Connecting rod joint wax mold forming method

A molding method and wax mold technology, which are applied in casting molding equipment, molds, cores, etc., can solve the problems of low wax mold accuracy, difficulty in demoulding wax molds, and high rejection rate, so as to improve the splicing efficiency and improve the gap. The effect of processing efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

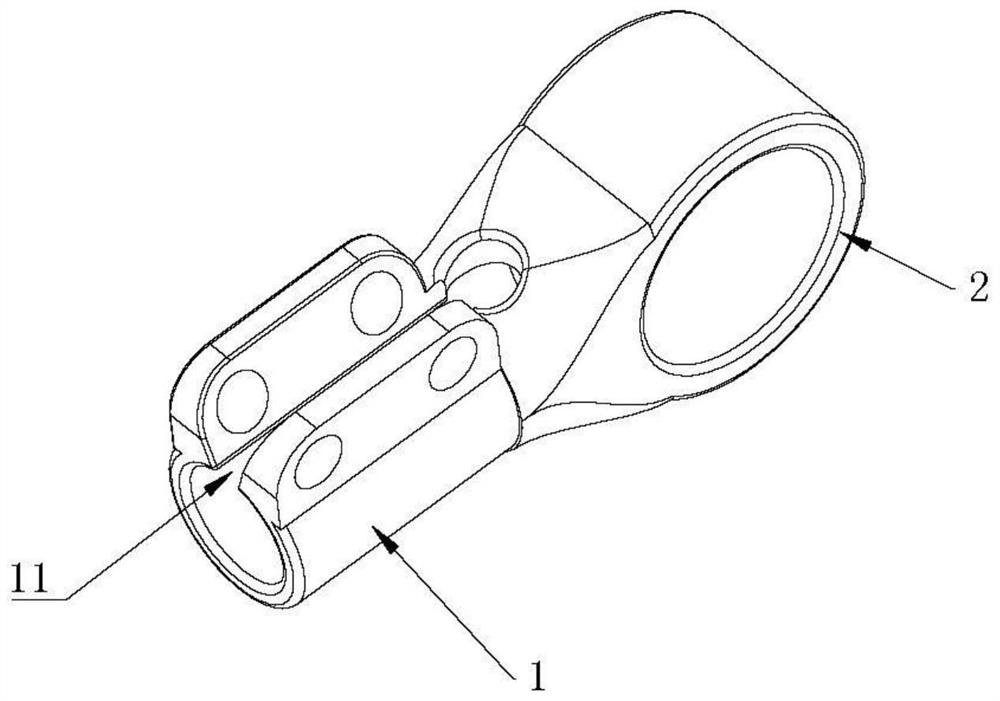

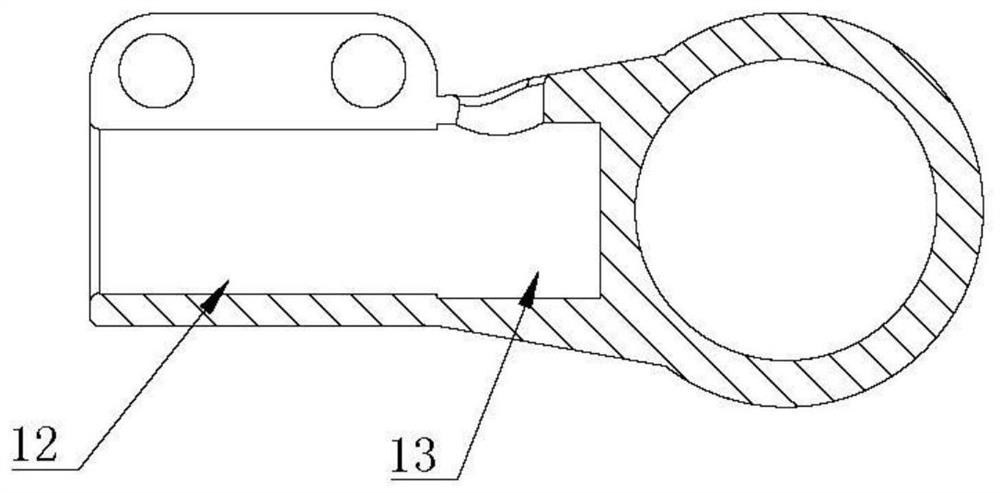

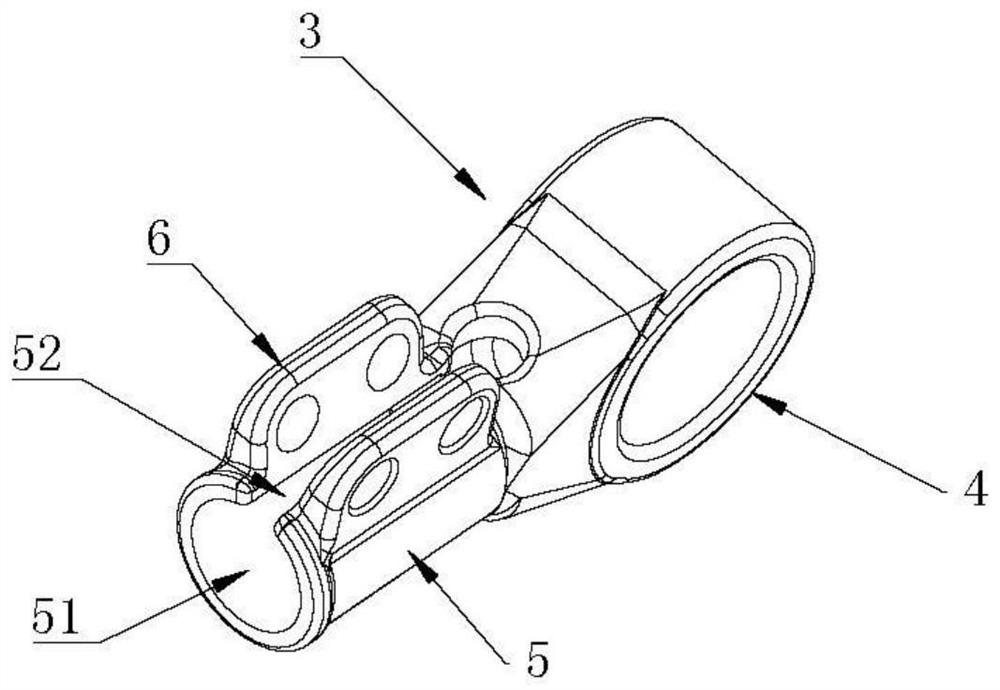

[0033] Such as Figure 1 to Figure 7 As shown, a method for forming a wax mold of a connecting rod joint in this embodiment, the specific steps are as follows:

[0034] 1) Molding the first wax pattern 3 in the first mold, the first wax pattern 3 includes the first bushing 4, the first body 5 and two ear parts 6, the first mold is provided with a core for easy core pulling Block, so that the first body 5 of the first wax pattern 3 obtained by molding is formed with a first blind hole 51. The diameter of the first blind hole 51 is larger than the diameter of the threaded hole of the connecting rod joint blank casting. The first blind hole 51 The hole 51 includes a through-hole section 511 located at the outer end of the first blind hole 51 and a tool retract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com