Patents

Literature

111 results about "O-Toluidine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

O-Toluidine (ortho-toluidine) is an organic compound with the chemical formula CH₃C₆H₄NH₂. It is the most important of the three isomeric toluidines. It is a colorless liquid although commercial samples are often yellowish. It is a precursor to the herbicides metolachlor and acetochlor.

Preparation method and application of anti-soil polymer

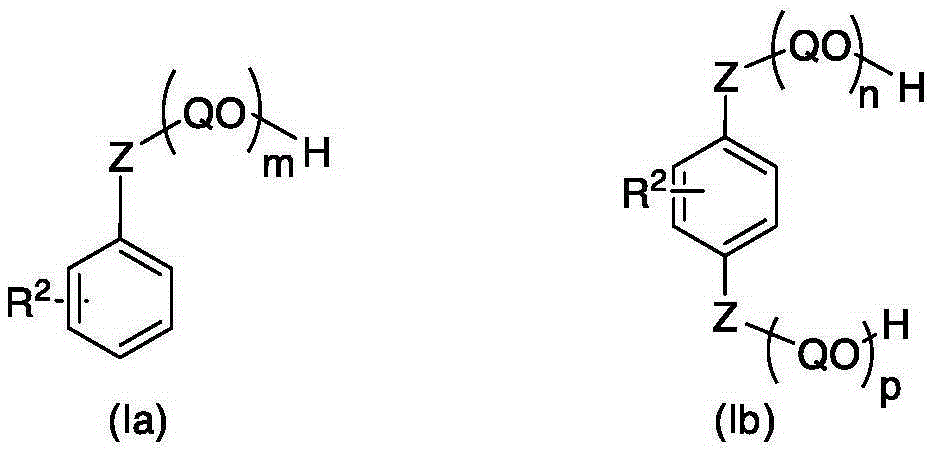

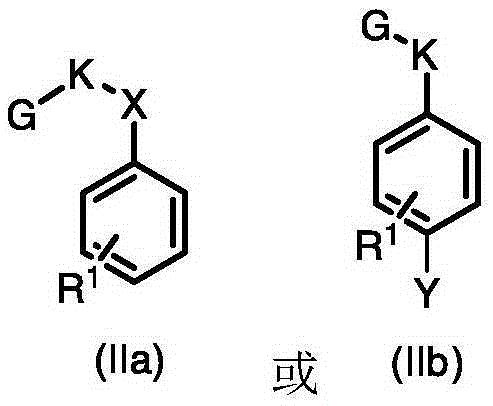

The invention provides a preparation method and application of an anti-soil polymer. The prepared polymer is used as a dispersant for a hydraulic cementing agent and / or an aqueous dispersion for potential hydraulic cementing agent and has good anti-soil performance. The preparation method the anti-soil polymer comprises a step of subjecting polyether macromonomer A with a special structure, monomer B containing a phosphoric acid or phosphorous acid group, optional monomer D and aldehyde C to condensation polymerization so as to prepare the anti-soil polymer, wherein the monomer D is selected from the group consisting of phenol, aniline, p- / o-aminobezene solfonic acid, p- / o-hydroxybenzoic acid, p- / o-aminobenzoic acid, p- / o-hydroxyezene solfonic acid, p- / o-toluidine and p- / o-methylphenol, a mol ratio of the polyether macromonomer A to the monomer B to the monomer D is 1: (0.5-12): (0-8.0), and a mol ratio of the polyether macromonomer A to the monomer B and the monomer D is 1: (0.5-12.0).

Owner:JIANGSU SOBUTE NEW MATERIALS +1

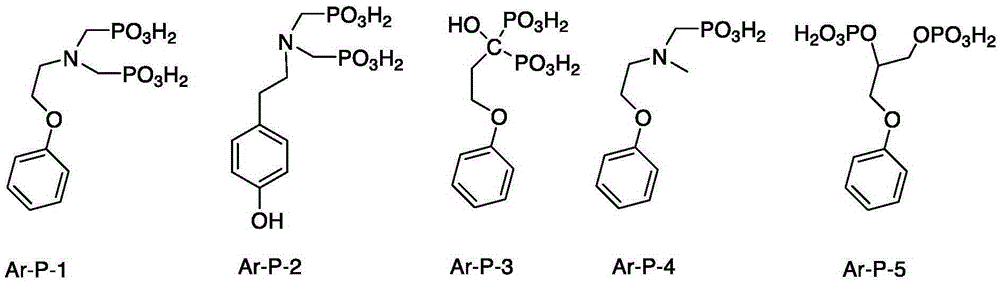

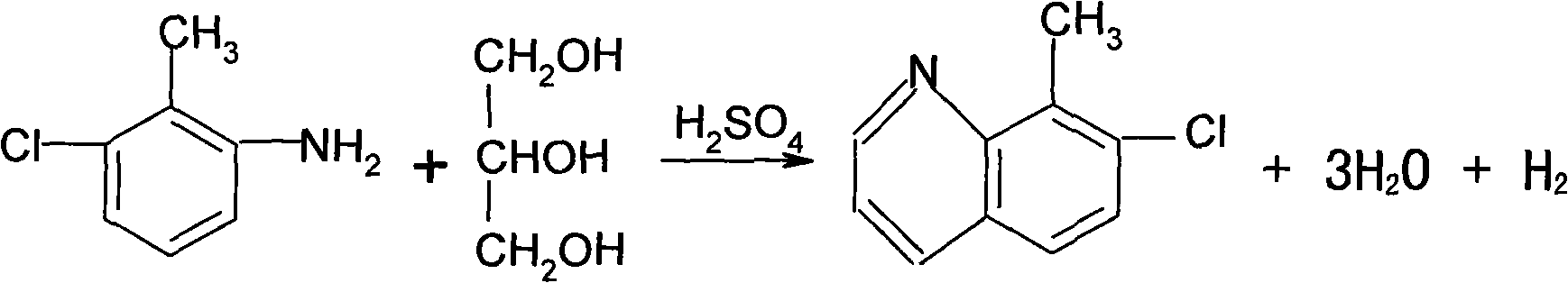

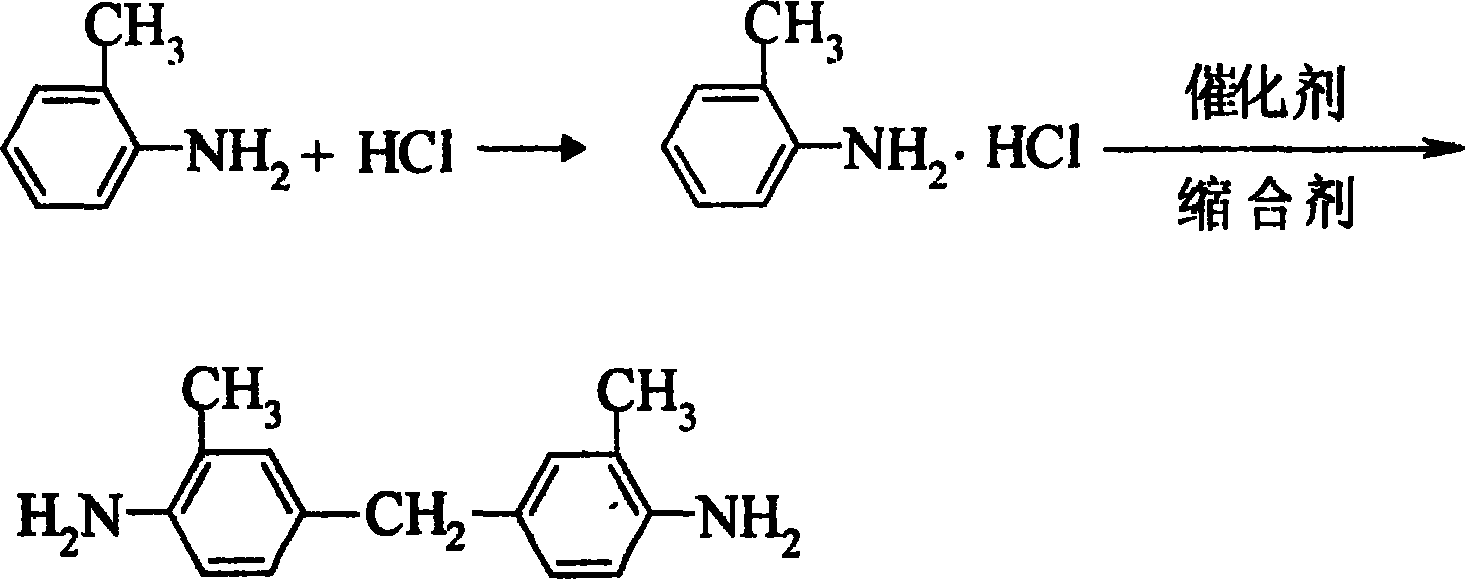

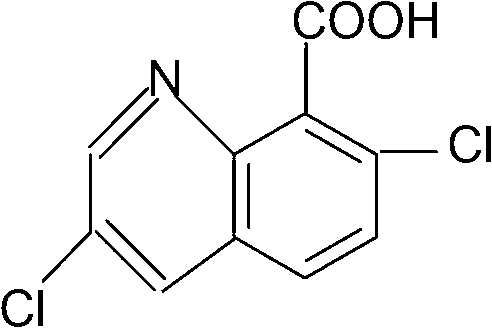

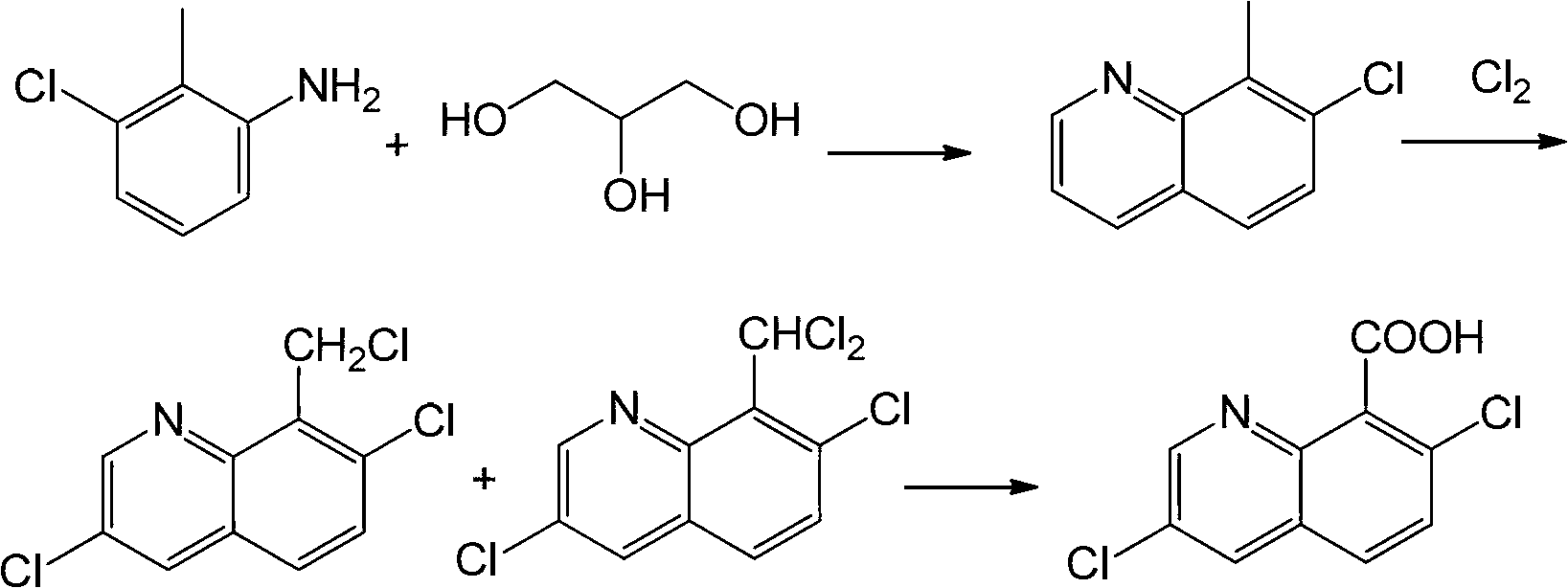

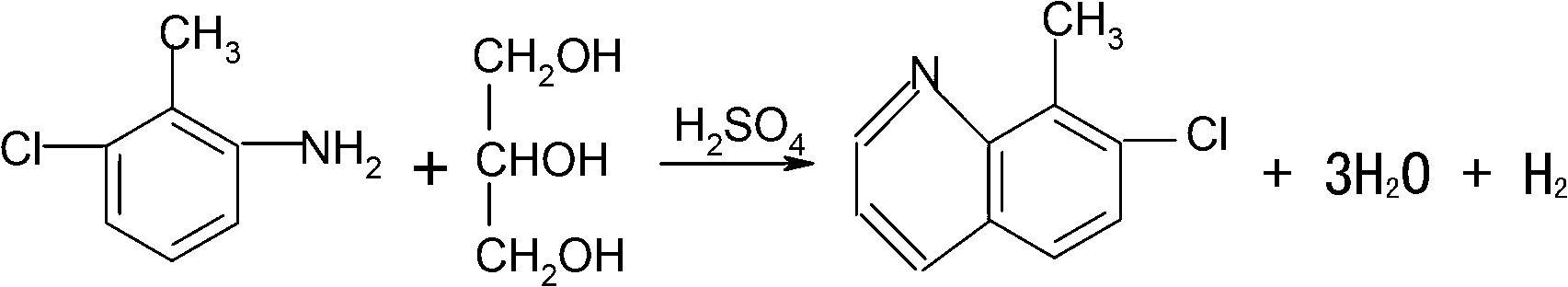

Method for synthesizing and refining quinclorac

The invention discloses a method for synthesizing and refining quinclorac. The synthesis method comprises the following steps of: preparing 7-chloro-8-methylquinoline by adopting m-chloro-o-toluidine and glycerol as raw materials; carrying out chlorination reaction on the 7-chloro-8-methylquinoline and chlorine to generate 3,7-dichloro-8-chloromethylquinoline; and finally oxidizing the 3,7-dichloro-8-chloromethylquinoline in concentrated sulfuric acid by concentrated nitric acid to obtain the quinclorac, wherein a chlorinating cocatalyst is added in the chlorination reaction, and an oxidizing cocatalyst is added in oxidation reaction. The synthesis method greatly improves reaction yield (larger than or equal to 65 percent) by using the chlorinating cocatalyst and the oxidizing cocatalyst and obtains a crude quinclorac product with higher content, and meanwhile, the quinclorac with high content (larger than or equal to 98 percent) is obtained by refining through using a one-step pressure kettle method. The process has the characteristics of simple and convenient operation, high yield, low cost, and the like.

