper die base and the upper die;and the upper die base, the upper die, the lower die and the lower die base are provided with guide holes with the inclined angle the same as the inclined angle of the array inclined holes in the circumferential direction of the head of an aero-engine annular flame barrel. The problem that flanging cannot be carried out on flanging holes which are not coincident in annular workpiece shaft direction is solved, flanging of one set of array inclined hole by one die in sequence is achieved, the location degree of the flanging holes is improved, and the production efficiency is imporved.

Owner:AECC AVIATION POWER CO LTD

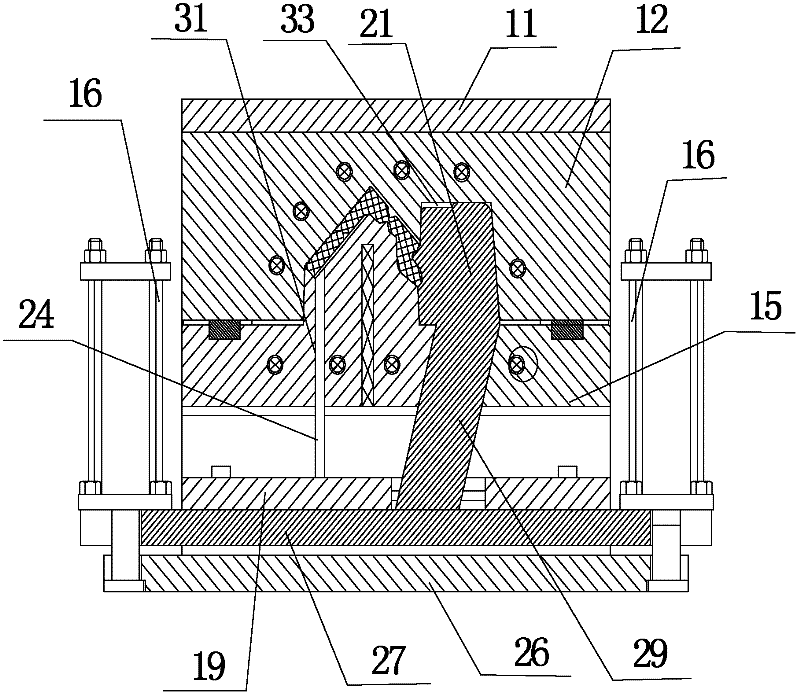

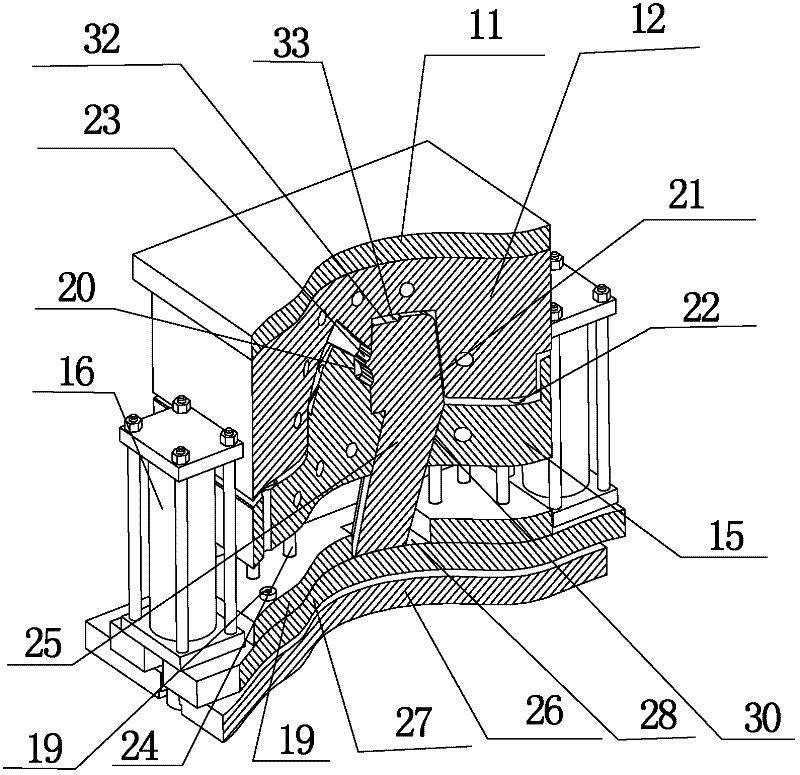

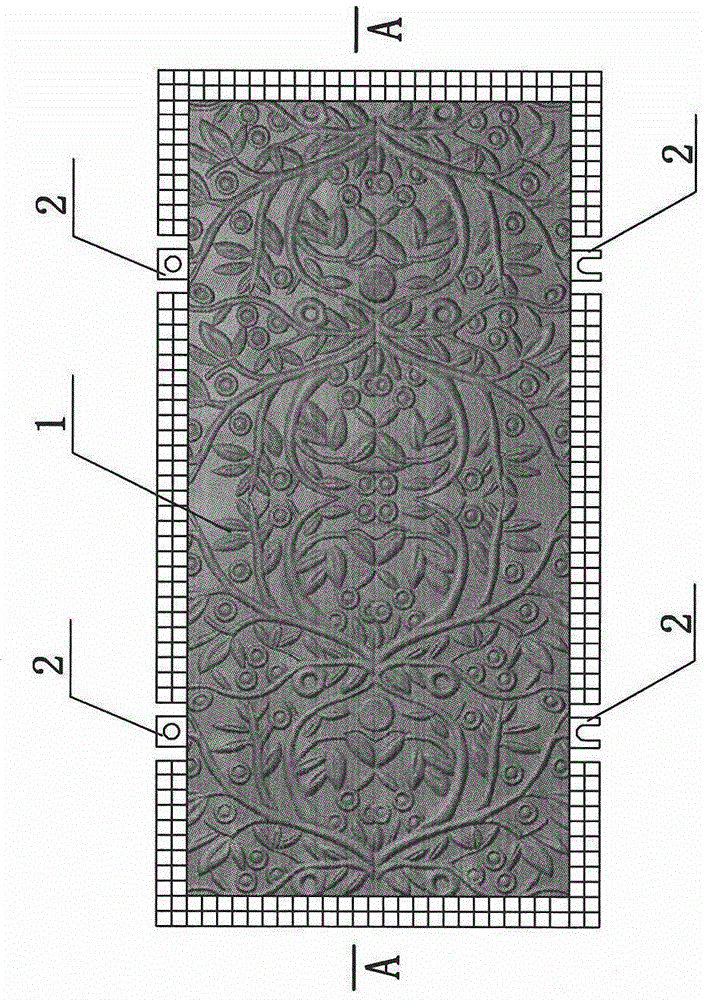

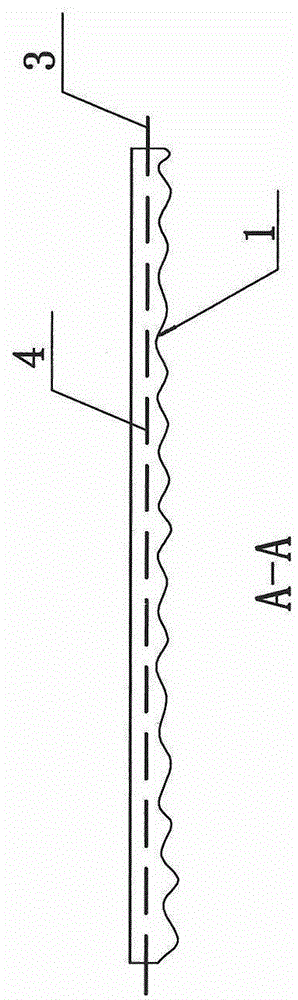

Hot pressing forming die for glass fiber reinforcement unsaturated polyester plastic products with complex structure

The invention provides a hot pressing forming die for glass fiber reinforcement unsaturated polyester plastic products with a complex structure. According to the invention, an integral core is arranged between an upper die and a lower die of the forming die, and after die locking of the upper die and the lower die, a forming die cavity of a product is formed by the upper die, the lower die and the integral core together; two oil cylinders are symmetrically arranged at two sides of the lower die, an ejector back plate is arranged above a lower die plate, a push plate is arranged on the ejector back plate, piston ends of the oil cylinders are fixedly connected with the lower die plate, cylinder body ends are fixedly connected with the ejector back plate, the ejector back plate pushes the integral core and pushes a push rod through the push plate, the push rod and the integral core synchronically move upwards, and at the same time, the integral core synchronically move outwards, thereby enabling ejection of a formed product and sideward opening of the integral core to be realized synchronically and demolding problems of formed products with a complex structure to be overcome. The forming die is especially applicable to forming of products with a complex structure and nonuniform wall thickness.

Owner:李慧玲

Method for forming deep concave and convex cement decorative plate by adopting mold box overlapping and vertical vibration

InactiveCN104690826AAvoid burrsSolve the problem of compact moldingMoulding surfacesShaping press ramMaterials scienceVertical vibration

