Method for preparing high depth-width ratio polymer nanorod array by sacrificing template

A nano-pillar array and high aspect ratio technology, which is applied in the field of sacrificing templates to prepare high aspect ratio polymer nano-pillar arrays, can solve the problems of increased cost and difficulty in the manufacturing process, and achieves high manufacturing efficiency, good biocompatibility, high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

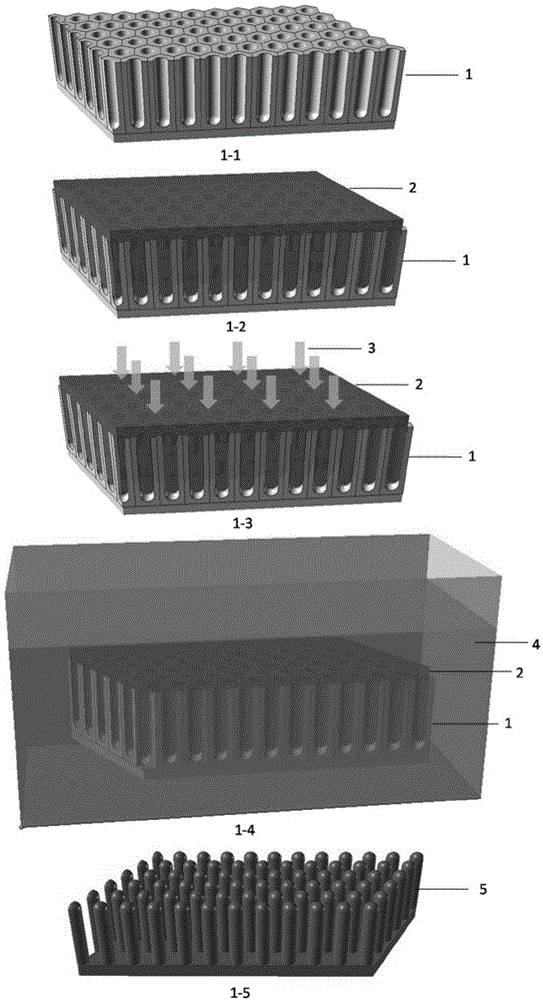

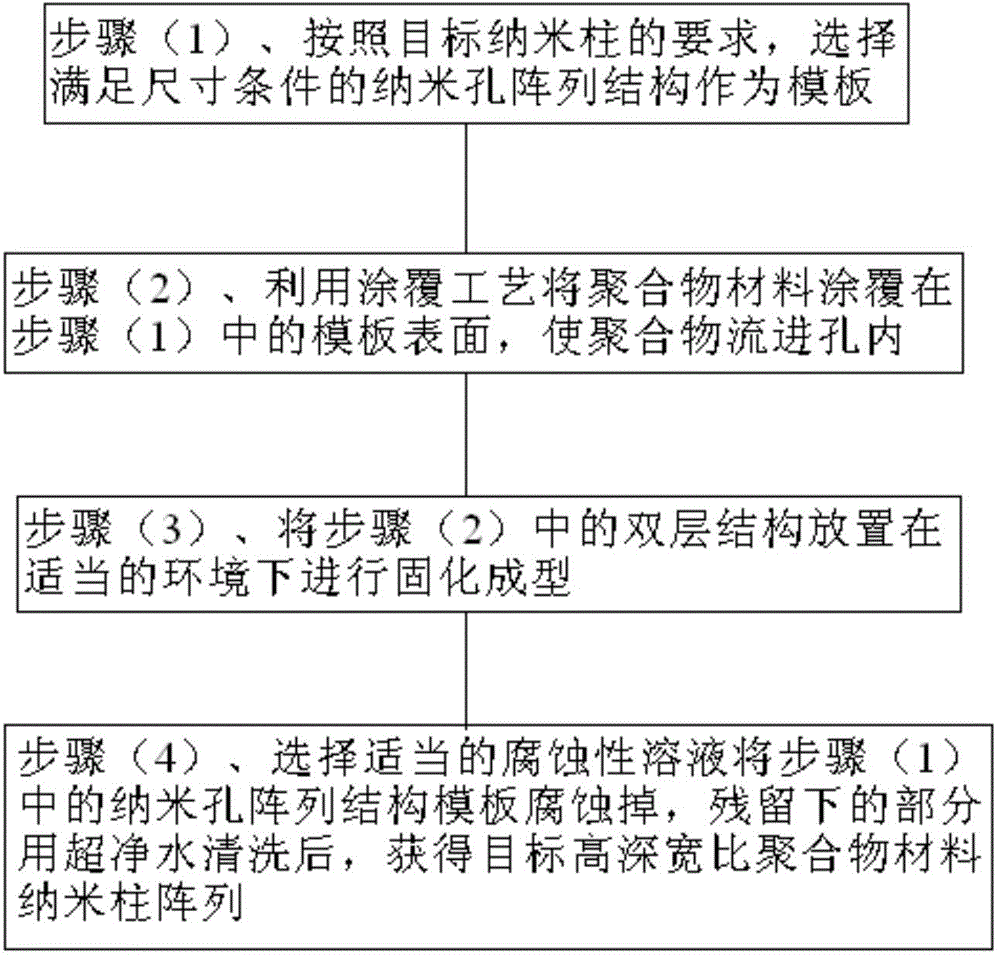

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The protection scope of the present invention should include all content of the claims. Through the following examples, those skilled in the art can realize all the contents of the claims of the present invention.