Owner:江苏绿利来股份有限公司

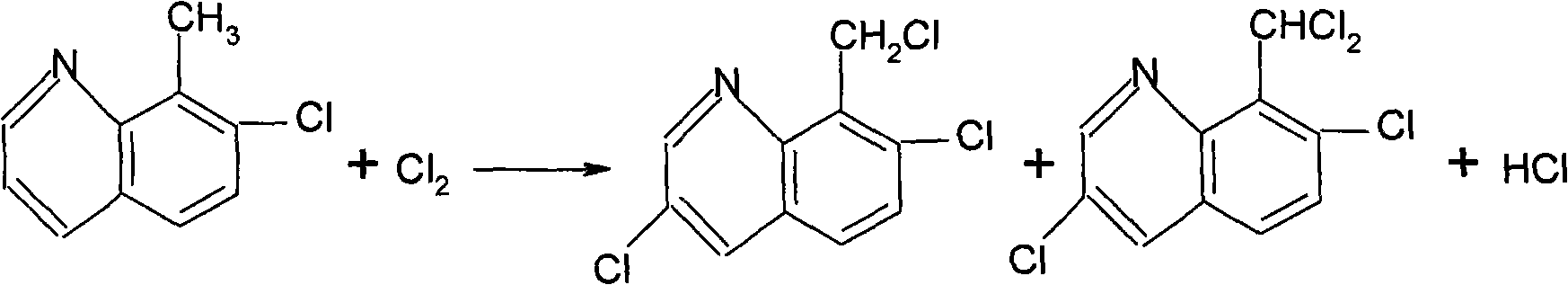

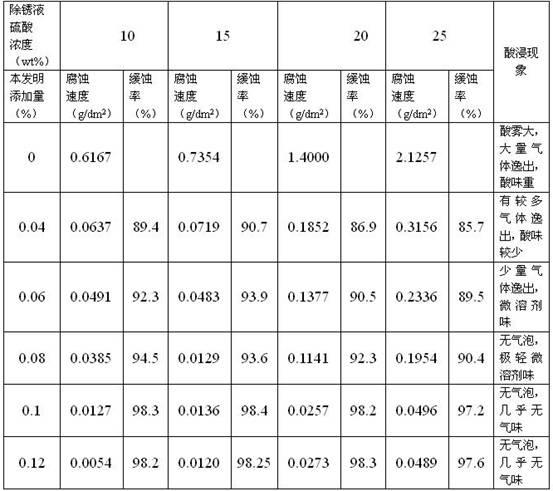

Sulfuric acid washing corrosion-retarding fog inhibitor and preparation method thereof

InactiveCN101851761AThe effect of suppressing acid mist is obviousThe effect of acid mist is obviousEthylenediamineGallic acid ester

The invention discloses a sulfuric acid washing corrosion-retarding fog inhibitor and a preparation method thereof. The sulfuric acid washing corrosion-retarding fog inhibitor comprises an inhibitor, a complexing agent and a wetting agent, wherein the inhibitor comprises di-o-tolyl-thiourea, o-toluidine, sulfonated protein and ethylene diamine tetraacetic acid; the complexing agent comprises sodium citrate, sodium tartrate, hydroxyacetic acid and gallic acid; and the wetting agent comprises sodium sulfonate, sodium carboxylate, L-548 and OP-10. The sulfuric acid washing corrosion-retarding fog inhibitor can retard the excessive corrosion of sulfuric acid to steel matrix, also can be used as an acid washing fog inhibitor, and has good stability at high temperature; and the capability of inhibiting acid fog can reach over 95 percent, the highest corrosion-retarding capability can reach over 98 percent, and the stability is no less than 5 hours.

Owner:NANFENG HOUSE KEEPING ELECTRIC APPLIANCES ZUNYI

Foamed polypropylene composite board and preparation method thereof

InactiveCN102504426ALight in massAvoid deformationSynthetic resin layered productsPolymer scienceThermal deformation

The invention discloses a foamed polypropylene composite board, which comprises a foamed polypropylene board and non-woven fabric or polyvinyl chloride of which single face or both faces are compounded onto the foamed polypropylene board, wherein the foamed polypropylene board comprises the following raw materials in parts by weight: 40-60 parts of modified polypropylene, 30-50 parts of co-polypropylene, 5-20 parts of glass fiber, 0-6 parts of ethylene-vinyl acetate copolymer, 0-10 parts of polyethylene, 1-4 parts of foaming agent azodicarbonamide (AC)or OT (o-Toluidine), 0.5-2 parts of foaming initiator, 0.3-1 part of cross-linking agent, 0.2-0.4 part of fire retardant and 0.2-0.5 part of mineral oil. The invention also provides a preparation method for the foamed polypropylene composite board. The foamed polypropylene composite board disclosed by the invention has the performances of light weight, high thermal deformation load temperature, hardness in deformation, high bending modulus, high tensile strength, high notch impact strength, low contractibility rate, good rebound resilience, good toughness, noise reduction, good sound insulation effect, easiness in processing, no water is not water absorbability and recyclability.

Owner:CHONGQING JUWENG PLASTIC MFG

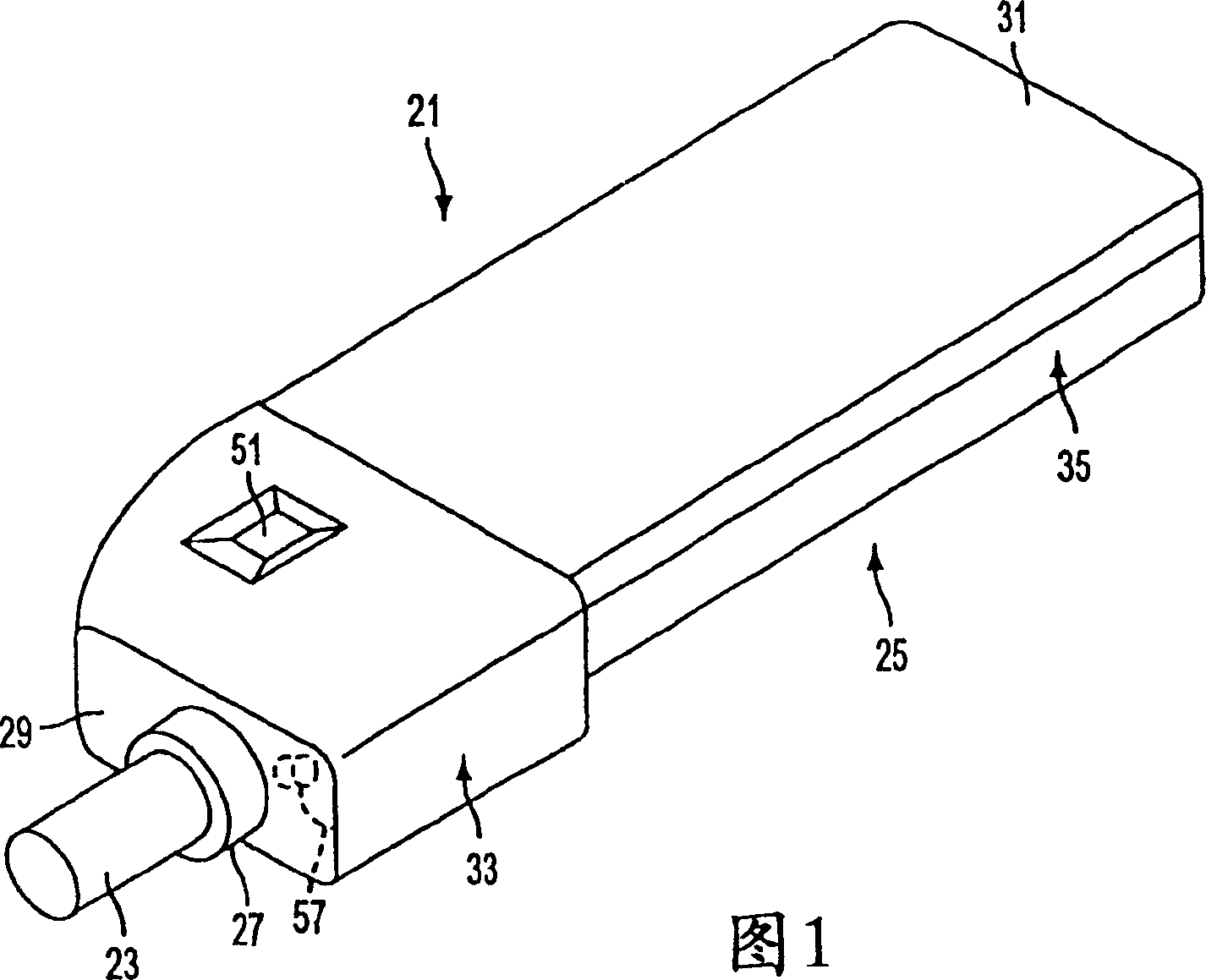

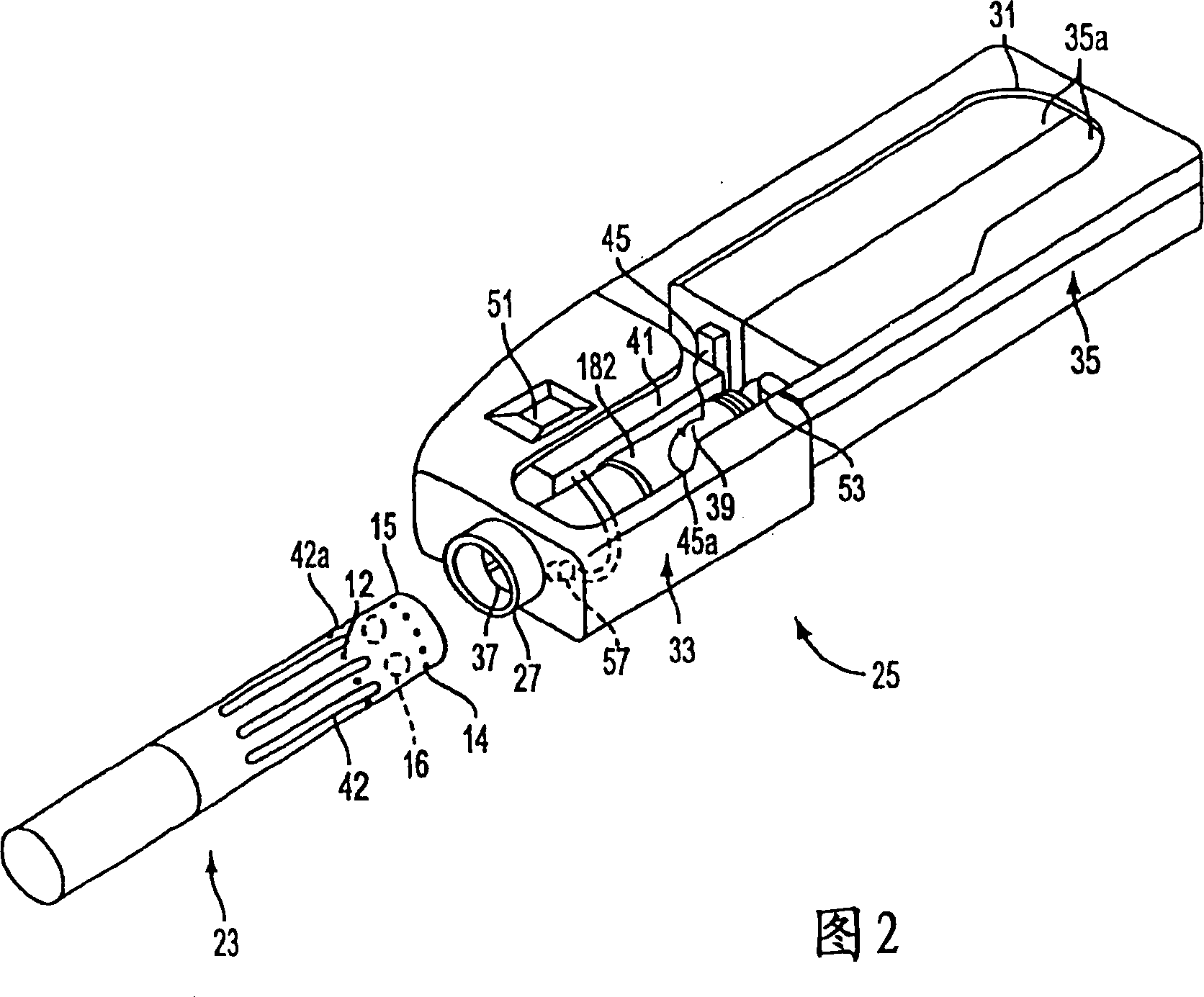

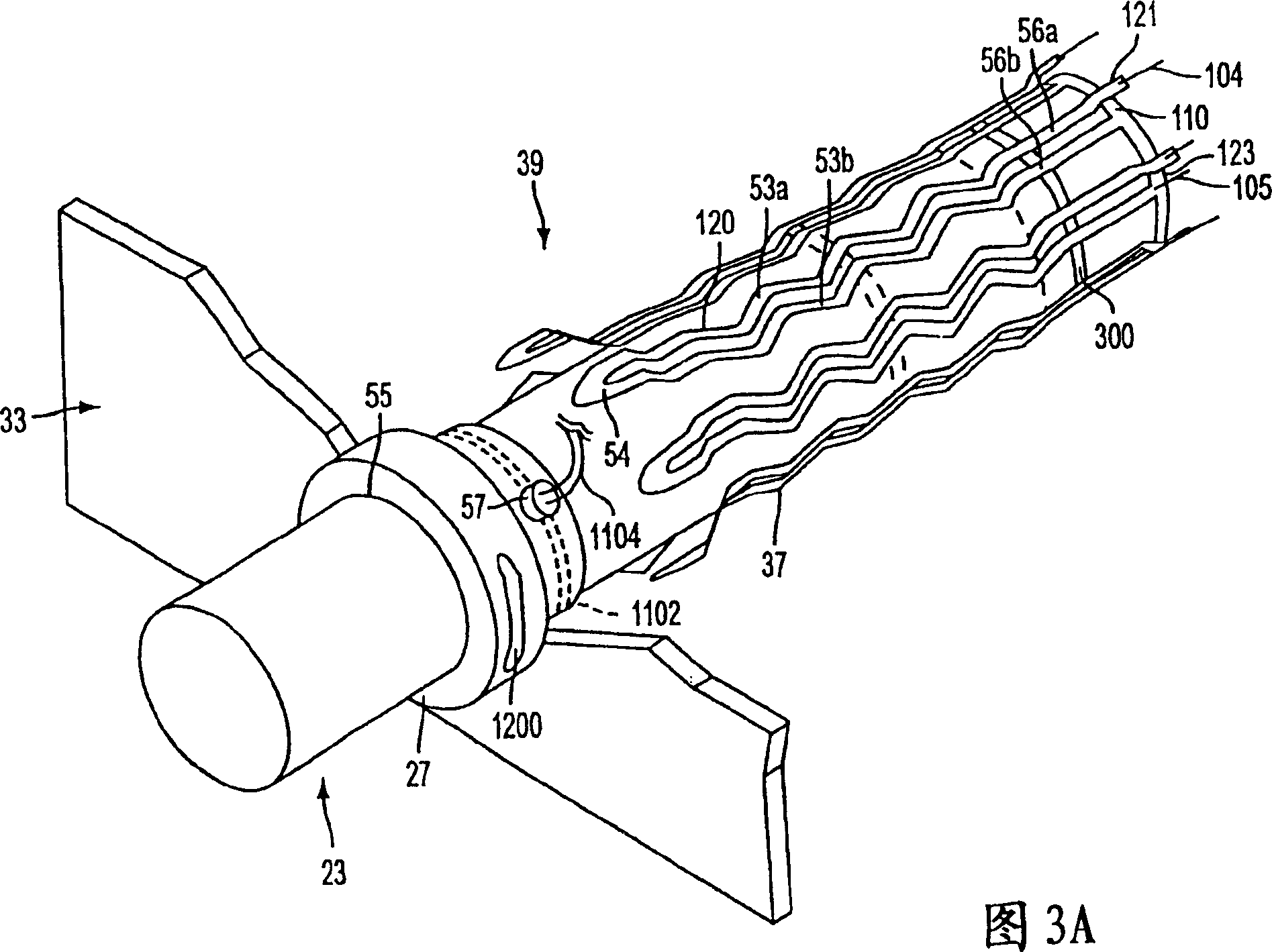

Electrical smoking system and method

InactiveCN1287699CReduce gaseous componentsIncandescent ignitionCigar manufactureAcrylonitrileEngineering

An electrical smoking system comprising a cigarette and an electric lighter, wherein the cigarette comprises a wrapper surrounding a tubular tobacco mat partially filled with material tobacco so as to define a filled tobacco rod portion and an unfilled tobacco rod portion. The wrapper includes an ammonium containing compound filler therein effective to reduce gaseous components of the tobacco smoke produced during smoking of the cigarette. The system includes a lighter comprising at least one heating blade and a controller adapted to control heating of the heater blade, the lighter arranged to at least partially receive the cigarette such that the heater blade heats a heating zone of the cigarette. The controller is operable to limit heating of the heater blade to a predetermined temperature range which allows delivery of tobacco smoke generated by heating the tobacco rod portion while reducing the content of at least one gaseous component in the tobacco smoke compared to smoking a cigarette having only calcium carbonate as the wrapper filler. The gaseous components which can be reduced include carbon monoxide, 1,3-butadiene, isoprene, acrolein, acrylonitrile, hydrogen cyanide, o-toluidine, 2-naphtylamine, nitrogen oxide, benzene, NNN, phenol, catechol, benz(a)anthracene, and benzo(a)pyrene.

