Preparation method of anti-bisphenol A monoclonal antibody

A technology of monoclonal antibody and bisphenol, applied in the field of detection, can solve the problems of poor specificity of polyclonal antibody and difficult to meet the monitoring and analysis of bisphenol A, and achieve the effect of sensitive on-site monitoring and effective monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

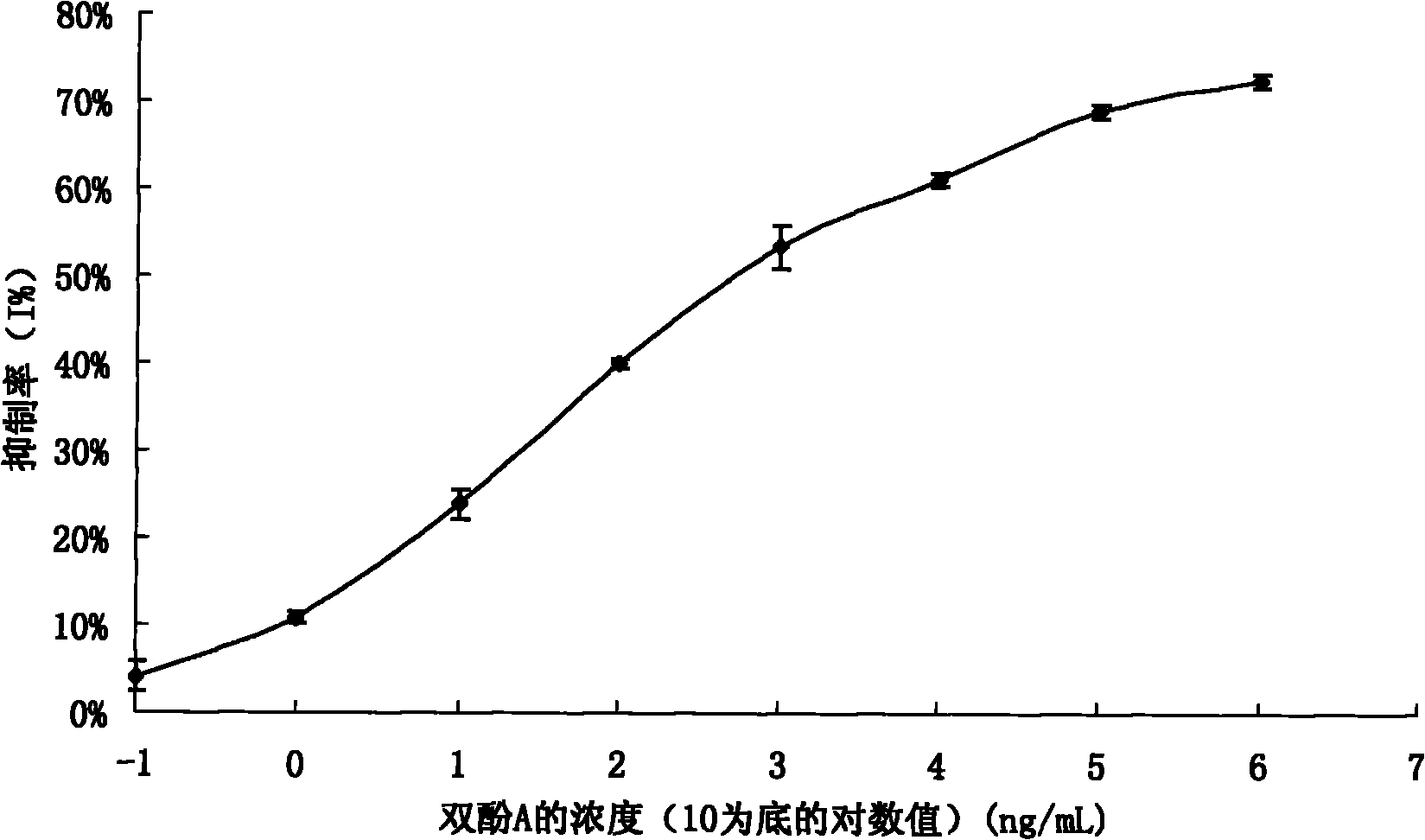

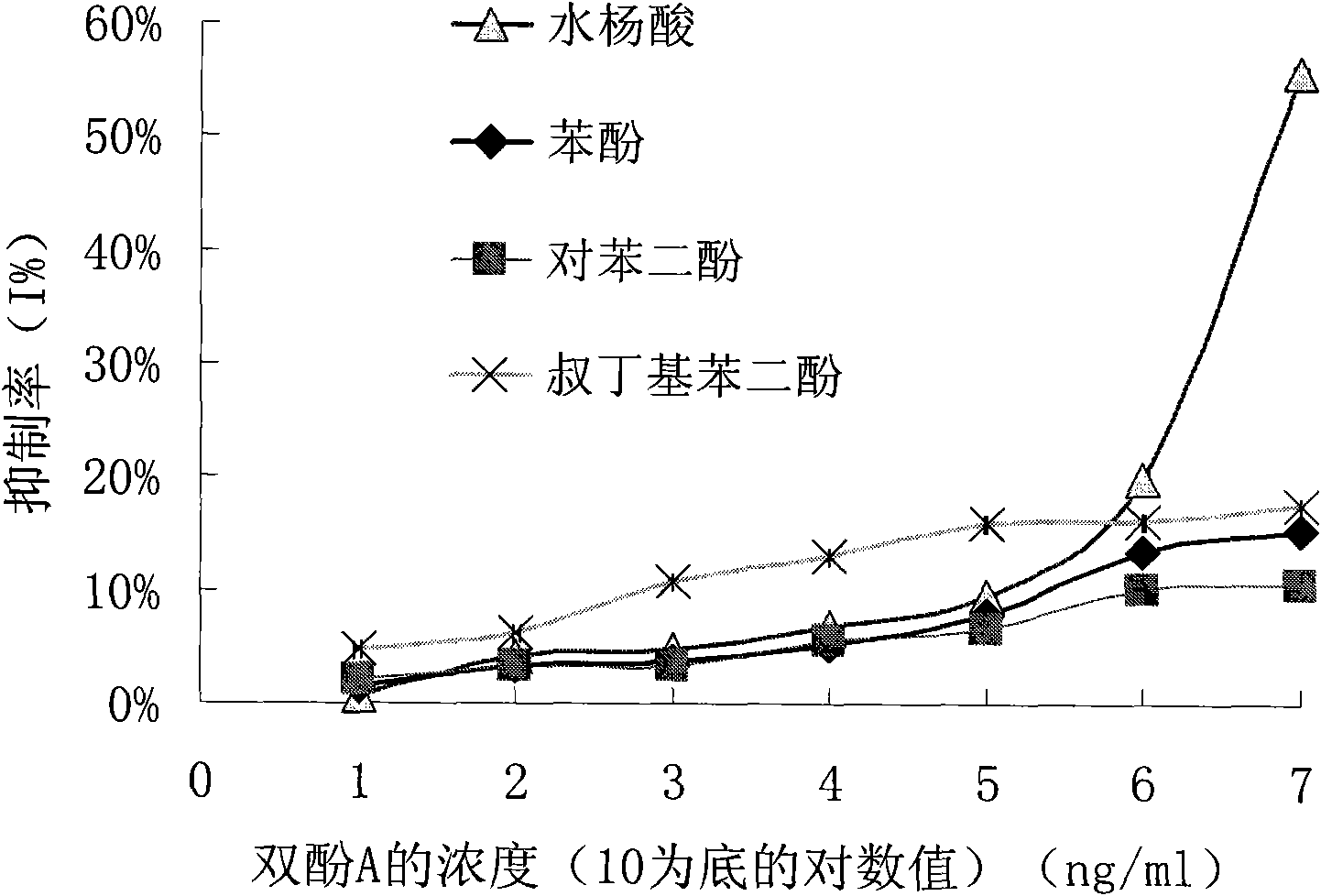

Examples

Embodiment Construction

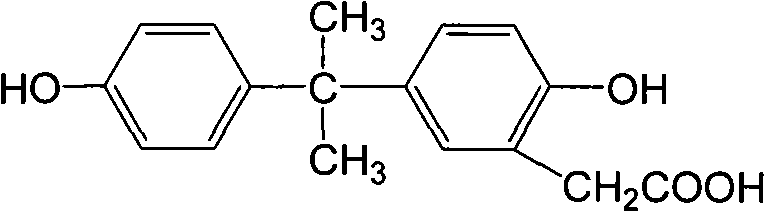

[0028] 1) Synthesis and identification of bisphenol A artificial immune antigen and coated antigen:

[0029] First, the structure of bisphenol A was modified, carboxyl groups were introduced, and the structurally modified bisphenol A was mixed with bovine serum albumin (BSA) and chicken eggs by carbodiimide and N-hydroxysuccinimide mixing method, respectively. Preparation of bisphenol A artificial immune antigen and coating antigen by coupling albumin (OVA). The artificial antigen was identified by ultraviolet spectrum and infrared spectrum, and the results showed that the synthetic artificial antigen had the characteristic absorption peaks of protein and bisphenol A in the ultraviolet spectrum, and the infrared spectrum of the artificial antigen showed the infrared characteristic absorption of bisphenol A and protein peak, the identification results indicated that the bisphenol A artificial antigen was synthesized successfully.

[0030] II) Preparation and screening of bisphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reaction rate constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com