Process for manufacturing corrosion resistant metal products

A metal and product technology, applied in the field of manufacturing technology of anti-corrosion metal products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

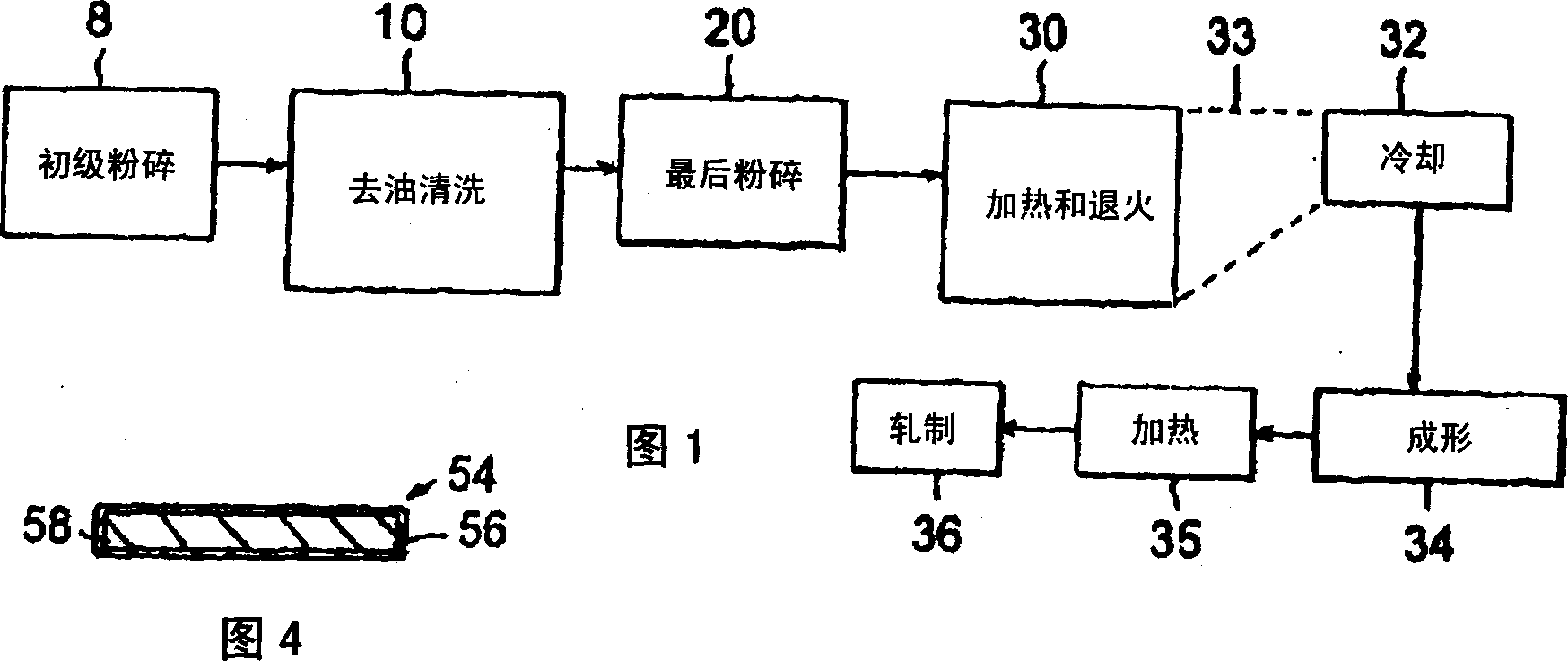

[0065] to prepare figure 2 The blanks shown are first collected and used with the above scrap consisting of mild steel or other suitable type of engineering steel. The debris is first crushed by the first crushing device 8, which may be a hammer mill or other commonly used crushing devices. In the crushing device 8, the debris is crushed for the first time, its size becomes smaller, the burrs are reduced, and it is convenient for further processing. But in this process, their size cannot be reduced much, because they have a lot of oil, which is easy to stick to the pulverizer.

[0066] The conveying mechanism conveys them from the pulverizer 8 to a commonly used degreasing device 10, so as to remove the oil stains, moisture and other impurities carried by them. To remove impurities, it is desirable to include in the apparatus 10 a rotary dryer through which the chips are passed to remove oil, water and impurities.

[0067] After passing through the device 10, the chips are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com