Die for car interior part

A technology for automotive interior parts and molds, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as difficulty in taking out automotive interior parts, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

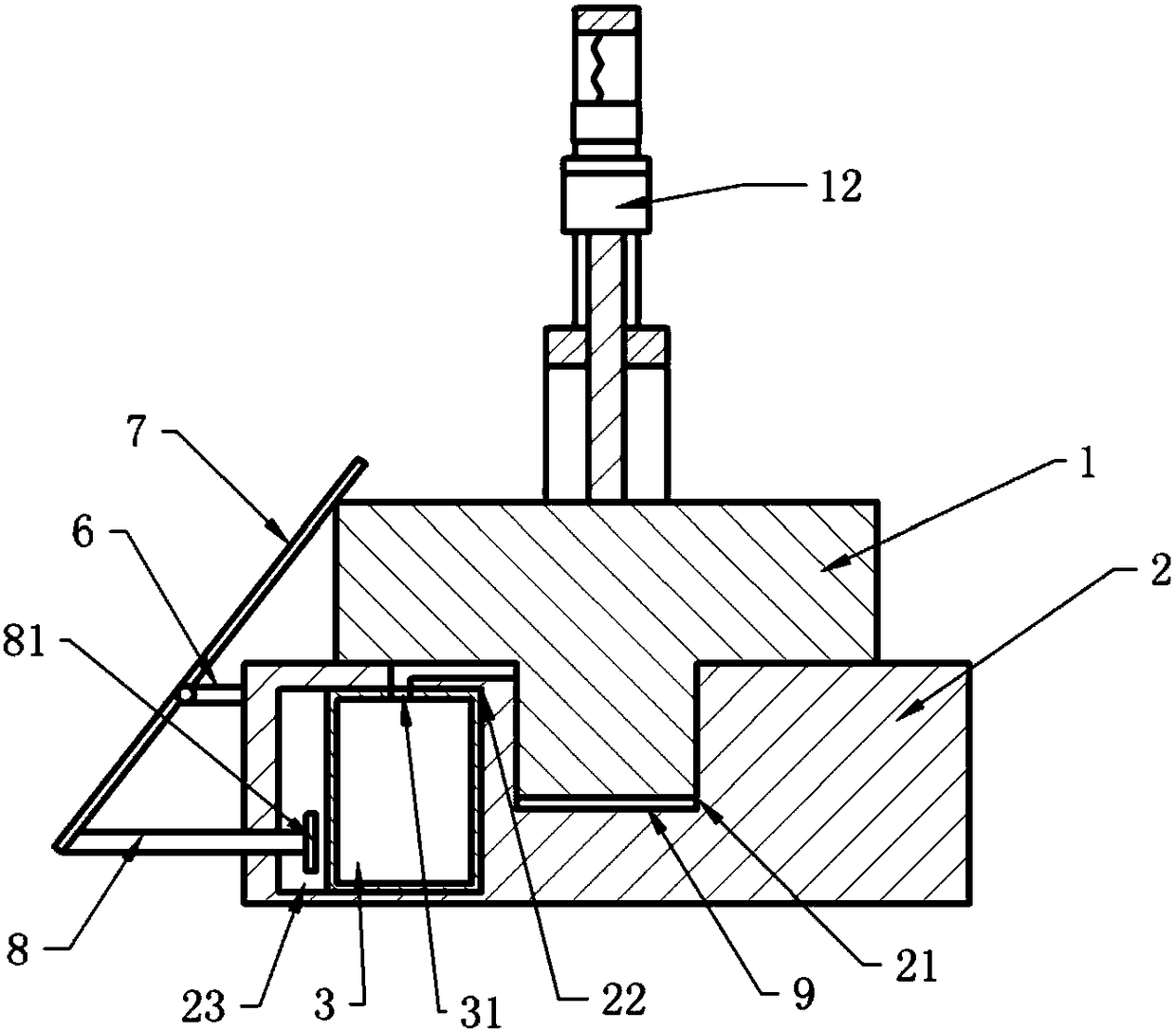

[0027] Further detailed explanation through specific implementation mode below:

[0028] The reference signs in the drawings of the description include: upper punch 1, sliding rod 11, support block 12, lower punch 2, cavity 21, oil guide groove 22, oil inlet chamber 23, oil inlet air bag 3, oil inlet 31 , electromagnet 4, conductive sheet 41, conductive wire 42, power supply 5, conductive needle 51, support rod 6, extrusion rod 7, push rod 8, push plate 81, iron block 9.

