Patents

Literature

98 results about "O-Hydroxybenzoic Acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

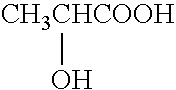

Fragranced Therapeutic Delivery System

The present invention relates to multi-functional topical delivery systems for providing long-lasting delivery of fragrance as. well as skin-supporting and / or pharmaceutically active ingredients comprising (i) an oil phase; (ii) an aqueous phase; (iii) phenoxyethanol at a concentration of from about 2.0% to about 2.7% based on the total weight of the composition; (iv) an effective exfoliating amount of a hydrophobic hydroxycarboxylic acid selected from the group consisting of orthohydroxybenzoic acid, hydroxycarboxylic acids containing a C12-C24 fatty acid esterified to the alpha carbon hydroxyl group, hydroxycarboxylic acids containing a C12-C24 fatty alcohol esterified to a carboxyl group; (v) a non-ionic emulsifier having an HLB of from about 7 to about 10; (vi) a fragrance composition; and (vii) at least one skin-supporting or dermatopharmaceutically active agent.

Owner:TREMO TEC GMBH

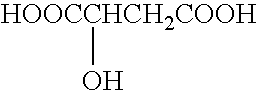

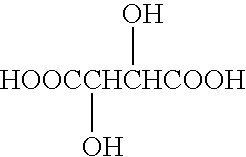

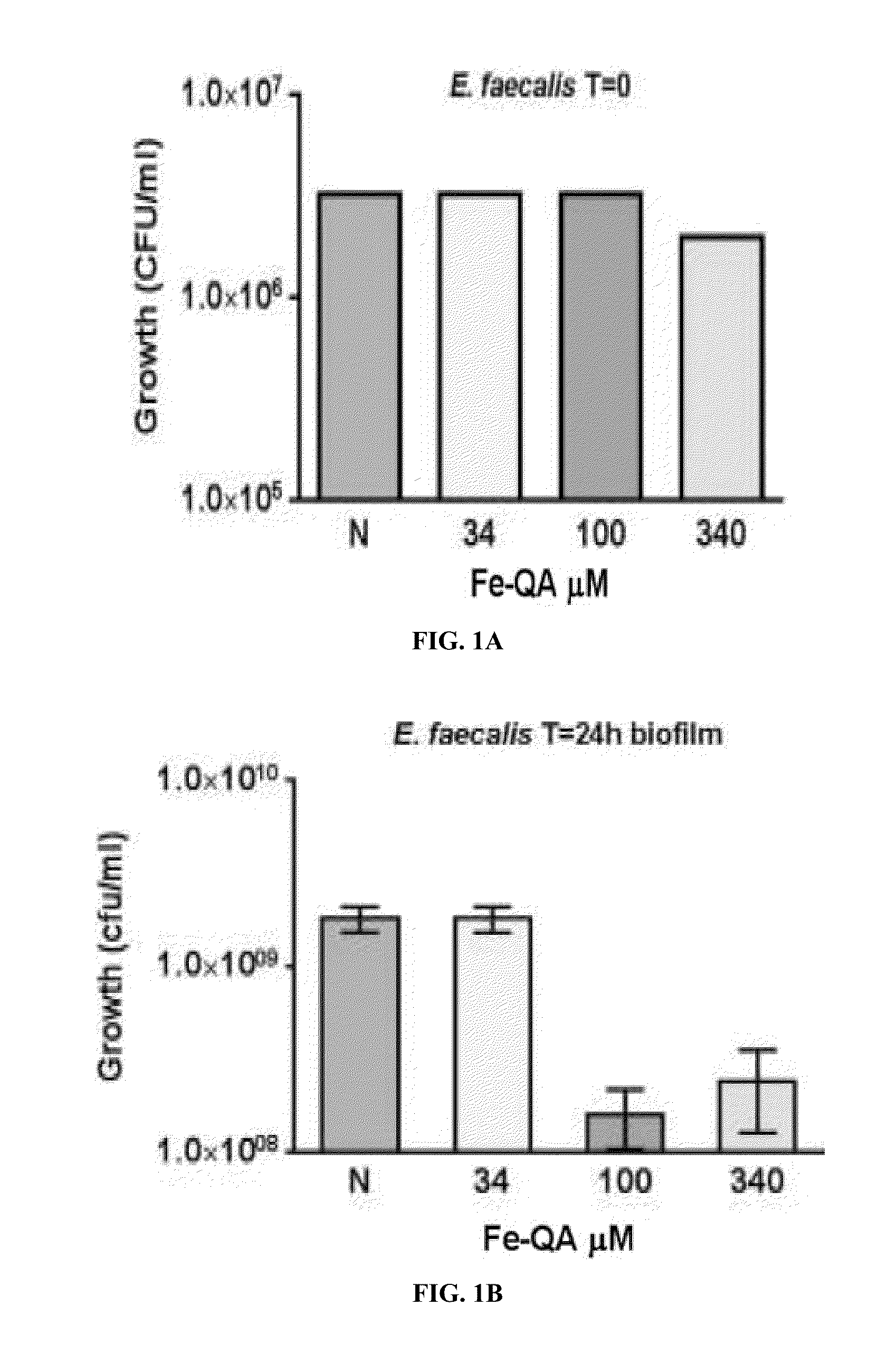

Antimicrobial compounds and compositions, and uses thereof

ActiveUS20160066578A1Improve growth performanceDecrease mortality adjusted feed conversion ratioCosmetic preparationsOrganic active ingredientsBenzoic acidMicrobial agent

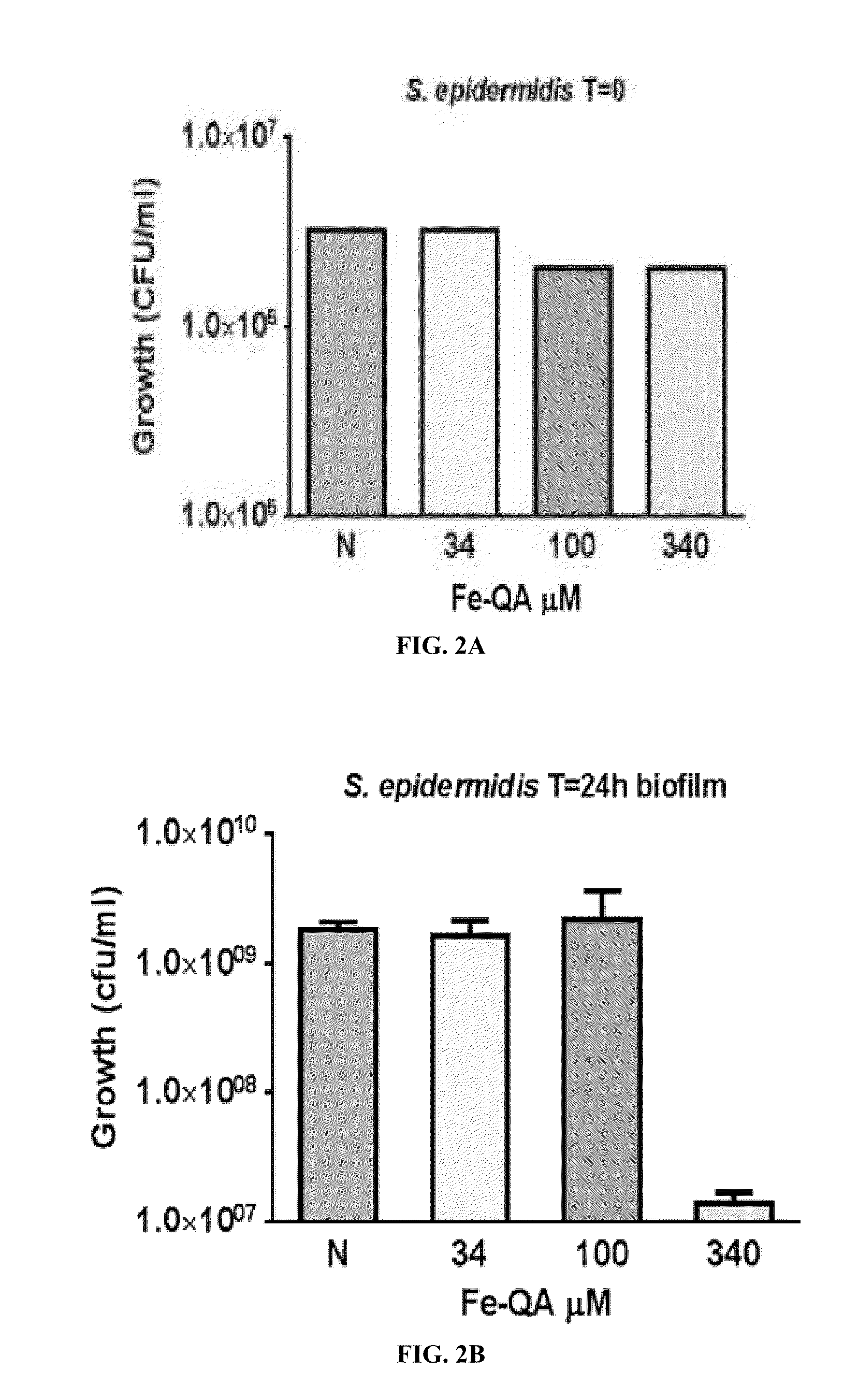

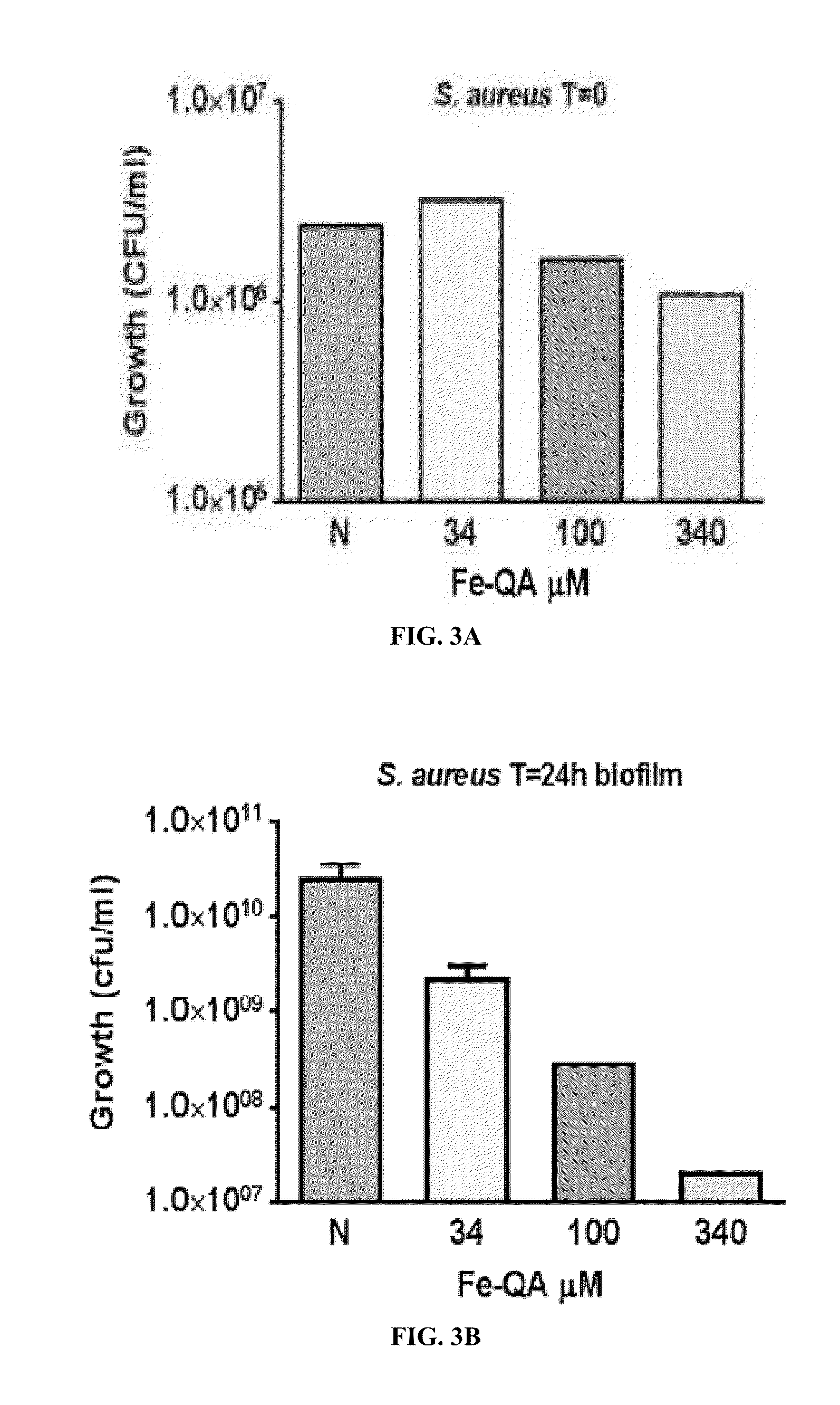

A method of enhancing the growth of an animal is provided. The method includes causing the animal to ingest or absorb an effective amount of one or more Fe III complex compounds, including but not limited to Fe III complexes comprising ligands bound to the iron centre selected from amino acids or α-hydroxy acids, o-hydroxy benzoic acids or pyridine-2-carboxylic acids, such as ferric quinate, ferric tyrosine, ferric DOPA and ferric phenylalanine. Compounds which are structural and / or functional variants, derivatives and / or analogs of the foregoing compounds, as further described herein are also disclosed. Methods for inhibiting, reducing, or preventing biofilm formation or buildup on a surface; the treatment of, inhibition of growth of, and inhibition of colonization by, bacteria, both in biological and non-biological environments; disinfecting surfaces, potentiating the effects of antibiotics and other anti-microbial agents, and increasing the sensitivity of bacteria and other microorganisms, to anti-microbial agents are also provided.

