Pedestal pan mold, and mold splitting technology and pedestal pan thereof

A toilet and mold technology, applied in the field of bathroom products, can solve problems such as inconvenient mold clamping, mold opening, high precision requirements, and inconvenient bonding operations, so as to improve molding work efficiency and product quality, and improve product regularity The effect of high degree and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

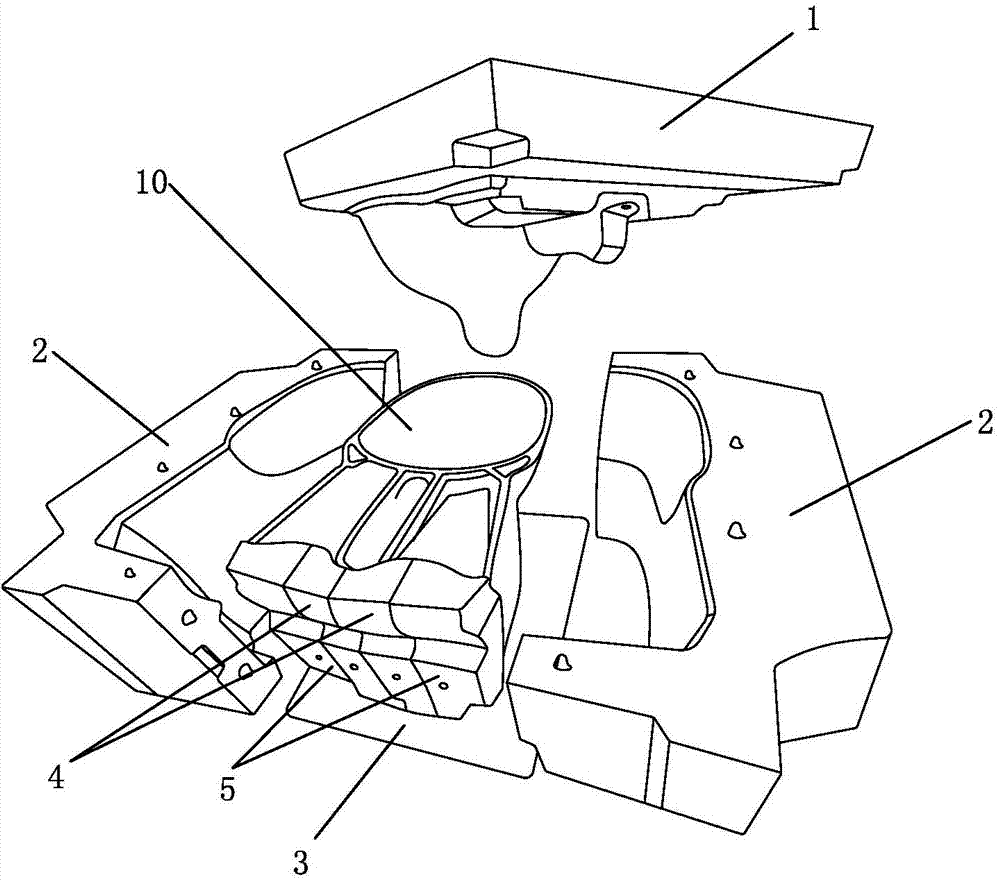

[0035] A toilet mold parting process of the present invention comprises the following steps:

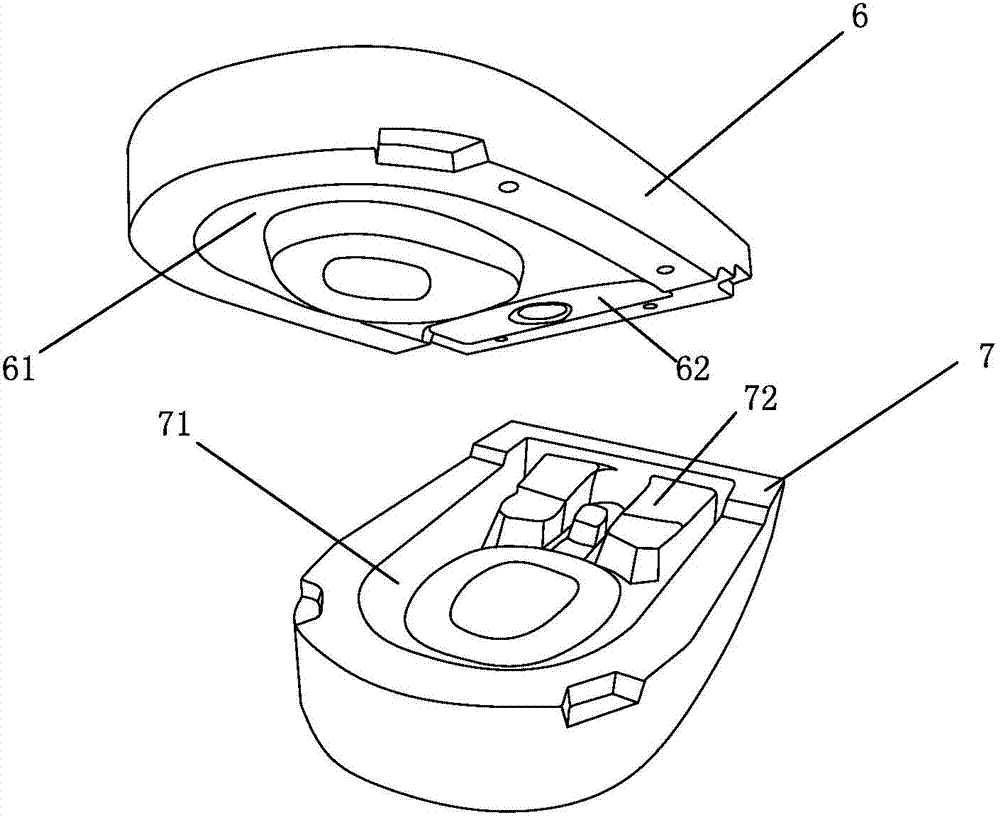

[0036] Separate the toilet into the toilet body and the seat with at least a toilet pan, sewage pipe, and jet water channel, and independently develop the main mold and the seat mold; divide the seat mold into the upper mold and the lower mold for the seat Production of seat rims with complete water guide rings.

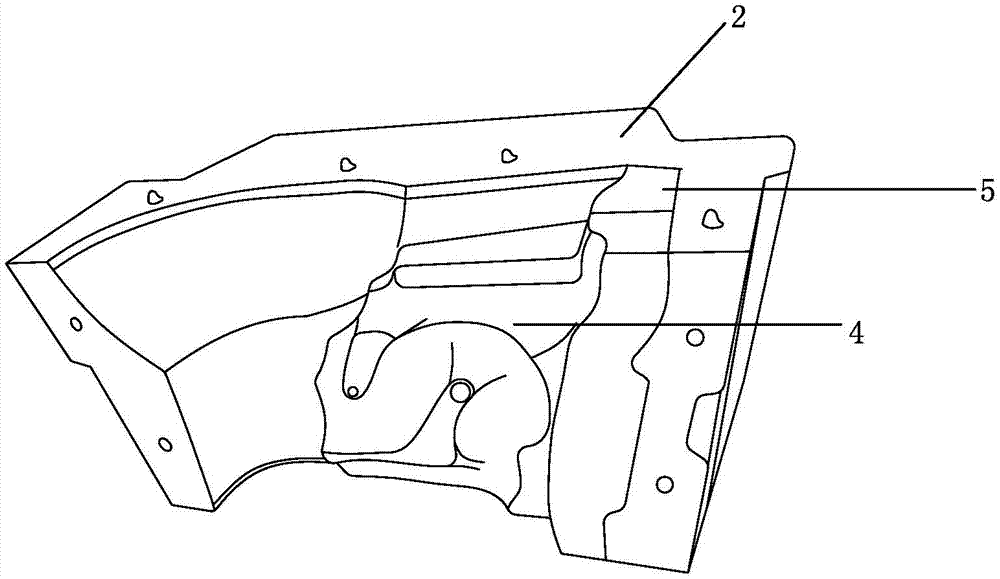

[0037] As a kind of preference, the main body mold is divided into surface mold, two side molds, pipe mold, side mold small parts and foot mold, which is used to produce the bedpan, sewage pipe and spray water channel, and also has the top mold located at the rear of the bedpan. The body of the toilet supporting the rib;

[0038] The rear part of the upper mold of the seat ring and the rear part of the lower mold of the seat ring have a concave-convex structure that cooperates with each other, and is used to produce the rear seat of the seat ring that is integrally formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com