3D printing bearing platform and full-automatic printing method based on bearing platform

A bearing platform, 3D printing technology, applied in the field of 3D printing, can solve problems such as unfavorable automation operation and low efficiency, and achieve the effect of improving efficiency and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

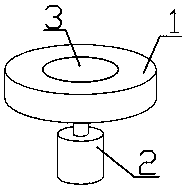

[0030] Such as figure 1 As shown, a 3D printing carrying platform includes a fixed platform 1 and a movable platform 3 spliced with each other, and the bottom of the movable platform 3 is connected with a driving device 2, and the driving device 2 is used to drive the working surface of the movable platform 3 The working surface of the relative fixed platform 1 is raised and lowered. The drive device 2 preferably includes a lift drive mechanism and a push rod for connecting the lift drive mechanism with the movable platform 3 .

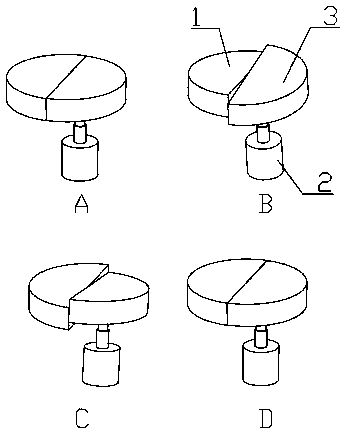

[0031] Such as Image 6 with 8 As shown, the movable platform 3 is cylindrical, the fixed platform 1 is provided with a through hole matching the movable platform 3, and the movable platform 3 is arranged in the through hole; the hole wall of the through hole A guide groove 11 is provided on it, and the guide groove 11 preferably extends parallel to the axis of the through hole. At least two connecting columns 31 are evenly distributed in a ring...

specific Embodiment approach 2

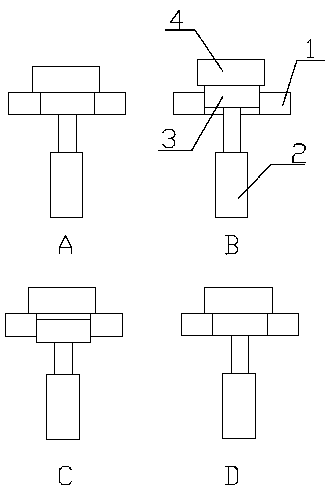

[0034] Such as image 3 with Figure 4 As shown, compared with Embodiment 1, the difference of this embodiment is that the movable platform 3 / fixed platform 1 is provided with a connecting shaft 32, and the movable platform 3 / fixed platform 1 is connected through the connecting shaft. 32 is rotatably connected with the fixed platform 1 / movable platform 3, and the axis of the connecting shaft 32 is parallel to the working surface of the fixed platform 1; the driving device 2 drives the movable platform 3 to rotate around the connecting shaft 32 relative to the fixed platform 1. In order to prevent the drive device 2 from being stuck during the rotation of the movable platform 3, both ends of the drive device 2 are hinged to corresponding components.

[0035] Such as image 3 Shown is a schematic diagram of the demoulding process of the printing platform (in the order of A-B-C-D). When the movable platform 3 rotates relative to the fixed platform 1 , the working surface of th...

specific Embodiment approach 3

[0036] Compared with Embodiment 1, the difference of this embodiment is that the guide groove 11 is in a spiral shape. Such as Figure 5 to Figure 8 As shown, the guide groove 11 includes several guide units 111, and the number of the guide units 111 is an integral multiple of the number of the connecting columns 31; each guide unit 111 includes two segments 112 with opposite directions of rotation, The two sections 112 are connected into one body, and transition smoothly at the joint; several guide units 111 are connected end to end in turn, and transition smoothly at the joint. The driving device 2 is a motor, and a flexible coupling 5 is arranged between the driving device 2 and the movable platform 3 .

[0037] Since the movable platform 3 moves up and down relative to the fixed platform 1, the model 4 receives a large longitudinal shear force, which may cause damage to the model 4 or cause the model 4 to deform. The spiral guide groove 11 makes the movable platform 3 ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com