Owner:PHILIP MORRIS PROD SA

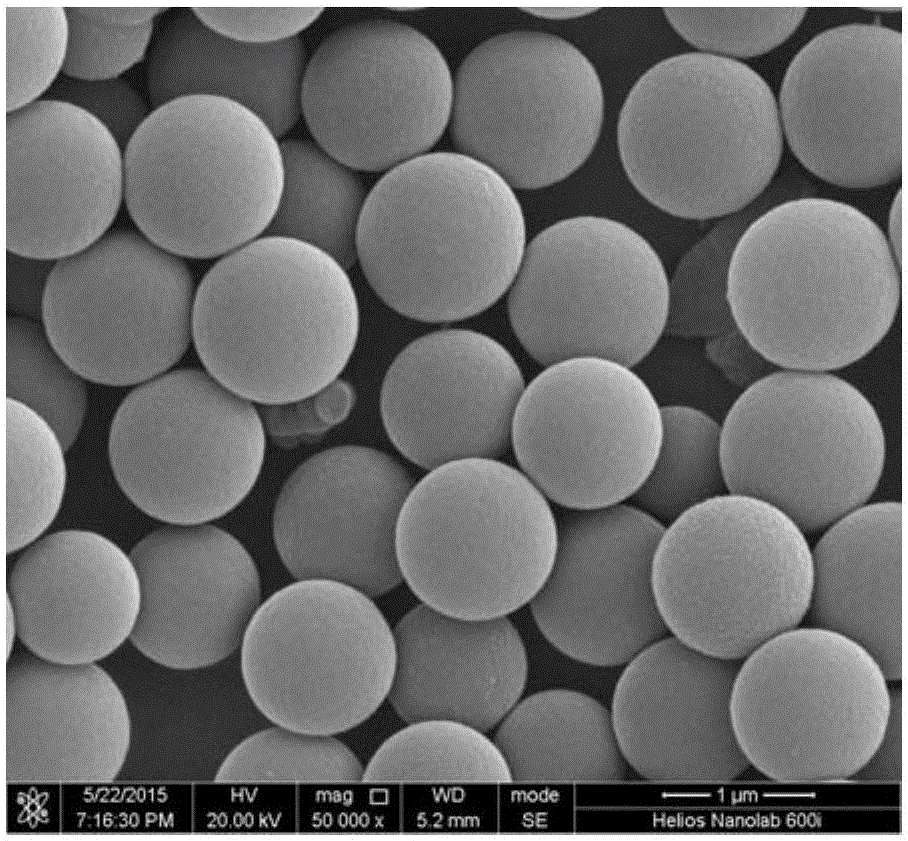

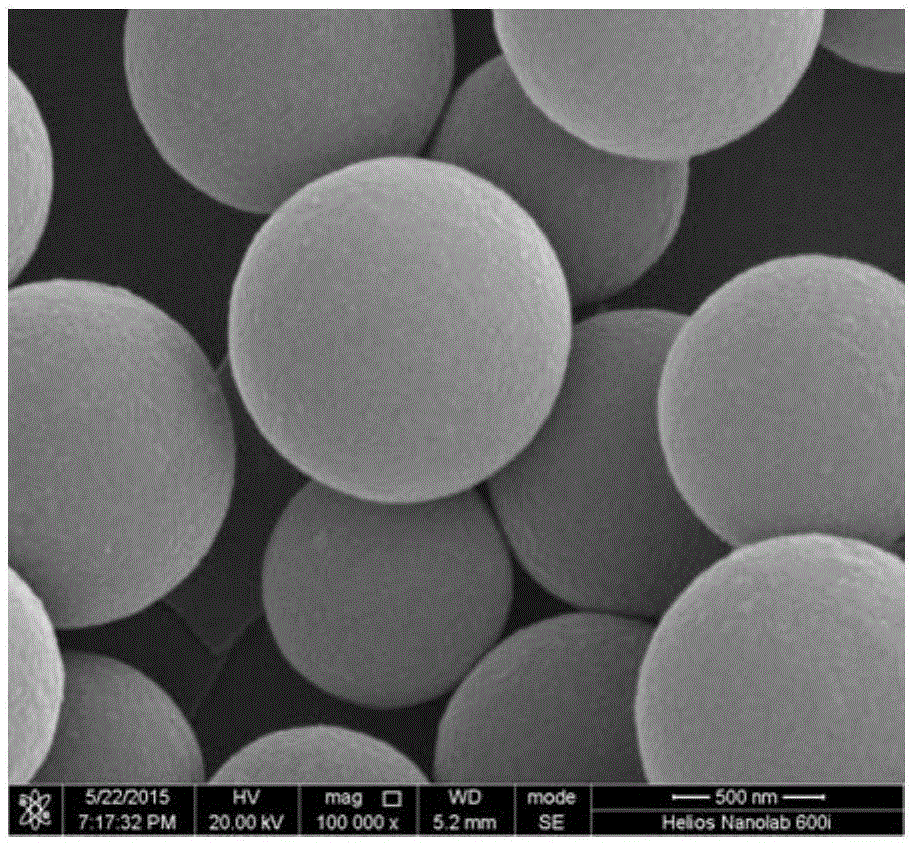

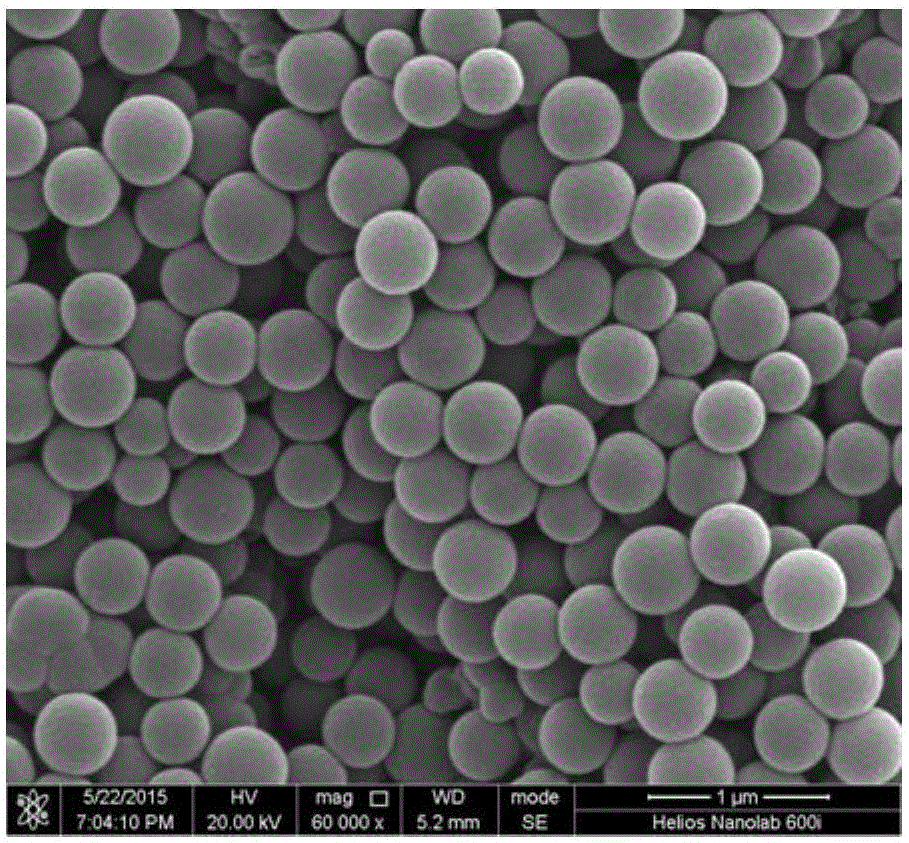

Preparation method of nitrogen-doped carbon microspheres

The invention relates to a preparation method of doped carbon microspheres, particularly a preparation method of nitrogen-doped carbon microspheres, which aims to solve the technical problems of high facility request and harsh reaction conditions in the existing preparation method of the exotic-atom-doped carbon material. The method comprises the following steps: 1. adding o-toluidine into a H3PO4 water solution, stirring uniformly, sequentially adding a H2O2 water solution and a FeCl3 water solution, and stirring uniformly to obtain a precursor solution; 2. transferring the precursor solution into a reaction kettle, carrying out hydrothermal synthesis, separating, cleaning and drying to obtain poly-o-toluidine microspheres; and 3. roasting the poly-o-toluidine microspheres in a vacuum tube furnace under the protection of nitrogen to obtain the nitrogen doped-carbon microspheres. The nitrogen-doped carbon microspheres can be used as a fuel cell high-efficiency ORR electrocatalyst and a supercapacitor electrode material.

Owner:HARBIN INST OF TECH

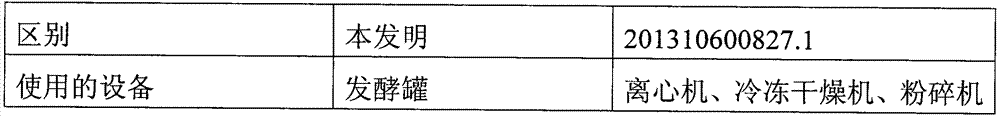

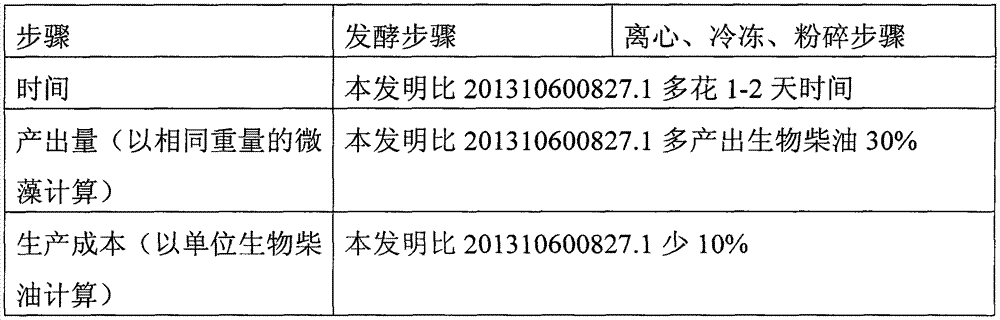

Method for producing biodiesel by microalgae fermentation

InactiveCN104498544AHigh yieldIncrease productivityBiofuelsMicroorganism based processesBiodieselPhosphate

The invention belongs to the technical field of energy and relates to a method for producing biodiesel by microalgae fermentation. The method comprises the following steps of 1, microalgae culture, 2, fermentation of the cultured microalgae by trichoderma harzianum and rhizopus oryzae as zymophyte and a fermentation culture medium containing 20-30g / L of microalgae, 3-5g / L of sodium citrate, 1.5-2.5g / L of o-toluidine, 10-15g / L of sodium chloride, 0.5-1g / L of potassium dihydrogen phosphate and 3-5g / L of magnesium sulfate, 3, extraction of grease in the fermentation products, and 4, enzymic catalytic reaction of the grease. The biodiesel obtained by the microalgae fermentation has a fast oil production rate and a low production cost.

Owner:RUIAN PULUO BIOTECH

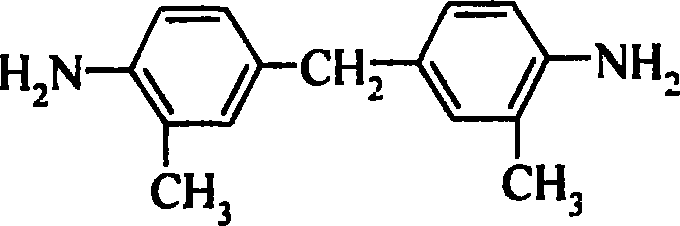

Preparation method of 3,3'-dimethyl-4,4'-diamino dibenzyl methane

InactiveCN1948267AHigh purityRaw materials are cheap and easy to getAmino preparation from aminesO-ToluidineCrystallization

The present invention discloses a preparation method of 3,3-dimethyl-4,4-diaminodiphenyl methane. Said method includes the following steps: using o-toluidine as raw material, making it be reacted with hydrochloric acid to form salt, making it and condensation agent implement condensation reaction in the presence of catalyst, using alkaline solution to neutralize reaction product, and using mixed solution to make recrystallization so as to obtain the invented object product. Its purity can be up to above 99%, and its yield is 77-82%, and its melting point is 158-159 deg.C.

Owner:SHANGHAI CHEM REAGENT RES INST

Aqueous metal antirust agent and preparation method thereof

InactiveCN103409743AEvenly dispersedGood dispersionMetallic material coating processesToluidineHuman health

The invention discloses an aqueous metal antirust agent and a preparation method thereof. The aqueous metal antirust agent is prepared from following raw materials by weight: 10-20 parts of dodecylbenzenesulfonic acid, 20-30 parts of pentaerythritol tetraoleate, 40-45 parts of butyl oleate, 10-15 parts of o-toluidine, 7-15 parts of sodium sulfate, 10-20 parts of sodium hydroxide, 10-15 parts of sodium silicate and 40-50 parts of water. The aqueous metal antirust agent can be uniformly dispersed in water without impurities such as suspended solids, etc. and has good dispersity. The content of volatile organic compounds is 0.3-0.5 ppm. The content of harmful volatile compounds is low, thus having no harm to human health, and therefore the aqueous metal antirust agent is environment friendly and healthy.

Owner:JIANGXI GRESS TECH CORP

Method for catalytically oxidizing quinclorac

The invention discloses a method for catalytically oxidizing quinclorac, which takes m-chloro-o-toluidine and glycerol as raw materials to carry out cyclization reaction for preparing 7-chlorine-8-methyl-quinolin, chlorination is carried out through the 7-chlorine-8-methyl-quinolin and chlorine gas, so 3, 7-dichloro-8-(chloromethyl) quinoline is obtained, finally, concentrated nitric acid, sulfuric acid and an oxidation catalyst are used to oxidize the 3, 7-dichloro-8-(chloromethyl) quinoline, wherein the oxidation catalyst is alkyl sulfonic acid, alkyl sulfuric acid or alkyl benzene sulfonic acid. The synthetic method uses the oxidation catalyst, so the reaction yield is greatly increased, the total yield can reach above 70%, and the quinclorac with higher content is obtained; and the method has the characteristics of simplicity in operation, high yield, short oxidization time, low cost and the like.

