Multi-axial direction composite material bent pipe and preparation method thereof

A composite material, multi-axial technology, applied in the direction of adhesive type, adhesive additive, polymer adhesive additive, etc., can solve the problem of difficult demoulding and circumferential pressure of special-shaped composite material elbow, and rough appearance of pipe fittings. , low strength of the core mold, etc., to achieve the effect of compact and reliable internal quality, regular appearance of internal and external surfaces, and high overall structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0048] The specific proportions (parts by weight) are shown in Table 1, and the soluble adhesive is obtained after mixing the components evenly.

[0049] Table 1

[0050]

Embodiment 7~14

[0052] Such as Figure 4 As shown, using the soluble adhesive obtained in Examples 1 to 6, a soluble mandrel was prepared. See Table 2 for the specific weight ratio and process, and see Table 2 for the compressive strength of the obtained soluble mandrel.

[0053] Table 2

[0054]

[0055]

Embodiment 15

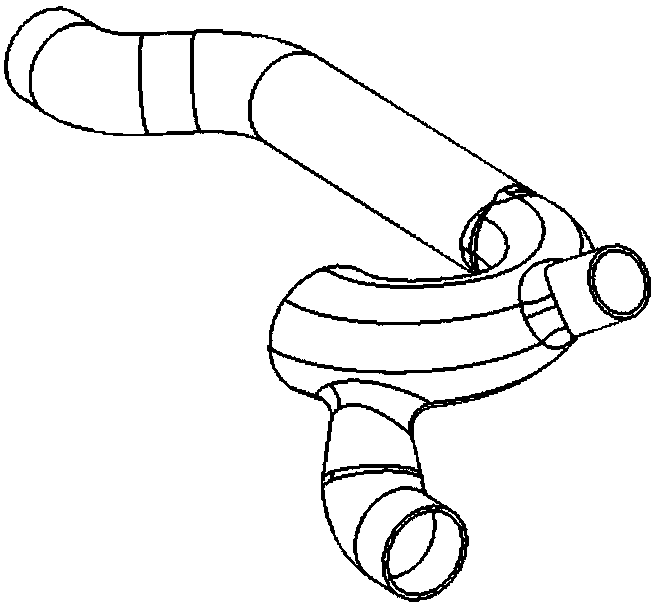

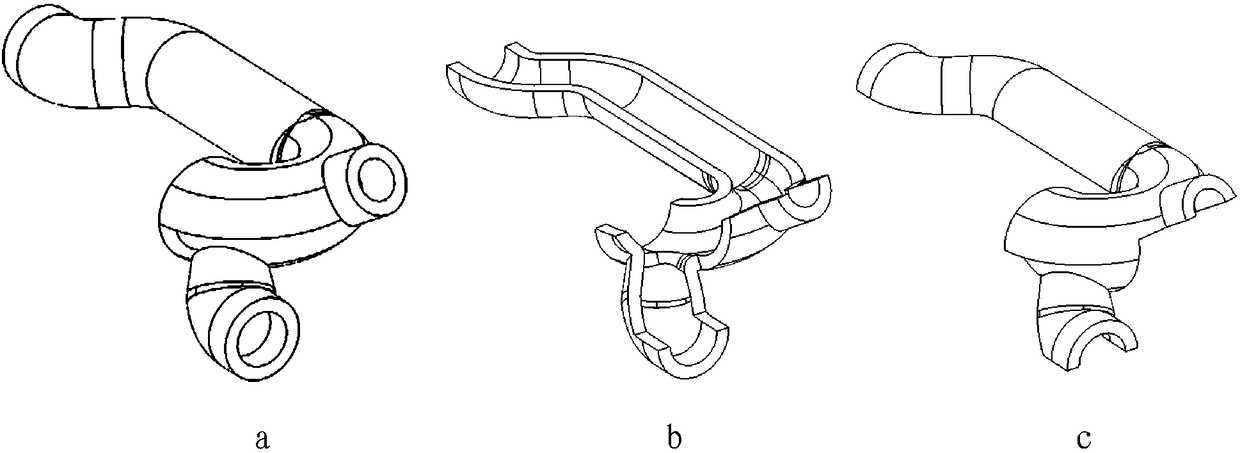

[0057] made as figure 1 The shown is a special-shaped elbow with 4 nozzles, the thickness of the pipe wall is 2mm, the inner diameter of the pipe main body is about Φ20mm, and the length of the main body is about 400mm. The thickness of a single layer is 0.2mm, and the curing temperature is 130°C.

