Method for producing flaxseed oil under nitrogen protection

A nitrogen protection, flaxseed technology, used in edible oil/fat, food science, application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

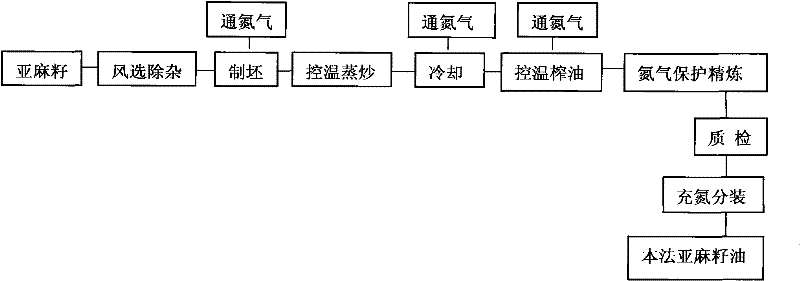

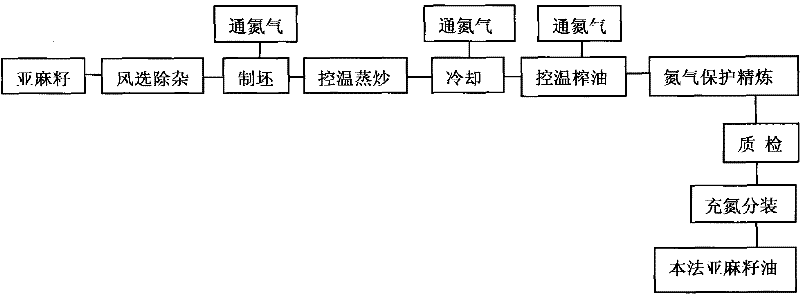

Image

Examples

Embodiment Construction

[0007] (1) Raw material screening and billet making

[0008] The impurity in the raw material is removed by means of air separation with a specific gravity machine, and flax (flax) seeds are crushed and poured into a material cylinder by a rolling mill method, and nitrogen gas is introduced into the material cylinder at the same time.

[0009] (2) Oil steaming and frying, nitrogen protection cooling

[0010] Put the raw material obtained in the step (1) into the steaming wok for steaming and frying, and control the steaming temperature at 100°C to 120°C by controlling the amount of steam in the steaming wok, steam for 30 minutes and then pour into the Cool the container under nitrogen.

[0011] (3) Nitrogen is introduced, and flax (flax) seed crude oil is initially pressed

[0012] Send the raw materials obtained in step (2) into the oil press for oil extraction. Nitrogen gas is introduced into the feeding port along the feeding direction, and the amount of nitrogen gas fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com