Owner:AKESO BIOMEDICAL

Clean viscous acid for acid fracturing of carbonate reservoir

ActiveCN102453480AGood retarding performanceExtended service lifeDrilling compositionAcid etchingHydrogen-Ion Concentrations

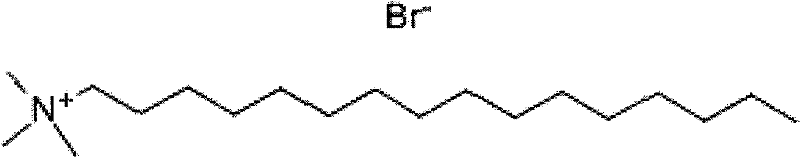

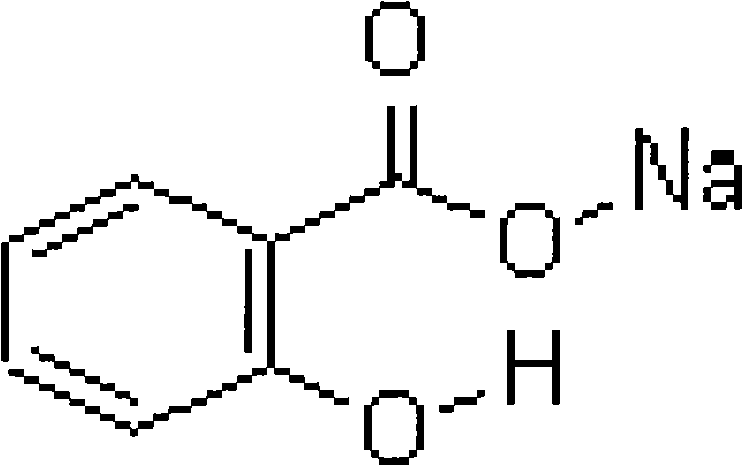

The invention discloses a clean viscous acid for acid fracturing of a carbonate reservoir, which is applied to the technical fields of acidification and acid fracturing of petroleum carbonate reservoirs. The clean viscous acid consists of the following components in percentage by weight: 3-7 percent of hexadecyl trimethyl ammonium bromide, 0.3-0.7 percent of sodium salicylate, 15-28 percent of hydrochloric acid, 0.125-0.25 percent of citric acid or 0.05-0.1 percent of CX-301 or 0.3-0.5 percent of TW-1 serving as an iron ion stabilizing agent, 0.2-0.25 percent of a diimidazoline quaternary ammonium salt and the balance of water. The clean viscous acid has high retardative property, the retarding rate can reach 42-56 percent, the fresh acid viscosity is 25-40 mPa.S, and the acid liquor viscosity rises during acid fracturing of the carbonate reservoir. When the hydrogen ion concentration falls till the pH is more than or equal to 2, the acid liquor viscosity rises for forming viscoelastic gel, the permeation resistance of an acid liquor in a high permeation layer is increased, and the length of an acid etching crack is prolonged. Reacted residual acid gel can undergo gel breaking automatically, is free from residues, is easy for discharging, and has small damage to stratums.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

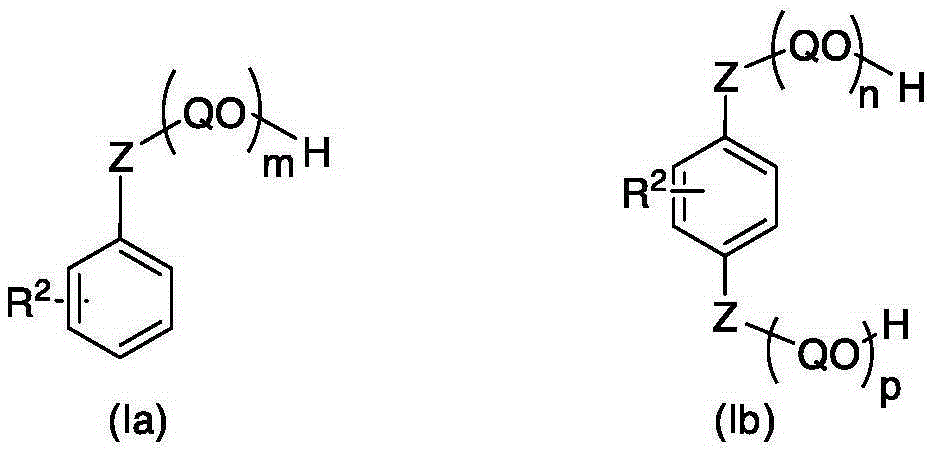

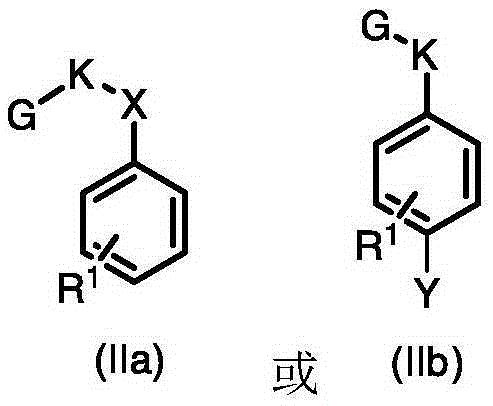

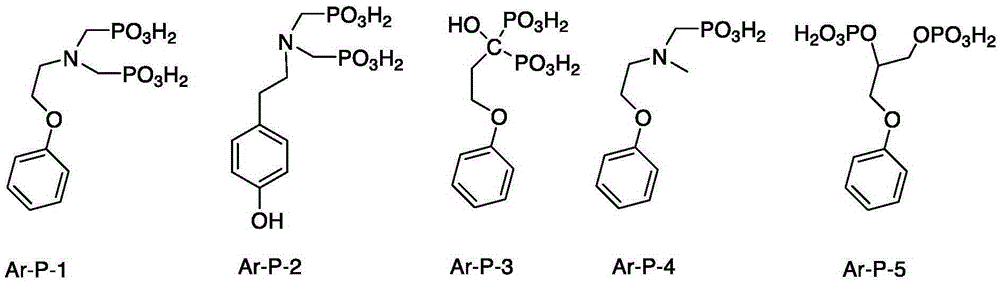

Preparation method and application of anti-soil polymer

The invention provides a preparation method and application of an anti-soil polymer. The prepared polymer is used as a dispersant for a hydraulic cementing agent and / or an aqueous dispersion for potential hydraulic cementing agent and has good anti-soil performance. The preparation method the anti-soil polymer comprises a step of subjecting polyether macromonomer A with a special structure, monomer B containing a phosphoric acid or phosphorous acid group, optional monomer D and aldehyde C to condensation polymerization so as to prepare the anti-soil polymer, wherein the monomer D is selected from the group consisting of phenol, aniline, p- / o-aminobezene solfonic acid, p- / o-hydroxybenzoic acid, p- / o-aminobenzoic acid, p- / o-hydroxyezene solfonic acid, p- / o-toluidine and p- / o-methylphenol, a mol ratio of the polyether macromonomer A to the monomer B to the monomer D is 1: (0.5-12): (0-8.0), and a mol ratio of the polyether macromonomer A to the monomer B and the monomer D is 1: (0.5-12.0).

Owner:JIANGSU SOBUTE NEW MATERIALS +1

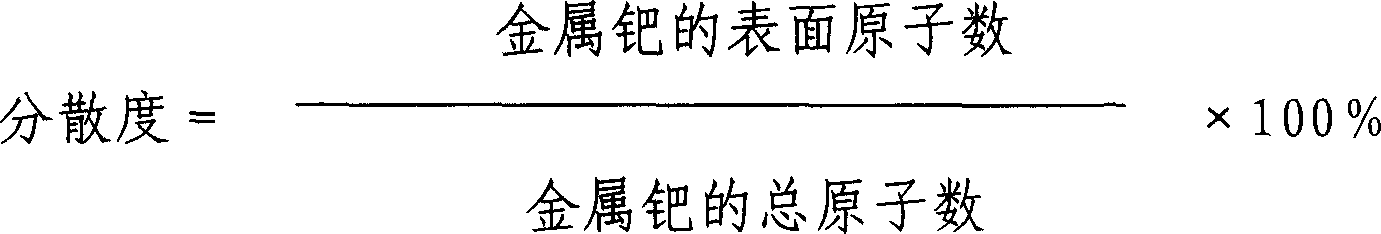

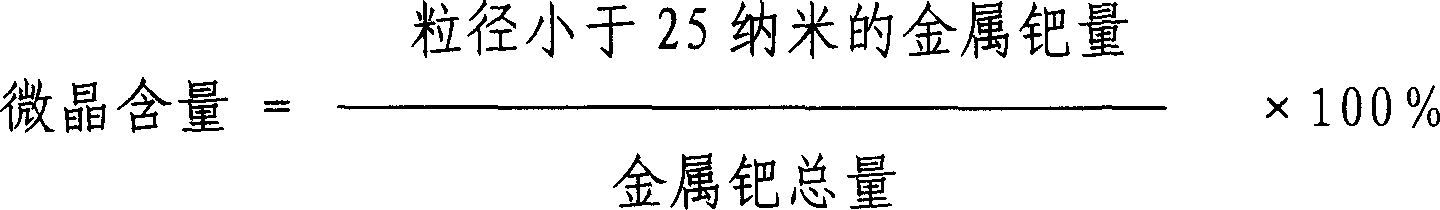

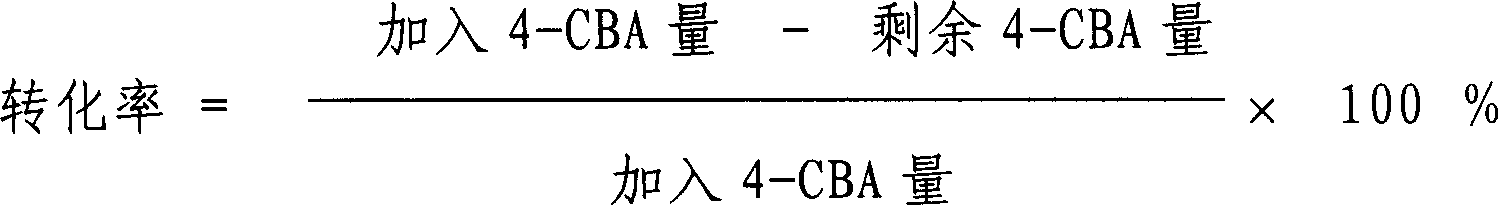

Method for preparing palladium/carbon catalyst for hydrogenation

InactiveCN1698953AGood dispersionHigh microcrystalline contentOrganic compound preparationCatalyst activation/preparationPhenanthrolineReducing agent

This invention relates to a method for preparing a hydrogenation palladium or carbon catalyst. The catalyst uses the particles or shaping active carbon as the carrier, loading active component metal Pd, wherein the Pd content is 0.2-5wt%. The preparing method comprises the following steps: a) acid cleaning the carrier active carbon; then flushing with water until neutral; drying; b) preparing Pd solution with water-soluble Pd compound and a complex builder; using Pd solution to immerse or spray the carrier active carbon, loading the Pd compound on the active carbon and then getting the catalyst prosoma, wherein the Pd compound content is 15-20wt% computed by Pd, the molecular ratio of complex builder and Pd is (0.01-1):1, the complex builder is any one from 8-bioquin, 2,3,4-trihydroxy-4-sulfonic acid azobenzene, ortho phenanthroline, o-aminophenol, o-hydroxybenzoic acid sodium or salicylaldehyde benzaldoxime; c) aging the catalyst prosoma, then deacidizing and getting the catalyst.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

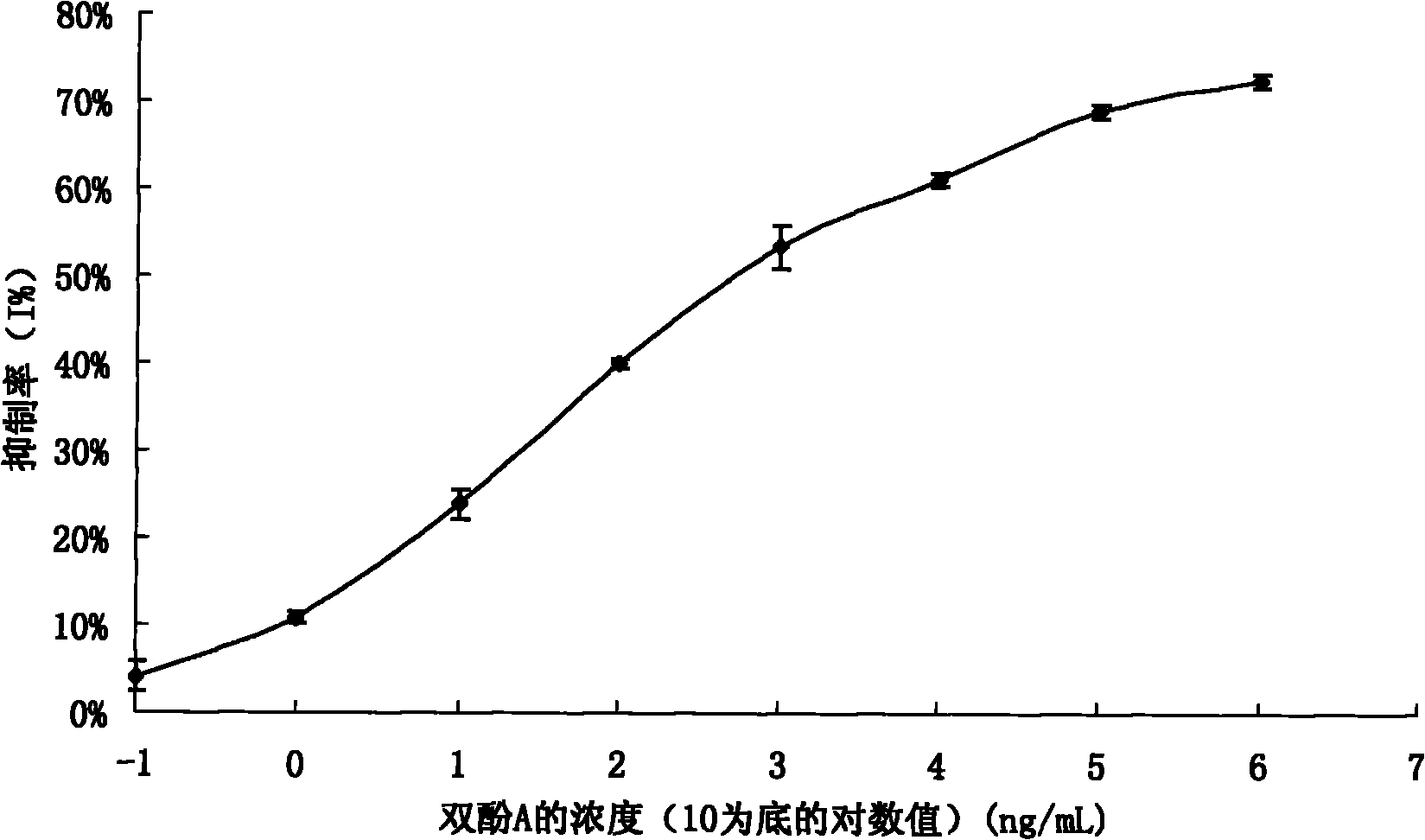

Preparation method of anti-bisphenol A monoclonal antibody

InactiveCN101863981AEffective monitoringRapid Field MonitoringSerum albuminTissue culturePolyethylene glycolCarrier protein

