Auxiliary hydraulic set for great tonnage press

An auxiliary hydraulic and large-tonnage technology, which is applied to presses, manufacturing tools, etc., and can solve problems such as large molds and heavy weights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

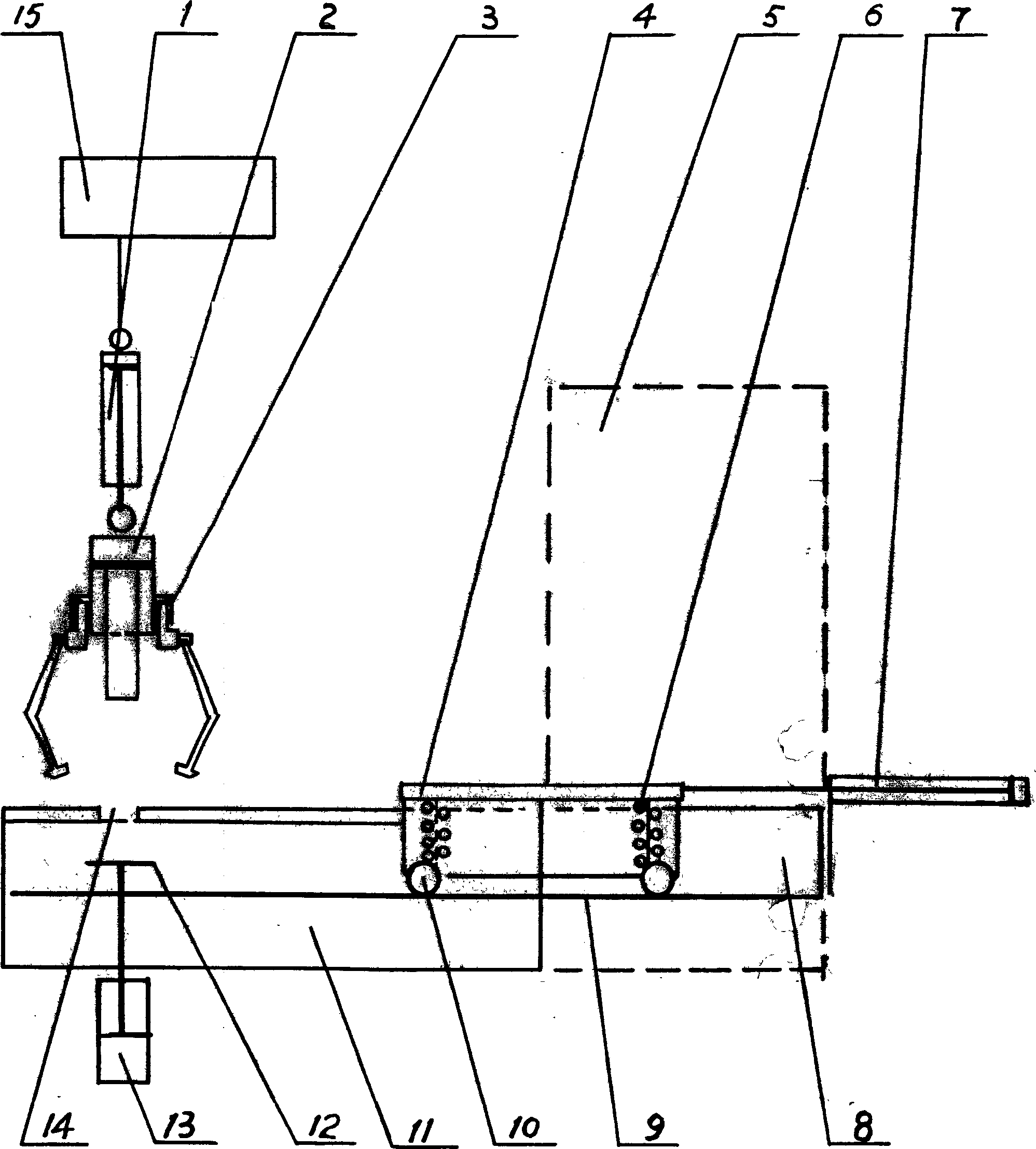

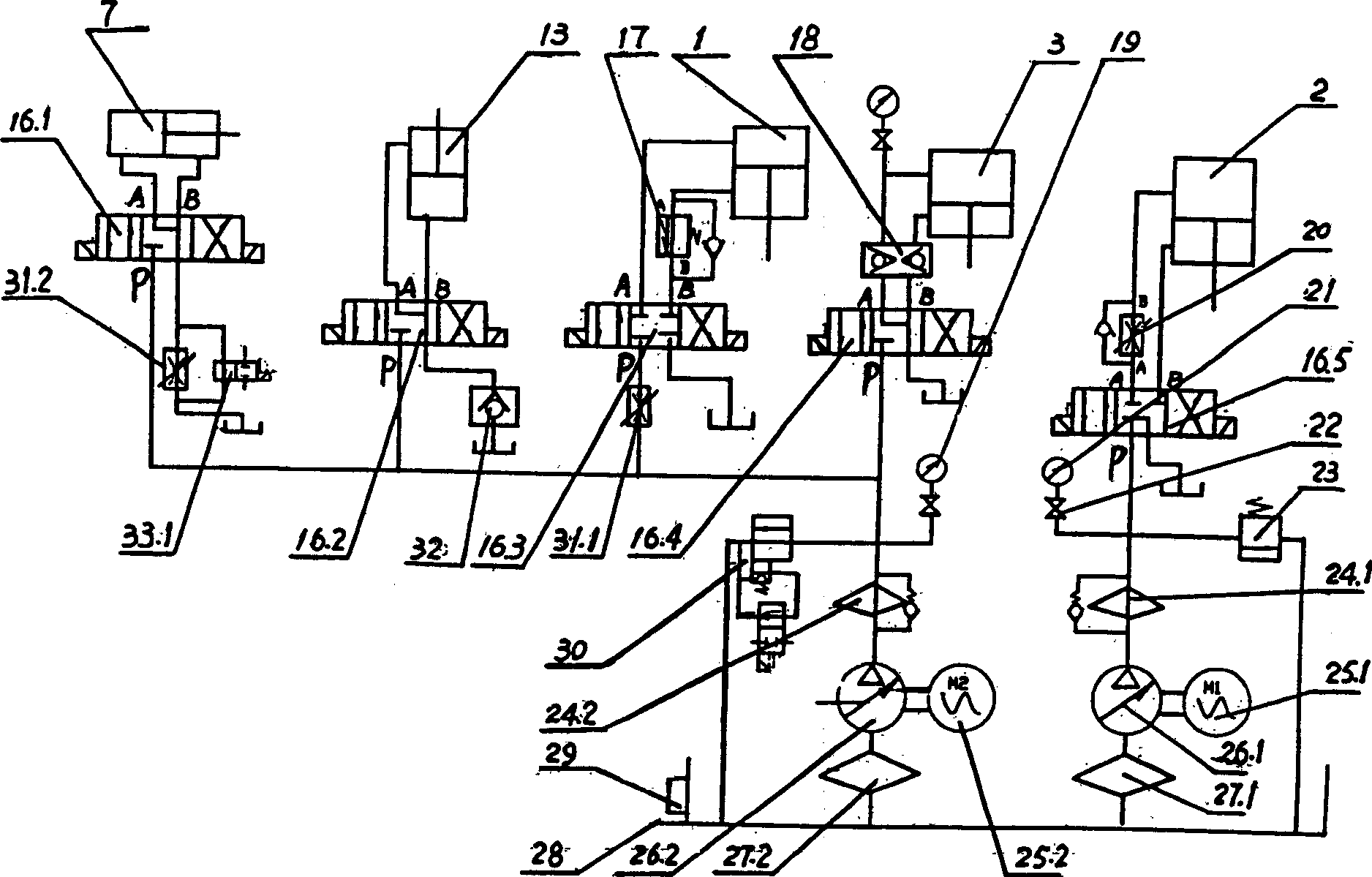

[0013] As shown in the figure, the press auxiliary hydraulic device with translation, lifting and jacking functions is a supplementary improvement to the existing large-tonnage press. Its specific structure is as follows:

[0014] The auxiliary hydraulic device of this large-tonnage press with the functions of translation, lifting and jacking consists of a floating movable platform 4 attached to the main press 5, a platform frame 11, and three jaws suspended above the platform frame 11. Composed of manipulators, it is characterized in that: the floating movable platform 4 is seated on the guide rail 9 of the platform frame 11 through the four rollers 10 arranged below it and the supporting spring 6 supporting the floating movable platform 4, At the same time, a translation hydraulic cylinder 7 connected with the floating movable platform 4 is provided on the side near the main press 5 of the floating movable platform 4, thus forming a displacement mechanism; in addition, on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com