A kind of manufacturing method of pure quartz glass hollow cylinder

A technology of quartz glass and manufacturing method, which is applied to glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of damaged pore walls in powder preforms, difficult to meet temperature requirements, unstable gas flow, etc., to ensure deposition. The effect of forming quality, reducing processing cost, and enhancing processing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

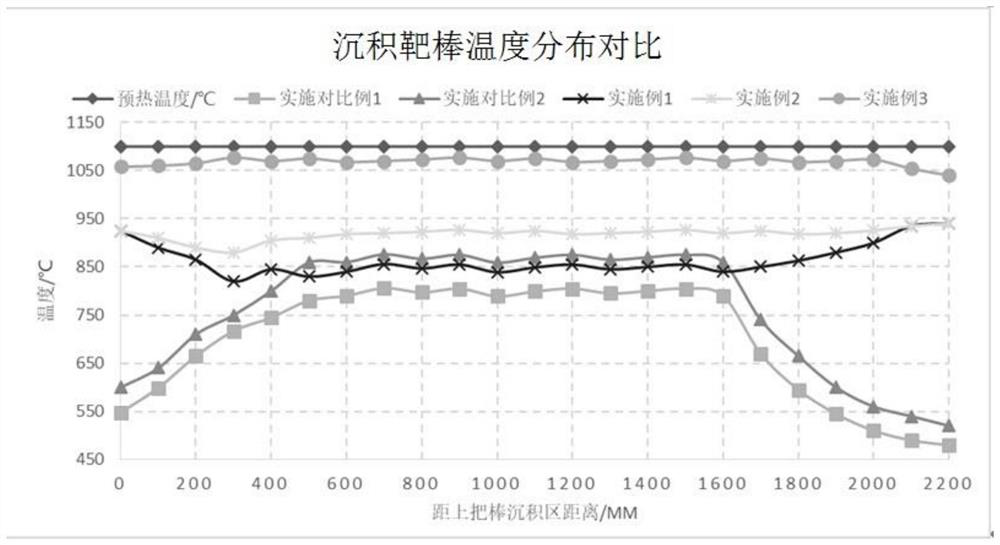

[0025] Embodiment 1: manufacture a quartz glass hollow cylinder with a length of 2200 mm and a weight of 120 kg.

[0026] The deposition target rod is a hollow rod structure, made of more than 99.9% alumina, with an outer diameter of 50mm, an inner diameter of 30mm, and a length of 3000mm. According to the empirical formula: (G / 100) 4 *Tmin / 4000≤Ra≤(G / 100) 4 *Tmin / 400 is calculated to be 0.68≤Ra≤5.70μm, in order to reduce the processing cost, choose Ra=1.60μm.