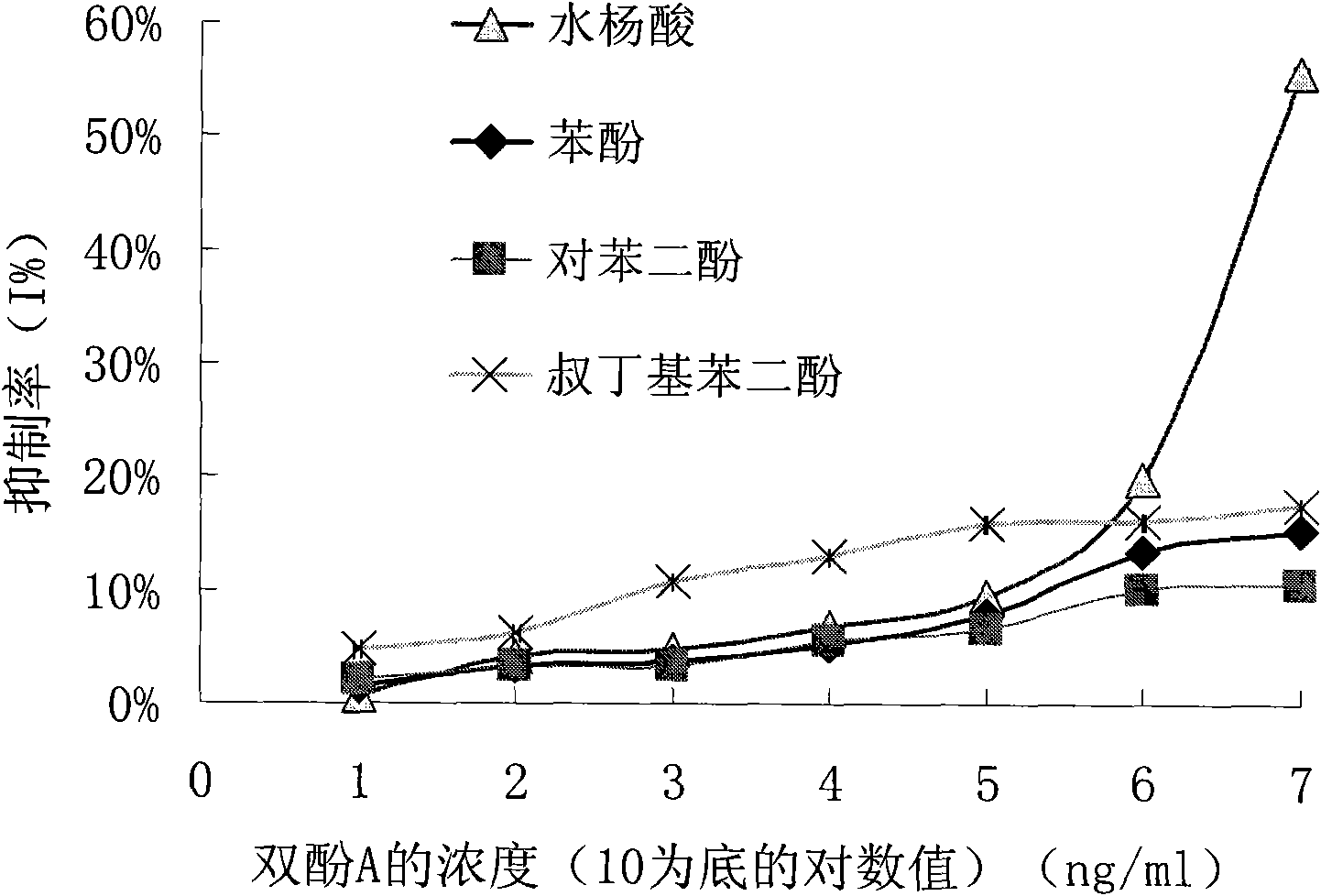

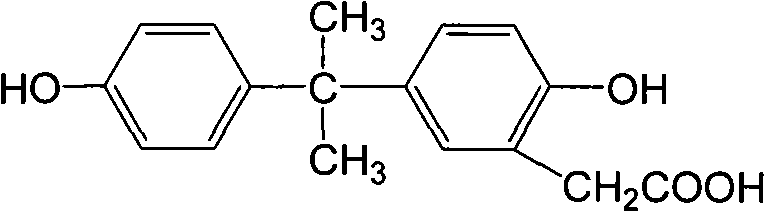

The invention discloses a preparation method of an anti-bisphenol A monoclonal antibody. The preparation method comprises the following steps of: combining bisphenol A and a macromolecule carrier protein to prepare an artificial immunity antigen and a coating antigen; preparing splenocyte suspension from a bisphenol A artificial immunity antigen immunity mouse; fusing the mouse splenocyte and mouse myeloma cells SP2 / 0 in the presence of polyethylene glycol; detecting by hybridoma technology and subcloning for many times to obtain positive hybridoma cells which can stably secrete bisphenol A antibody, wherein the secreted antibody belongs to the IgG1 subclass; and establishing a bisphenol A indirect competition ELISA (Enzyme-Linked Immunosorbent Assay) test by utilizing the monoclonal antibody secreted by cell lines with high antibodytiter, wherein the minimum limit of detection can reach 0.324ng / mL. The antibody has no cross reaction with compounds with benzene ring structures, such as benzene, phenol, tert-butylphenol, p-hydroxylphengl, o-hydroxybenzoic acid and the like, has strong specificity and can be used for immunity detection of bisphenol A.

Owner:GUANGDONG UNIV OF TECH

Rosin scaling powder

ActiveCN104084714AHigh flux activityImprove solder joint qualityWelding/cutting media/materialsSoldering mediaGlutaric acidFatty acid glycerol esters

The invention discloses rosin scaling powder. The rosin scaling powder comprises, by weight, 10 parts to 20 parts of rosin modified phenolic resin, 5 parts to 10 parts of rosin glyceride, 70 parts to 80 parts of organic solvents, 2 parts to 5 parts of surfactants, 1 part to 3 parts of activators and 1 part to 2 parts of film forming agents, wherein the organic solvents are one kind of ethyl alcohol, propyl alcohol, butanol, acetic ether and butyl acetate, the surfactants are sodium dodecyl benzene sulfonate or fatty glyceride, the activators are one kind of glutaric acid, itaconic acid, o-hydroxybenzoic acid, malic acid and succinic acid, and the film forming agents are nitrocellulose. Residues of the rosin scaling powder are easy to remove, and injuries to the human body and environment pollution can be avoided.

