Core drawing mechanism of bellows birthmouth injection machine

A technology of core-pulling mechanism and socket, applied in the field of core-pulling mechanism, can solve the problems of slow and uniform heating, low processing efficiency, thinning of tube wall, etc., and achieve the effects of improved work efficiency, fast molding time and good molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

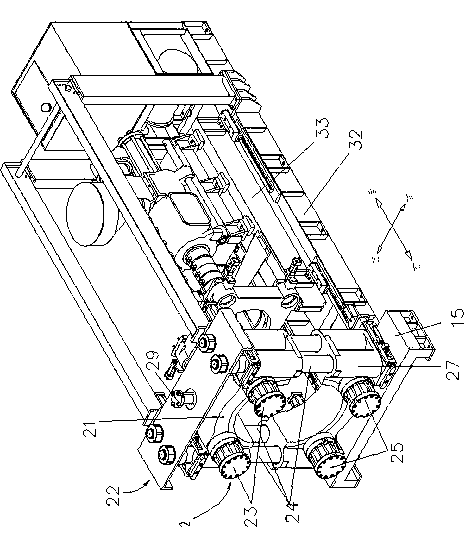

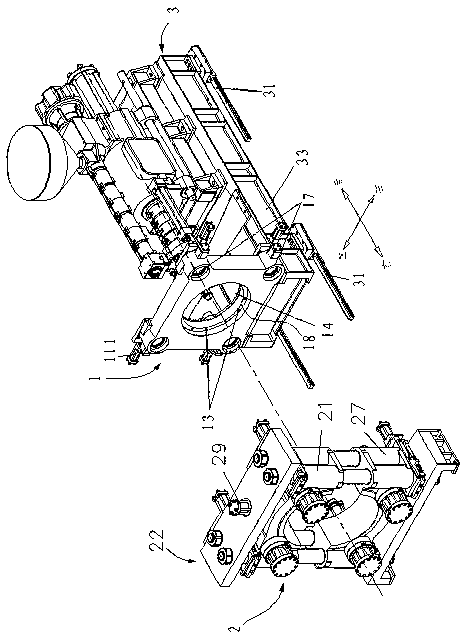

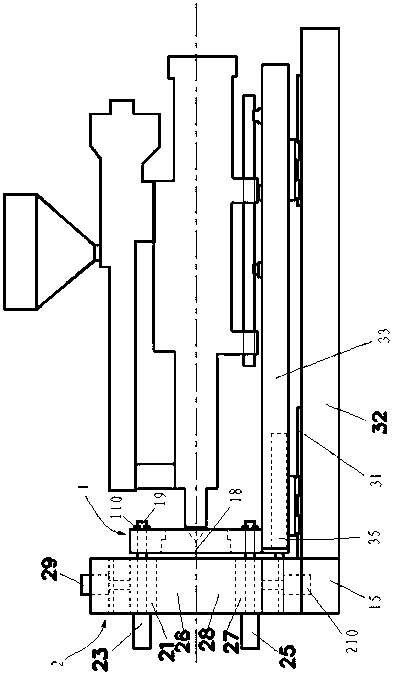

[0020] Referring to Figures 1 to 4, it can be seen that:

[0021] The present invention includes: a core template 1, a core pulling device 2, and a sliding frame 33, as shown in FIG. 2 .

[0022] The core template 1 is a plate for fixing the core mold, which is a rectangular plate, the middle part of which is provided with a core mold positioning hole 14, and the hole wall of the core mold positioning hole is provided with an annular boss 18 connecting the core mold. The boss is provided with screw holes 13, and the mandrel enters the mandrel positioning hole 14 from the front of the core template 1 to connect with the boss, and is fixed with screws. The guide post hole is used to pass through the core-pulling guide post 19, and lock the core-pulling guide post through the core-pulling lock 117, as shown in Fig. 2 and Fig. 3 .

[0023] The core pulling device 2 is a device for locking and opening the mandrel. The mold of the bellows socket is composed of a semicircular upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com