The invention belongs to a method for forming a cement decorative plate with deep concave and convex patterns by adopting mold box overlapping and vertical vibration. Forming mold boxes comprise a movable mold box and a forming machine mold box which are overlapped, the movable mold box comprises a mold frame and a plastic mold box loaded in the mold frame, and the plastic mold box comprises an outer hard plastic box and an inner elastic soft plastic box; a vibrator is arranged at the upper part of a press head of a forming machine, and a vibrating table at the lower part of the forming machine and the vibrator at the upper part of the press head are started simultaneously during vibrating. With the adoption of the method, the problem about demolding of the deep concave and convex decorative surface can be solved very well, and the problem about forming compaction when the inner elastic soft plastic box is used by a cement mixing material is solved.

Owner:上海欧墅节能科技股份有限公司 +1

Quick low-cost CVD compacting method for carbon/carbon composite material

InactiveCN108220913AUniform and denseRapid densificationChemical vapor deposition coatingCarbon compositesOperability

The invention discloses a quick low-cost CVD compacting method for a carbon / carbon composite material. The method comprises the following steps: assembling a preform and an inner core mold tougher forhigh-temperature pre-treatment; placing the treated perform and inner core mold between upper and lower graphite electrodes of a deposition chamber of CVD equipment; and carrying out heating and introducing carbon source gas for 40-200h to prepare a carbon / carbon composite material product at one time. The method disclosed by the invention has the advantages and characteristics that 1, the methodintegrates advantages of a temperature differential method, a gas limiting method and a spontaneous heating characterized deposition process, so that influence of crusting of pyrolytic carbon on thesurface layer on deposition and compaction can be prevented effectively, the ability of the carbon source gas diffused to the perform is enhanced, and the deposition efficiency can be improved greatly; 2, the problem that density is not uniformly increased is solved, and the product quality is consistent; 3, the production energy consumption is low and the process and production cost is relativelylow; 4, the control degree of an air flow is high, and the utilization ratio of gas is high; 5, the perform and the graphite inner core mold are easily demolded, so that the operability is good; and6, the density state of the product can be controlled precisely, so that an accurate product effect is obtained.

Owner:AEROSPACE RUITIAN CARBON MATERIALS CO LTD

Composite material polyurethane rigid foam decorative marble pillar

InactiveCN103866961ANo crackNo deformationCovering/liningsPolyureas/polyurethane adhesivesChemistryPolyurethane

Owner:FINEHOPE POLYUREHTHANE PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com