Owner:GUANGXI ZHONGCHANG RESIN

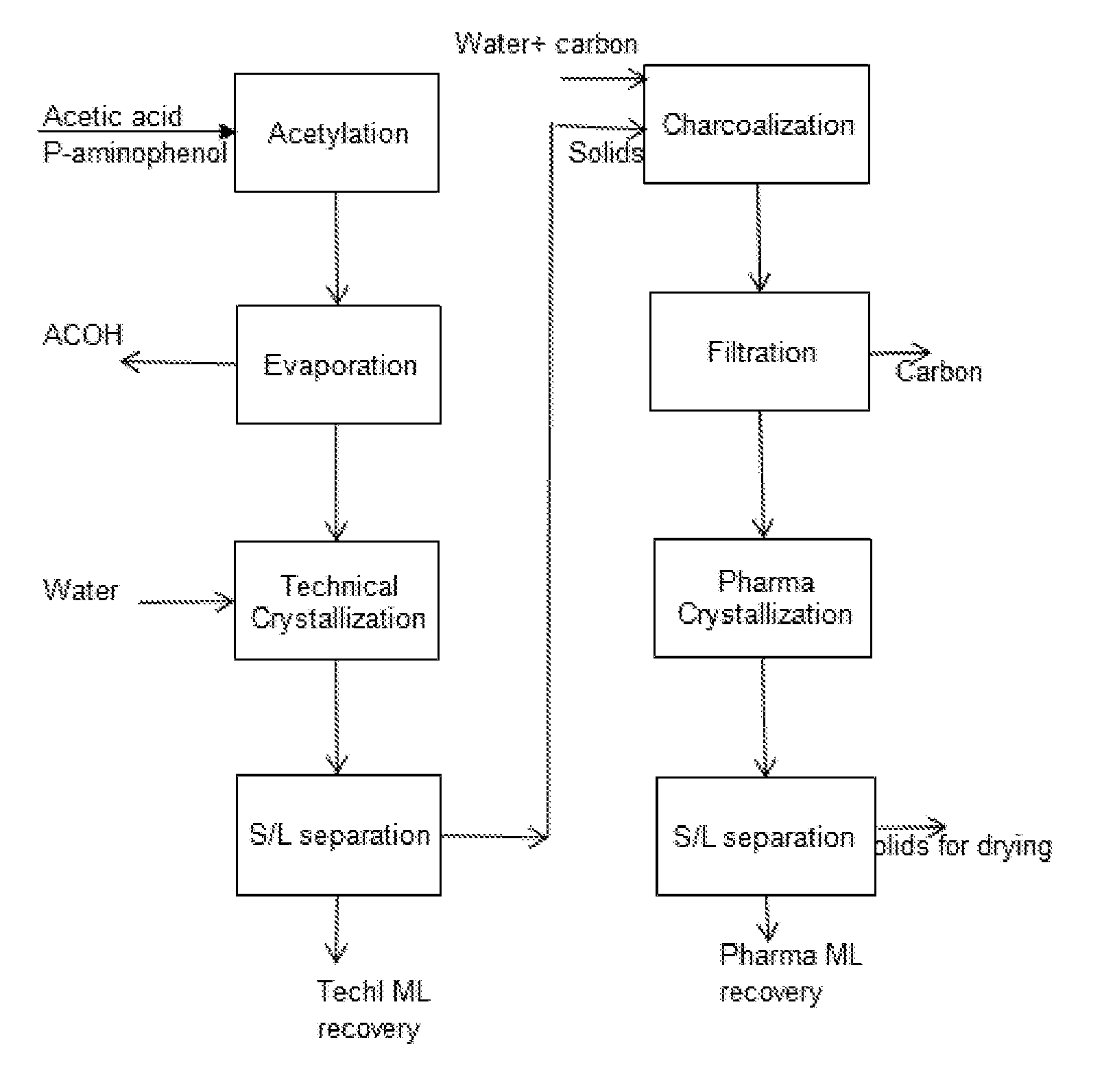

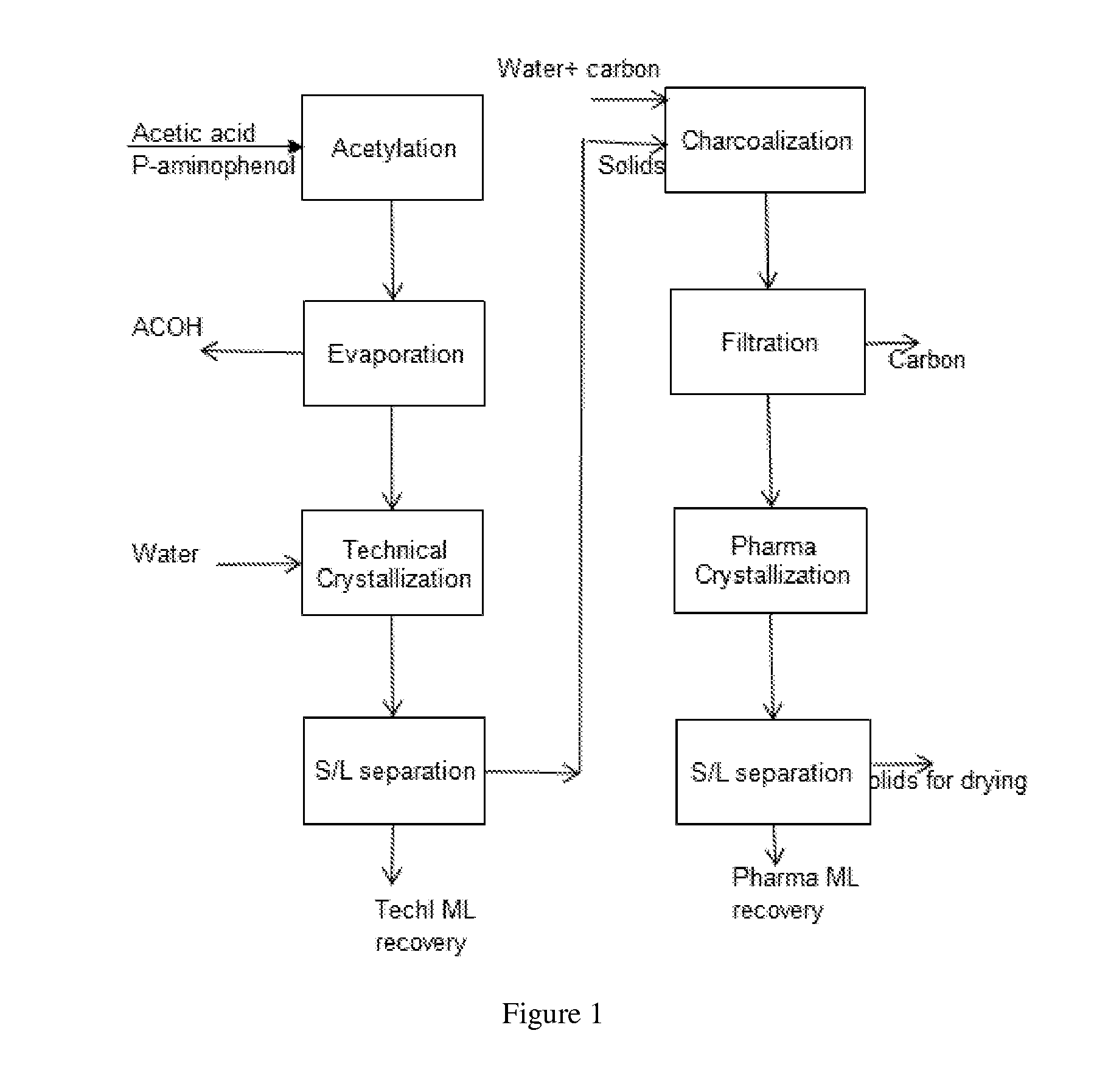

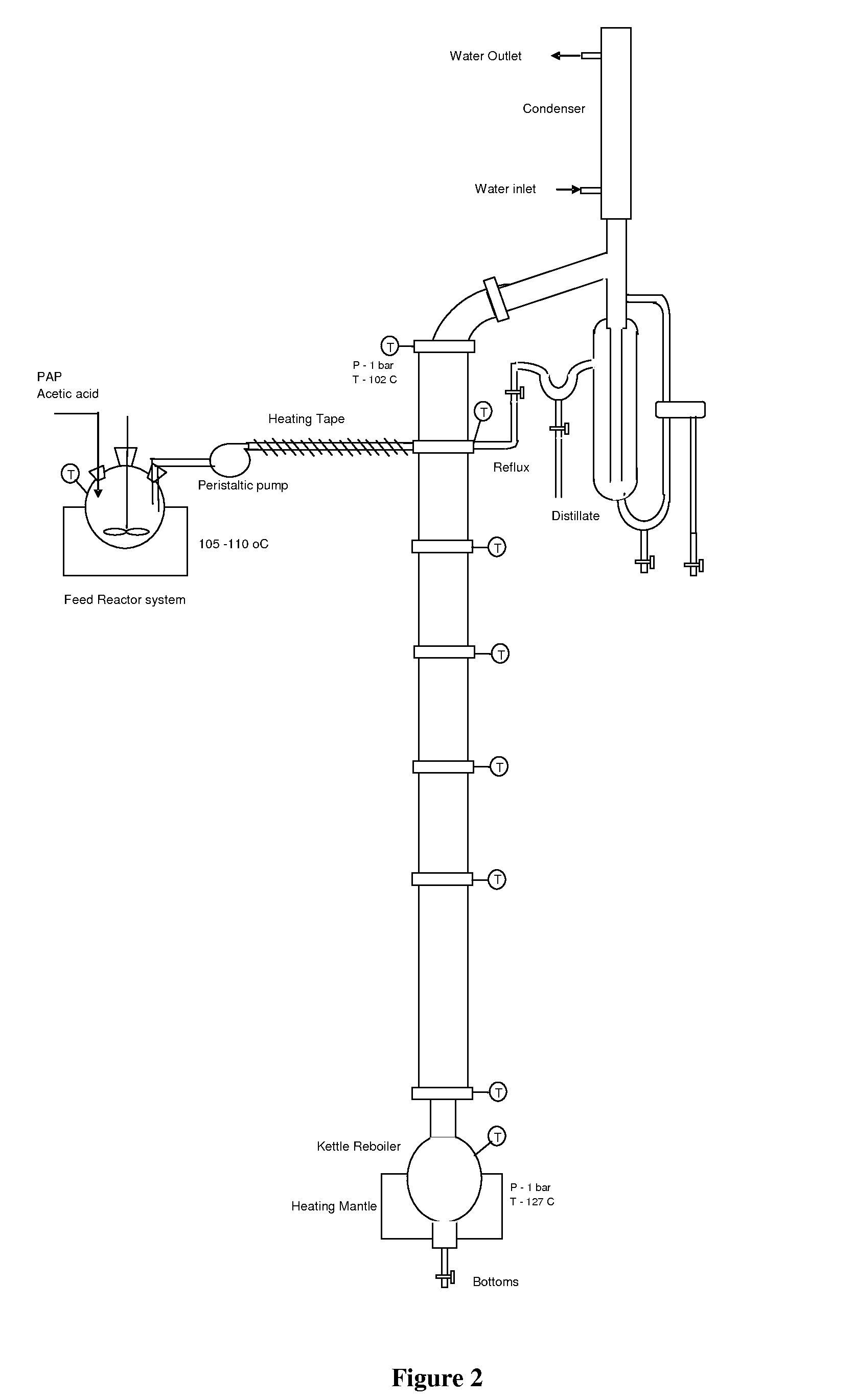

Reactive distillation process for preparation of acetaminophen

ActiveUS20120065423A1Delayed reaction timeGood colorOrganic compound preparationCarboxylic acid esters preparationAcetic acidBenzoic acid

The present invention relates to continuous processes for the preparation of primary and secondary N-acetylated aromatic amines of formula I or O-acetylated product of o-hydroxy benzoic acid of Formula II using acetic acid as an acetylating agent.wherein R1 has a definition of hydrogen atom, C1-C4 alkyl group or C1-C4 alkoxy group.

Owner:GRANULES INDIA LIMITED

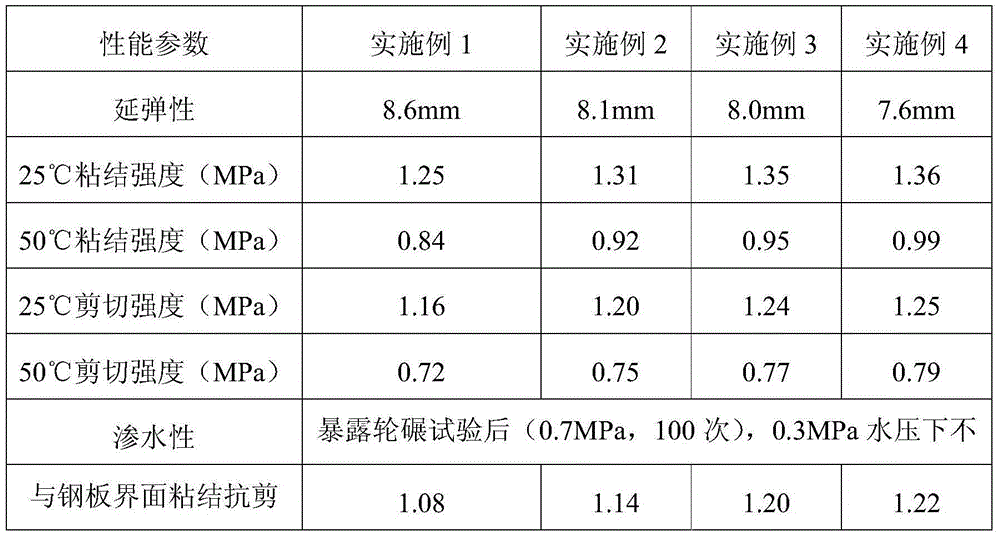

Waterborne epoxy modified second order reaction type waterproof binding material and preparation method

ActiveCN104449555ASolve cohesionEasy to move between layersNon-macromolecular adhesive additivesBituminous material adhesivesEpoxyMass ratio

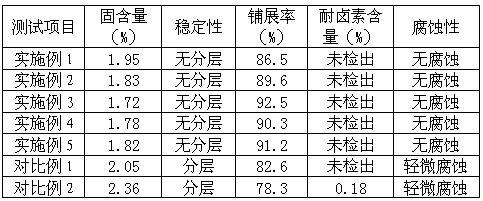

The invention discloses a waterborne epoxy modified second order reaction type waterproof binding material and a preparation method. The preparation method comprises steps as follows: A, emulsified asphalt, waterborne epoxy resin, o-hydroxybenzoic acid, an emulsifier, a defoaming agent and a stabilizing agent are prepared at a mass ratio, the emulsified asphalt is added to a container firstly, pH is regulated by hydrochloric acid to 4.5-6.0, the materials are added while stirred, and manual stirring is continuously performed for 5-10 min until a mixed liquid is uniform; a high-speed shearing machine stator is put in the mixed liquid, the rotating speed is regulated to 200-400 revolutions / min, a switch is switched on, shearing is performed for 30-50 min, and a second order reaction type waterproof binding material component A is obtained; and B, the second order reaction type waterproof binding material component A and a second order reaction type waterproof binding material component B are prepared at a mass ratio of 100: (8-18) and are directly mixed in the container, the mixed materials are continuously and manually stirred for 5-10 min, poured into a proper container and uniformly arranged on an underlying layer in a coated manner, or the mixed materials are continuously stirred for 5-10 min and placed in an asphalt distribution truck for distribution.

Owner:陈妙青

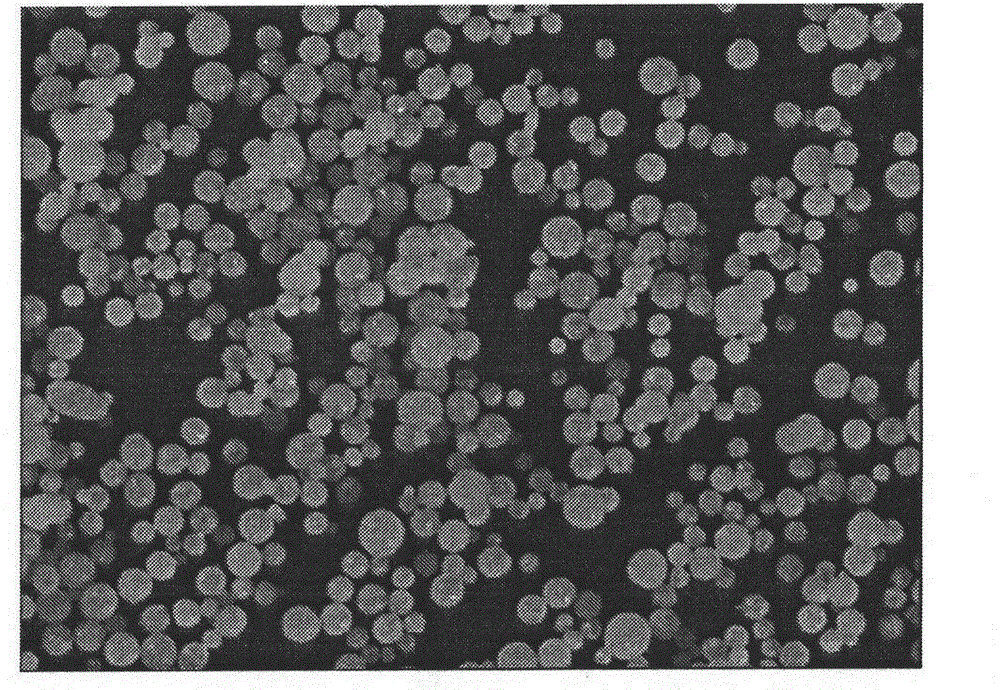

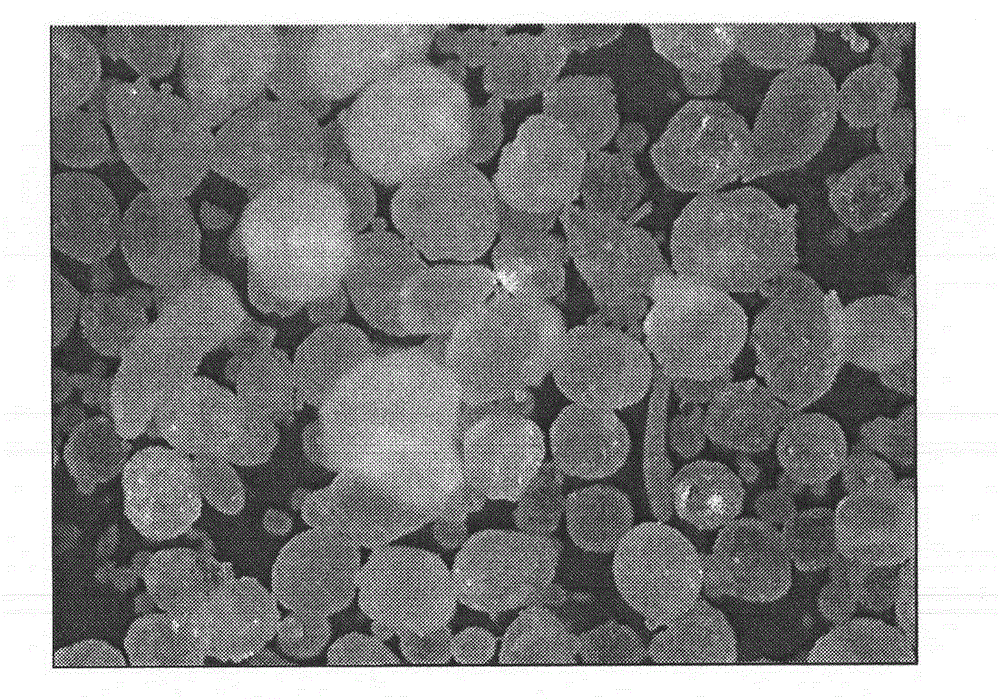

Catalyst component for olefin polymerization, method for preparing catalyst component, catalyst for olefin polymerization and method for olefin polymerization

The invention relates to a catalyst component for olefin polymerization and a method for preparing the catalyst component, the catalyst component contains a magnesium halide adduct, a titanium compound and a product which is obtained from the reaction of an internal electron donor compound, wherein the magnesium halide adduct contains magnesium halide, alcohol except methanol, methanol and ortho hydroxyl-benzoate ester, and contains or does not contain water. The invention further relates to a catalyst which contains the catalyst component and is used for olefin polymerization, an application of the catalyst for olefin polymerization and a method for olefin polymerization. The catalyst particles for olefin polymerization have smooth surfaces, uniform sizes, stronger breakability resistance during the polymerization process and better hydrogen adjustment sensitivity for olefin polymerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

