Pipe -shaped car parts die casting mold

A technology for automobile parts and die-casting molds, which is applied in the field of die-casting molds, can solve the problems of difficult demoulding of pipe holes, easy deformation, and difficulty in filling, and achieves the effects of simple and reliable structure, convenient core pulling and good gas collection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

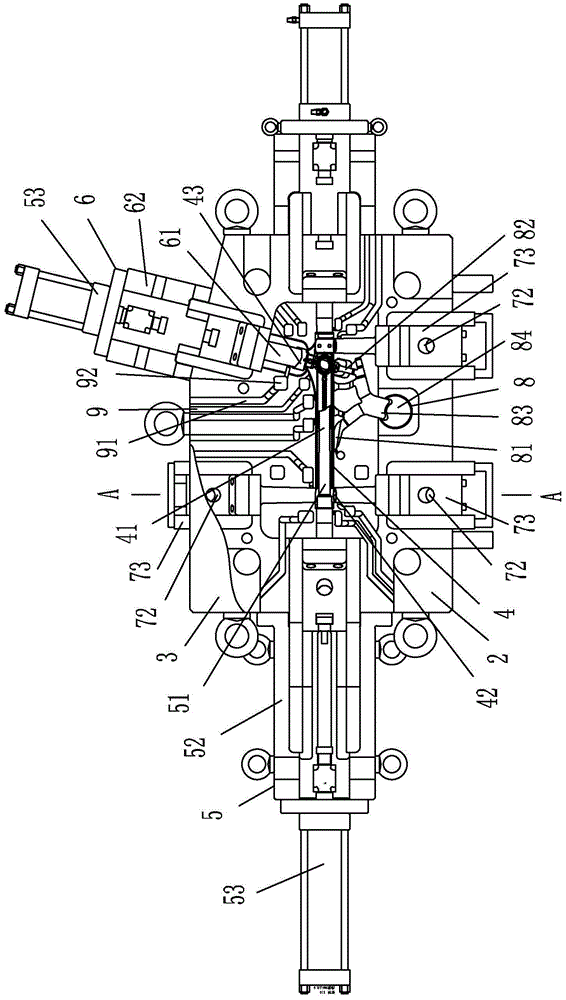

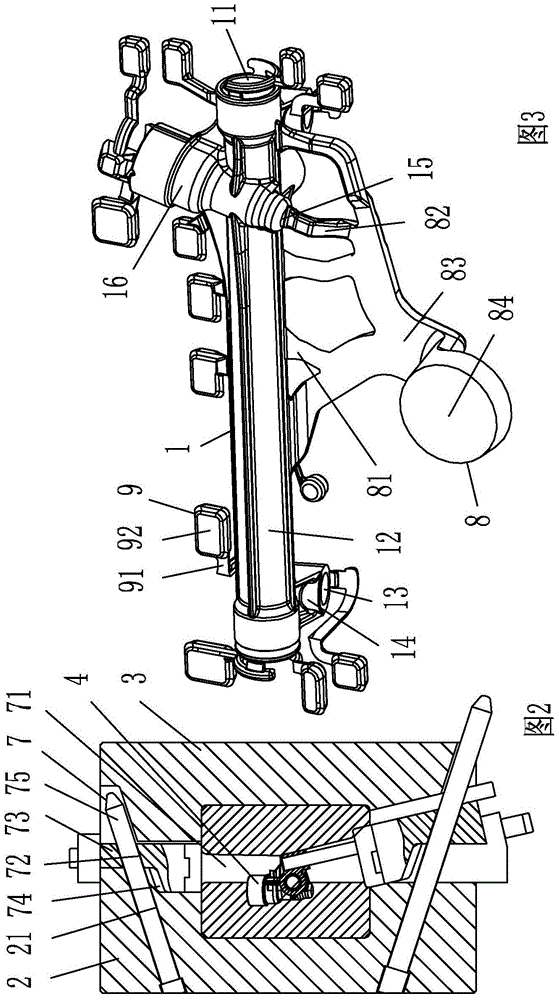

[0015] as attached figure 1 , attached figure 2 , attached image 3 Shown: a kind of die-casting die of tubular auto parts, comprising upper mold 2, lower mold 3, cavity 4 formed by upper mold 2 and lower mold 3, two main hole pumps with oppositely arranged main hole cores 51 Core device 5, a through-hole core-pulling device 6 provided with a through-hole core 61, three side-hole core-pulling devices 7 each provided with a side-hole core 71, a casting system 8 and an exhaust system 9; the cavity 4 includes a main pipe Cavity 41, side cavity 42 and inclined tube cavity 43; casting system 8 includes four main tube inrunners 81 located on one side of the main cavity 41 and respectively connected to the main cavity 41 and one connected to the inclined tube cavity. The inclined tube inrunner 82 connected to one end of 43, the connecting runner 83 connected with the incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com