Forming mould for composite material part of box type closed-angle structure

A composite material and forming mold technology, applied in the field of aviation manufacturing, can solve problems such as demoulding, and achieve the effect of quality assurance of parts and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

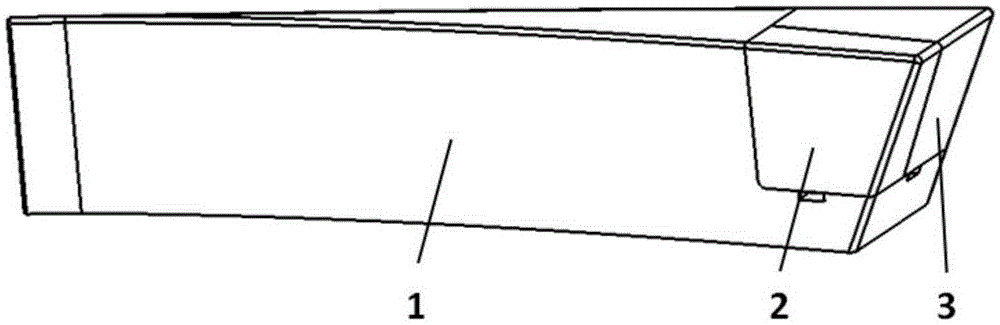

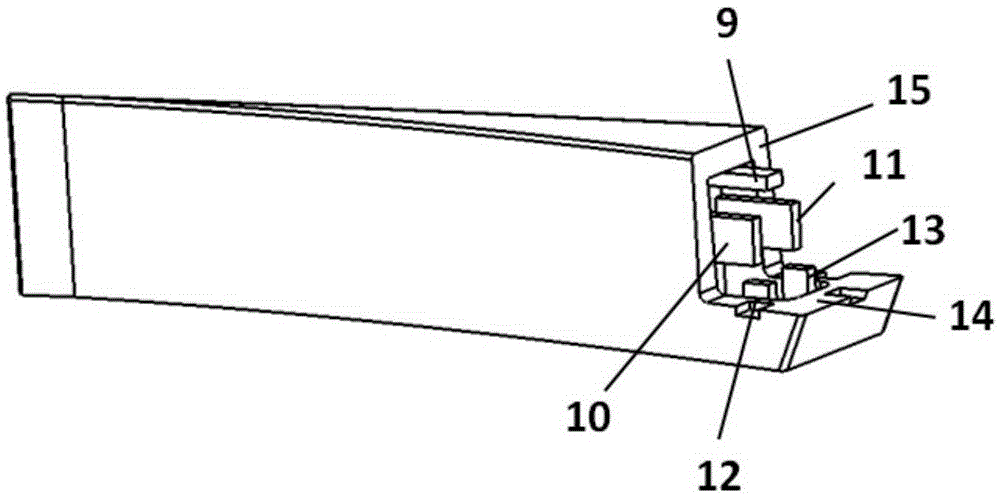

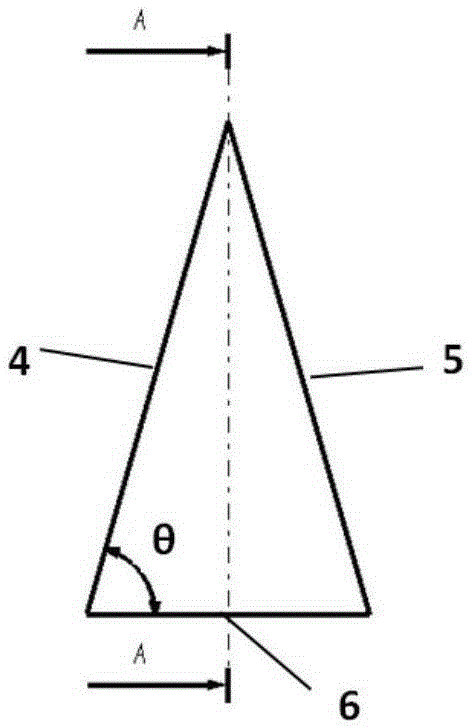

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings. The mold includes a main body mold 1, a left split body mold 2, and a right split body mold 3, wherein the left split body mold 2 passes through the upper stop bar 9, the left stop bar 10, the left lower stop bar 12 and the main body mold at the lower separation surface 14 and the inside The separation surface 15 is combined with the main mold 1; the right split mold 3 is combined with the main mold 1 at the lower separation surface 14 and the inner separation surface 15 through the upper limit rod 9, the right limit rod 11, and the right lower limit rod 13 ; The left split body 2 is combined with the right split body 3 on the left and right split surfaces 16 . The combined overall mold outer surface includes left side 4, right side 5, middle side 6, and web surface 7, which jointly form a shape consistent with the inner shape of the box-shaped closed-angle structure c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com