Owner:江苏绿利来股份有限公司

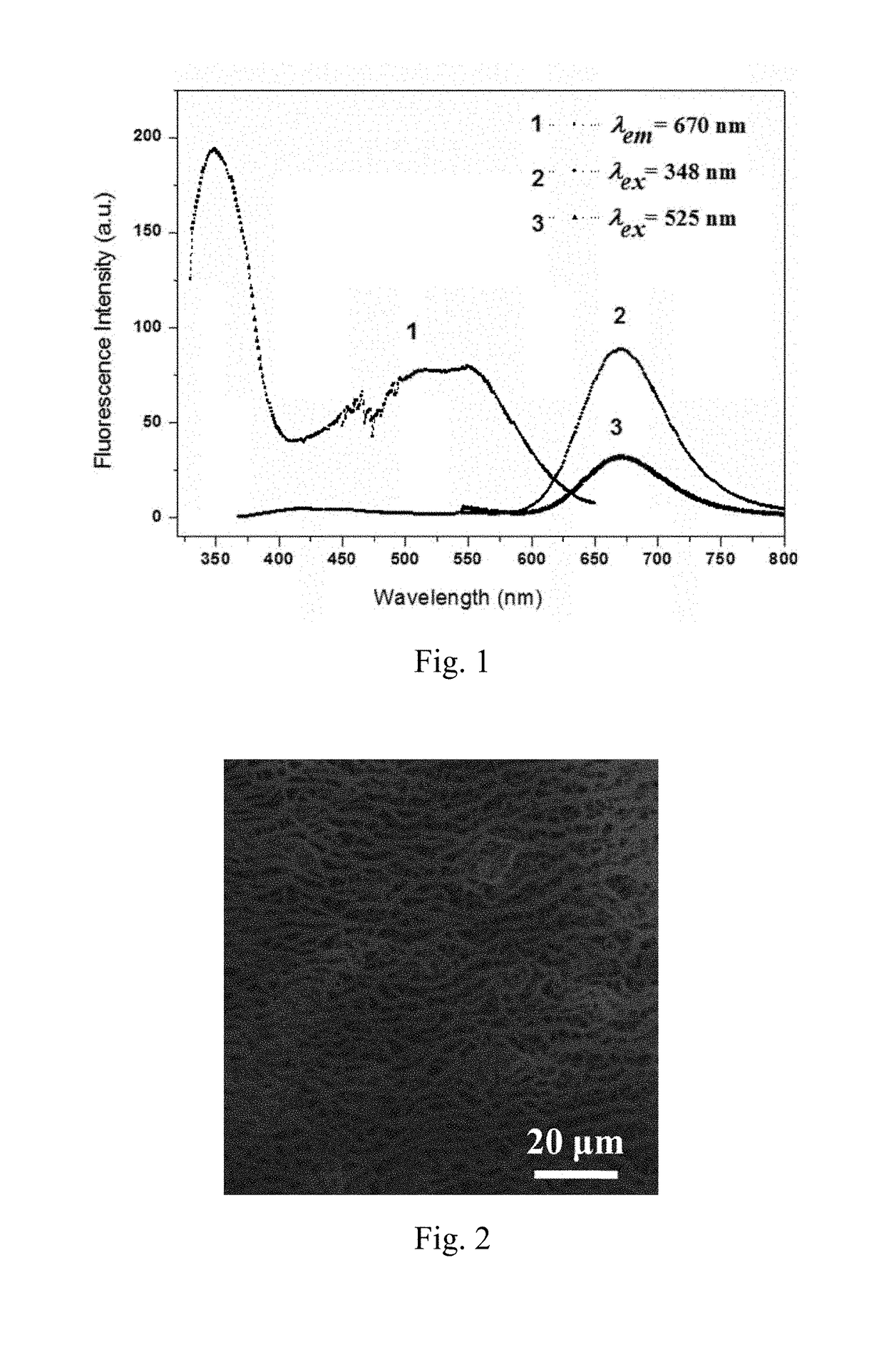

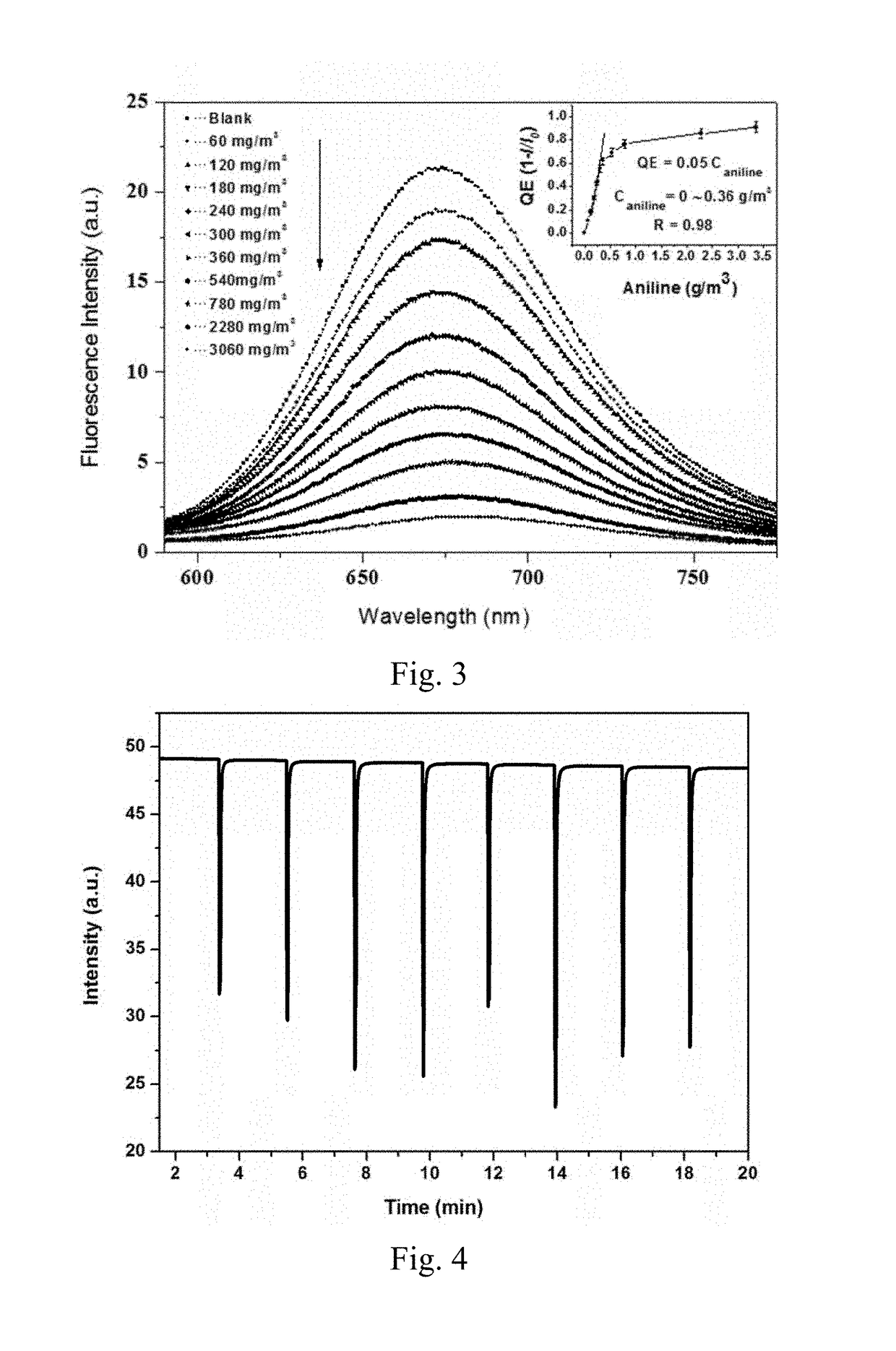

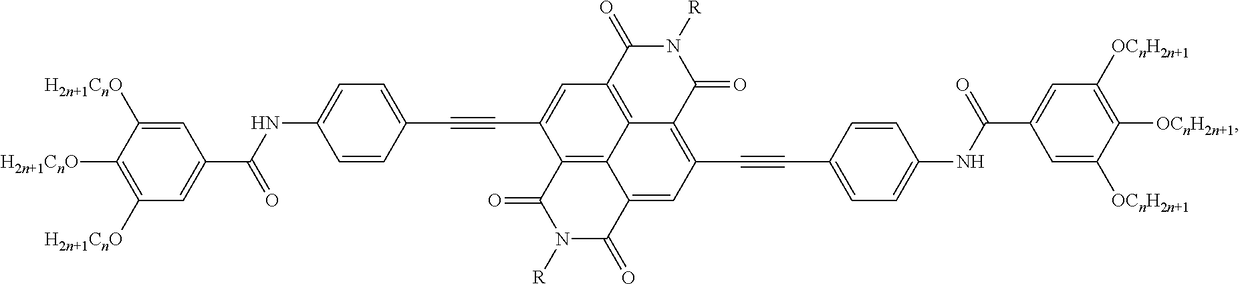

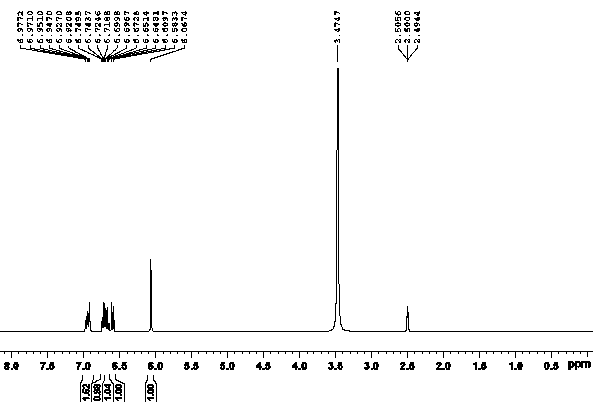

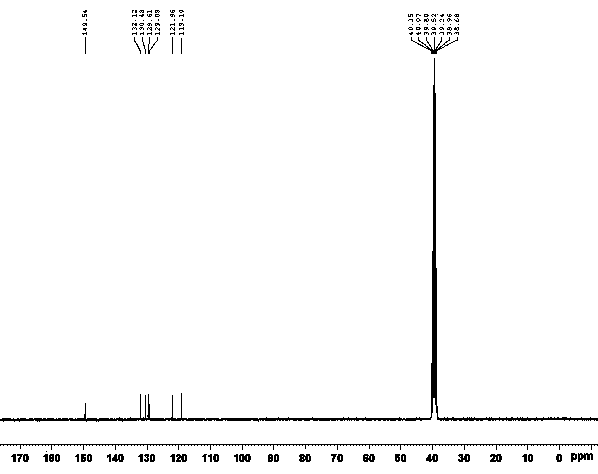

Preparation method and application of fluorescent compound having sensing ability to aniline and o-toluidine gas, and fluorescent film with the same

ActiveUS20190062629A1Easy to operateImprove stabilityOrganic chemistryFluorescence/phosphorescenceSolubilityTerra firma

The present invention discloses a fluorescent compound having a sensing ability to aniline and o-toluidine, a preparation method thereof, a preparation method and application of a fluorescent sensing film. The compound contains a naphthalenediimide (NDI) unit, two alkynyl aniline conjugate fragments and two long alkyl chain fragments; compared with perylene anhydride (PDI), naphthalenediimide (NDI) has better solubility, rich photophysical property, good photochemical stability and strong π-π stacking effect; these building units make the prepared fluorescent compound have supramolecular characteristics and more abundant gelling behavior and assembly behavior. Therefore, the sensing film prepared with the fluorescent compound is controllable in the microstructure, good in stability, high in sensitivity, long in service life and able to be repeatedly used. The present invention achieves the sensitive detection of aniline, and more importantly, the detection is completely reversible, so as to lay the solid foundation for the realization of aniline fluorescence sensor.

Owner:SHAANXI NORMAL UNIV

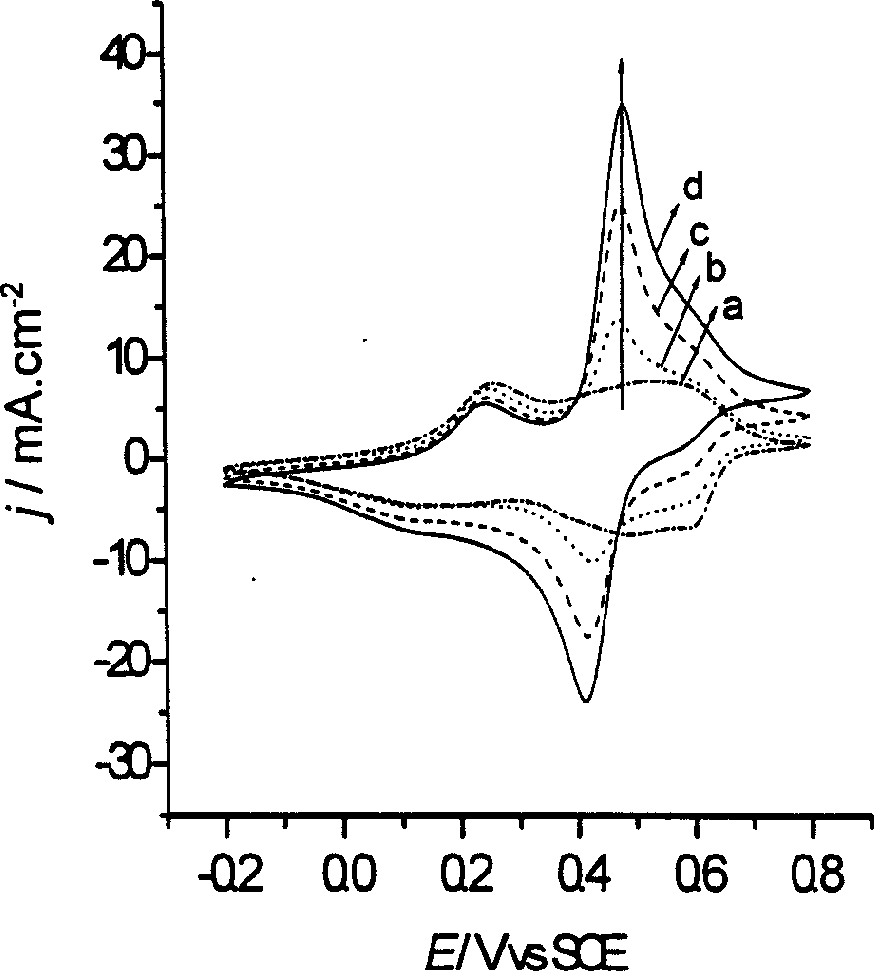

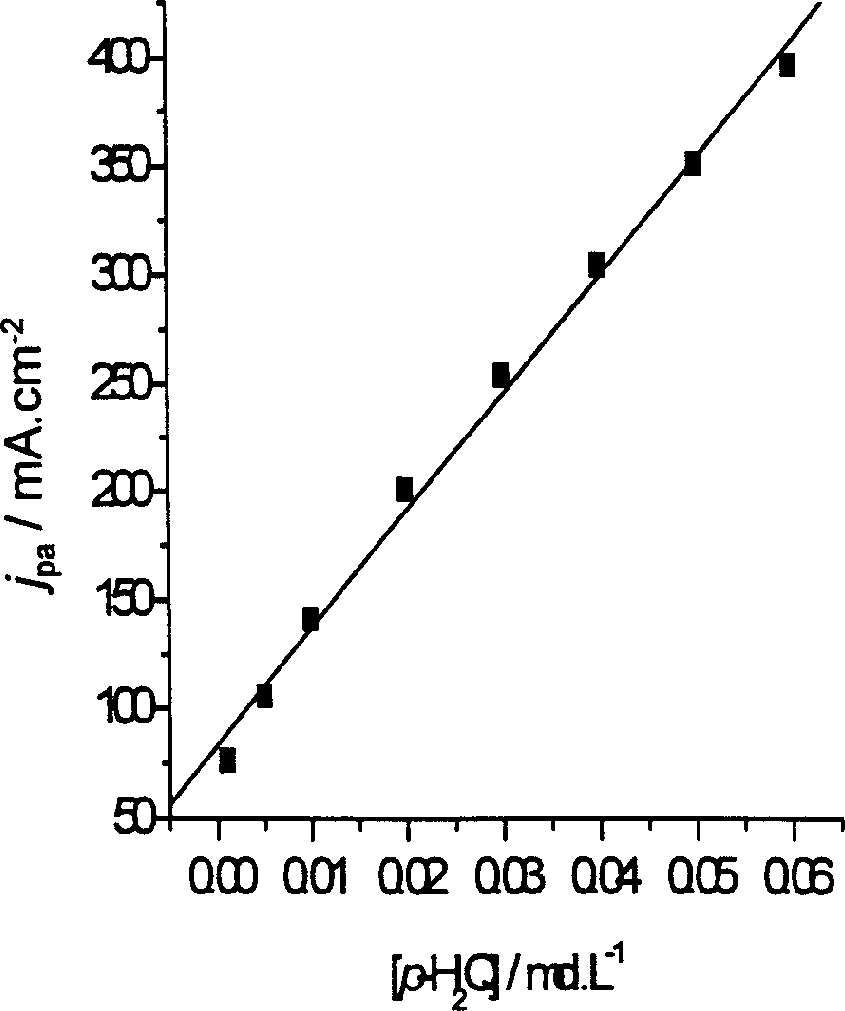

Electronic conducting polymer membrane electrode for detecting dihydroxy-benzene and its prepn method

