LED (Light-emitting Diode) automobile light and preparation method thereof

A technology of LED car lights and LED light sources, applied in lighting and heating equipment, cooling/heating devices of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problem of affecting the service life and stability of LED car lights Decreased performance, unaware of the heat dissipation performance of the heat pipe, etc., to achieve the effect of enhanced heat dissipation, reduced thermal resistance, and solved the problem of mold release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

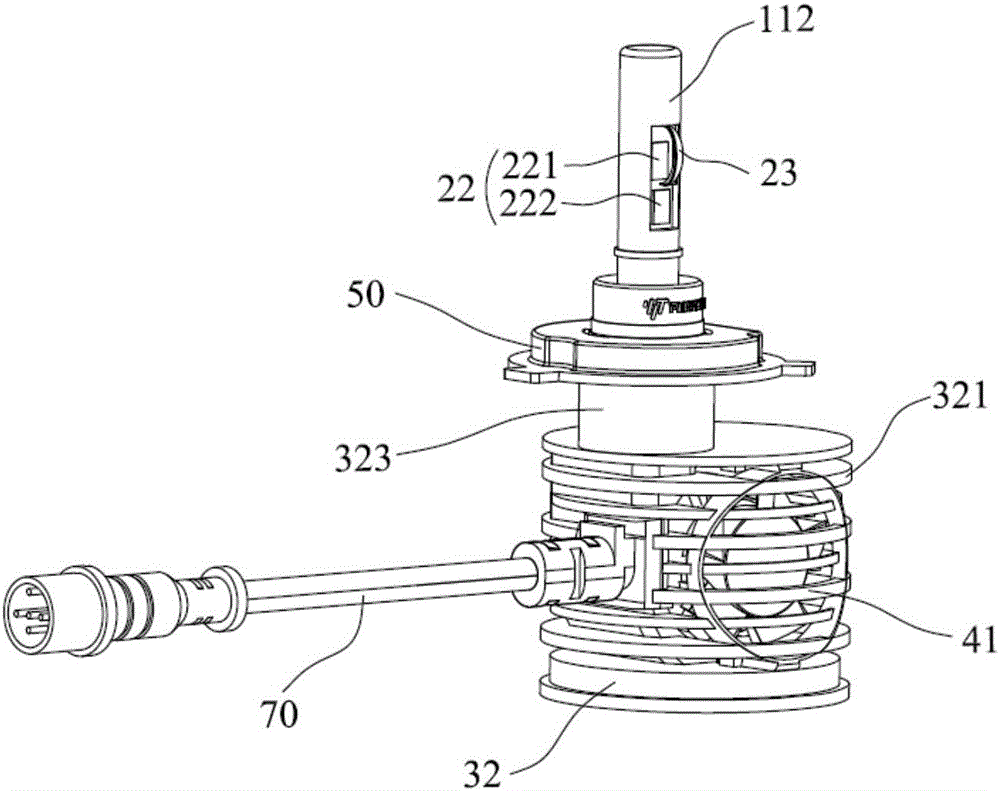

[0044] Figures 1 to 3 The structure of the LED vehicle lamp as Embodiment 1 of the present invention is shown. see figure 1 and 2 As shown, the LED car lamp has a metal heat pipe 10 including a light source installation section 11 and a heat conduction section 12; wherein, the light source installation section 11 is covered with a cylindrical cap 112, and the light source installation section 11 has two oppositely arranged and facing On the opposite light source installation surfaces 111 , the LED light sources 20 exposed from the cap 112 are disposed on both light source installation surfaces 111 . The LED light source 20 includes a heat conduction substrate 21 welded on the light source installation surface 111 and a plurality of LED light emitting elements 22 such as LED beads or LED chips disposed on the heat conduction substrate 21 . In this embodiment, the thermally conductive substrate 21 is a ceramic-based circuit board; it is easy to understand that the thermally ...

