Method for forming deep concave and convex cement decorative plate by adopting mold box overlapping and vertical vibration

A vibration molding and decorative board technology, applied in the direction of molding pressure head, molding surface, ceramic molding machine, etc., to avoid burrs and solve the problem of compact molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

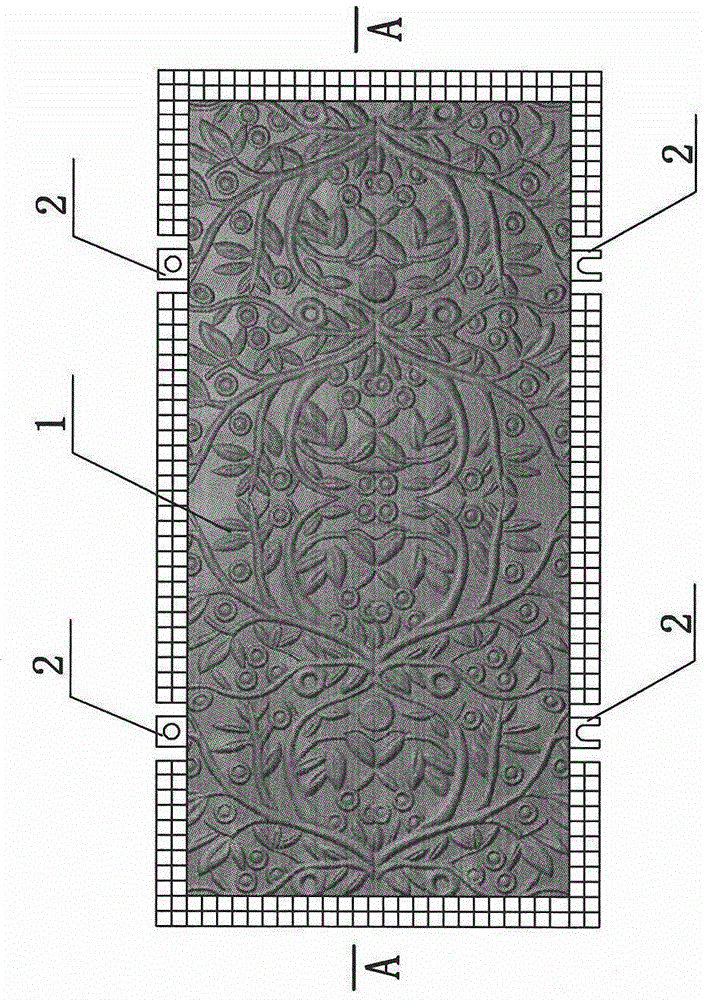

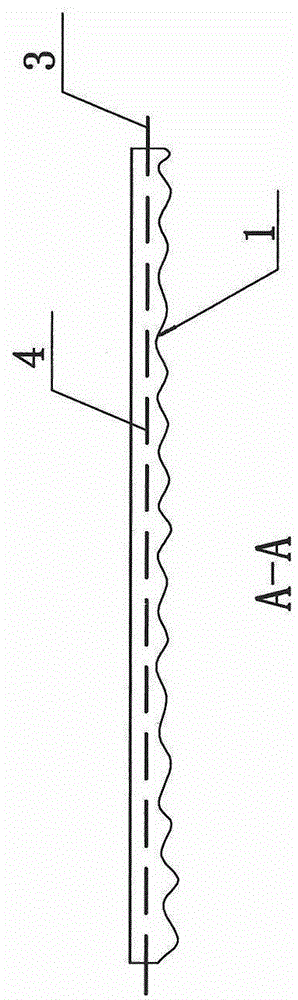

[0024] Such as figure 1 and figure 2 The cement decorative board shown is equipped with such image 3 and Figure 4 As shown in the steel wire mesh, the outer surface is prefabricated with a deep concave-convex decorative pattern 1 with a small demoulding slope; metal pendants 2 (used to install and connect metal embedded parts) are arranged at a certain distance on the cement decorative plate and the lower end surface; cement decorative Steel mesh lap joints are reserved on the four sides of the board.

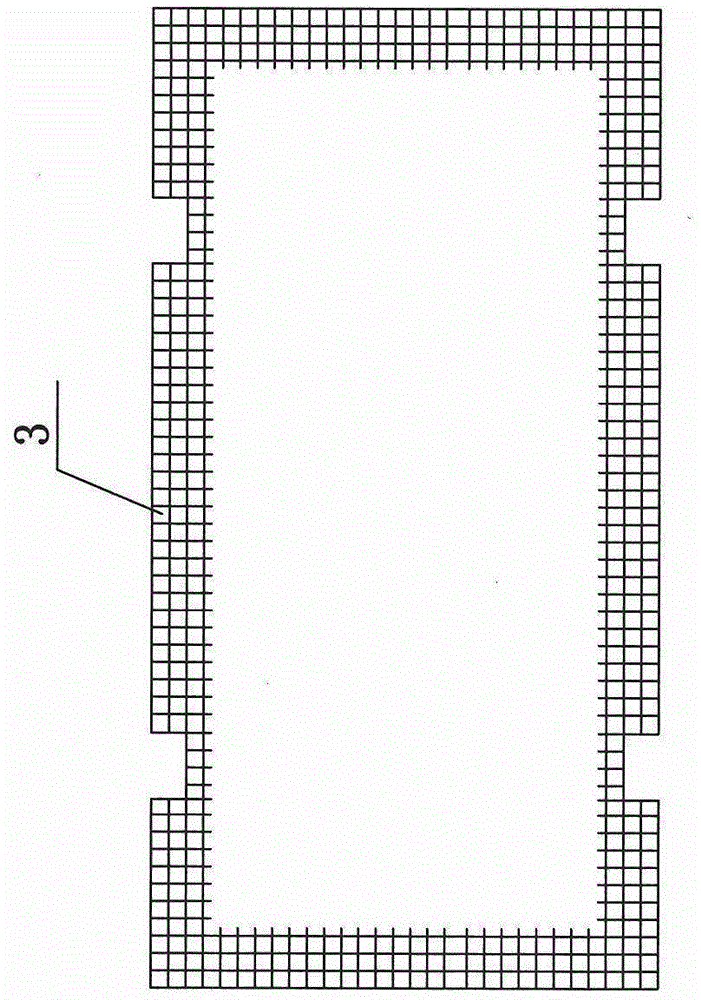

[0025] The steel wire mesh of the cement decorative plate is cut (can be cut by a punching machine) and separated into an outer mesh 3 and an inner mesh 4, the outer mesh 3 is arranged on the periphery of the cement decorative plate, and the four sides extend out of the cement decorative plate to an appropriate width (both The four sides reserve steel wire mesh joints), and the inner mesh sheet 4 is arranged in the middle of the cement decorative board.

[0026] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com