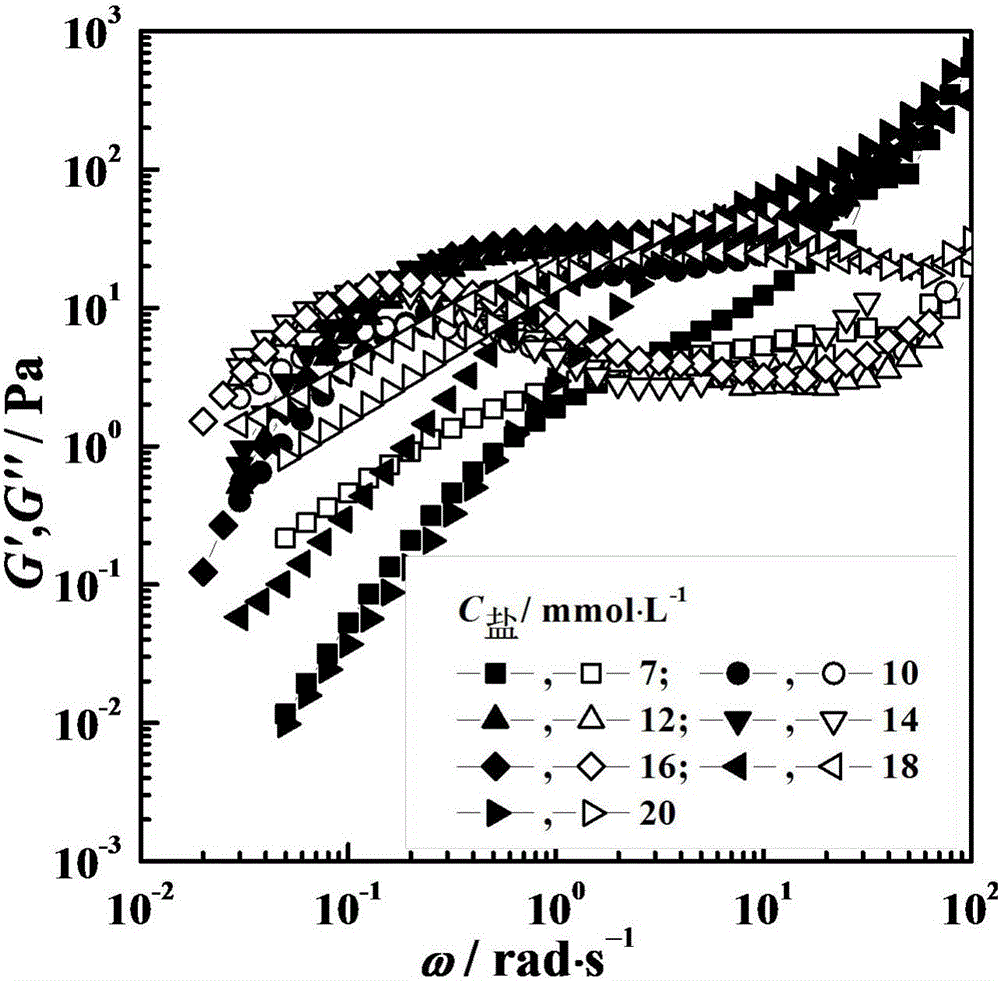

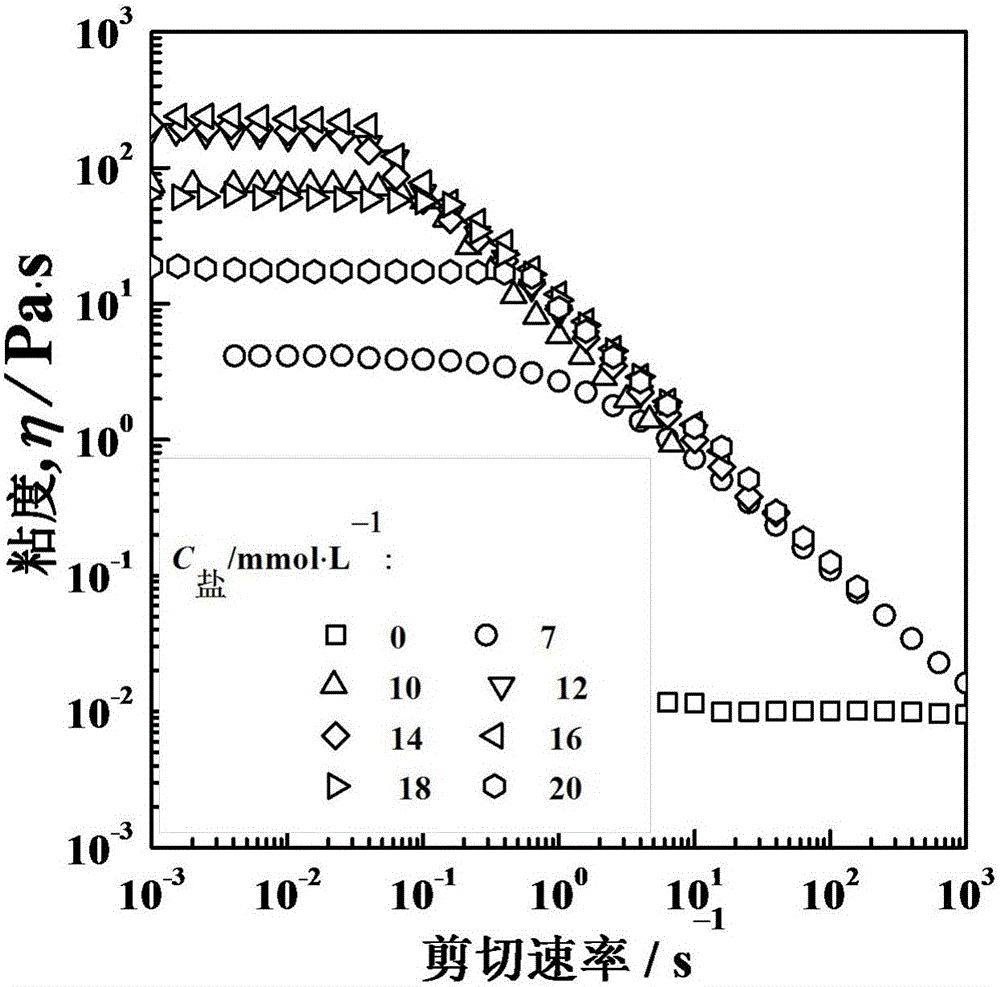

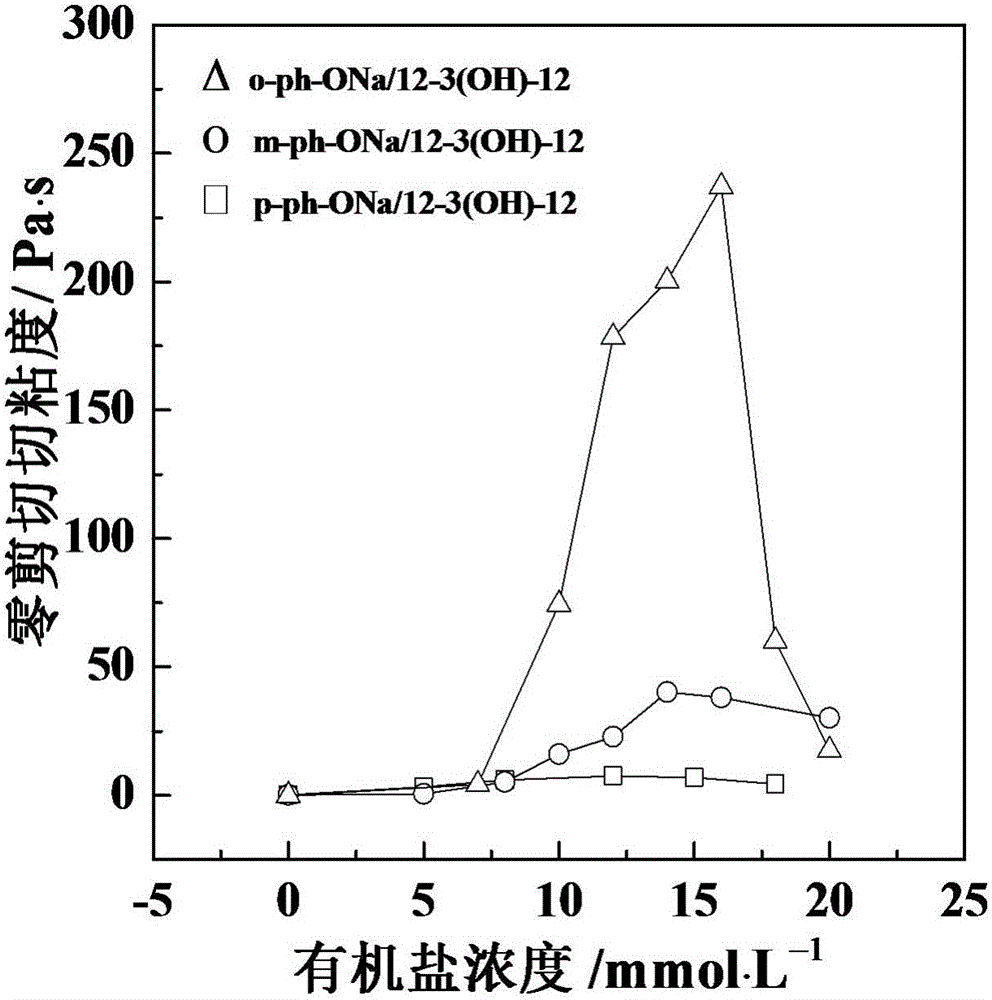

Viscoelastic system formed by functional Gemini surface active agent

InactiveCN106000217AAffect self-organizing behaviorRich in self-organizing behaviorTransportation and packagingMixingSurface-active agentsHydroxybenzoate

The invention discloses a viscoelastic system formed by a functional Gemini surface active agent and belongs to the technical field of a surface active agent. According to a preparation method of a viscoelastic surface active agent solution provided by the invention, organic salt comprises sodium o-hydroxybenzoate, 3-hydroxy-benzoic aci monosodium salt and sodium p-Hydroxybenzoate; Gemini surface active agent with hydroxyl group is taken as the main component and is compounded with few organic salts, and then the viscoelastic surface active agent solution is obtained; the preparation of the viscoelastic surface active agent solution comprises the two processes of compounding and testing viscoelastic property; Gemini cationic surface active agent is prepared into the solution in certain concentration and then is compounded with the salt at different ratio, thus, the viscoelastic surface active agent solution is acquired.

Owner:JIANGNAN UNIV

Composite binder for powder injection moulding and preparation and application method

ActiveCN105860886AImprove liquidityGood liquidity lowNon-macromolecular adhesive additivesTransportation and packagingMicrocrystalline waxInjection moulding

The invention discloses composite binder for powder injection moulding and a preparation and application method. The composite binder for powder injection moulding comprises raw materials including furfuryl alcohol, trimethylolpropane, polypropylene, o-hydroxybenzoic acid, polyacrylamide, palm wax, microcrystalline wax and epoxidized soybean oil and further comprises boric acid and water. The composite binder combining thermoplasticity and a thermosetting system is adopted, advantages of thermoplasticity and the thermosetting system are utilized, on one hand, the problems that conventional binder is excessively long in thermal degreasing time and low in production efficiency are solved, and the degreasing rate can reach 90% or above within 6 hours; on the other hand, the yield rate of a powder injection moulding product is raised, and quality of a finished product is improved.

Owner:ANHUI SANLIAN UNIV

Polyurethane anticorrosive floor paint

InactiveCN105925159AImprove wear resistanceImprove high temperature resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsBenzoic acidPolymer science

The invention discloses polyurethane anticorrosive floor paint, including the following components according to parts by weight: 90-96 parts of waterborne polyurethane resin, 15-20 parts of urea resin, 5-9 parts of oxidized polyethylene wax, 5-9 parts of dipropylene glycol butyl ether, 4-6 parts of salicylic acid, 5-12 parts of polyurethane curing agent, 7-10 parts of pure acrylic emulsion, 5-8 parts of phytase, 3-8 parts of imidazoline amphoteric electrolyte, 5-8 parts of anatase nano titanium dioxide, 3-5 parts of p-toluenesulfonic acid, 10-15 parts of polyurethane dispersant, and 4-9 parts of o-hydroxybenzoic acid. The polyurethane anticorrosive floor paint has good wear resistance and high temperature resistance, enables improved binding strength of a coating layer with a floor and increased curing speed at various temperatures, and also has good water resistance and chemical corrosion resistance.

Owner:SUZHOU KEMIAO NEW MATERIAL

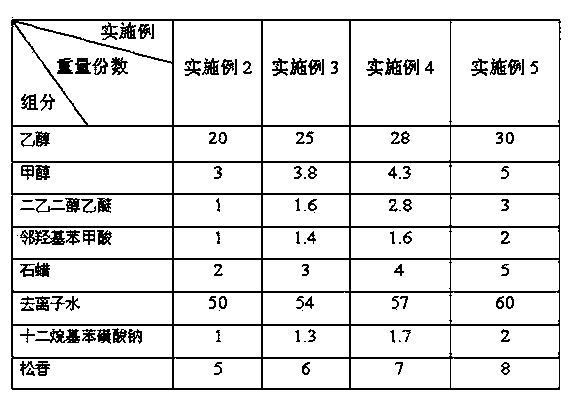

Traffic control circuit welding welding-assisting material and preparing method thereof

ActiveCN103831548AImprove anti-aging propertiesImprove high and low temperature resistanceWelding/cutting media/materialsSoldering mediaBenzoic acidDiethylene glycol monoethyl ether

The invention discloses a traffic control circuit welding welding-assisting material and a preparing method of the welding-assisting material and relates to the technical field of welding. The traffic control circuit welding welding-assisting material comprises, by weight, 20-30 parts of ethyl alcohol, 3-5 parts of methyl alcohol, 1-3 parts of diethylene glycol monoethyl ether, 1-2 parts of o-hydroxybenzoic acid, 2-5 parts of wax, 1-2 parts of emulgator, 50-60 parts of deionized water and 5-8 parts of colophony. The traffic control circuit welding welding-assisting material can be used for obviously improving the high-low temperature resisting feature and the welding strength of a welded finished product and meanwhile, can protect the health of an operating worker and the atmosphere environment.

Owner:河北雄业华阳交通科技有限公司

Hot-melting welding material

InactiveCN104985353AEven and smooth weldingImprove solderabilityWelding/cutting media/materialsSoldering mediaBenzoic acidButanedioic acid

The invention discloses a hot-melting welding material. The hot-melting welding material is prepared from the following raw materials in parts by weight: 6-8 parts of copper oxide, 7-10 parts of aluminum, 1-4 parts of magnesium oxide, 6-9 parts of methanol, 40 parts of deionized water, 5-11 parts of o-hydroxybenzoic acid, 2-6 parts of Mo, 6-10 parts of alcohol, 0.5-3 parts of dibromosuccinic acid, 2-4 parts of soda ash, 8-13 parts of chromium metal, 4-7 parts of quartz, 5-10 parts of phenolic resin, 2-4 parts of metal nickel, 6-11 parts of polyethylene ethanol and 5-8 parts of organic acid. The hot-melting welding material has the beneficial effects of good weldability, uniform and smooth welding and high welding quality, and is harmless to environment.