InactiveCN1601268AOvercoming the drawbacks of conductivityImprove electrochemical stabilityMaterial electrochemical variablesBenzenePolymer science

The invention relates to an electronic conductive polymer film electrode used for detecting paradioxybenzone and its preparation method. Said invention is characterized by adopting macromolecular function acid to make doping so as to raise electrochemical stability of polymer film and catalytic power of polymer for catalyzing paradioxybenzene. Said polymer film electrode includes indifferent electrode base body and conductive polymer film, said conductive polymer film is poly-o-toluidine in whith toluene-p-sulfonic acid is doped, and the attachment quantity of polymer on the base body electrode surface is 0.3-1.0 mg.-sq.cm. Said invention also provides its preparation method and concrete steps, its once operation can prepare several medified electrodes.

Owner:XIAMEN UNIV

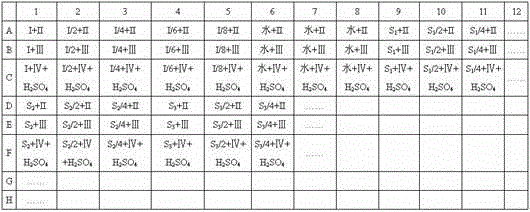

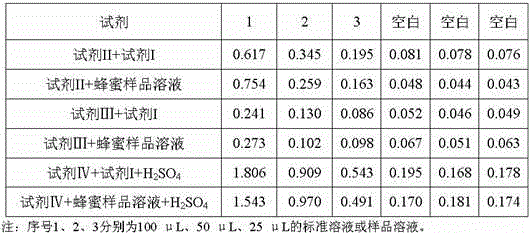

Kit for simultaneously and rapidly measuring content of glucose, fructose and total sugar and application of kit

InactiveCN104360012ALarge amount of processingSimple methodAnalysis using chemical indicatorsColor/spectral properties measurementsBiotechnologyFructose

The invention discloses a kit for simultaneously and rapidly measuring content of glucose, fructose and total sugar and an application method of the kit. The kit is developed based on a principle that carbohydrates are dehydrated to generate hydroxymethyl furfural under the acid action and the hydroxymethyl furfural and a developing agent are condensed to form a colored compound. The kit comprises four reagents, wherein the reagent I refers to a mixed standard substance of glucose, fructose and cane sugar; the reagent II refers to an ortho-toluidine reagent and is used for measuring the content of glucose; the reagent III refers to a resorcinol reagent and is used for measuring the content of fructose; and the reagent IV refers to a phenol reagent and is used for measuring the content of total sugar. The kit is used for simultaneously measuring the content of glucose, fructose and total sugar, has the characteristics of high specificity and high sensitivity, can realize high-flux and rapid detection of the glucose, fructose and total sugar, is large in sample treatment amount and relatively low in cost, is suitable for measuring the content of glucose, fructose and total sugar in honey, fruits and vegetables and other samples and is particularly suitable for large-scale field sample analysis.

Owner:FUJIAN AGRI & FORESTRY UNIV

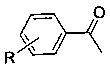

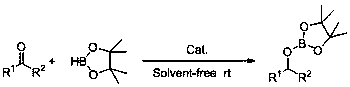

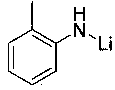

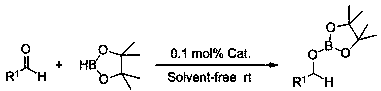

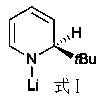

Method for preparing borate on basis of lithium o-toluidine

InactiveCN108440589AEfficient hydroboration reactionReduce pollutionOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsLithiumKetone

The invention discloses a method for preparing borate on basis of lithium o-toluidine. Borane is added to a reaction bottle subjected to dehydration and deoxidation treatment in a water-free and oxygen-free environment in an inert gas atmosphere, then, a lithium o-toluidine catalyst is added, the mixture is uniformly mixed, ketone is added, a hydroboration reaction is conducted, the reaction is ended by exposing the mixture to the air, and borate is obtained. The ketone is aromatic ketone or heterocyclic ketone. It is found for the first time that lithium o-toluidine can extremely efficientlycatalyze the hydroboration reaction of aromatic ketone or heterocyclic ketone with borane, and a new scheme is provided for preparing borate through the hydroboration reaction of a carbonyl compound and borane.

Owner:SUZHOU UNIV

Method of preparing borate ester by performing hydroboration reaction based on o-toluidine lithium

InactiveCN108409771AEfficient hydroboration reactionReduce pollutionOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsBottleOxygen

The invention discloses a method of preparing borate ester by performing hydroboration reaction based on o-toluidine lithium. The method comprises the following steps of under the conditions without water and oxygen, in an inert gas atmosphere, adding borane in a reaction bottle subjected to dehydration and deoxygenation treatment, then adding the o-toluidine lithium as a catalyst, performing uniform mixing, then adding aldehyde for hydroboration reaction, and performing exposure in the air for reaction termination to obtain the borate ester as a product, wherein the aldehyde is selected fromfatty aldehydes. By adopting the method disclosed by the invention, the catalyst has better universality to the fatty aldehydes of different structures, and more selections are provided to obtain borate ester compounds of different substituent group structures.

Owner:ZHANGJIAGANG INST OF IND TECH SOOCHOW UNIV +1

Method for preparing anti-aging agent differential temperature programmed desorption (DTPD)

InactiveCN102557966AReduce manufacturing costOrganic compound preparationAmino compound preparationMethylanilinePhysical chemistry

A method for preparing an anti-aging agent differential temperature programmed desorption (DTPD) belongs to the technical field of organic chemistry. Defined amount of o-methylaniline, ferric chloride and toluene are added in about 12%-15% by-product raw material in an anti-aging agent DTPD synthetic process, by means of condensation reaction, 4-hydroxy diphenylamine, 2'-methyl-4-hydroxy diphenylamine in the by-products are converted into effective components of the anti-aging agent DTPD, production cost is reduced, and economic benefits of the DTPD are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

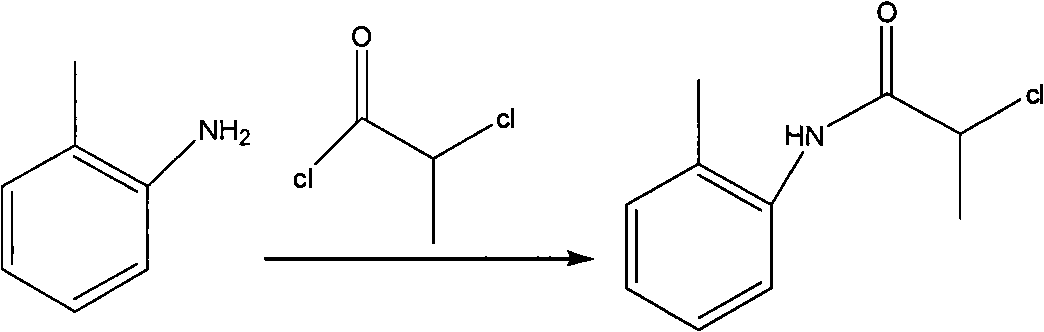

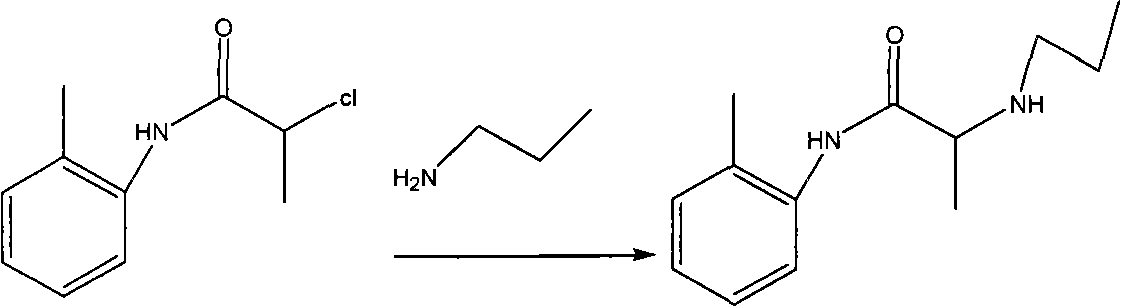

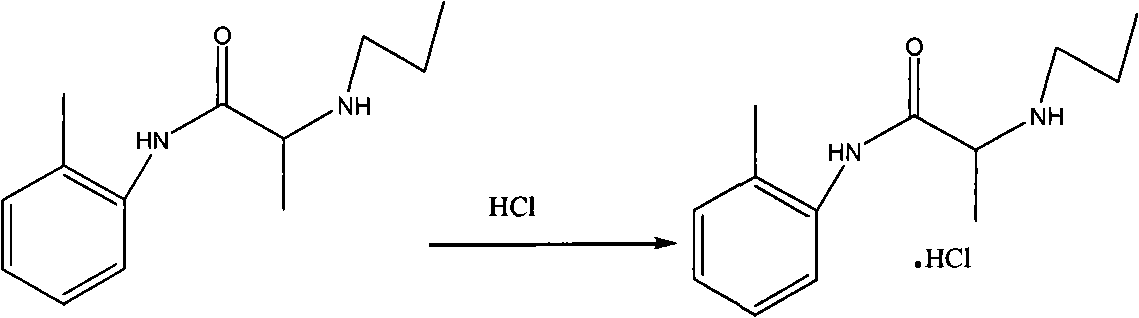

Method for preparing N-(2-Methylphenyl)-2-(propylamino)propa-namide

ActiveCN102093248ANo toxic substancesHigh yieldOrganic compound preparationCarboxylic acid amides preparationPropylaminePotassium

The invention provides a method for preparing N-(2-Methylphenyl)-2-(propylamino)propa-namide. The method comprises the following steps: (1) carrying out amidation reaction based on o-toluidine as a raw material, 2-chloropropionyl chloride as an amidation reagent and potassium cardonate as a catalyst, and preparing an intermediate; (2) carrying out ammoniation reaction on the intermediate prepared in the step (1) and propylamine, so as to prepare crude prilocainum; and (3) dissolving the prepared crude prilocainum in ethyl acetate or acetone, and regulating the pH value to 1-3 with more than or equal to 35% concentrated hydrochloric acid so as to salify. The method has the advantages that harsh reaction conditions such as high temperature, high pressure and the like do not exist in the process route, raw material is available, operation is simple, yield is high, and the method is suitable for industrial production.