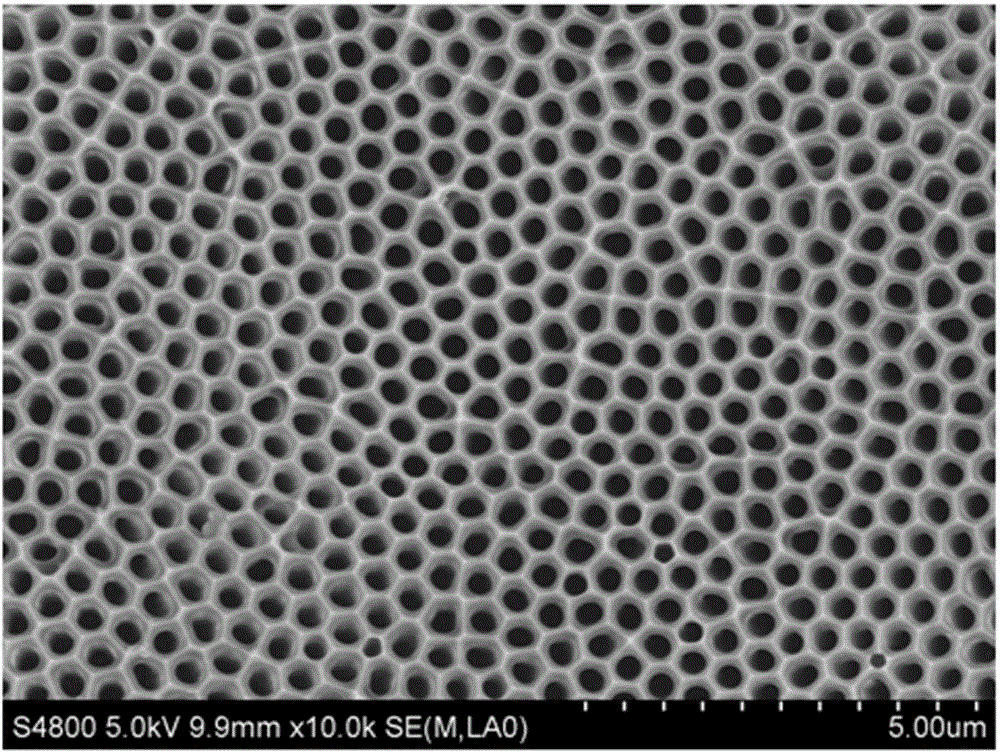

[0030] Such as figure 1 As shown in 1-1, a porous anodized aluminum template 1 with a pore diameter of 300 nanometers and a depth of 30 microns is used. The template area is 3 cm × 3 cm and the mass is 2 grams. The surface is cleaned with an alcohol solution.

[0031] Such as figure 1 As shown in 1-2, prepare a liquid mercapto-ene material with a viscosity of 3.5 centipoise and a Young’s modulus of 5 GPa. Use a dropper to drop a drop of liquid mercapto-ene material on template 1, and gently tilt and shake template 1 to form A uniform layer of mercapto-ene material layer 2 with a thickness of 1 mm, and at the same time, the mercap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com