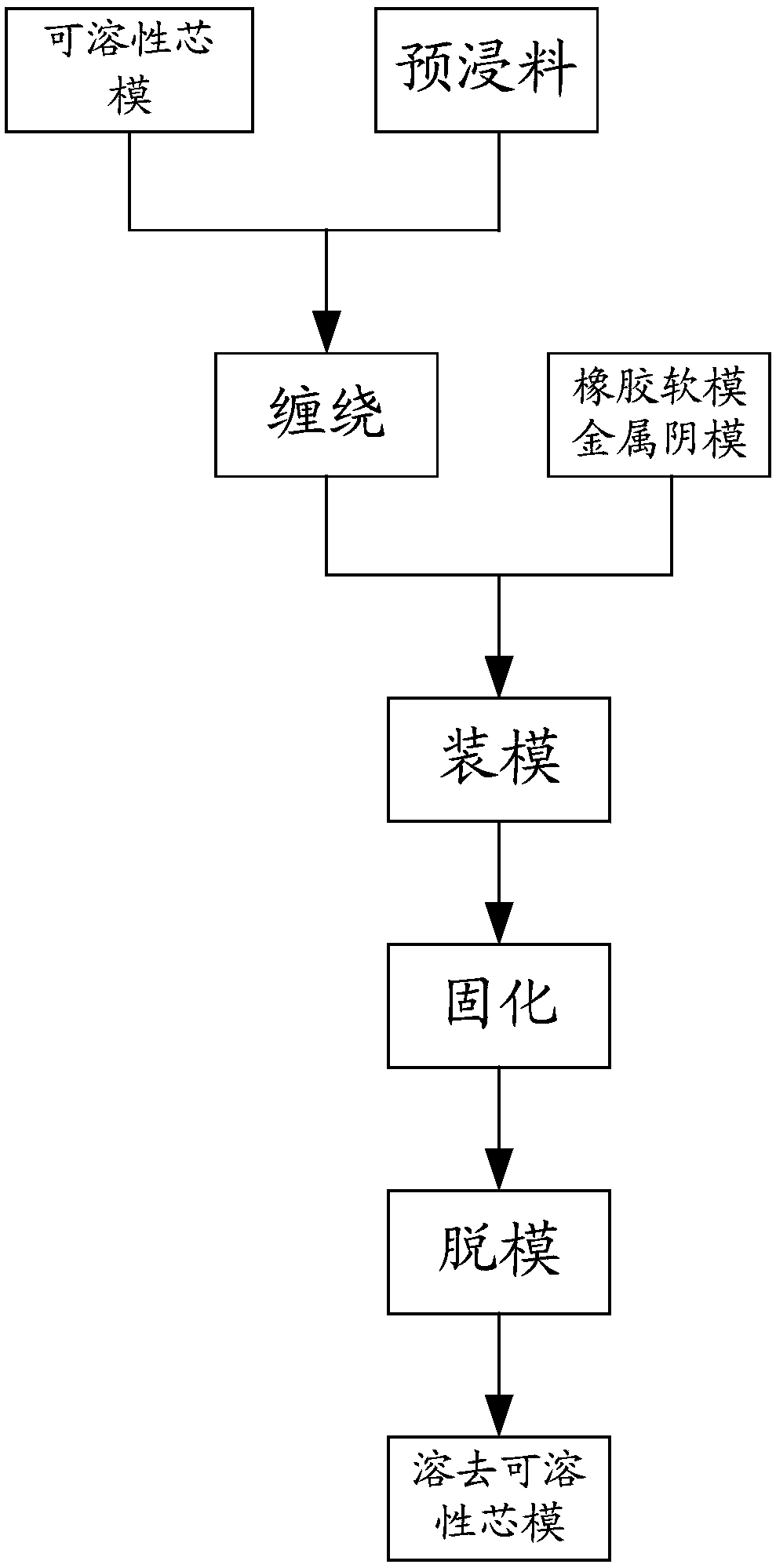

[0058] The specific preparation process is as image 3 Shown:

[0059] 1. Prepare soluble mandrel, prepreg, rubber soft mold and metal negative mold.

[0060] (1) Soluble mandrel preparation, such as Figure 4 shown.

[0061] Using the soluble adhesive of Example 5, using the ratio of Example 11, after fully mixing the components, the mixed materials are respectively filled into the upper and lower half mold cavities of the mandrel molding; after the upper and lower molds are closed, sequentially from Pour the remaining materials into the 4 nozzles, tamp them in turn, and assemble the nozzle pressure plates in turn; then put the assembled mold into the oven, heat at 178°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com