Owner:BENGBU BBCA MEDICINE SCI DEV

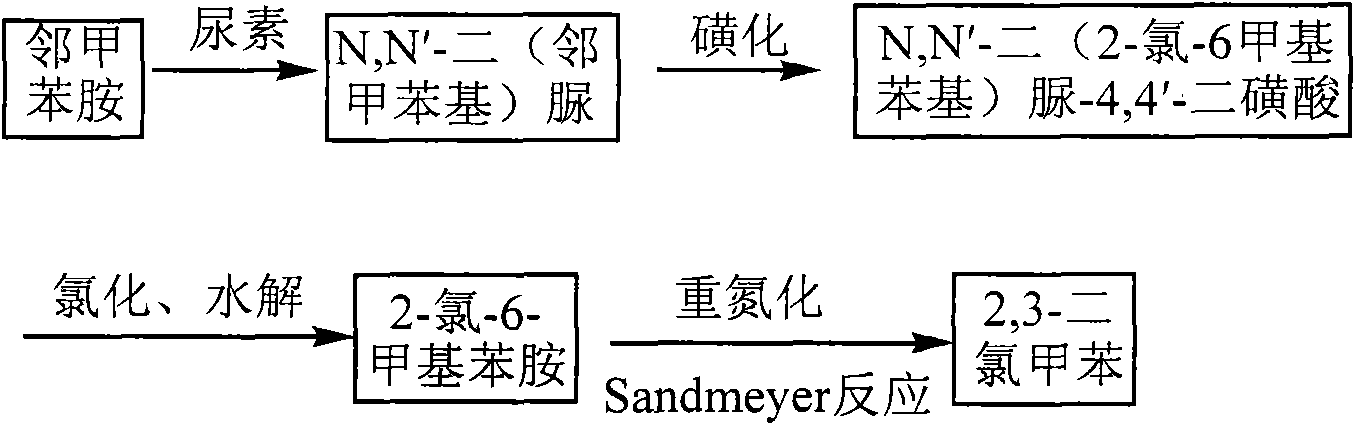

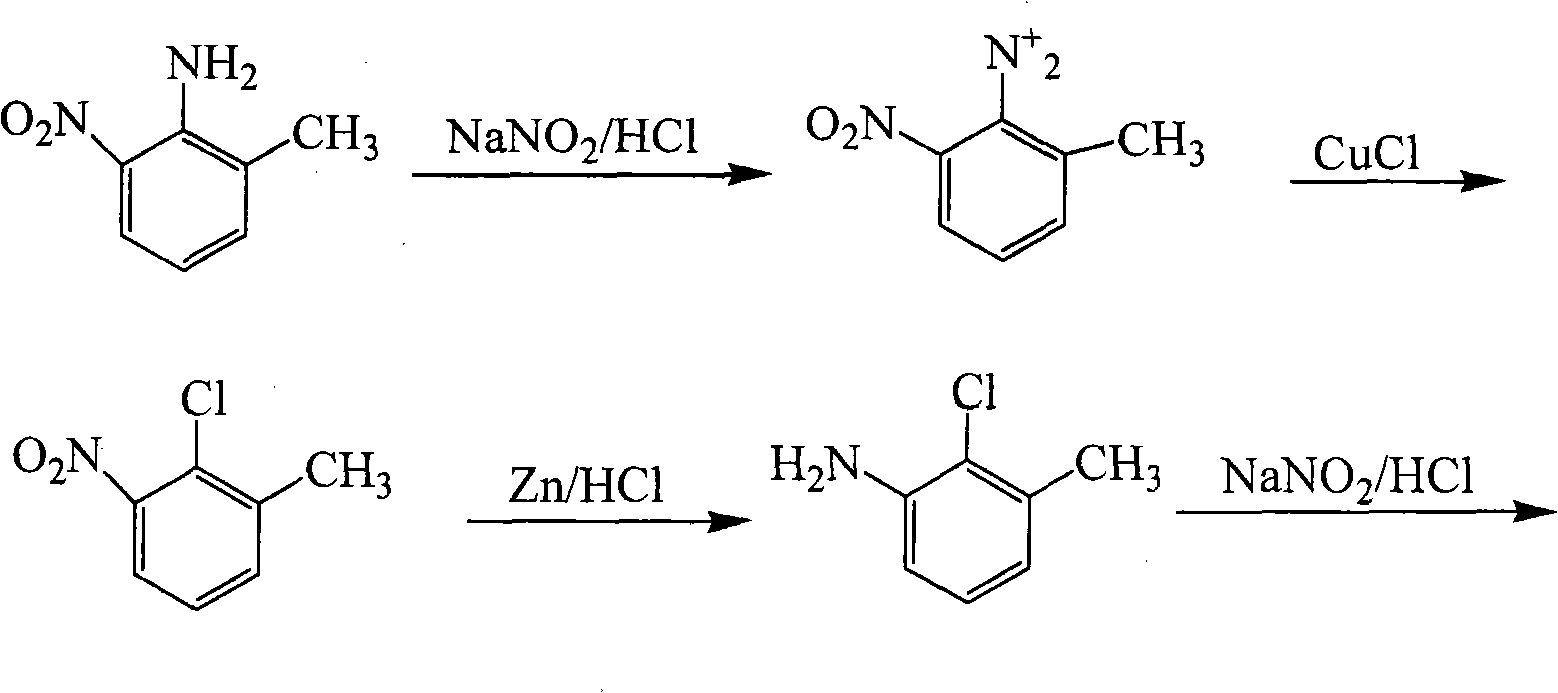

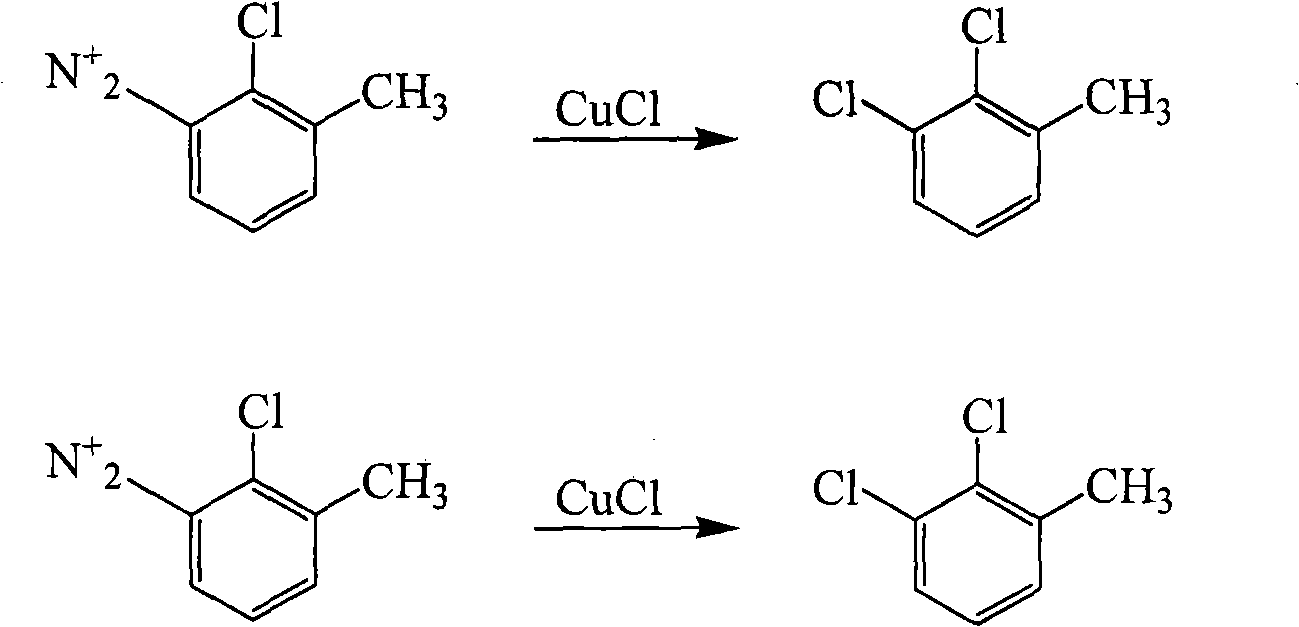

Method for preparing 2,3-dichlorotoluene

InactiveCN102079688ALow priceThe reaction operation is not cumbersomeChemical recyclingHalogenated hydrocarbon preparationSandmeyer reactionMethylaniline

The invention discloses a method for preparing 2,3-dichlorotoluene. The method comprises the following steps of: performing condensation on o-toluidine serving as an initiative raw material and urea to obtain N,N'-di(tolyl) urea; forming a sulfonic blocking group at an amino para-position through sulfonation; performing chlorination, removing carbonyl through hydrolysis and removing the blocking group through hydrolysis to obtain 2-chlorine-6-methylaniline; and performing diazotization and a Sandmeyer reaction to synthesize 2,3-dichlorotoluene to obtain the product. The method has the advantages of environmental friendliness, simple process, low cost and the like.

Owner:INNER MONGOLIA UNIV OF TECH

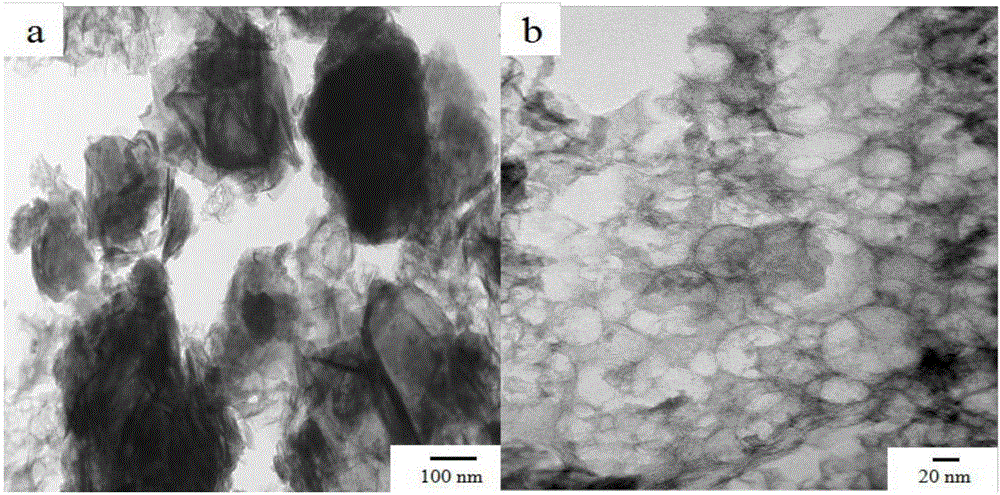

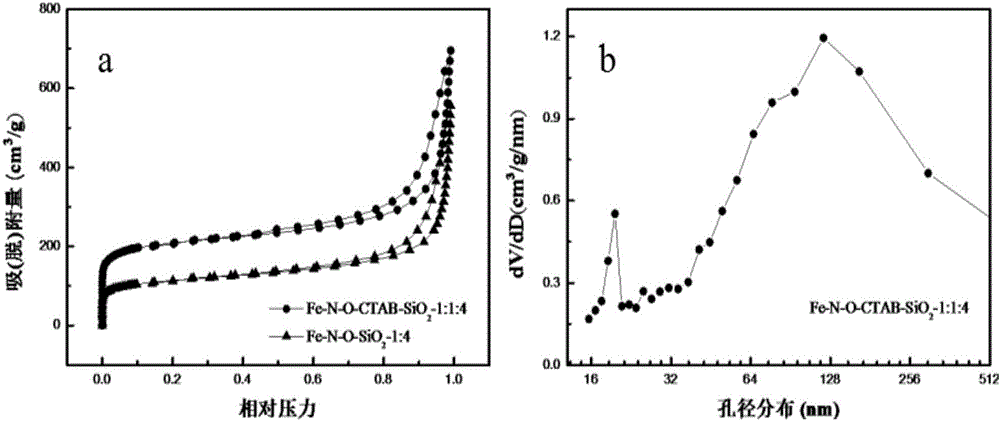

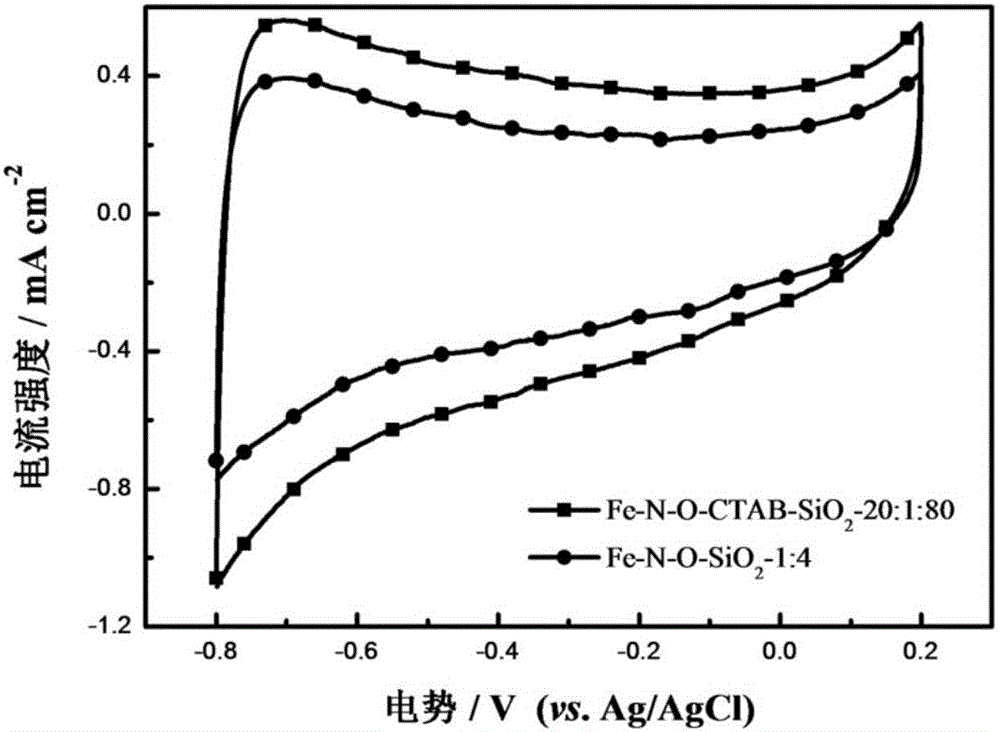

Three-dimensional porous Fe-N-C catalyst based on cetyl trimethyl ammonium bromide as carbon material pore-forming agent and preparation method

InactiveCN106602080AImprove catalytic performanceEasy to passCell electrodesDecompositionCalcination

The invention belongs to the field of fuel-cell catalysts, and relates to a three-dimensional porous Fe-N-C catalyst based on cetyl trimethyl ammonium bromide as a carbon material pore-forming agent and a preparation method. The three-dimensional porous Fe-N-C electrocatalyst is obtained through high-temperature calcination of o-toluidine as a C source and an N source, FeCl3.6H2O as a metal source, CTAB as a soft template and SiO2 as a hard template under an N2 atmosphere. In the preparation process, the size and the shape of a micelle can be accurately controlled through changing the concentration of the CTAB, a three-dimensional interconnected porous structure with a lot of active sites exposed on the surface can be finally formed after the templates are removed due to CTAB micelle decomposition after high-temperature calcination, the quantity of the active sites for catalytic oxygen reduction reaction is ensured, the mass transfer requirements can be met and improvement of the ORR activity of the catalyst is facilitated. Compared with a traditional Fe-N-C electrocatalyst, the three-dimensional porous Fe-N-C catalyst has the advantages that the three-dimensional porous structure of the catalyst is more beneficial to oxygen transfer and adsorption, the preparation process is flexible and controllable, the raw materials are cheap and available, massive production is facilitated and the three-dimensional porous Fe-N-C catalyst has relatively high practical value.

Owner:DALIAN UNIV OF TECH

Method for synthesizing 3,3'-dimethyl-4,4'-diamidodiphenylmethane

InactiveCN102249931ASimple processSimple methodOrganic compound preparationWater/sewage treatmentPotassium hydroxidePhosphoric acid

The invention provides a novel environmentally-friendly method for synthesizing 3,3'-dimethyl-4,4'-diamidodiphenylmethane (2MMDA1). The method comprises the following steps: by taking o-toluidine, hydrochloric acid and formaldehyde as raw materials, carrying out condensation reaction on the raw materials in the presence of no catalyst so as to obtain the hydrochloride of 2MMDA1; and then filtering, washing, drying and recrystallizing so as to obtain a target product, wherein sewage generated in the process is regulated by using diluted phosphoric acid so that the pH reaches about 7.0, the sewage is subjected to standing and precipitation, and supernate is taken for later use. The yield of 2MMDA1 is 75-85%, and the purity of 2MMDA1 is 95%. Relative to reported processes, the method provided by the invention has the advantages that: (1) the catalyst is not introduced in the reaction process, and sewage generated in the process and secondary pollution of solvent used for recrystallization can be avoided; and (2) ammonia water, potassium hydroxide and phosphoric acid are used as neutralization reagents, the finally generated sewage is rich in NH<4+>, k<+> and PO4<3-> ions which are necessary for plant growth; and the sewage after dilution can be directly used for irrigating a tree farm and a grass land, thereby achieving the harmless utilization of the sewage.

Owner:LANZHOU JIAOTONG UNIV

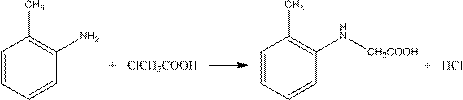

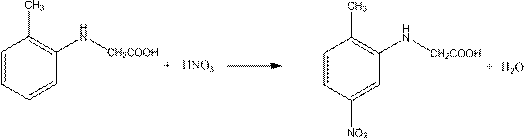

Production method of fast scarlet base G

InactiveCN109942434AReduce the amount of materialPrevent oxidationOrganic compound preparationAmino-carboxyl compound preparationAcetic acidDecomposition

The invention provides a production method of fast scarlet base G, belonging to the field of production of pigment intermediates. The production method is characterized by comprising the following steps: salifying, nitration, double decomposition and the like. By carrying out salifying through o-toluidine and acetic acid, the oxidization of amino can be prevented, and an ortho-para group of aminocan be changed into a meta-position orientating group; mixed acid is prepared from acetic acid, so that the concentration of nitric acid can be effectively decreased, and the control speed can be controlled; and by carrying out material separation through methyl tert-butyl ether, the complete material separation can be realized, and the quantity of materials dissolved in acetic acid is decreased.Therefore, the nitration production of the fast scarlet base G can be realized at a normal temperature, the reaction conditions are mild, and the production risk is relatively low.