Embodiment 2

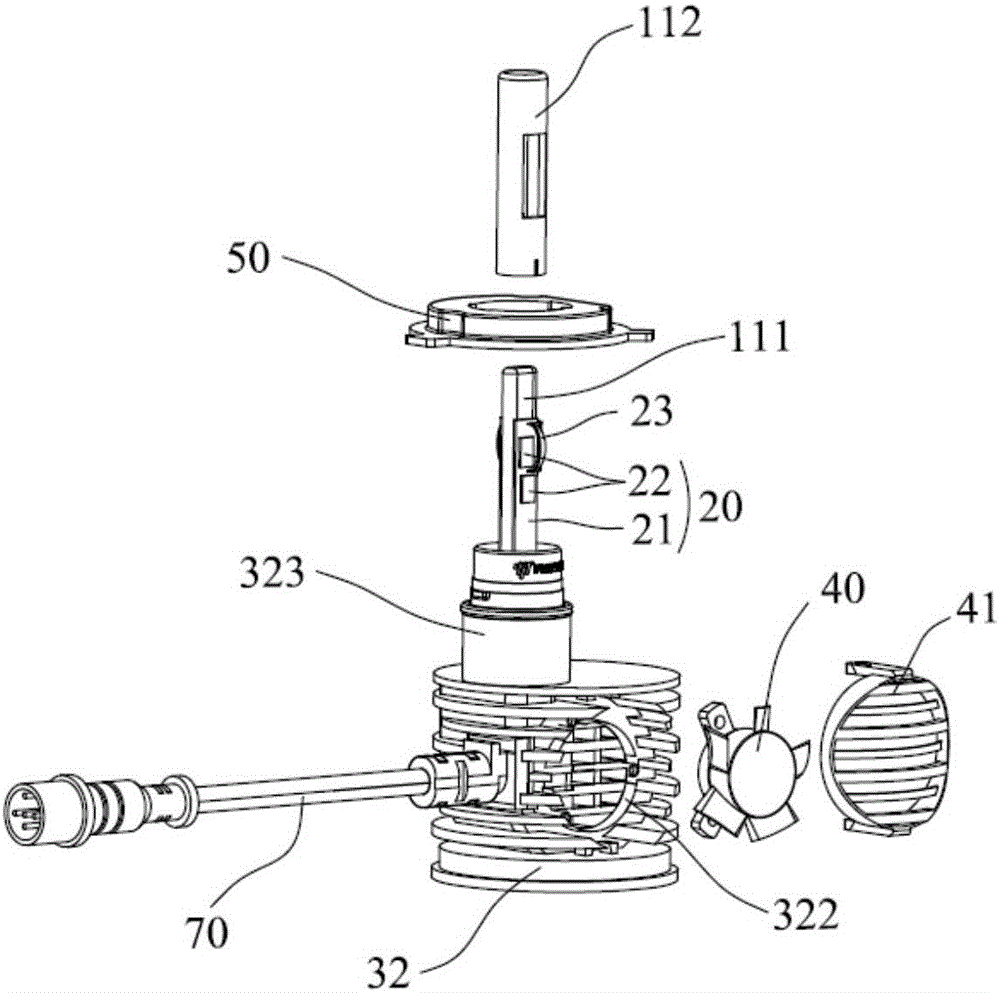

[0051] Figures 4 to 9 The structure of an LED vehicle lamp as Embodiment 2 of the present invention is shown. see Figures 4 to 9 As shown, the LED car lamp has a metal heat pipe 100 including a light source installation section 101 and a heat conduction section 102; wherein, the light source installation section 101 is covered with a cylindrical cap 103, and the light source installation section 101 has two oppositely disposed and facing On the opposite light source installation surface 1011 , the LED light source 120 exposed from the cap 103 is disposed on both light source installation surfaces 1011 . The LED light source 120 includes a heat conduction substrate 121 welded on the light source installation surface 1011 , a reflective member 123 and a plurality of LED light emitting elements 122 disposed on the heat conduction substrate 121 .

[0052] The heat sink 130 includes a metal radiator 131 and a thermally conductive plastic spacer 132 . The metal heat sink 131 in...

Embodiment 3

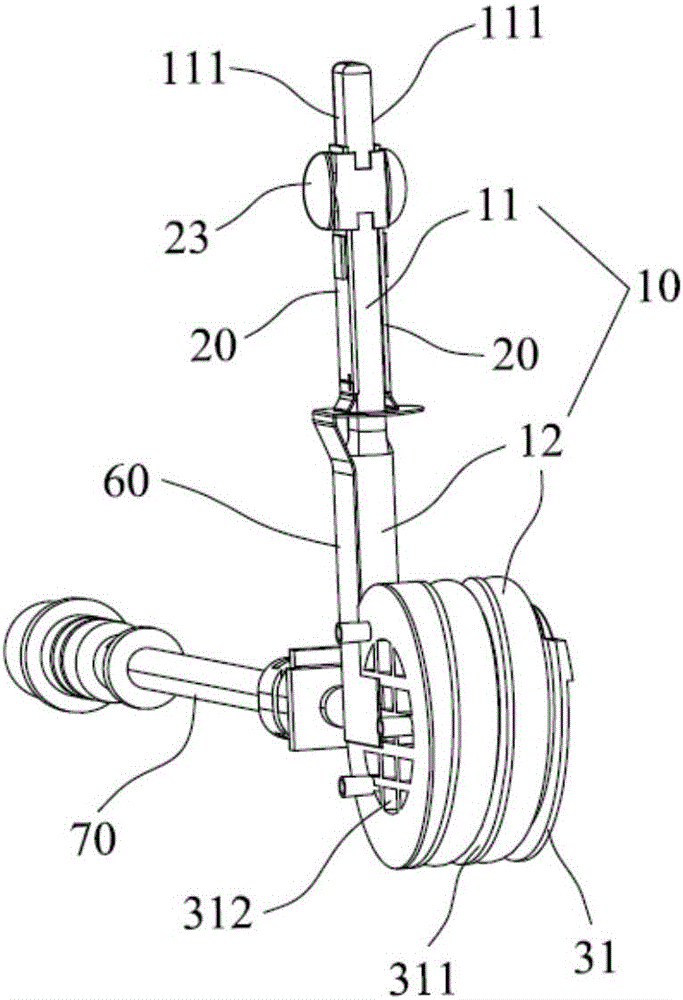

[0062] Figure 10 It is a perspective view of Embodiment 3 of the LED vehicle lamp of the present invention. Such as Figure 10 As shown, the difference between this embodiment and Embodiment 2 mainly lies in that the LED lamp of this embodiment does not include a cooling fan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com