Ultrasonic vibration assisted drawing forming device and method for thin-walled micro fine pipe

An ultrasonic vibration and microtube technology, applied in metal drawing forming tools, metal wire drawing, metal processing equipment, etc., can solve the problems of low surface quality and easy fracture, achieve good surface quality, improve plastic performance, and solve the problem of stripping. The effect of the puzzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

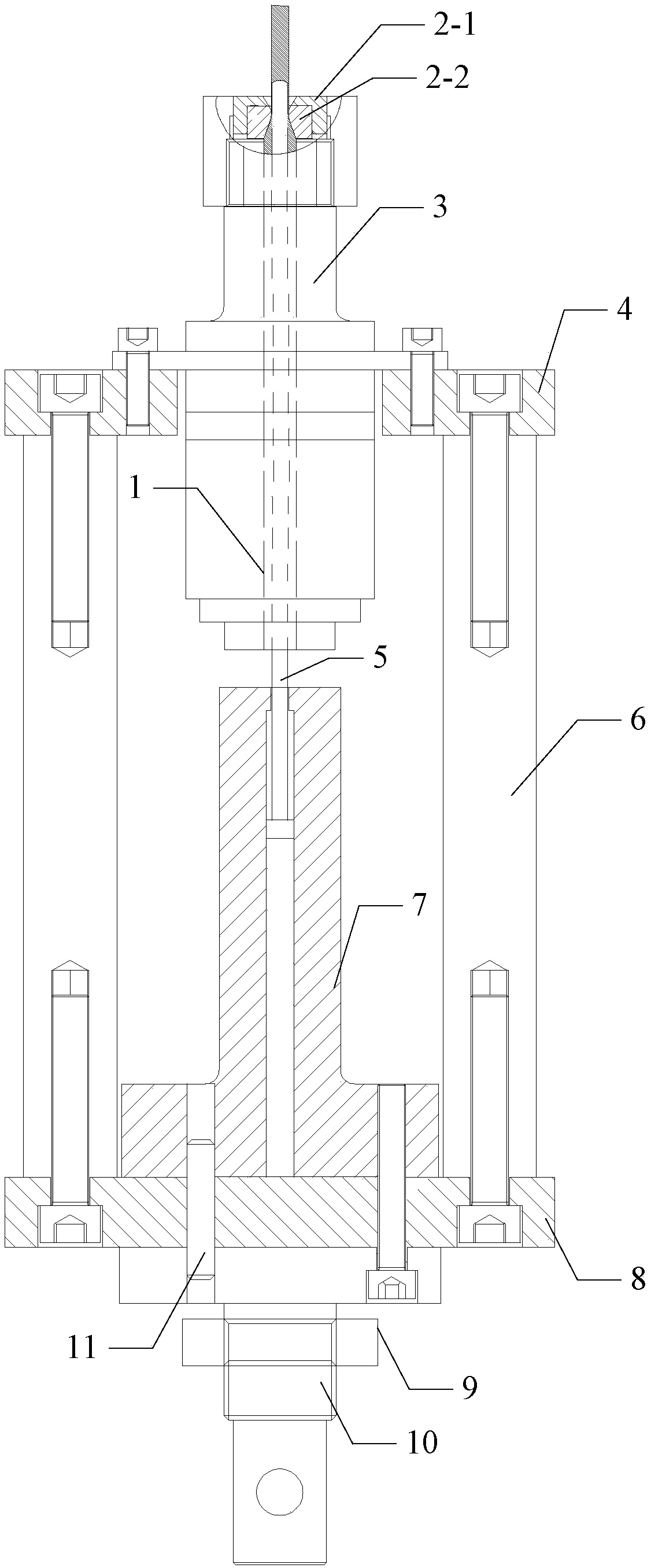

[0020] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the thin-walled microtube ultrasonic vibration-assisted drawing forming device described in this embodiment includes a drawing die, an ultrasonic vibrator 3, an upper die holder 4, a drawing mandrel 5, a support column 6, and a mandrel guide Seat 7, lower mold seat 8, fixing nut 9 and connector 10;

[0021] One end of the connector 10 is fixedly connected with the lower machine base of the tensile testing machine; the other end of the connector 10 is fixed on the bottom surface of the lower mold base 8 by a fixing nut 9;

[0022] The mandrel guide seat 7 is arranged on the top surface of the lower mold base 8;

[0023] The bottom end of the ultrasonic vibrator 3 passes through the upper mold base 4, and the ultrasonic vibrator 3 is fixed on the upper mold base 4;

[0024] The drawing die is tightly and rigidly connected to the top of the ultrasonic vibrator 3; the drawing die is fixed on...

specific Embodiment approach 2

[0029] Specific embodiment 2: This embodiment is to further limit the thin-walled microtube ultrasonic vibration assisted drawing forming device described in specific embodiment 1. In this embodiment, the drawing die includes a die support member 2- 1 and die insert 2-2;

[0030] The die insert 2-2 is tightly and rigidly connected to the top of the ultrasonic vibrator 3;

[0031] The die supporting part 2-1 supports and wraps the outside of the die inserting part 2-2.

[0032] In this embodiment, the die supporting part 2 - 1 and the die inserting part 2 - 2 reduce the difficulty and cost of drawing forming of the drawing die, and facilitate the replacement of the drawing die.

specific Embodiment approach 3

[0033] Embodiment 3: This embodiment further defines the ultrasonic vibration-assisted drawing and forming device for thin-walled microtubes described in Embodiment 1. In this embodiment, a pin 11 is also included;

[0034] Both the lower die base 8 and the mandrel guide seat 7 are provided with pin holes, and the pins 11 pass through the pin holes of the lower die base 8 and the pin holes of the mandrel guide seat 7 at the same time to complete the alignment of the die base 8 and the mandrel. The positioning of the guide seat 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com