Die for producing four-way tube

A technology for four-way pipes and moulds, which can be used in household appliances, other household appliances, applications, etc., and can solve the problem of unsuitable multi-pipe product demoulding, difficult core-pulling and demoulding of molds, and core-pulling of Y-direction curved pipes Problems such as difficulty in modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is a specific embodiment of the present invention and a further description of the technical solutions of the present invention, but the present invention is not limited to these embodiments.

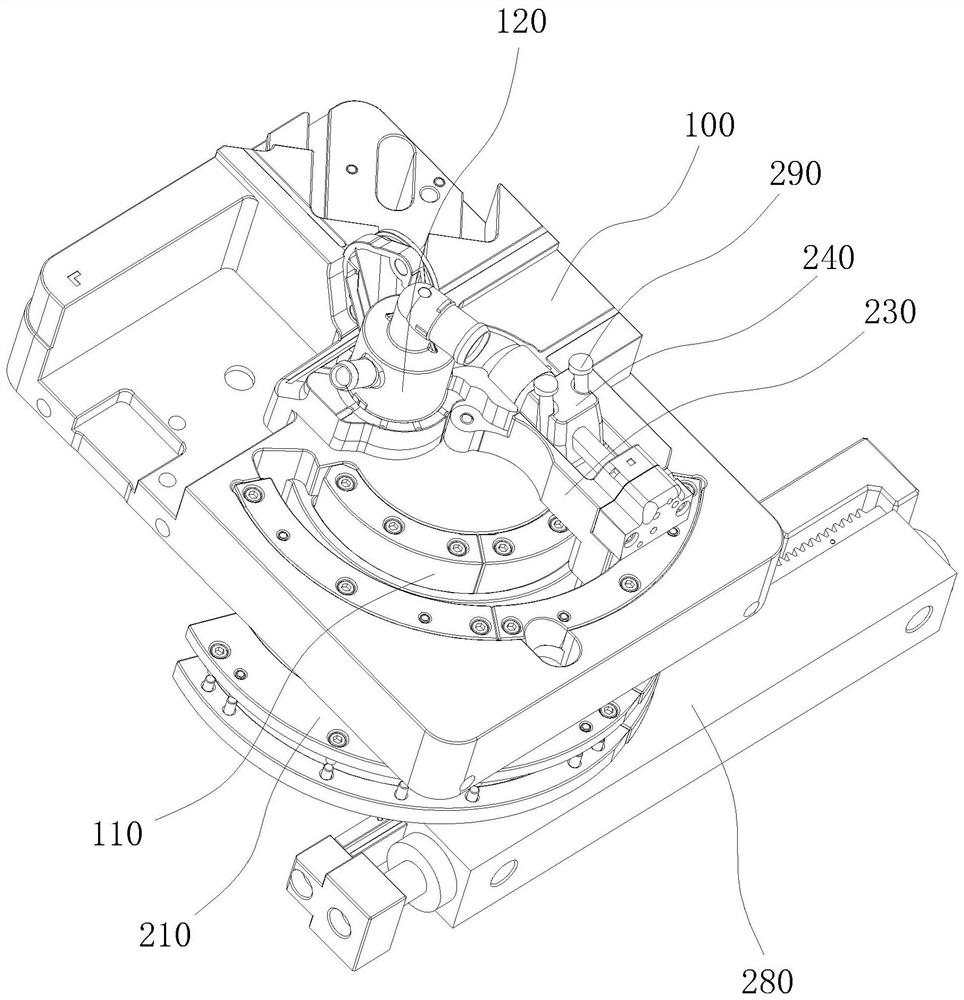

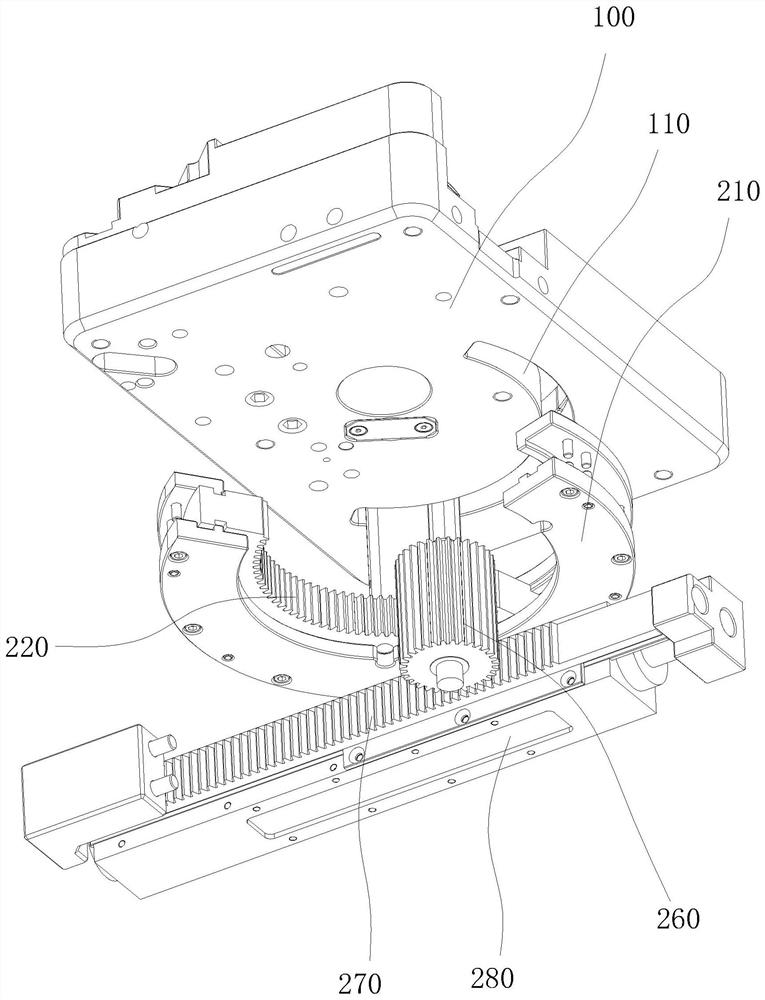

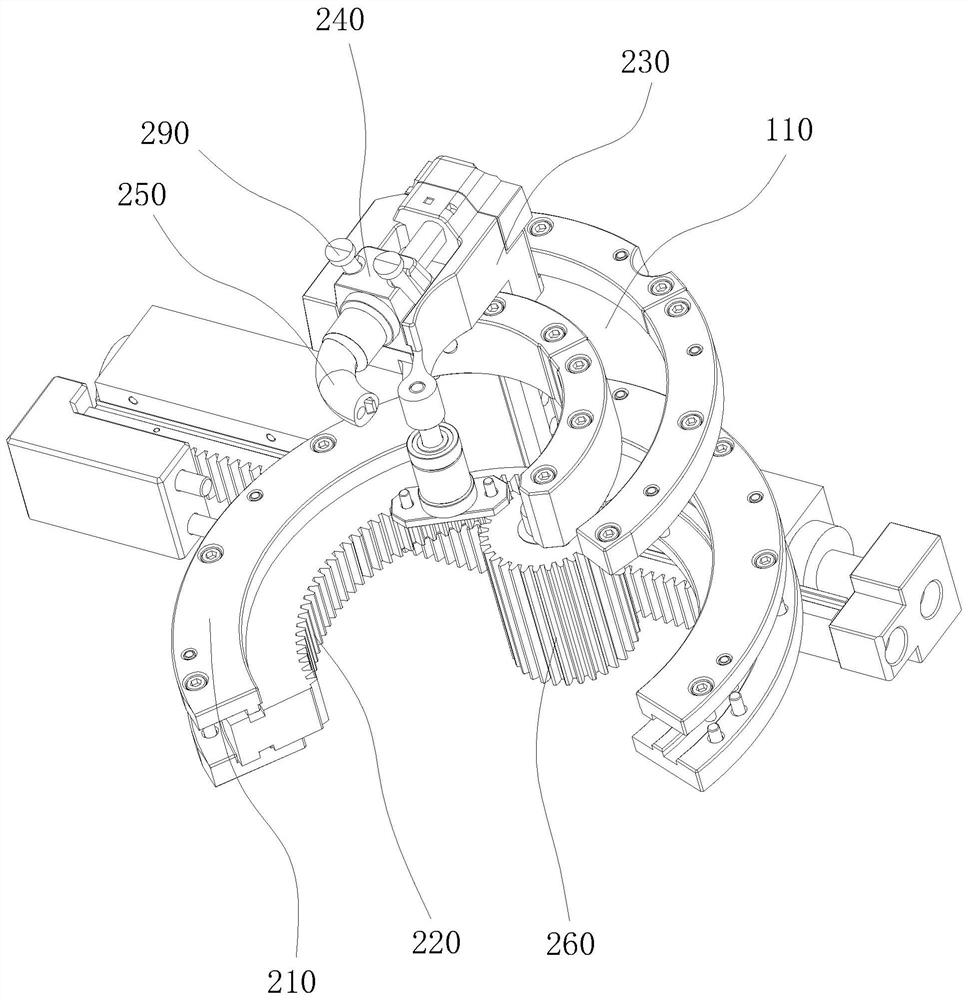

[0041] like figure 1 , figure 2 , image 3 As shown, a mold for producing four-way tube, including: moving mold core 100, fixed seat (not shown), curved rack 220, connect lens 230, first slider seat 240, arc The shape core 250 and the gear 260, the working principle is rotated by the connecting rod 230 and the arc-shaped core 250 rotates about the workpiece, and causes the curved core 250 toward the curved rack 220. The radial movement can be moved while moving the curved core 250 while moving the curved trajectory of the curved bend while the curved core 250 can move radial movement 250 from Y. Pull it into the curved head.

[0042] Here, it is worth mentioning that in some products, especially in the main pipe of the plastic four-pass tube, the flange tube, oblique tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com