Owner:QINGDAO ENGAO MOTION CONTROL TECH

Electrostatic spraying powder and application method thereof in sealing copper gate valve

InactiveCN104629578AImprove anti-corrosion performanceFlat surfaceRosin coatingsPretreated surfacesEpoxySodium Bentonite

The invention discloses electrostatic spraying powder and an application method thereof in a sealing copper gate valve, and relates to the technical field of electrostatic spraying powder. The electrostatic spraying powder is prepared from the following raw materials in parts by weight: 60-65 parts of epoxy resin, 15-20 parts of modified rosin resin, 12-15 parts of nanometer ceramic powder, 10-12 parts of nanometer calcium carbonate, 10-12 parts of dodecanol ester, 8-10 parts of polyvinyl chloride, 8-10 parts of organic bentonite, 5-8 parts of nitrocellulose, 5-8 parts of zinc oxide, 3-5 parts of o-hydroxy phenyl benzoate, 3-5 parts of naphthenic acid soaps, 2-3 parts of tributyl phosphate, 2-3 parts of cetyl trimethyl ammonium chloride, 3-5 parts of castor oil oxide, 15-20 parts of butyl acetate and 20-25 parts of water. The electrostatic spraying powder suitable for the sealing copper gate valve, which is disclosed by the invention, is prepared through the addition of various coating additives by taking the epoxy resin and the modified rosin resin as main raw materials and carrying out modifying treatment by adopting the nanometer ceramic powder and the nanometer calcium carbonate, and a coating obtained after the electrostatic spraying powder is sprayed not only has high anti-corrosion property, but also achieves the smoothness and flatness of a surface, so that the beautiful degree of the valve is increased.

Owner:ANHUI SRILL VALVE CO LTD

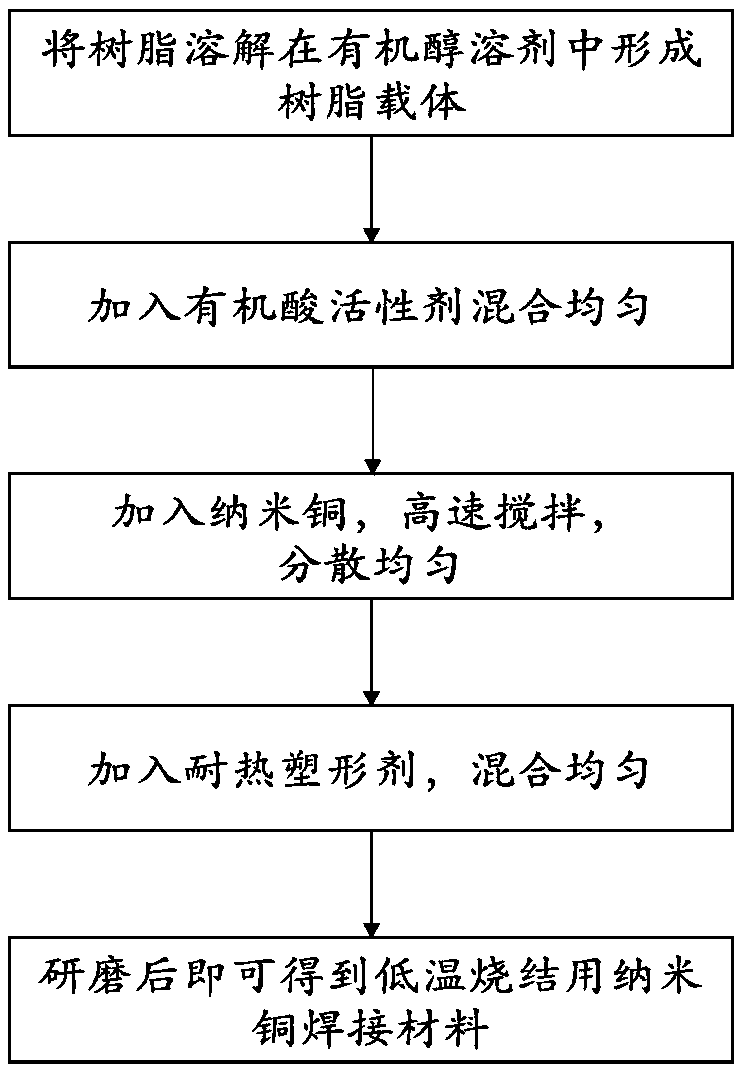

Preparing method of low-temperature nano copper welding material

InactiveCN107553007AImprove conductivityPrevent or reduce oxidationWelding/cutting media/materialsSoldering mediaGlutaric acidSalicylic acid

The invention provides a preparing method of a low-temperature nano copper welding material. The method comprises the steps that resin and organic alcohol are mixed, and a resin carrier is obtained; the resin carrier, the organic alcohol and nano copper are mixed, stirring is carried out until the nano copper is evenly dispersed, then, a mixture is evenly mixed a heat-resisting shaping agent, grinding is carried out, and the low-temperature nano copper welding material is obtained; the organic acid is selected from one or multiple of adipic acid, oxalic acid, malonic acid, succinic acid, sebacic acid, pimelic acid, malic acid, succinic acid, glutaric acid, dimethyl glutaric acid, o-hydroxybenzoic acid, phthalic acid, salicylic acid and itaconic acid. The manner that the resin, the organicalcohol and the organic acid are adopted to serve as a flux to be mixed with the nano copper, and the welding material is prepared is adopted, the organic acid is used, oxidization of the nano copperin the use process can be effectively prevented or reduced, and conductivity of welding materials can be improved; the welding materials can clean the welding copper face, and product reliability is improved; in the sintering process, the organic acid is gradually dissipated, and the effect that the welding material residue do not need to be cleaned is achieved.

Owner:GUANGDONG UNIV OF TECH

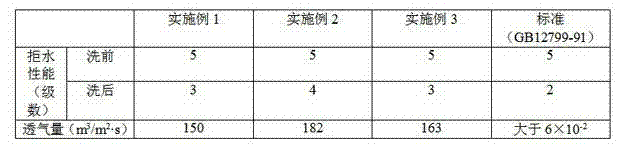

Waterproof breathable cotton cloth

InactiveCN103750583AWaterproof and breathableLayered productsProtective garmentPolymer sciencePolyvinyl alcohol

The invention discloses waterproof breathable cotton cloth which comprises a waterproof layer and a cotton cloth layer. The waterproof layer is manufactured through the following raw materials by weight: 20-30 parts of polyvinyl alcohol, 20-40 parts of para-toluenesulfonic acid, 40-60 parts of hydroxyl sodium benzoate, 20-40 parts of silicon dioxide, 10-30 parts of dehydrated sorbitan stearate and 20-30 parts of surfactant. The water repelling capability of the cotton cloth is still larger than 2 after the cotton cloth is washed, the breathable quantity is 150-182 m<3> / m<2>*s. The cotton cloth has good waterproof breathable performance.

Owner:HEBEI TANGLON TEXTILE GRP CO LTD

Medical dialyzing paper

ActiveCN104099805AGood antibacterial effectImprove breathabilityCoatingsCoatings without pigmentsStearatePolyacrylamide

The invention relates to paper, and provides a medical dialyzing paper which is good in bacteria-blocking effect, excellent in air permeability, high in intensity, and high in production efficiency. The paper comprises a paper substrate, and coating layers coated on the upper surface and the lower surface of the paper substrate, wherein the paper substrate comprises 65 to 80 parts by weight of broadleaf wood, and 20 to 35 parts by weight of coniferous wood as raw materials; the coating layers comprise the following raw materials in parts by weight: 70 to 85 parts of ethylene-vinyl acetate copolymer, 3 to 4 parts of polyacrylamide, 3 to 5 parts of barium stearate, 15 to 20 parts of staybelite, 5 to 7 parts of tert-carbonic acid glycidyl ester, 0.6 to 1.0 part of tertiary butyl hydroquinone, 0.3 to 0.9 part of erucicamide, and 0.2 to 0.4 part of o-hydroxybenzoic acid phenyl ester.

Owner:福建星城纸业有限公司

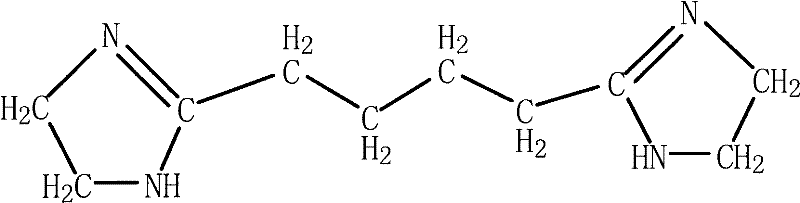

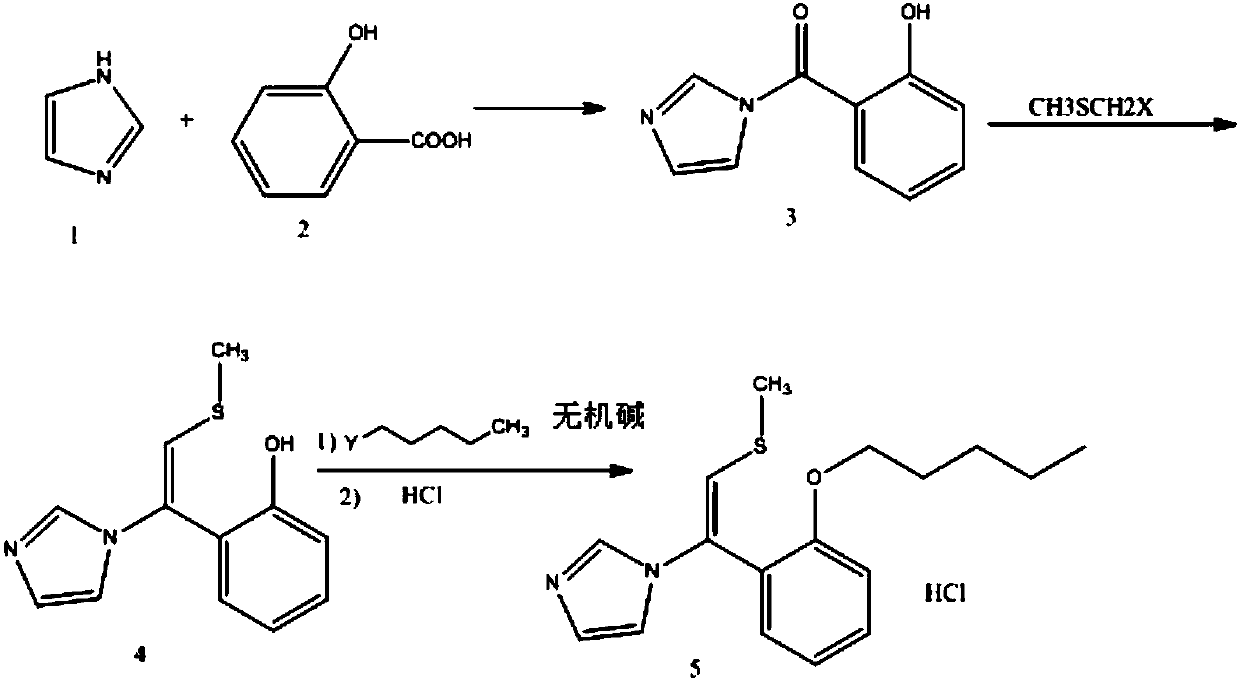

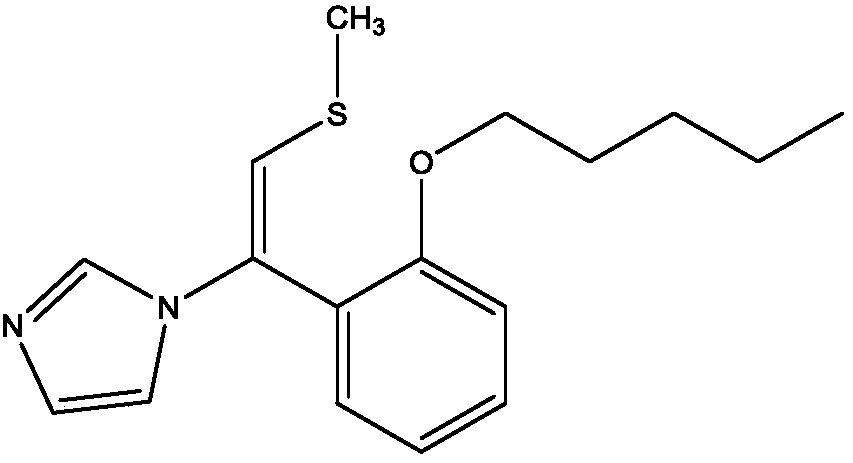

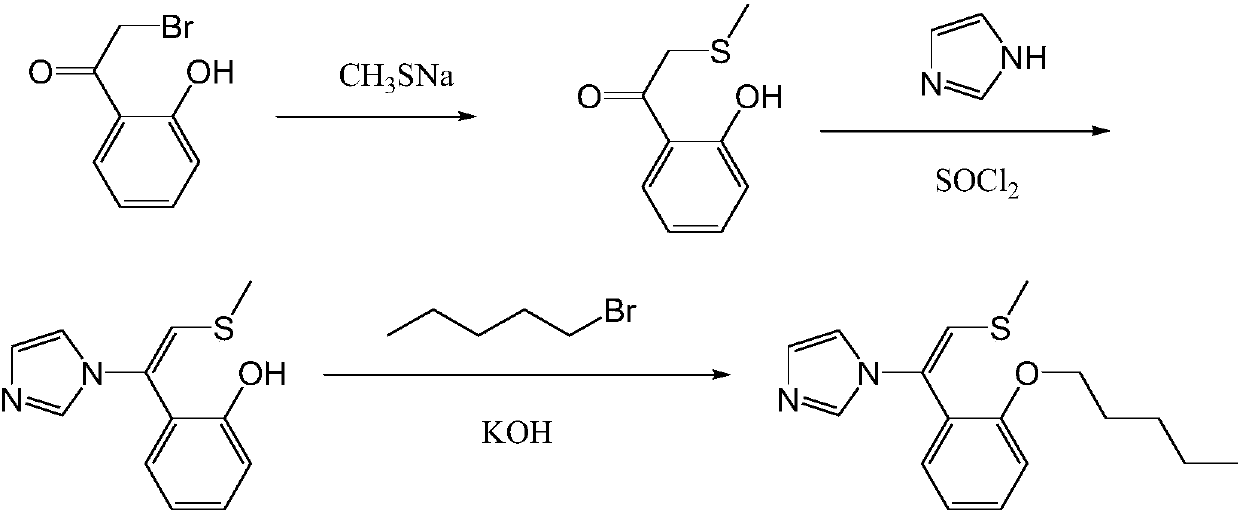

Neticonazole hydrochloride preparation method

The invention discloses a neticonazole hydrochloride preparation method, which comprises: carrying out an acylation reaction on imidazole and o-hydroxybenzoic acid, carrying out a wittig reaction on the product of the acylation reaction and 1-halogenated dimethyl sulfide, carrying out a reaction on the product of the wittig reaction and 1-halogenated pentane in an inorganic alkali, and salifying the product of the reaction and hydrochloric acid to obtain the neticonazole hydrochloride. According to the present invention, the method can avoid the use of the methanethiol and thionyl chloride, has characteristics of environmental protection, mild reaction condition, simple operation, simple post-treatment and high product purity, and is suitable for industrial production.

