Aero-engine annular flame barrel array inclined hole flanging die and using method thereof

A technology for aero-engines and flanging molds, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as inability to flang at the same time, inconsistent flanging holes, etc., to improve processing efficiency, ensure part quality, and improve position degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

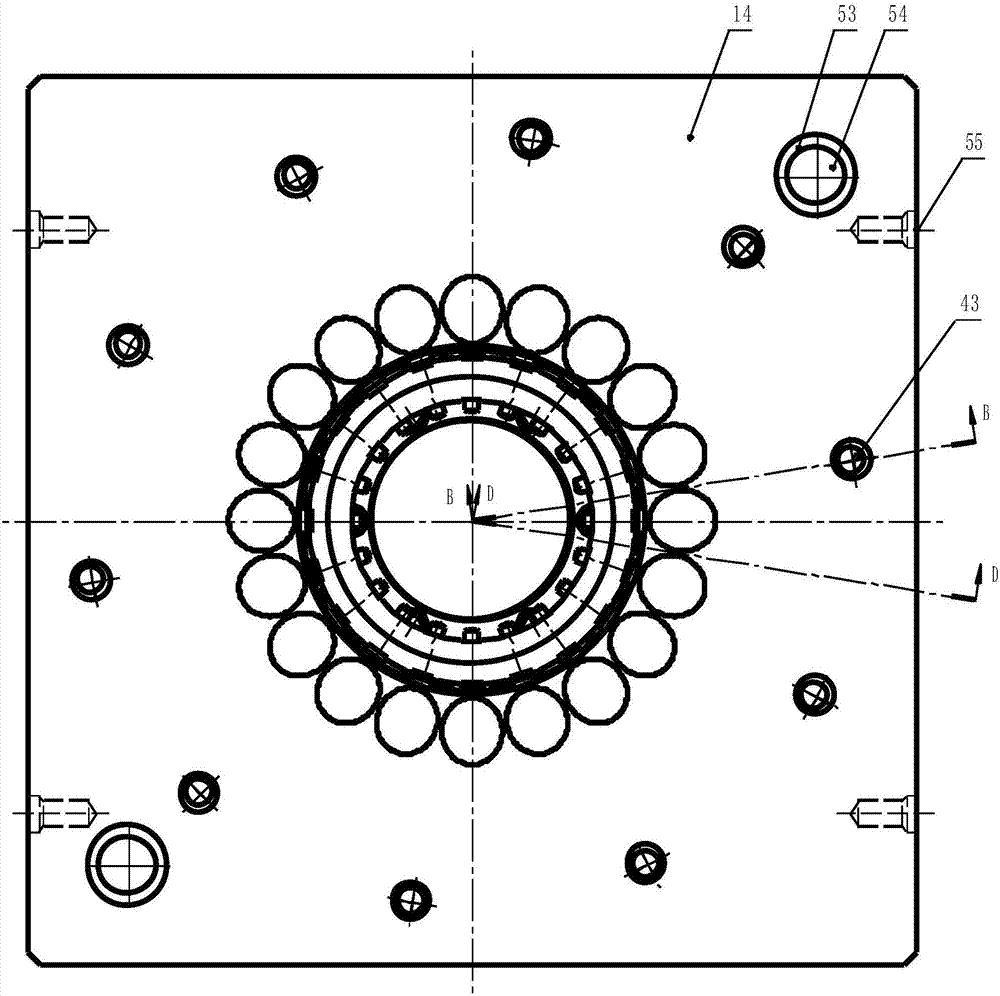

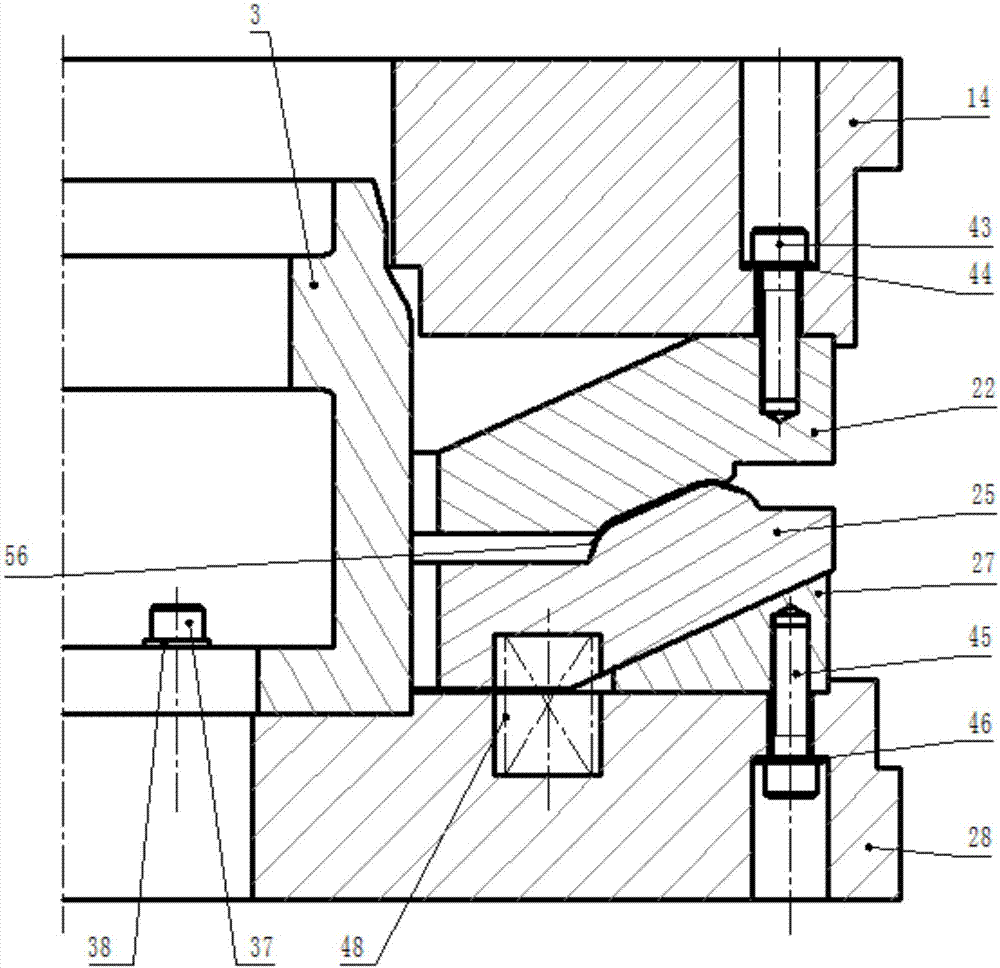

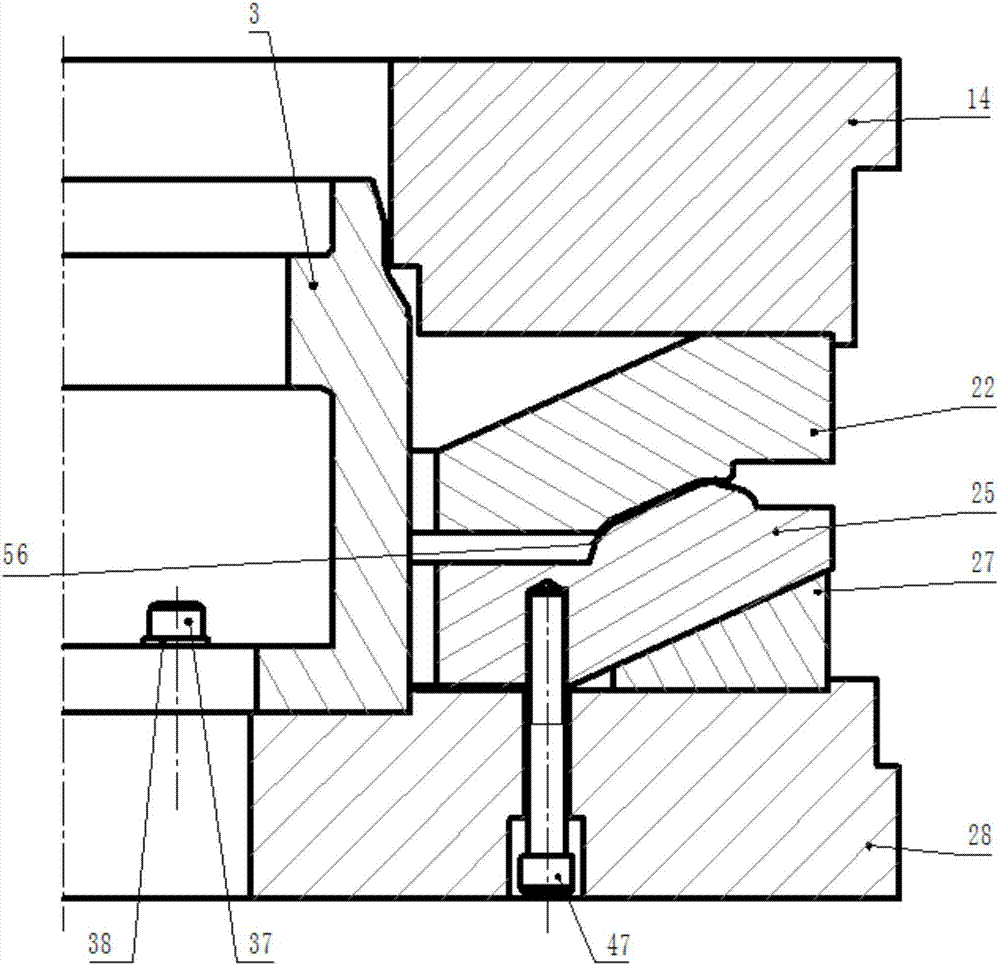

[0030] The invention provides an aero-engine annular flame tube array oblique hole flanging mold, such as Figure 1-3 Shown, comprise upper mold base 14 and lower mold base 28, be provided with upper mold 22 and lower mold 25 between upper mold base 14 and lower mold base 28, and upper mold 22 is connected with upper mold base 14, and lower mold 25 is connected with upper mold base 28. The lower die base 28 is connected; and a guide post 54 is arranged between the upper die base 14 and the lower die base 28, and the guide post 54 is covered with a guide post sleeve 53; A plurality of guide holes matching the axial array oblique holes on the head of the flame tube.

[0031] Such as Figure 2-3 As shown, the upper mold base 14 and the upper mold 22 are fixedly connected by a plurality of second hexagon socket bolts 43,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com