Manual demoulding device

A technology of demoulding device and mold box, which is applied in the direction of unloading device, preparation of test samples, manufacturing tools, etc., to achieve the effect of high reliability, outstanding substantive features, and easy placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

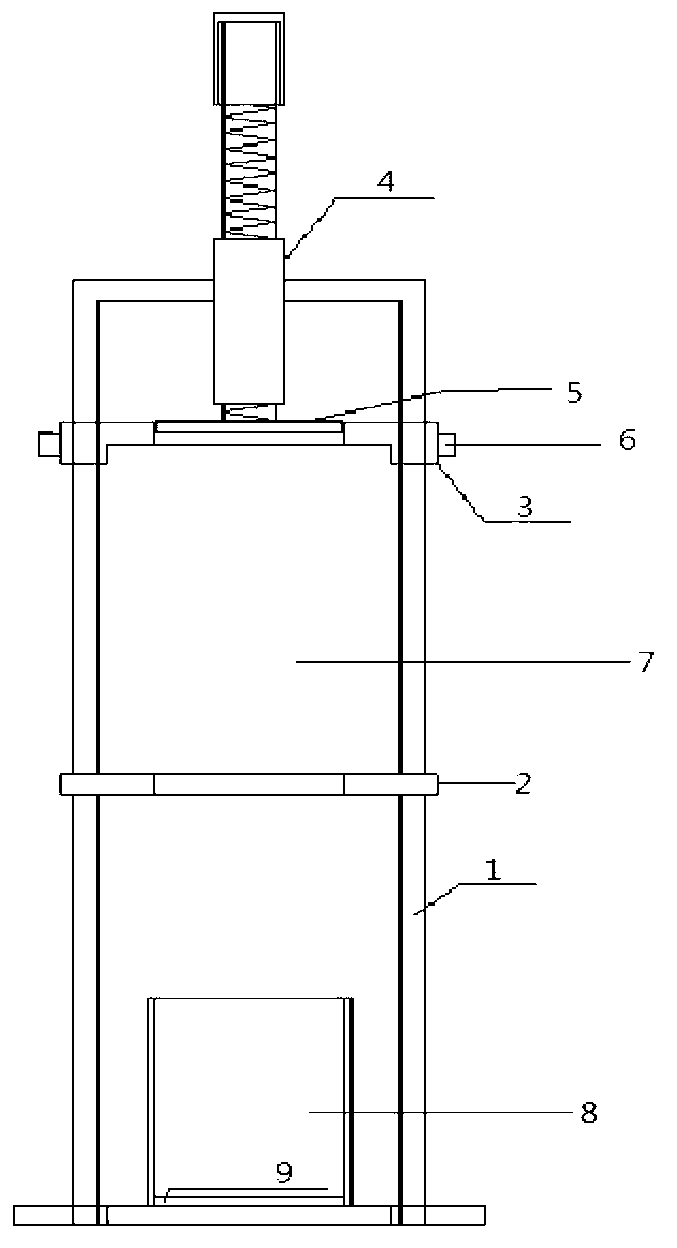

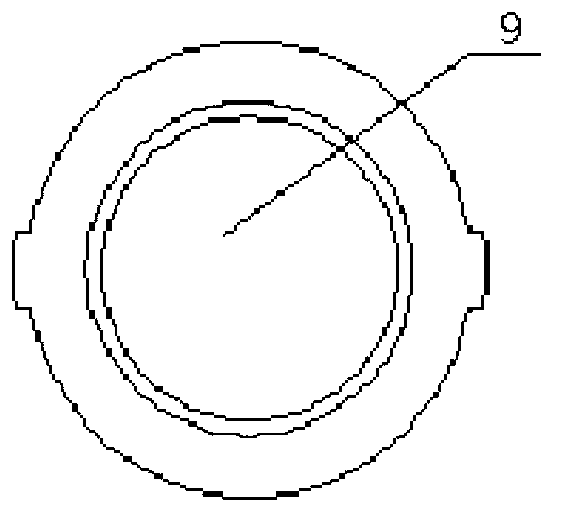

[0011] The main structure of this embodiment includes a support frame 1, a fixed plate 2, an upper top plate 3, an Acme screw 4, a pressure plate 5, a fixing bolt 6, a mold placement chamber 7, a detachable mold box 8 and a rubber pad 9. The shape of the support frame 1 is a hollow cuboid, with a height of 215mm, an outer diameter of 100mm, and an inner diameter of 80mm. The fixed plate 2 is fixedly installed on the support frame 1, 100mm away from the lower end of the support frame 1, and the fixed plate 2 There is a through hole with a diameter of 40mm in the center, and the upper top plate 3 is installed on the supporting frame 1 through fixing bolts 6, and the upper top plate 3 can slide up and down by adjusting the fixing bolts 6 on both sides of the upper top plate 3, and the center of the upper top plate 3 is opened. There is a through hole with a diameter of 40mm; the top of the supporting frame 1 is provided with a through hole, the diameter of the through hole is grea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com