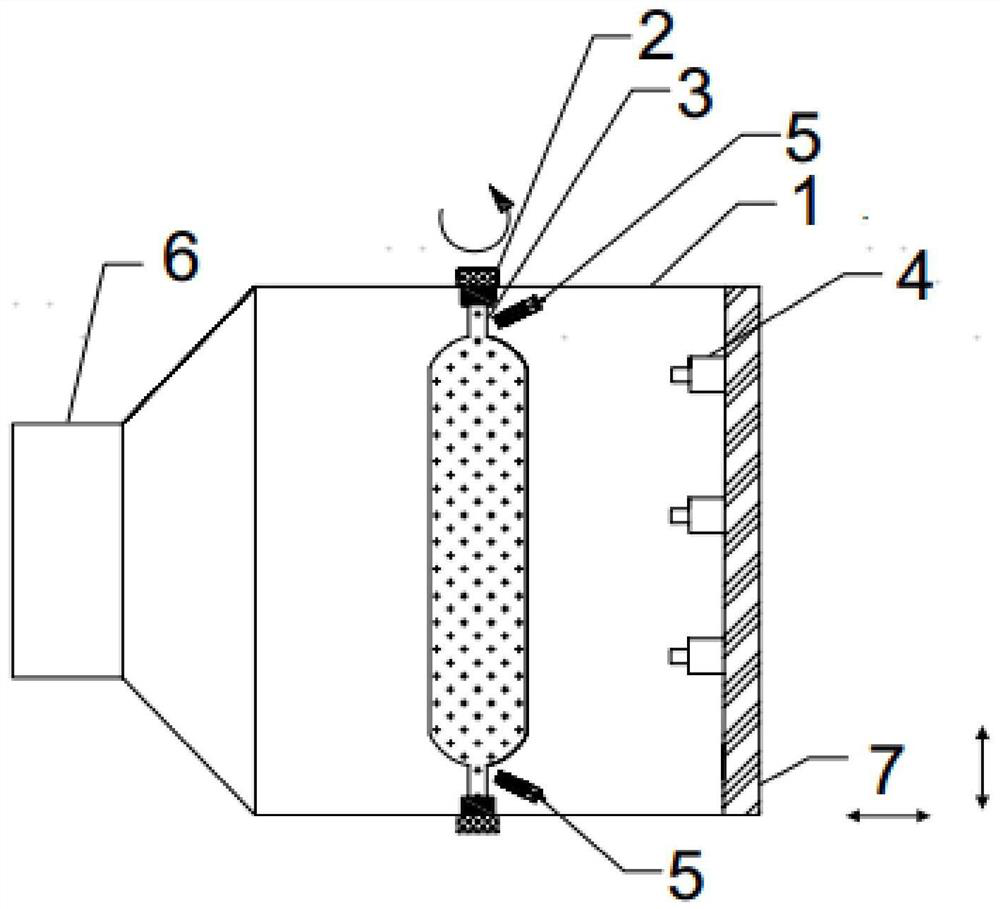

[0027] The deposition target rod 3 is installed in the chuck that rotates up and down, such as figure 1 As shown, it is an OVD (outside vapor deposition method) deposition device, the deposition chamber is a vertical target rod deposition method, including a deposition chamber 1, and an upper and a lower rotary chuck 2 are installed in the deposition chamber, corresponding to the rotary chuck A blowtorch assembly 4 is installed on one side of the deposition chamber, and the blowtorch assembly is installed in paralle...

Embodiment 2

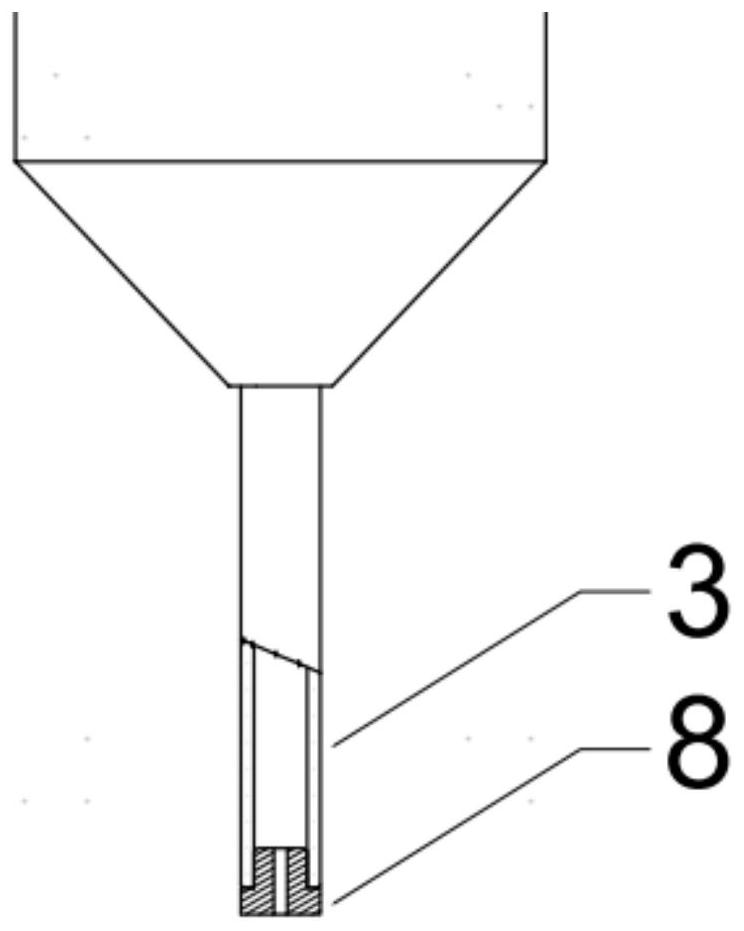

[0030] With embodiment 1, the difference is that the upper and lower ends of the inner hole of the hollow rod deposition target rod 3 are provided with opening plugs 8, which are Teflon plugs, and the aperture of the opening plugs is 10mm, which reduces The aperture at the end of the hollow rod is used to control the flow of the airflow in the hollow rod, reduce the difference in temperature of the deposition target rod in different directions, and is beneficial to equalize the temperature. The rest remained unchanged, and the second stage of the actual deposition was measured, and the temperature of the target rod was monitored, and the temperature change was smaller and more uniform than that of Example 1.

Embodiment 3

[0032] Same as Example 2, the difference is that the hole diameter of the hole plug is reduced to 5 mm, and the rest remains unchanged. The second stage of actual deposition is measured, and the temperature of the target rod is monitored. Compared with Example 2, the temperature change is smaller and more uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com