Flotation collecting agent for copper sulfide ore

A technology of copper sulfide ore and collector, applied in flotation, solid separation and other directions, can solve the problems of difficult grade and recovery rate, waste of mineral resources, different floating speed, etc., to improve concentrate grade and recovery rate, mineral The effect of high floating speed and stable flotation foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

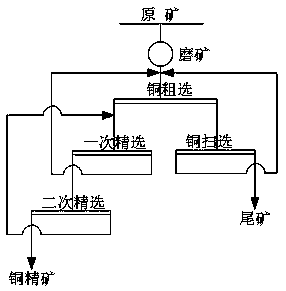

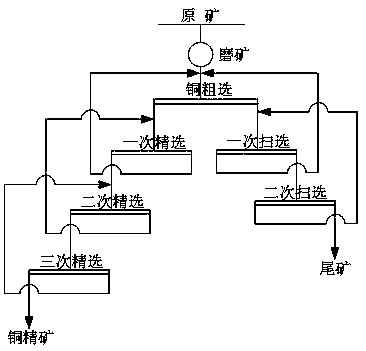

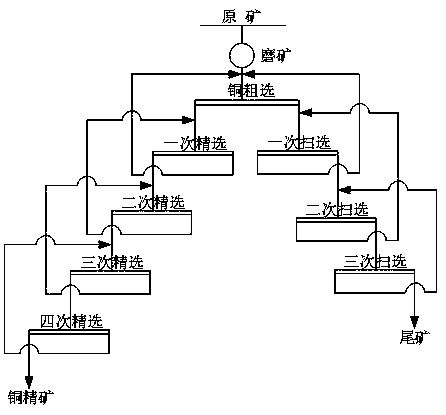

Image

Examples

Embodiment 1

[0017] A kind of flotation collector of present embodiment copper sulfide ore, comprises the raw material of following weight portion: 8 kilograms of dialkyl phosphates, 1 kilogram of octylphenol polyoxyethylene ethers, 2 kilograms of polyoxyethylene stearates, 1 kg of triethylenetetramine, 3 kg of o-hydroxybenzoic acid, 4 kg of activator; wherein the activator prepares the following raw materials in parts by weight: 13 kg of linoleic acid, 2 kg of sodium dodecylbenzenesulfonate, silane coupling agent KH-560 2 kg, polyoxyethylene oleate 2 kg, cyclomethicone 5 kg, fumaric acid 3 kg, ethylenediaminetetraacetic acid EDTA 6 kg, linoleic acid, dodecylbenzene Mix sodium sulfonate, silane coupling agent KH-560, and polyoxyethylene oleate, heat to 70°C, then add cyclomethicone, stir for 25 minutes, then add fumaric acid, ethylenediamine EDTA tetraacetate, continue to stir for 50 minutes, and keep heating at 70°C throughout the whole process to obtain an activator, and take 4 kg for su...

Embodiment 2

[0024] A kind of flotation collector of present embodiment copper sulfide ore, comprises the raw material of following weight portion: 9 kilograms of dialkyl phosphates, 1.5 kilograms of octylphenol polyoxyethylene ethers, 2.5 kilograms of polyoxyethylene stearates, 1.5 kg of triethylenetetramine, 4.5 kg of o-hydroxybenzoic acid, 4.5 kg of activator; wherein the activator prepares the following raw materials in parts by weight: 15 kg of linoleic acid, 3 kg of sodium dodecylbenzenesulfonate, silane coupling agent KH-560 2.5 kg, polyoxyethylene oleate 2.5 kg, cyclomethicone 5.5 kg, fumaric acid 3.5 kg, EDTA 7 kg; linoleic acid, dodecylbenzene Mix sodium sulfonate, silane coupling agent KH-560, and polyoxyethylene oleate, heat to 73°C, then add cyclomethicone, stir for 27 minutes, then add fumaric acid, ethylenediamine EDTA tetraacetate, continue to stir for 60 minutes, and keep heating at 73°C throughout the whole process to obtain an activator, and take 4.5 kg for subsequent us...

Embodiment 3

[0031] A kind of flotation collector of present embodiment copper sulfide ore, comprises the raw material of following weight portion: 10 kilograms of dialkyl phosphates, 2 kilograms of octylphenol polyoxyethylene ethers, 3 kilograms of polyoxyethylene stearates, 2 kilograms of triethylenetetramine, 5 kilograms of o-hydroxybenzoic acid, 5 kilograms of activator; wherein activator prepares the raw material of following weight portion: 16 kilograms of linoleic acid, 4 kilograms of sodium dodecylbenzenesulfonate, silane coupling agent KH-560 3 kg, polyoxyethylene oleate 3 kg, cyclomethicone 6 kg, fumaric acid 4 kg, EDTA 8 kg; linoleic acid, dodecylbenzene Mix sodium sulfonate, silane coupling agent KH-560, and polyoxyethylene oleate, heat to 75°C, then add cyclomethicone, stir for 30 minutes, then add fumaric acid, ethylenediamine EDTA tetraacetate, continue to stir for 65 minutes, and keep heating at 75°C throughout the whole process to obtain the activator, take 5 kg for later ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com