Owner:JIANGSU YUNYANG PHARMA GRP

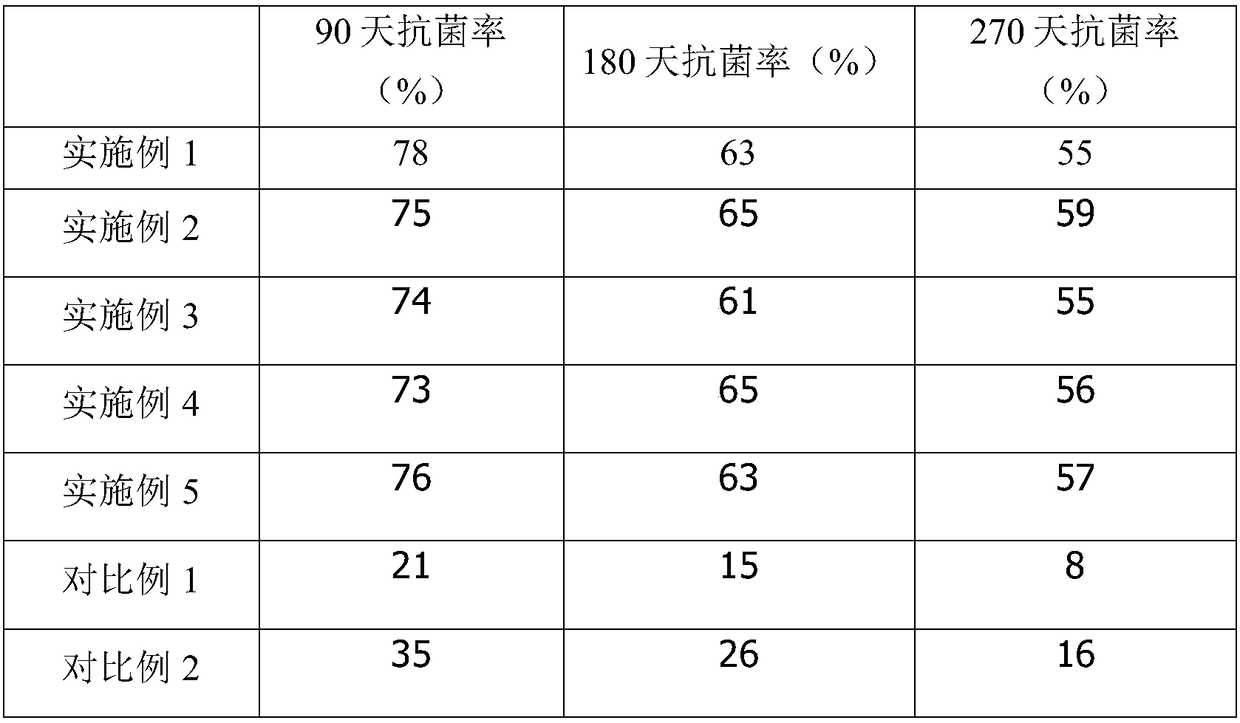

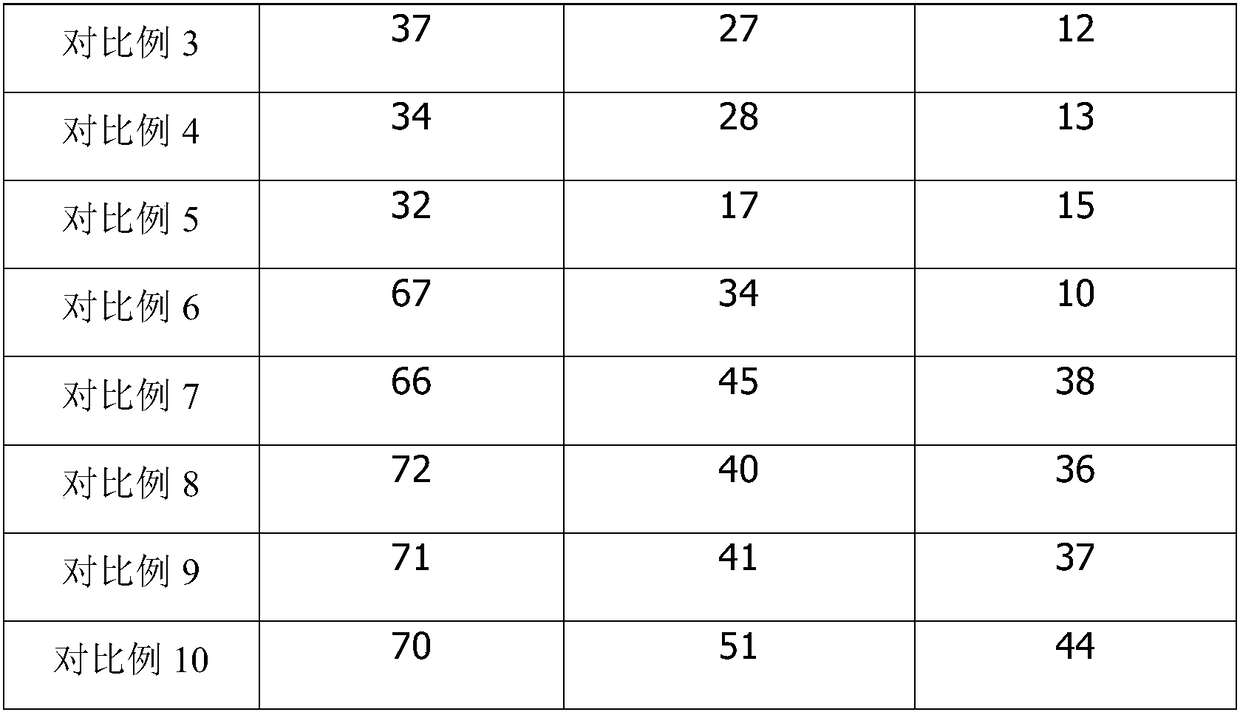

Environment-friendly non-poisonous durable antibacterial polypropylene material

ActiveCN108250578AImprove antibacterial propertiesHigh mechanical strengthMaleic anhydridePolypropylene

The invention relates to an antibacterial polypropylene material and a preparation method thereof. The antibacterial polypropylene material is prepared from the following raw materials: homo-polypropylene resin, nanometer calcium silicate, a maleic anhydride grafted polypropylene homopolymer, a titanium dioxide dispersing agent, an antioxidant, salicylic acid phenyl ester, an 8-hydroxyquinoline Lacoordination complex, methyl ammonium iodide and ferrocene methyl alcohol; the preparation method comprises the following steps of pre-dispersion, mixing, squeezing and the like. The prepared antibacterial polypropylene is good in antibacterial effect, environment-friendly and non-poisonous, the mechanical strength and thermal deformation temperature are improved, and the shrinking percentage islowered.

Owner:SHANGHAI JINCHANG ENG PLASTICS CO LTD

Low-solid no-clean soldering flux and preparation method thereof

InactiveCN108788520AReduce corrosionLow solid contentWelding/cutting media/materialsSoldering mediaSalicylic acidFilm-forming agent

The invention discloses a low-solid no-clean soldering flux and a preparation method thereof. The low-solid no-clean soldering flux is prepared from the following raw materials in parts by weight: 25to 35 parts of resin, 5 to 10 parts of resin emulsifying agents, 3 to 8 parts of o-hydroxybenzoic acid, 2 to 4 parts of fluoboric acid, 3 to 6 parts of salicylic acid, 3 to 6 parts of tripolyvinylimide, 2 to 5 parts of N,N-dimethylethanolamine, 0.3 to 0.6 part of film forming agents, 0.8 to 1.4 parts of surfactant, 1.2 to 1.6 parts of corrosion inhibitors and 20 to 35 parts of cosolvent. The low-solid no-clean soldering flux has the advantages of less residual after soldering, less corrosion and high stability, and the environmental requirements are satisfied.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

Epoxy self-leveling terrace paint

InactiveCN105907249AGood water solubilityImprove fullnessAntifouling/underwater paintsPaints with biocidesSalicylic acidFirming agent

The invention discloses epoxy self-leveling terrace paint. The terrace paint is prepared from, by weight, 68-74% of waterborne epoxy resin, 18-26 parts of co-condensed resin, 5-10 parts of alkyl sulfate, 6-8 parts of ethylhexyl glycidyl ether, 5-8 parts of anatase nanometer titanium dioxide, 4.5-6.5 parts of epoxy curing agent 2.4-3.6 parts of dodecylbenzene sulfonic acid, 4-6 parts of 2,2,4-Trimethyl-1,3-pentanediolmono(2-methylpropanoate), 4-6 parts of salicylic acid, 4-7 parts of citric acid, 5-9 parts of epoxy dispersion agent, 4-9 parts of salicylic acid phenyl ester, 9-15 parts of polyvinyl acetate, 18-24 parts of acrylic emulsion and 5-9 parts of oxidized polyethlene wax. The epoxy self-leveling terrace paint has the advantages of being good in water solubility, good in fullness and the like, guarantees high solid content and low viscosity of a product, and makes the product have good leveling performance. Meanwhile, the terrace paint is high in abrasion resistance and anti-fouling performance, application property is improved, the surface is easier to clean, no water stains are left, and market value is very good.

Owner:SUZHOU KEMIAO NEW MATERIAL

Kitchen garbage deodorizing and insect-killing spray liquid and preparation method thereof

InactiveCN110800738ASpray evenlyImprove the bactericidal effectBiocideDispersed particle separationO-Hydroxybenzoic AcidOrganosilicon

The invention discloses a kitchen garbage deodorizing and insect-killing spray liquid and a preparation method thereof. The kitchen garbage deodorizing and insect killing spray liquid is composed of the following components: 3 to 10 g of copper sulfate, 3 to 10 g of an organosilicon quaternary ammonium salt antibacterial agent, 3 to 5 g of o-hydroxybenzoic acid, 2 to 3 g of sodium dichloroisocyanurate, 10 to 15 g of sodium acetate, 3 to 4 g of cyclodextrin (beta-CD) and 100 to 500 g of water or ethyl alcohol. The preparation method comprises the following steps: adding 3-10 g of copper sulfate, 3-10 g of the organosilicon quaternary ammonium salt antibacterial agent, 3-5 g of o-hydroxybenzoic acid, 2-3 g of sodium dichloroisocyanurate and 10-15 g of sodium acetate into 100-500 g of water,stirring and dissolving, finally adding cyclodextrin (beta-CD), and gently and slowly stirring uniformly to obtain the kitchen garbage deodorizing and insect-killing spray liquid. The kitchen garbagedeodorizing and insect-killing spray liquid has the effects of inhibiting garbage stinking and insect growth and the like.

Owner:FUZHOU KELI TECH DEV

Composite for manufacturing automobile seat cover and preparation method of composite

The invention relates to a composite for manufacturing an automobile seat cover and a preparation method of the composite. The composite is prepared from the following constituents in parts by mass: 50-70 parts of butadiene rubber, 15-30 parts of silicon carbide fibers, 10-25 parts of polyacrylate fibers, 15-30 parts of diatomite, 2-9 parts of aluminum oxide, 1-7 parts of azodicarbonamide, 2-7 parts of phenyl salicylate, 3-9 parts of aluminum borate whiskers, 0.1-0.5 parts of unsaturated polyester resin, 0.5-1.8 parts of titanium dioxide, 0.1-0.5 parts of epoxy resin, 1-3 parts of color master batch and 1-2 parts of 2,4-dihydroxybenzophenone. The automobile seat cover manufactured from the composite provided by the invention has excellent performance of breathability, static resistance, ultraviolet resistance and pressure resistance, is good in elasticity, abrasion resistance and dirt resistance, and can also effectively absorb peculiar smell in an automobile.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

Compound ultraviolet light absorber and preparation method thereof

The invention relates to the technical field of plastic additives, in particular to a compound ultraviolet light absorber and a preparation method thereof.The compound ultraviolet light absorber is formed by compounding 50-70% by weight of a compound ultraviolet light absorber and 30-50% by weight of a compound antioxidant, and the compound ultraviolet light absorber comprises two or more of phenyl o-hydroxybenzoate, 2- (2'-hydroxy-5'-methyl-phenyl) benzotriazole, 2, 4-dihydroxy benzophenone, 2 -(2'-hydroxy-3', 5' -dicyclopentadienyl ) benzotriazole and 2- (2'- hydroxy -3'- tert-butyl -5'- methylphenyl)- 5-chlorobenzotriazole, wherein the composite antioxidant comprises tetrakis [3 -(3' ,5' - di-tert-butyl -4'- hydroxyphenyl) propionic acid] pentaerythritol, glucose oxide alcohol, and comprises two or more of 2,6 di-tert-butyl p-cresol and copper dialkyl dithiophosphate.

