Preparation method and application of anti-soil polymer

A polymer and soil technology, applied in the field of polymer preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

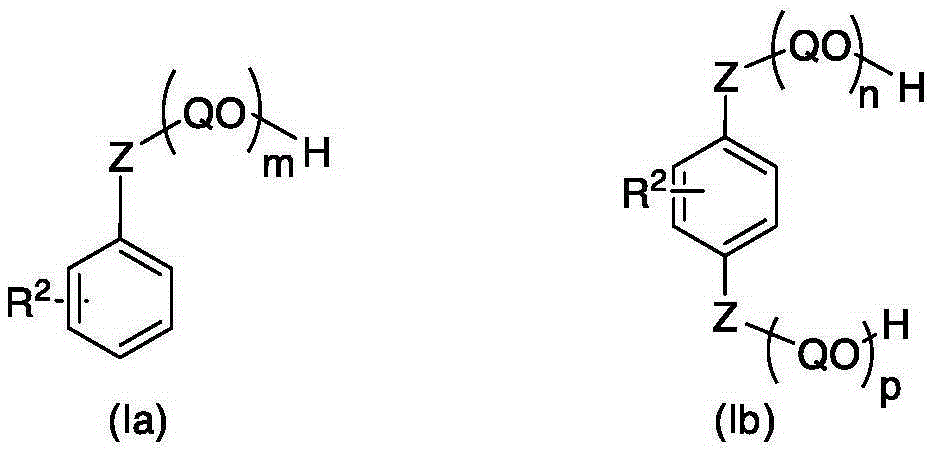

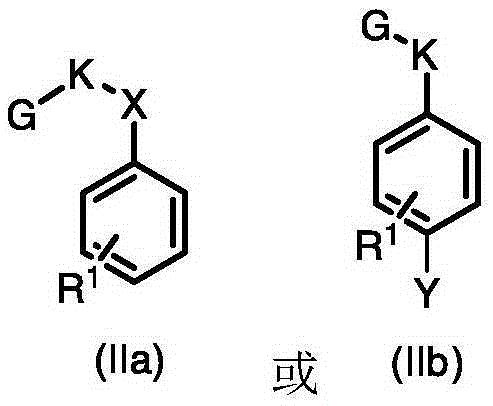

Method used

Image

Examples

preparation example Construction

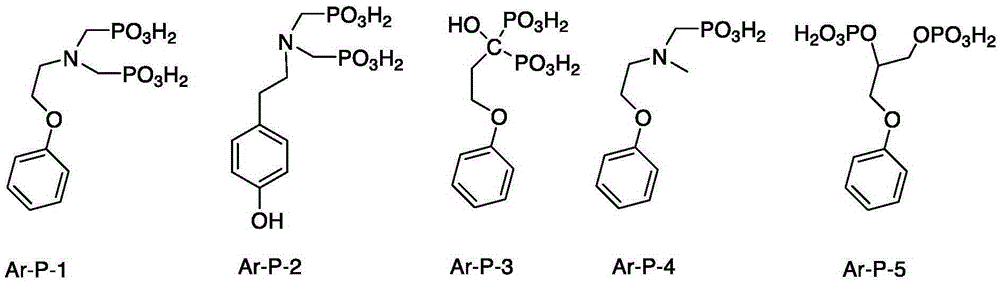

[0066] The preparation method of monomer Ar-P-3 is: take 16.6g (0.1mol) of 3-phenoxypropionic acid and place it in a 250ml three-necked flask, add 43.94g (0.32mol) of phosphorus trichloride within 30min, and heat up to React at 75°C for 12 hours, then add 101.1 g (5.6 mol) of water, and heat up to 105°C for hydrolysis for 1 hour. The reaction was cooled to room temperature. The water in the reaction was distilled off under reduced pressure, and then the crude reaction product was washed three times with cold methanol, and the remaining methanol was vacuumed off to obtain the final target product with a reaction yield of 75%. Other similar structures can be carried out in this way.

[0067]The preparation method of the monomer Ar-P-5 is as follows: take 16.8g (0.1mol) of 3-phenoxy-1,2-propanediol in a 250ml three-necked flask, add 25.36g (0.22mol, 80%wt) of phosphoric acid, Add 30ml of toluene, stir evenly, put a water separator on the three-necked bottle, raise the temperatu...

Embodiment 1

[0070] In this embodiment, A / B=1:2, C / (A+B)=1.0.

[0071] In a 1000ml four-neck flask equipped with electric mechanical stirring and constant temperature heating oil bath, add 250g (0.25mol) of p-methylphenoxy polyethylene glycol M1 (Mw=1000) whose structural formula is shown below, phosphoric acid monomer Ar-P-116 2.5g (0.50mol), water 45g (2.5mol), sulfuric acid 12.5g (0.125mol), heated and stirred until it was a homogeneous phase. Subsequently, 60.75 g (0.75 mol) of 37% formaldehyde aqueous solution was slowly added dropwise. After completion of the dropwise addition, the reaction was carried out at 100° C. for 5 hours. After the reaction, dilute with 30% lye to a pH of about 10, and continue the reaction at 105°C for 0.5-1 hour to remove unreacted formaldehyde. The reaction was cooled to room temperature and diluted with water to about 30%-40%.

[0072]

Embodiment 2

[0074] In this embodiment, A / B=1:2, C / (A+B)=1.0.

[0075] In a 1000ml four-neck flask equipped with electric mechanical stirring and constant temperature heating oil bath, add p-methylphenoxypolyethylene glycol (Mw=2000) 500g (0.25mol), phosphoric acid monomer Ar-P-1162.5g (0.50mol), water 45g (2.5mol), sulfuric acid 12.5g (0.125mol), heated and stirred until it was a homogeneous phase. Subsequently, 60.75 g (0.75 mol) of 37% formaldehyde aqueous solution was slowly added dropwise. After completion of the dropwise addition, the reaction was carried out at 100° C. for 5 hours. After the reaction, dilute with 30% lye to a pH of about 10, and continue the reaction at 105°C for 0.5-1 hour to remove unreacted formaldehyde. The reaction was cooled to room temperature and diluted with water to about 30%-40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com