Owner:山东世纪阳光科技有限公司

Epoxy flooring coating with high wear resistance, and preparation method thereof

InactiveCN104263188AHigh bonding strengthImprove adhesionEpoxy resin coatingsEpoxyRolling resistance

The invention discloses an epoxy flooring coating with high wear resistance, and a preparation method thereof. The epoxy flooring coating with high wear resistance is prepared from the following raw materials by weight: 400-500 parts of E-51 epoxy resin, 200-300 parts of 6101 epoxy resin, 25-35 parts of diethylenetriamine, 20-30 parts of 2-methylimidazole, 15-25 parts of N,N-di(glycidyl)-o-toluidine, 5-10 parts of N,N-diethyl-1,3-diaminopropane, 3-6 parts of aluminium acetylacetonate, 2-3 parts of tetraisopropyl di(dioctyl phosphite)titanate, 40-80 parts of nano compound powder, 1-2 parts of butyltin tris(2-ethylhexanoate), 50-100 parts of tungsten disulfide, 40-60 parts of dimethylbenzene, 140-180 parts of butyl acetate, 100-150 parts of alundum powder, 80-120 parts of carborundum, 3-5 parts of a dispersant HT-A203, 1.5-2.5 parts of a leveling agent BYK-388, 2-4 parts of a defoaming agent T-202 and 1-2 parts of a thixotropic agent BYK-410. The epoxy flooring coating with high wear resistance has high bonding strength to a matrix, good adhesive force, extremely low shrinking percentage in a hardening process, and smooth and clear appearance, and is seamless on the whole. The coating has excellent wear resistance, rolling resistance, permeability resistance, weather resistance and corrosion resistance, can guarantee that the coating does not fracture or fall off, and is durable in use.

Owner:SUZHOU ZHONGLI HEAT PRESERVATION & ENERGY SAVING MATERIAL CO LTD

Preparation method of pyrrole-o-toluidine copolymer with porous structure

InactiveCN105513826ASimple compositionLow costHybrid capacitor electrodesHybrid/EDL manufacturePyrroleVacuum drying

The invention discloses a preparation method of a pyrrole-o-toluidine copolymer with a porous structure. The preparation method of the pyrrole-o-toluidine copolymer with the porous structure comprises the following steps: 1, dissolving pyrrole and o-toluidine in an organic solvent to form an organic phase; 2, dissolving ammonium persulfate and low-carbon alcohol in water to form a water phase; 3, mixing the organic phase with the water phase, then standing and reacting; 4, filtering, then vacuum drying to obtain the pyrrole-o-toluidine copolymer. The method is simple and practicable, is mild in reaction conditions, simple in composition of a reaction system and free of additional templates, can be used for preparing the polymer of a loose and porous structure by only relying on the easily-removed low-carbon alcohol, and is pure in product, simple and convenient in post-treatment, low in cost and low in requirement on equipment performance; the obtained product presents the loose and porous structure, has high specific capacity, energy density, power density and high cycling stability, is especially suitable for being applied to supercapacitor electrode materials, and can also be applied to the field of sensing, catalysis and heavy metal ion adsorption materials.

Owner:XIAN UNIV OF SCI & TECH

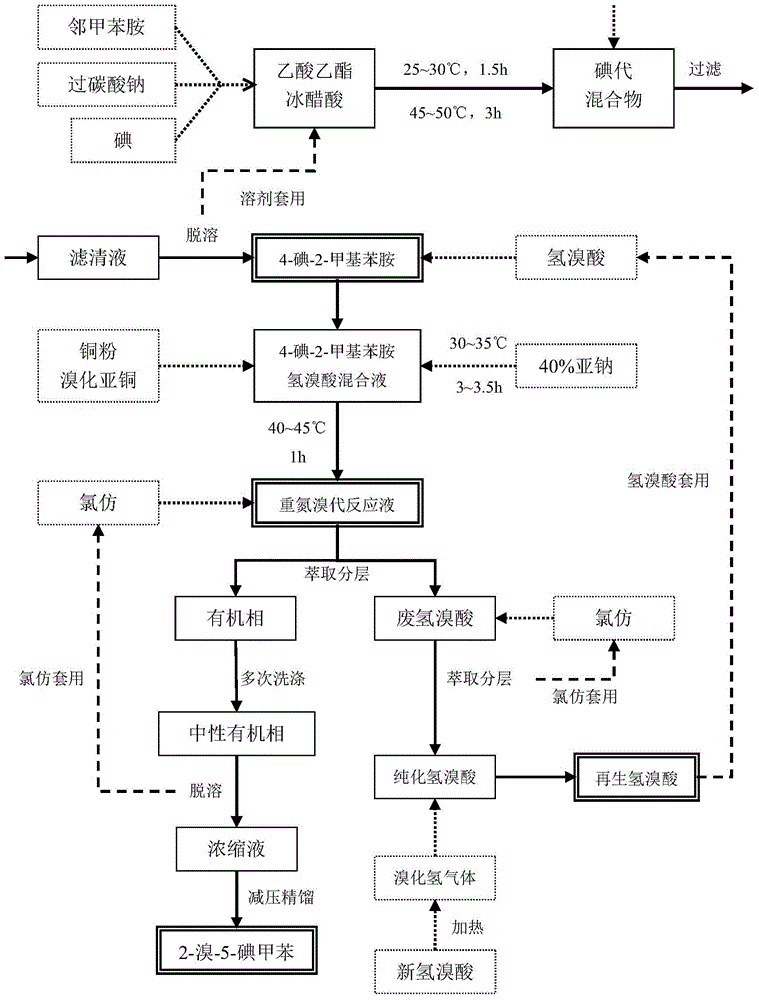

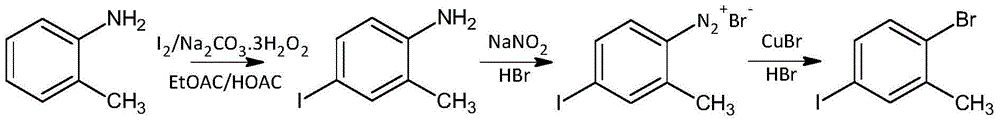

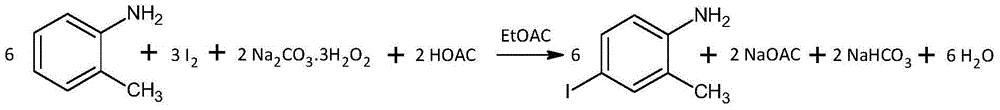

Synthetic method of 2-bromo-5-iodotoluene

InactiveCN105016963AReliable oxidationGuaranteed to be stable and safeOrganic compound preparationAmino compound preparationPtru catalystToluidine

The invention discloses a synthetic method of 2-bromo-5-iodotoluene. The product is prepared by using o-toluidine as a staring material through iodination, diazotization and bromination, wherein in the step of iodination, iodine powder is used as an iodination reagent, sodium percarbonate is used as an oxidizing agent and an ethyl acetate / glacial acetic acid mixed solution is used as a solvent; the steps of diazotization and bromination are completed by adopting a one-pot method, and sodium nitrite and hydrobromic acid are used as reaction reagents and copper powder / copper bromide is used as a bromination catalyst in the steps. The method for synthesizing 2-bromo-5-iodotoluene by utilizing the process route has the advantages that the raw materials in the step of iodination are safe and accessible; the process is simple and convenient to operate; the reaction conditions are mild; the raw material conversion rate is high; the total mole yield of iodine atoms can be 72% or above; the steps of diazotization and bromination are combined, are completed by the one-pot method and are simple and convenient to operate; few byproducts are generated; hydrobromic acid can be used indiscriminately multiple times after being treated, so that the cost is saved and the material is more environment-friendly.

Owner:江苏威格瑞斯化工有限公司

Metal antirust agent and production technique thereof

InactiveCN106086854AReduced release rateEfficient removalMetallic material coating processesPhosphateEtidronic acid

The invention relates to a metal antirust agent and a production technique thereof. The metal antirust agent comprises 13-17 parts of citric acid, 6-9 parts of acetic acid, 8-12 parts of etidronic acid, 5-11 parts of sodium phytate, 7-10 parts of hexamethylene tetramine, 5-8 parts of triethanolamine, 7-9 parts of sodium chloride, 13-17 parts of polyethylene glycol, 9-15 parts of silicon dioxide, 3-7 parts of manganous dihydrogen phosphate, 2-4 parts of ammonium molybdate, 9-13 parts of epoxidized soybean oil, 1-3 parts of a corrosion inhibitor, 7-11 parts of o-toluidine, 6-9 parts of sodium sulfonate, 2-5 parts of sodium carboxylate, 3-6 parts of polydimethylsiloxane, 3-5 parts of a defoaming agent, 2-4 parts of a dispersing agent and 3-6 parts of bactericide. The metal antirust agent contains special additives and can permeate rust, corrosives, oil stains, mud and the like so that a connecting piece can be released slowly and removed easily, and dirt such as incrustation and dust adhering to the surface of metal can be effectively removed; and besides, an antirust oil film is reserved on the surface of metal or other materials, so that moisture and water are effectively isolated and the service life of the connecting piece is effectively prolonged.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

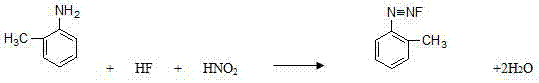

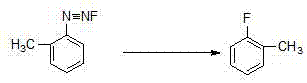

Preparation method of o-fluorotobuene

InactiveCN107445792ALess side effectsHigh yieldHalogenated hydrocarbon preparationNitrous acidSide reactionSodium nitrite

The invention discloses a preparation method of o-fluorotobuene. The method comprises the following steps: (1) acid formation reaction: adding an anhydrous hydrogen fluoride raw material into a reaction kettle and stirring; adding sodium nitrite into the reaction kettle, introducing frozen salt water to cool and carrying out reaction to obtain a nitrous acid; (2) diazotization reaction: adding o-toluidine into the reaction kettle containing the nitrous acid, stirring and carrying out the diazotization reaction; (3) thermal decomposition reaction: transferring diazonium liquid obtained in the step (2) into a tubular reactor; heating and carrying out the thermal decomposition reaction to obtain an o-fluorotobuene crude product; (4) post-treatment: carrying out washing and steam distillation on the o-fluorotobuene crude product obtained in the step (3), regulating a pH value, pressing into a rectifying tower for distillation to obtain the qualified o-fluorotobuene. The preparation method disclosed by the invention has the beneficial effects that energy consumption is low, continuous production is realized, the problems of long production period of fluorination reaction and low yield of products are solved, the occurrence of side reaction is reduced, and a good foundation is laid for preparing high-purity o-fluorotobuene.

