Reducing coupling injection mold core-pulling mechanism

A technology for injection molds and core-pulling mechanisms, applied in the field of injection molds for pipe joints with different diameters, can solve problems such as high energy consumption, increased size and volume of molds and injection molding machines, and increased manufacturing costs of molds and injection molding machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

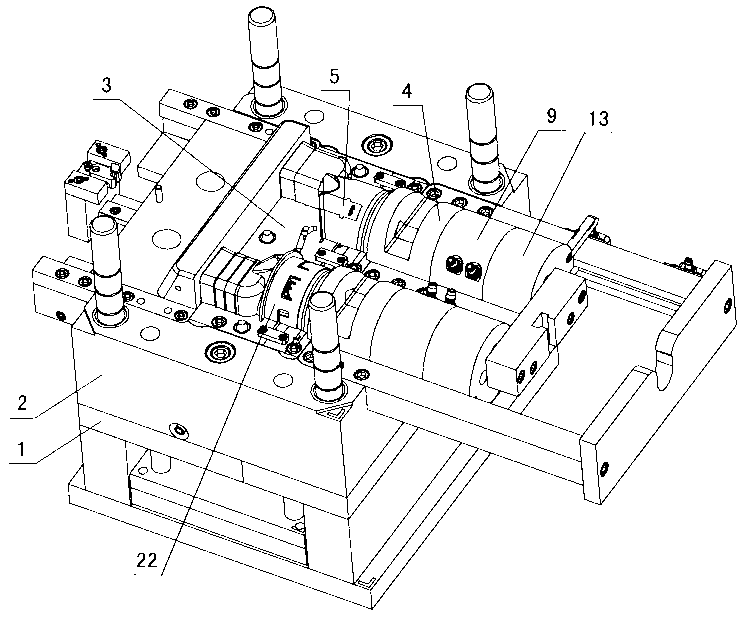

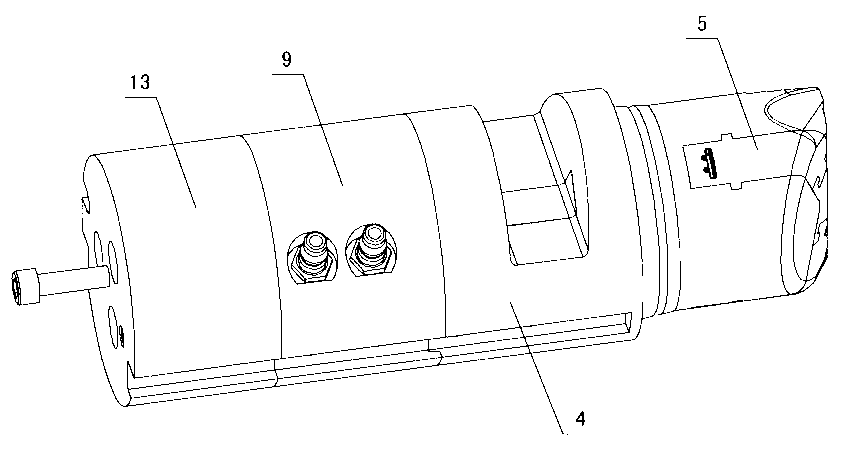

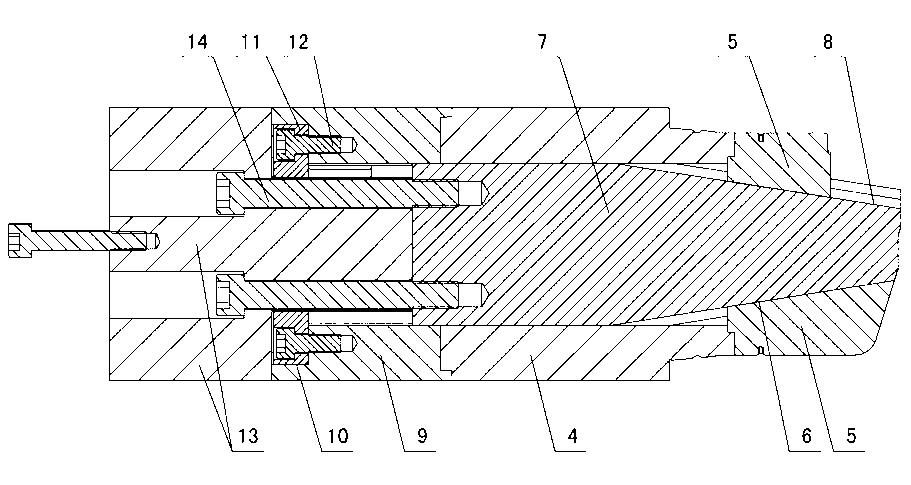

[0013] The invention relates to a core-pulling mechanism for injection molds of pipe joints with different diameters, such as figure 1 — Figure 7 As shown, it includes a movable mold backing plate 1 and a movable template 2, and a movable mold insert 3 is installed on the movable template. 2 and the movable mold insert 3 are equipped with a floating core-pulling mechanism, the secondary internal core-pulling mechanism includes a main core 4, the front end of the main core is connected to the inner core-pulling small slider 5, and the inside of the inner core-pulling small slider is shaped on Inner inclined sliding surface 6, sliding rod 7 is set in the main core, and the outer inclined sliding surface 8 is formed on the sliding rod, the outer inclined sliding surface 8 matches the inner inclined sliding surface 6, and the connecting seat 9 is installed at the rear end of the main core , the rear end of the connecting seat is shaped with a mounting groove 10, a fixing plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com