Owner:河南瑞奇特新材料有限公司

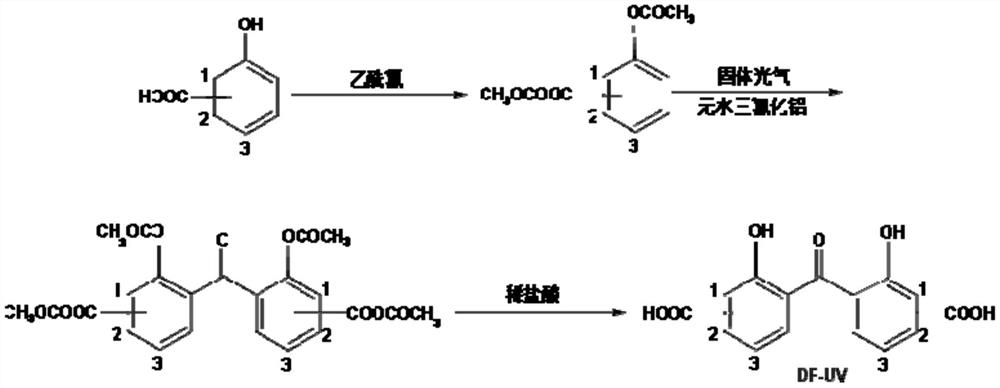

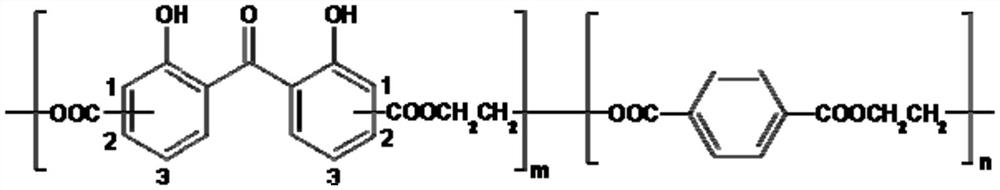

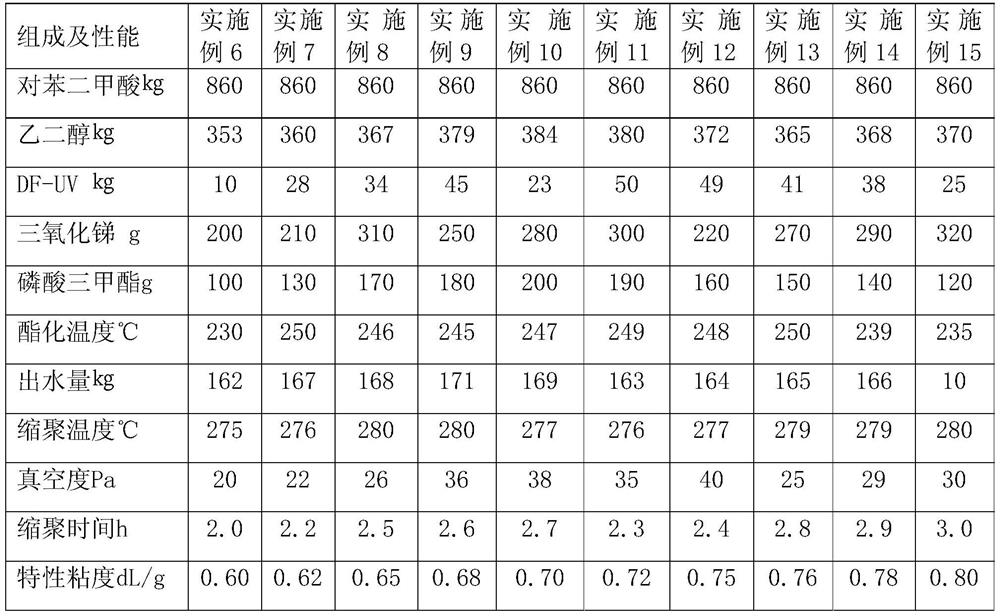

Preparation method of ultraviolet-resistant polyester film

ActiveCN112080025ALong-lasting UV resistanceLow toxicityOrganic compound preparationPreparation from carboxylic acid anhydridesPolymer scienceUltraviolet lights

The invention discloses a preparation method of an ultraviolet-resistant polyester film, which is characterized by comprising the following steps: adding o-hydroxybenzoic acid and acetone into a reaction kettle, dropwisely adding acetyl chloride, and carrying out esterification reaction to obtain o-cresol diacetate; adding dichloroethane, N, N-dimethylformamide and anhydrous aluminum trichloride,dropwise adding a dichloroethane solution of solid phosgene, carrying out an acylation reaction, and distilling to recover the solvent; adding dilute hydrochloric acid and performing cooling, standing, solid precipitation, suction filtration, water washing and recrystallization after a hydrolysis reaction to obtain an ultraviolet light absorber; performing condensation polymerization reaction on terephthalic acid, ethylene glycol, an ultraviolet light absorber, antimonous oxide and trimethyl phosphate to obtain polyester chips; drying the polyester chips, extruding through an extruder, preparing a cast sheet through a cold drum, longitudinally stretching and transversely stretching the cast sheet, carrying out heat setting, and cooling to obtain the ultraviolet-resistant polyester film. The ultraviolet-resistant polyester film prepared by the method is suitable for solar backboard base films, building films, furniture films, packaging films and the like.

Owner:四川东方绝缘材料股份有限公司

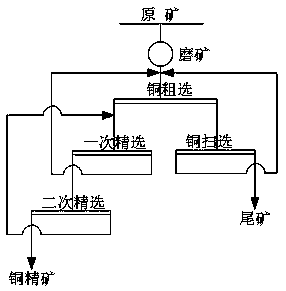

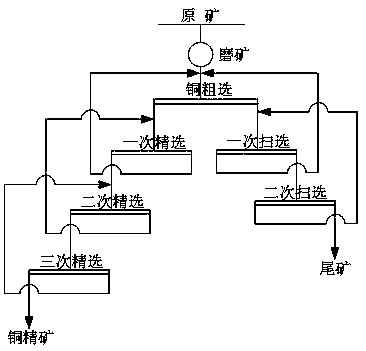

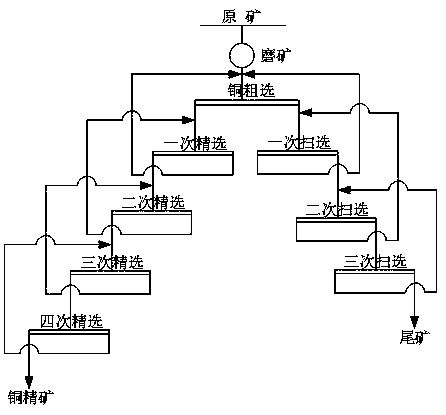

Flotation collecting agent for copper sulfide ore

The invention discloses a flotation collecting agent for copper sulfide ore, and belongs to the technical field of mineral processing. The flotation collecting agent comprises the following raw materials of, by weight, 8-10 parts dialkyl phosphate, 1-2 parts of octyl phenol polyoxyethylene, 2-3 parts of polyoxyethylene stearate, 1-2 parts of triethylene tetramine, 3-5 parts of o-hydroxybenzoic acid and 4-5 parts of activating agents. The collecting agent has the double properties of collecting and foaming, collecting performance is good, the selectivity is good, the mineral floating speed is fast, the flotation foam is stable, the concentrate grade and the recovery rate can be effectively improved, and the collecting agent is an ideal selective collecting agent for the copper sulfide ore.

Owner:KUNMING UNIV OF SCI & TECH

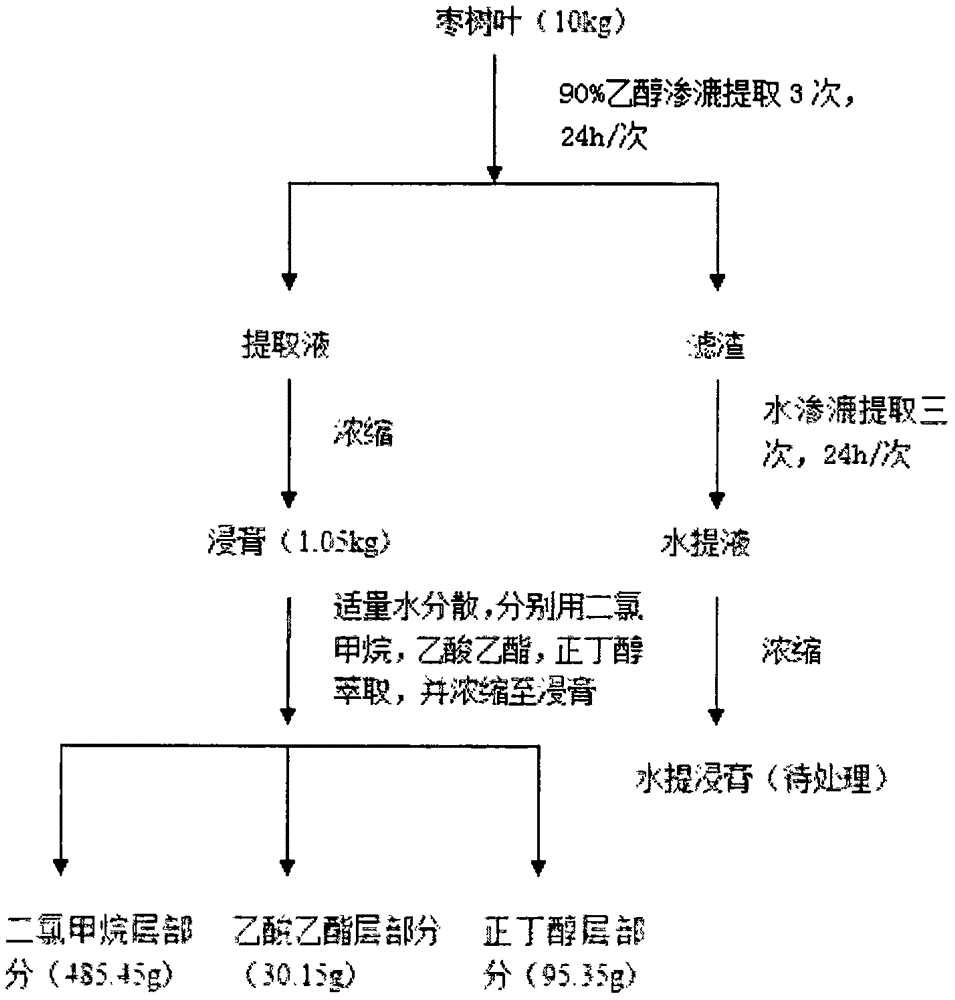

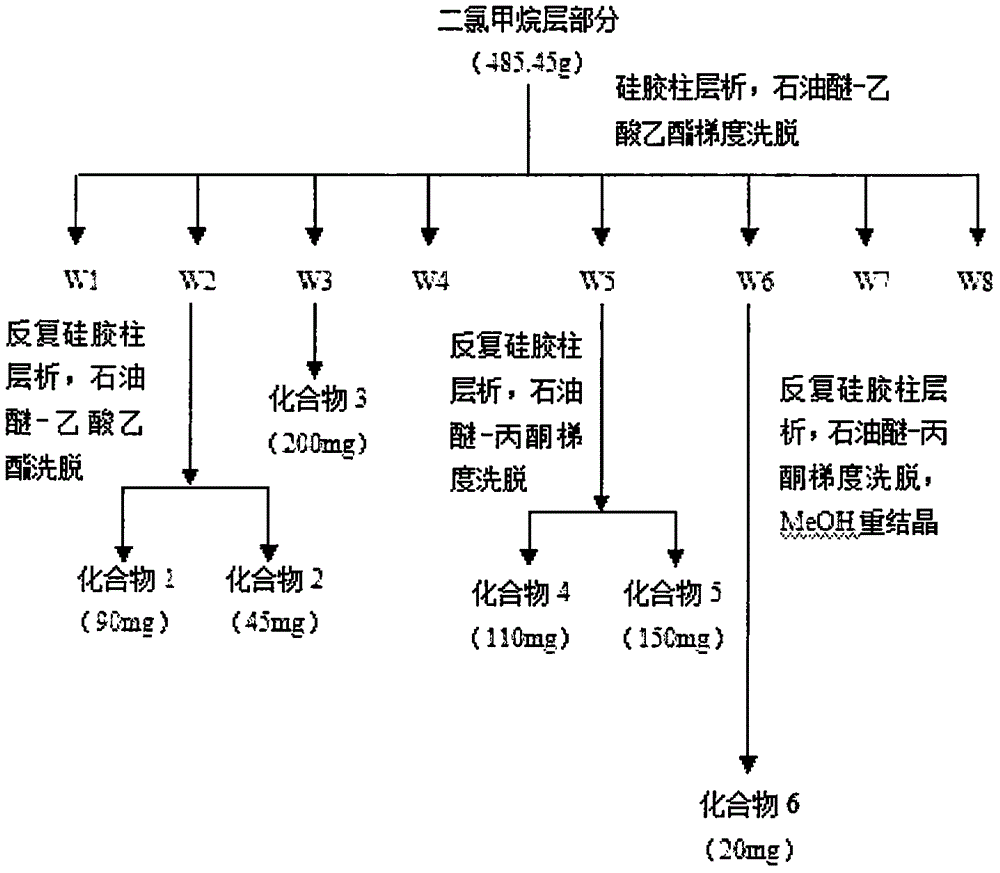

Red jujube leaf standard extract, as well as preparation method and application thereof

InactiveCN105687367AGood hepatoprotective activityDigestive systemPlant ingredientsBenzoic acidBenzaldehyde

The invention discloses a red jujube leaf standard extract, as well as a preparation method and application thereof. The extract is prepared from the following components: 134.96mu g / g of alphitolic acid-3-O-trans-p-coumaroyltormentic acid, 5.27mu g / g of alphitolic acid-3-O-cis-p-coumaroyltormentic acid, 6.75mu g / g of benzoic acid, 6.47mu g / g of 2,4-dyhydroxyl phenol, 77.14mu g / g of p-hydroxybenzoic acid, 2.24mu g / g of o-hydroxybenzoic acid, 25.13mu g / g of rutin, 10.25mu g / g of p-hydroxy benzaldehyde, 3.84mu g / g of maslinic acid-3-O-trans-p-coumaroyltormentic acid, 1.71mu g / g of p-hydroxyl-cis-cinnamic acid, 9.38mu g / g of p-hydroxyl-trans-cinnamic acid and 1.85mu g / g of 3,4-dihydroxy-benzoic acid. Activity test results indicate that the red jujube leaf extract has liver-protecting activity, and can be used for preparing liver-protecting medicines.

Owner:NORTHWEST UNIV

Hot melting welding material

InactiveCN109014651AImprove stabilityImprove high temperature resistanceWelding/cutting media/materialsSoldering mediaPolyethylene glycolCopper oxide

The invention relates to a hot melting welding material, and belongs to the technical field of welding materials. The hot melting welding material comprises the following raw materials of, by weight,30-50 parts of copper oxide, 5-10 parts of metallic aluminium powder, 1-3 parts of magnesium oxide, 3-9 parts of o-hydroxybenzoic acid, 4-8 parts of ethyl alcohol, 0.5-2 parts of dibromosuccinic acid,2-5 parts of cuprous oxide, 1-4 parts of sodium carbonate, 6-10 parts of metallic zinc powder, 2-8 parts of quartz, 3-8 parts of phenolic resin, 1-3 parts of metal fluorine powder and 4-10 parts of polyethylene glycol. The welding point has good stability and high surface evenness and has certain toughness compared with an existing brittle welding line, the possibility of fracture is reduced, theuniformity of the welding point is improved, and the number of times of repeated welding is reduced.

Owner:HUNAN MECHANICAL & ELECTRICAL POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com