Preparing method of low-temperature nano copper welding material

A welding material and nano-copper technology, applied in the direction of welding/cutting medium/material, welding equipment, welding medium, etc., can solve problems such as increased melting point, danger, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

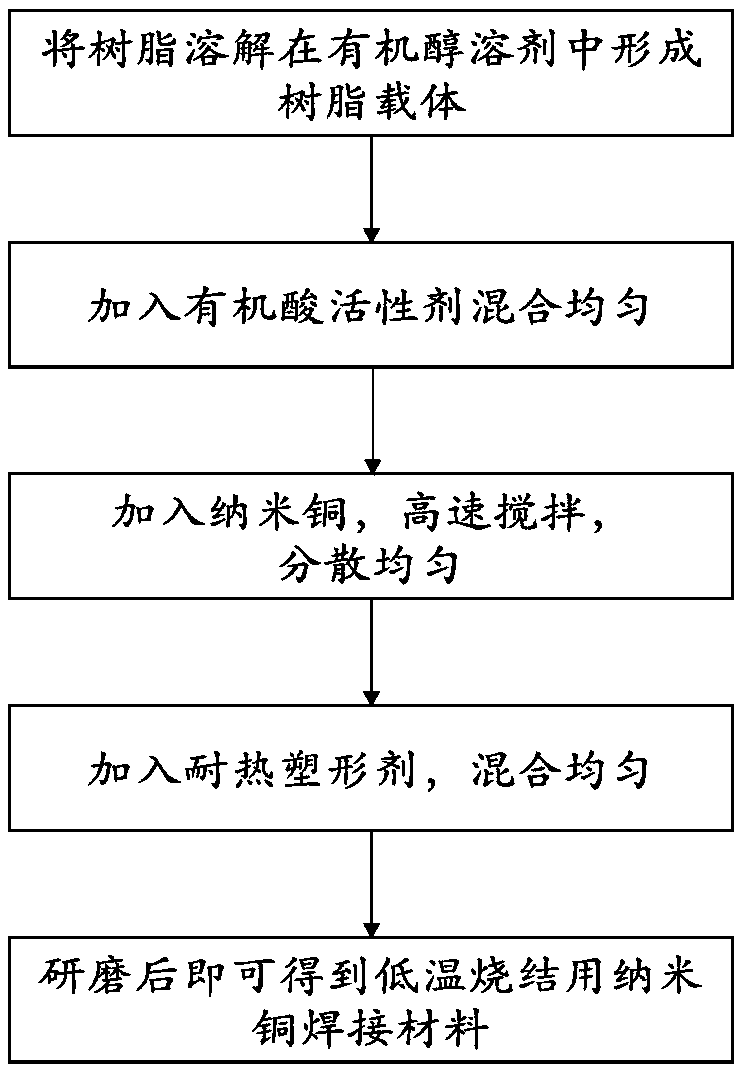

[0020] The present invention provides a kind of preparation method of nano-copper welding material for low temperature, comprising the following steps:

[0021] mixing the resin and organic alcohol to obtain a resin carrier;

[0022] Mix the resin carrier with organic acid and nano-copper, stir until the nano-copper is evenly dispersed, then mix evenly with heat-resistant plastic agent, and grind to obtain nano-copper welding material for low temperature;

[0023] The organic acid is selected from adipic acid, oxalic acid, malonic acid, succinic acid, sebacic acid, pimelic acid, malic acid, succinic acid, glutaric acid, dimethylglutaric acid, o-hydroxybenzoic acid , one or more of phthalic acid, salicylic acid and itaconic acid.

[0024] The invention mixes the resin and the organic alcohol to obtain the resin carrier. In the present invention, the resin is preferably selected from one or more of epoxy resins, phenolic resins, acrylic resins and silicone resins; more prefera...

Embodiment 1

[0034] Epoxy resin E-51 10 mass parts, triethylene glycol 20 mass parts, stir and mix uniformly; Add the phthalic acid of 5 mass parts, mix homogeneously, add the nano-copper powder (30nm) 60 mass parts of ethanol solvent protection, 700rpm After stirring for 30 minutes, 5 parts by mass of polypropylene were added; after mixing with a three-roller mill, a nano brazing material for low-temperature sintering was obtained.

[0035] The method provided in Example 1 can effectively prevent or reduce the oxidation of copper nanoparticles during use and improve the conductivity of the welding material. In addition, the soldering material can also clean the soldered copper surface, improving product reliability. The organic acid itself will be gradually consumed during the sintering process, which can achieve the effect of no-cleaning welding material residues.

Embodiment 2

[0037] 8 mass parts of phenolic resin, 15 mass parts of Polyethylene Glycol, stirring and mixing; Add the dimethyl glutaric acid of 6 mass parts, mix homogeneously, add the nano-copper powder (50nm) 65 mass parts of propanol solvent protection, 800rpm Stirring at low temperature for 25 minutes; adding 6 parts by mass of vinyl cellulose; and mixing with a three-roll mill to obtain nano-brazing material for low-temperature sintering.

[0038] The method provided in Example 2 can effectively prevent or reduce the oxidation of copper nanoparticles during use and improve the conductivity of the welding material. In addition, the soldering material can also clean the soldered copper surface, improving product reliability. The organic acid itself will be gradually consumed during the sintering process, which can achieve the effect of no-cleaning welding material residues.

[0039]As can be seen from the above examples, the present invention provides a method for preparing a low-temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com