Preparation method of ultraviolet-resistant polyester film

A polyester film, UV-resistant technology, applied in the preparation of carboxylate esters, organic compounds, carboxylic anhydrides, etc., can solve the requirements of high coating precision, uniformity and coating effect, copolyester anti-corrosion Reduced UV performance, reduced UV resistance of materials and other issues, to achieve long-term UV resistance, high synthesis yield, and easy storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

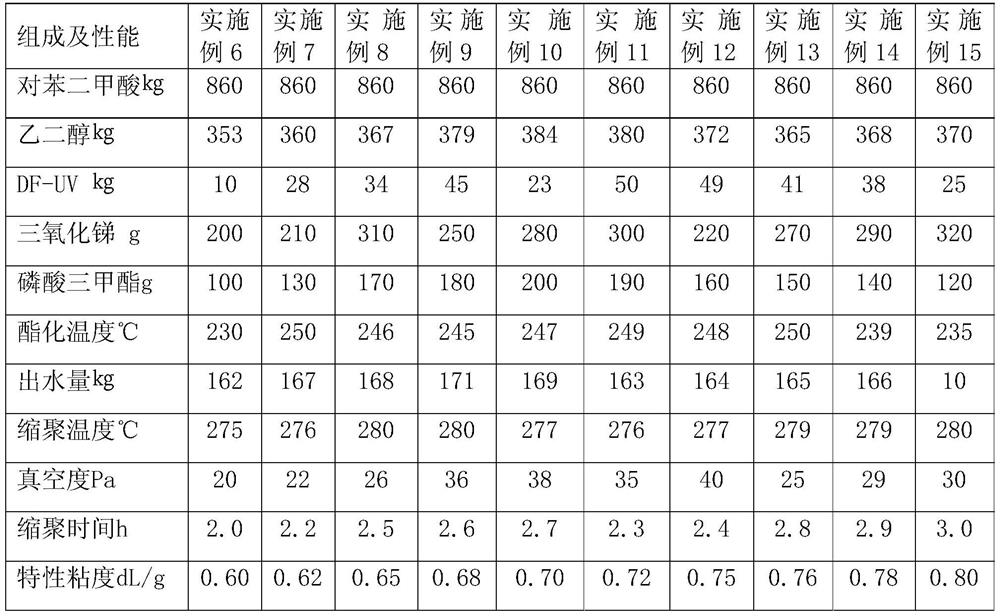

Examples

preparation example Construction

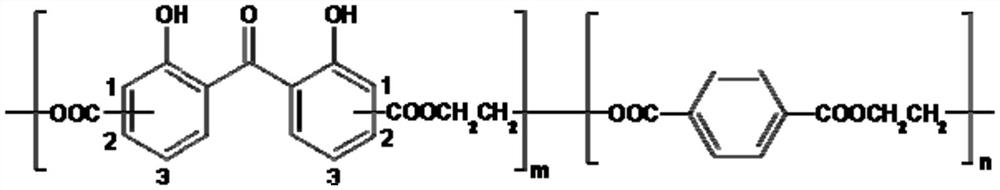

[0038] A preparation method for UV-resistant polyester film, comprising the following steps (part one to part three):

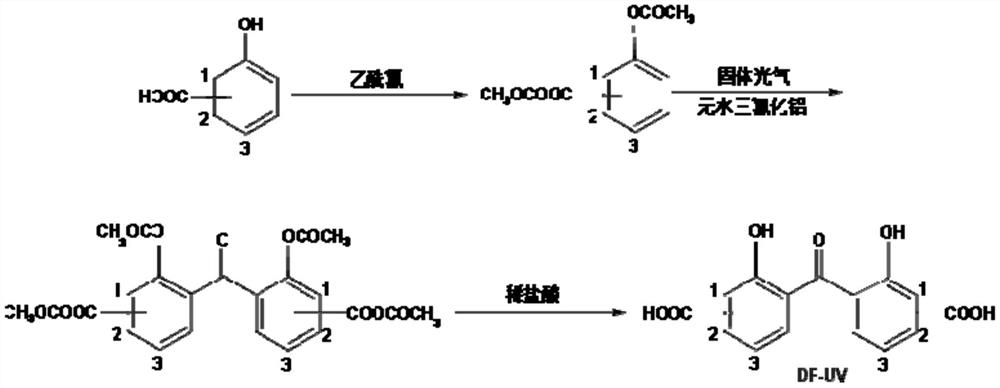

[0039] The preparation of the first part novel ultraviolet absorber

Embodiment 1-1

[0041] ①Esterification reaction: Put 138kg of o-(m-, p-)hydroxybenzoic acid and 276kg of acetone into the reaction kettle, stir and dissolve at room temperature, add 166kg of acetyl chloride dropwise within 2h under cooling conditions, and keep the reaction at 30°C for 2h. The hydrogen chloride generated in the reaction process enters the absorption tower to obtain dilute hydrochloric acid. After the reaction is completed, the solvent is recovered by distillation and cooled to room temperature to obtain 220 kg of o-(m-, p-)formic acid phenol diacetate, with a yield of 99.6%, without refining, directly For the next acylation reaction;

[0042] ②Acylation reaction: Put the esterification product of the previous step, 445L of dry dichloroethane, 0.57kg of N,N-dimethylformamide and 150kg of anhydrous aluminum trichloride into the reaction kettle, stir and dissolve at room temperature, Raise the temperature to 70°C, slowly add 57kg of solid phosgene in dichloroethane solution (100L...

Embodiment 1-2

[0046] ①Esterification reaction: Put 138kg of o-(m-, p-)hydroxybenzoic acid and 303kg of acetone into the reaction kettle, stir and dissolve at room temperature, add 169kg of acetyl chloride dropwise within 2.5h under cooling conditions, and keep the reaction at 40°C for 2h The hydrogen chloride generated in the reaction process enters the absorption tower to obtain dilute hydrochloric acid. After the reaction is completed, the solvent is reclaimed by distillation and cooled to room temperature to obtain 220 kg of o-(middle, p-)formic acid phenol diacetate, with a yield of 99.3%, without refining. directly used in the next acylation reaction;

[0047] ②Acylation reaction: Put the esterification product of the previous step, 463L of dry dichloroethane, 1.3kg of N,N-dimethylformamide and 198kg of anhydrous aluminum trichloride into the reaction kettle, stir and dissolve at room temperature, Raise the temperature to 45°C, slowly add 66kg of solid phosgene dichloroethane solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com