Demolition mechanism for automobile auxiliary instrument shell

A technology of demolding mechanism and sub-instrument, which is applied to household appliances, other household appliances, household components, etc., can solve the problems that the demolding mechanism cannot achieve demoulding, the inverted buckle angle is large, and the products are easily strained, and the design strength is achieved. Excellent, high pass rate, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

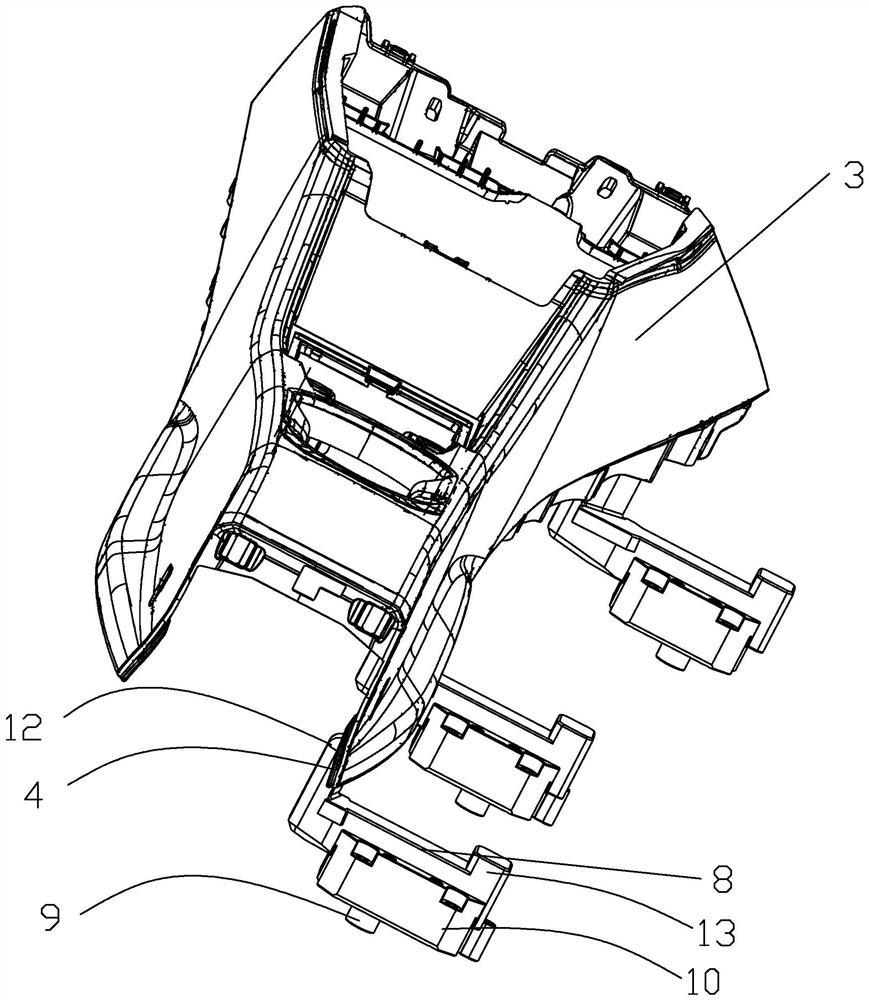

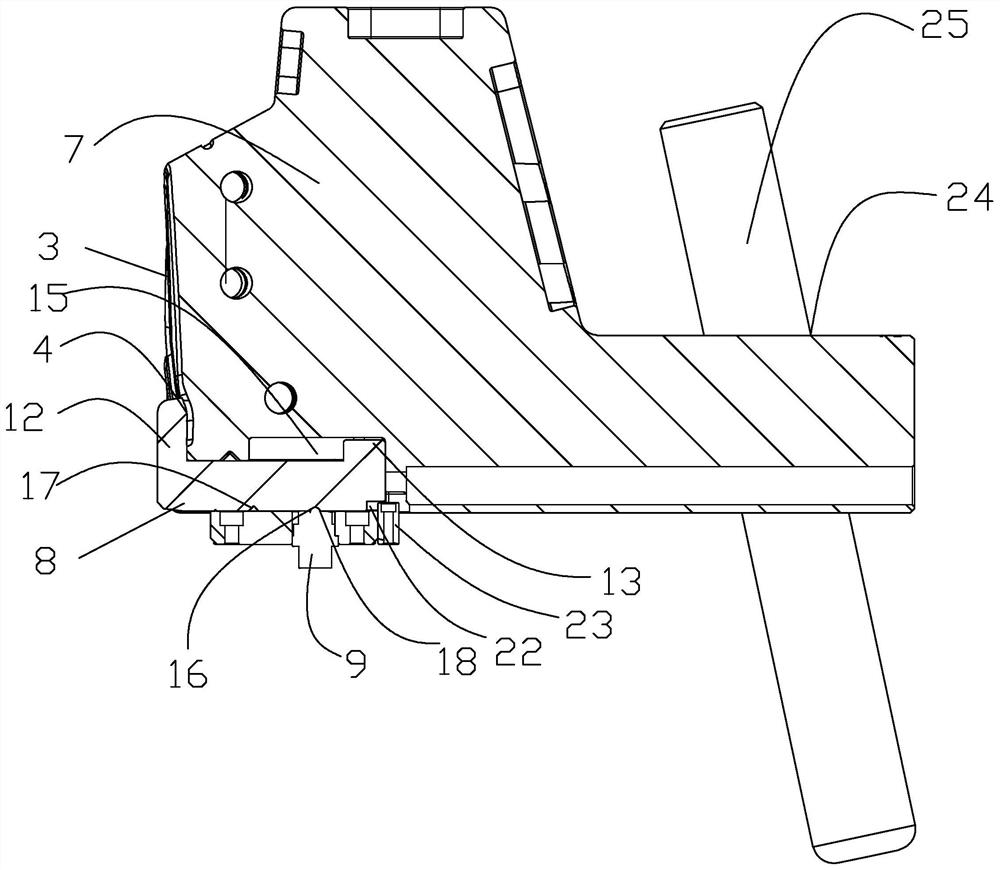

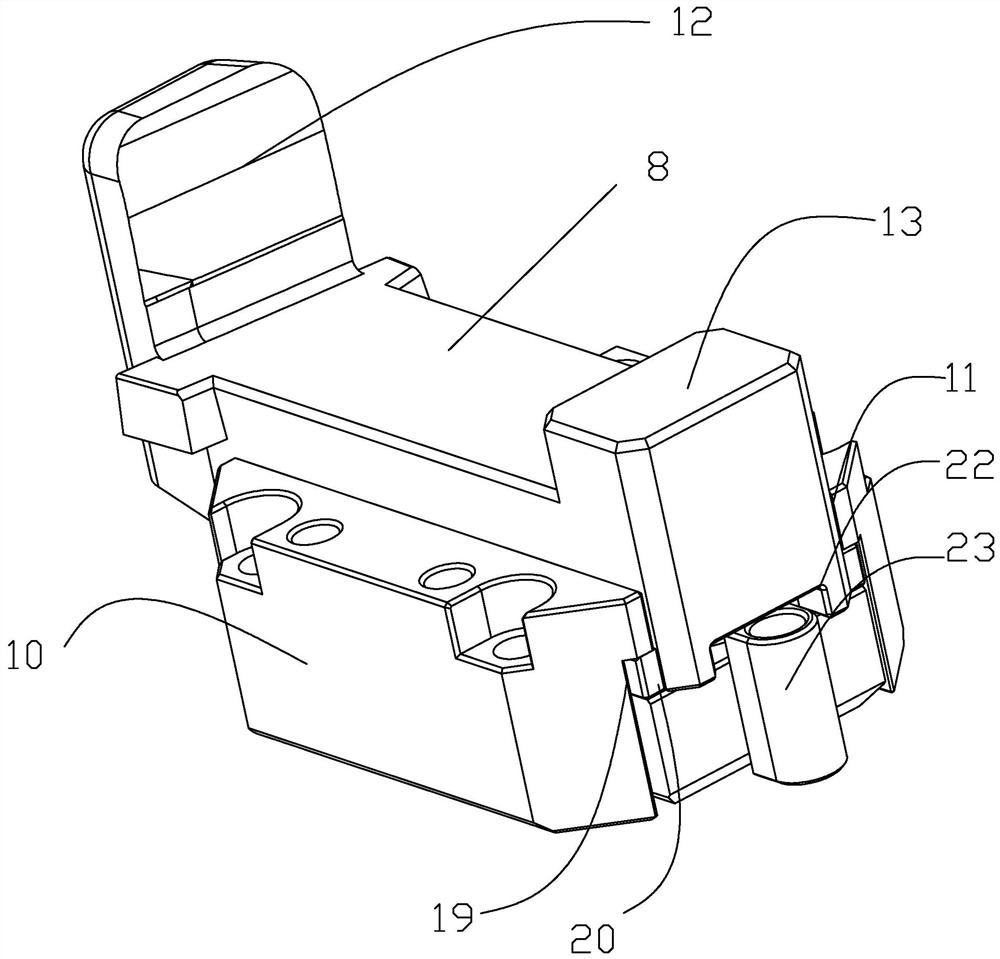

[0023] As shown in the figure, the present invention provides a demoulding mechanism for an automobile accessory instrument housing, which includes an upper mold 1, a lower mold 2 and a product 3, the inner side of the lower end of the product 3 is provided with an undercut 4, and the lower mold 2. The upper surface is provided with a lower mold core 5 for molding the inner surface of the product 3. The lower surface of the upper mold 1 is provided with an upper mold core for molding the upper surface of the product 3. The lower mold 2 is also provided with a mold core for molding the product. 3. The slider 7 on the outer side. There is a cavity for the molded product 3 between the lower mold core 5, the upper mold core and the slider 7 when the upper mold 1 and the lower mold 2 are closed. The lower mold core The side of the 5 has a part for f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com