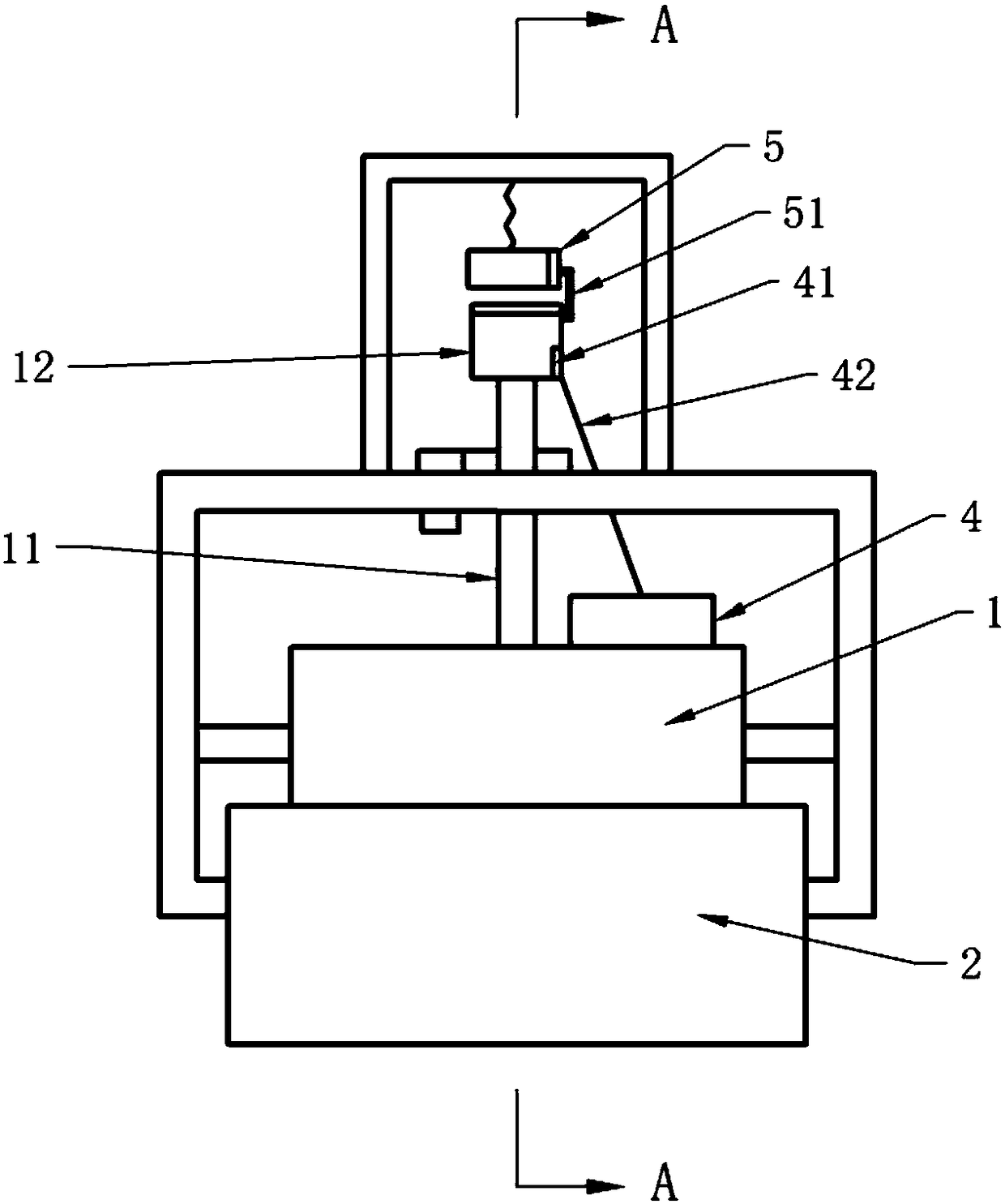

[0029] The embodiment is basically as attached figure 1 Shown:

[0030] A mold for automotive interior parts, including an upper punch 1, a lower die and an inverted U-shaped bracket, the bracket includes a horizontal plate and two vertical plates, and the two vertical plates are respectively installed on the left and right side walls of the lower die . The two vertical plates are longitudinally provided with limiting grooves, and the left and right side walls of the upper punch 1 are provided with projec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com