Owner:山东福尔有限公司

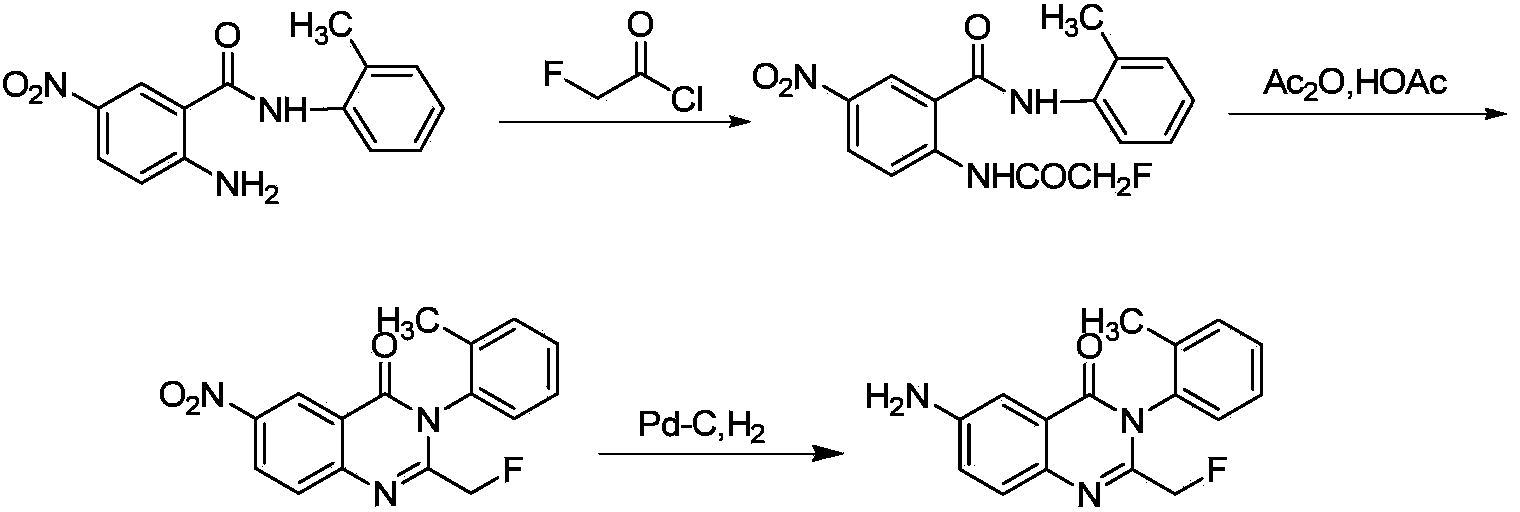

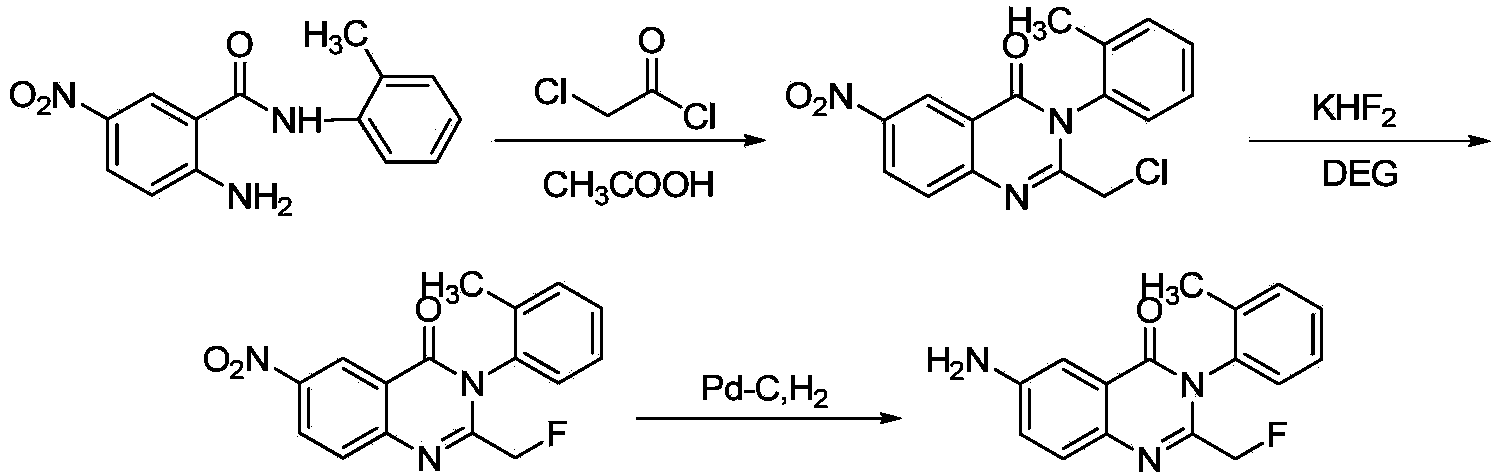

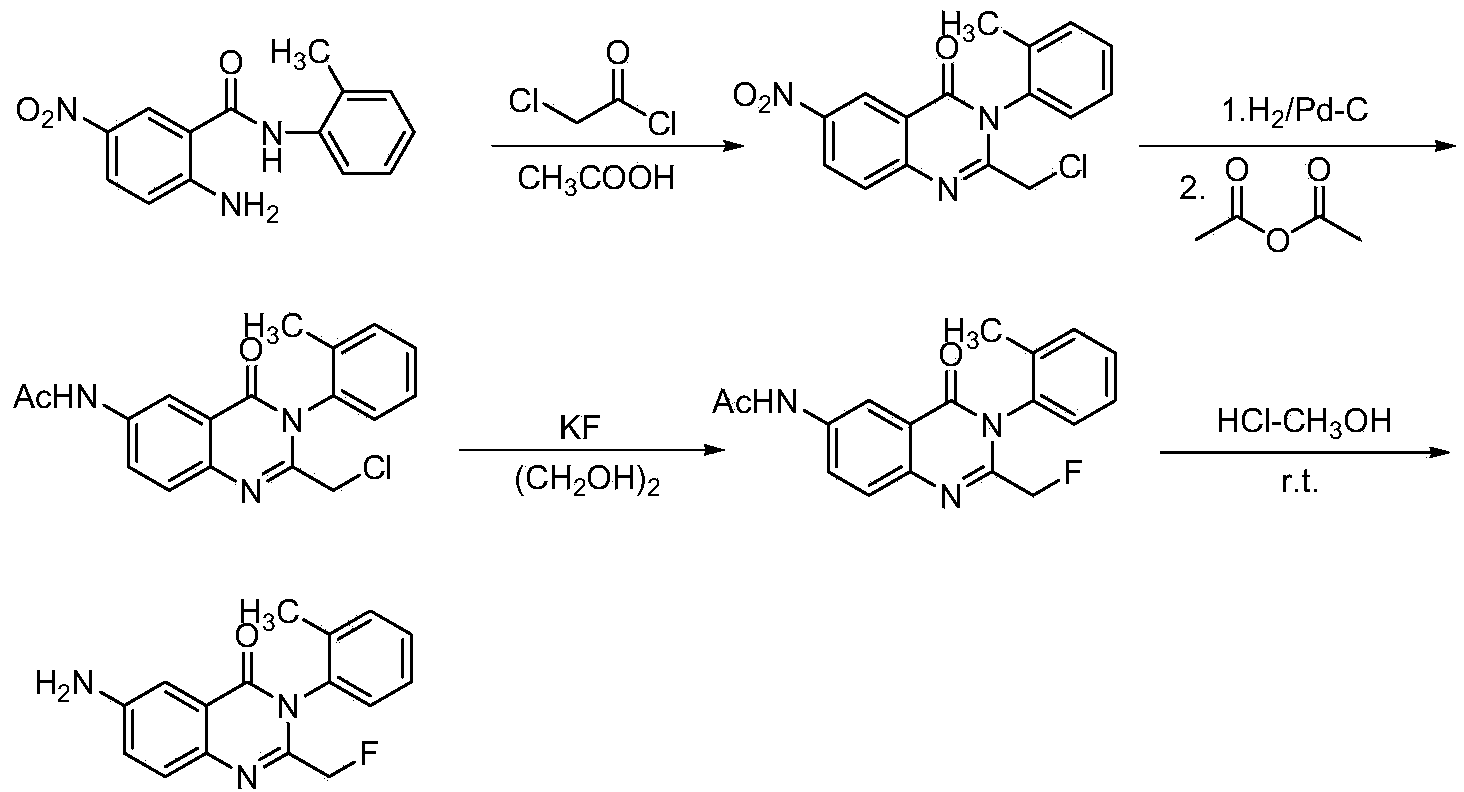

Afloqualone preparation method

The present invention discloses a afloqualone preparation method, which comprises: adopting an isatin anhydride as a starting raw material, carrying out nitration, reduction and acetylation to synthesize a key intermediate N-(2-amino-5-acetylaminobenzoyl)o-toluidine, and then carrying out aminolysis, cyclization, fluorine exchange and deprotection to obtain the target product afloqualone. The afloqualone preparation method has characteristics of cheap and easily-available raw materials, production cost reduction, elimination of use of highly-toxic and highly-harmful reagent fluoroacetyl chloride in the existing literature method, safety and environmental protection. In addition, tetrabutyl ammonium bromide is adopted as the phase transfer catalyst of the fluorine exchange reaction so as to substantially improve the conversion rate of the fluorine exchange reaction, and the total yield of the target product afloqualone prepared from the starting raw material isatin anhydride can be more than 60.0%.

Owner:ZHEJIANG UNIV OF TECH +1

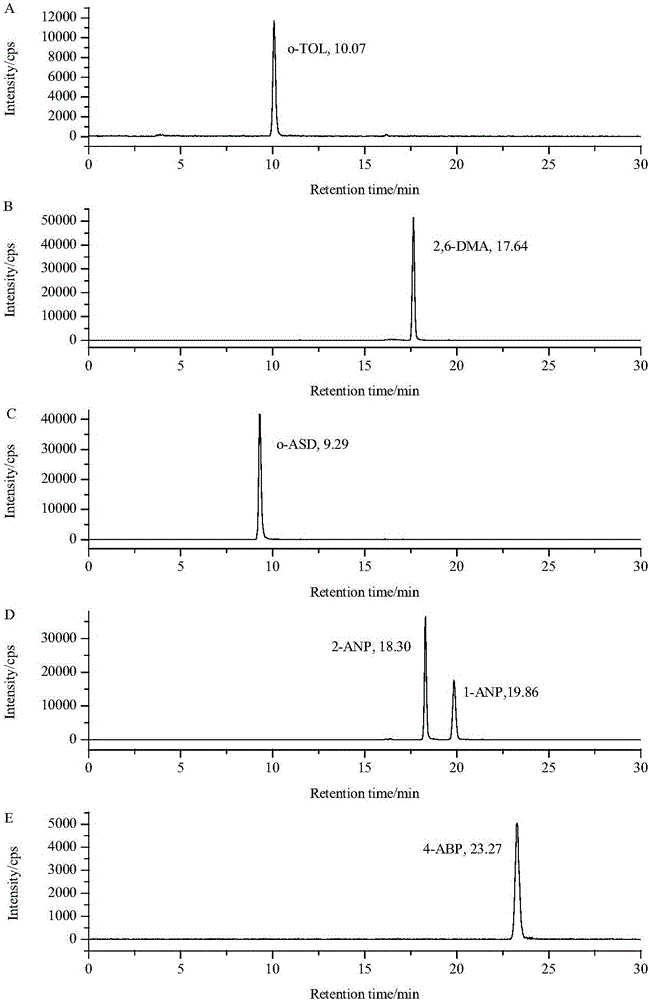

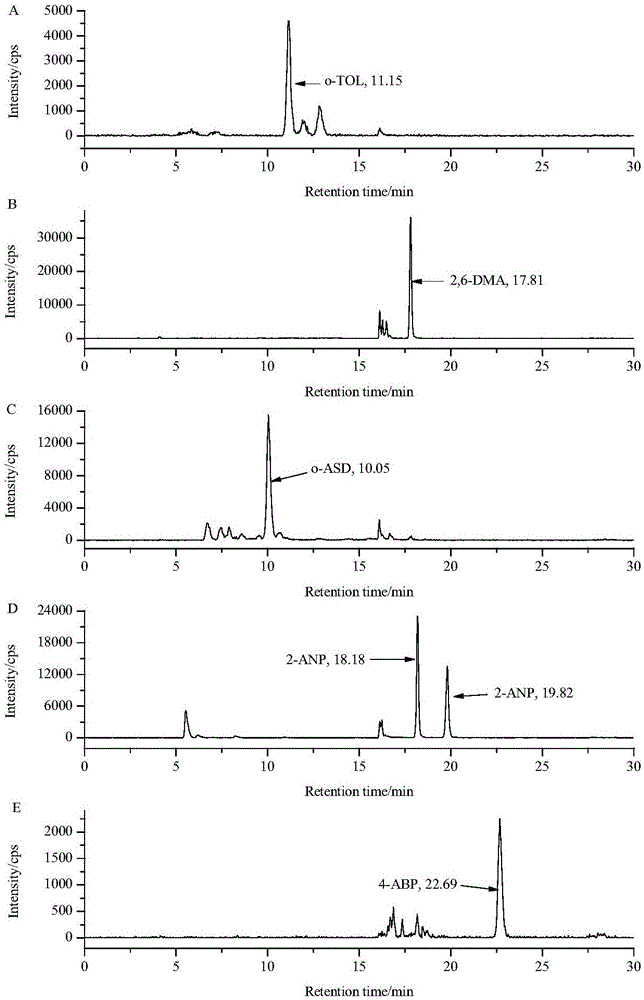

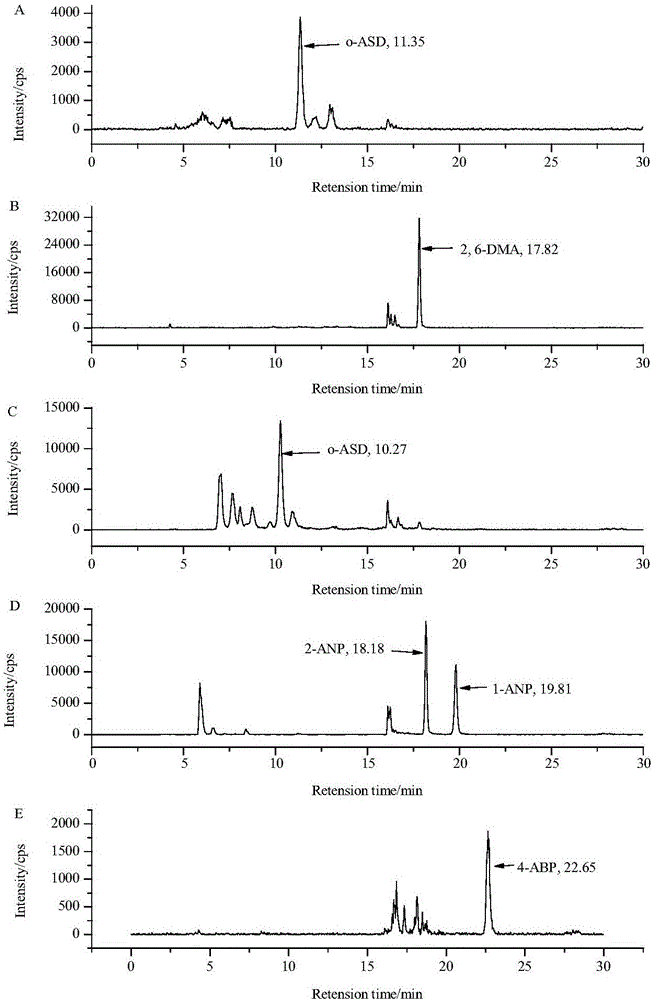

Method for determining six aromatic amine compounds in cigarette mainstream smoke by using online SPE/LC-MS/MS

ActiveCN106290687AEasy to handleAutomate the processComponent separationOnline speDimethylaniline N-oxide

The invention discloses a method for determining six aromatic amine compounds in cigarette mainstream smoke by using online SPE / LC-MS / MS. It uses the Cambridge filter and an absorption bottle containing 2% formic acid solution to capture the aromatic amine compounds in the main cigarette smoke particle and gas phase matters, respectively, ultrasonically extracting the filter by 2% formic acid solution, adding interior labels into the two solutions and determining the six aromatic amine compounds by online SPE / LC-MS / MS, including o-toluidine, 2,6-dimethylaniline, o-anisidine, 1-aminonaphthalene, 2-aminonaphthalene and 4-aminobiphenyl. The method has the advantages of simplifying the sample pretreatment process and extracting with the formic acid solution to reduce the pollution. The two-dimensional in-line solid-phase extraction composed of the cationic column and the reversed-phase C18 column is used to purify the sample to be tested and the purification effect is good; each target is quantitatively analyzed using their specific internal standard, effectively reducing the matrix effect.

Owner:中国烟草总公司山东省公司

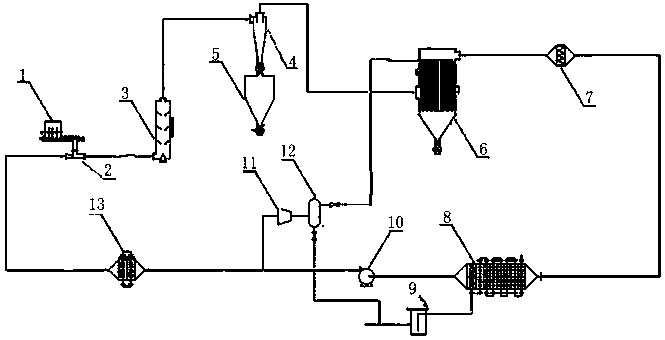

Closed-cycle drying process for 3,3'-dimethyl-4,4'-diaminodiphenylmethane

ActiveCN107940901AImprove drying efficiencyNo need for mechanical stirringDrying solid materials with heatDrying gas arrangementsEnvironmental effectCyclonic separation

The invention discloses a closed-cycle drying process for 3,3'-dimethyl-4,4'-diaminodiphenylmethane. The closed-cycle drying process is adopted, so that a solvent in wet materials is evaporated underaction of hot air; o-toluidine and MDT products are taken out by tail gas; dust content in the tail gas is enabled to meet requirements of a gas cycle and a compressor through cyclone separation, cloth-bag dust removal and medium-effect filter dust removal; the tail gas enters a condenser, the o-toluidine and water are condensed and recycled, so that content of o-toluidine in circulating air is reduced, and therefore, concentration of the o-toluidine in the tail gas is always kept to be lower than the lower explosive limit; the tail gas is pressurized by a circulating fan to re-enter a dryingprocess system to circulate, so that the drying effect is improved; MDT particles of waste gas in a drying process are removed by a cloth-bag dust remover and a medium-effect filter, so that dust content in the gas meets requirements of the gas cycle and the compressor, and therefore, a gas closed cycle is realized; and residual o-toluidine in the waste gas is condensed and recycled, so that emission of poisonous gas is avoided, and therefore, the closed-cycle drying process has very good economical and environmental effects.

Owner:ZHEJIANG UNIV OF TECH +1

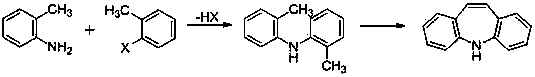

Method for synthesizing iminostilbene

InactiveCN103483257ASimple reaction conditionsFew reaction stepsOrganic chemistryToluidineOrganosolv

The invention discloses a method for synthesizing iminostilbene. The method is characterized in that o-toluidine and o-halotoluene are heated for reacting with each other in an organic solvent in the presence of a catalytic amount of a copper compound and L-proline as well as alkali to prepare a target product, namely iminostilbene. According to the method for synthesizing iminostilbene, disclosed by the invention, o-toluidine reacts with o-halotoluene through a 'one-pot method' to directly obtain iminostilbene, reaction steps are greatly shortened, the reaction can be carried out at a relatively low temperature, and the yield can reach more than 40%, so that the simple method for synthesizing iminostilbene is short in step, relatively high in yield and low in cost.

Owner:JIANGSU TOHOPE PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com