Automatic donkey-hide gelatin block demolding device and demolding method

An automatic demoulding and pushing device technology, applied in the field of packaging machinery, can solve problems such as low production efficiency and easily damaged rubber lumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

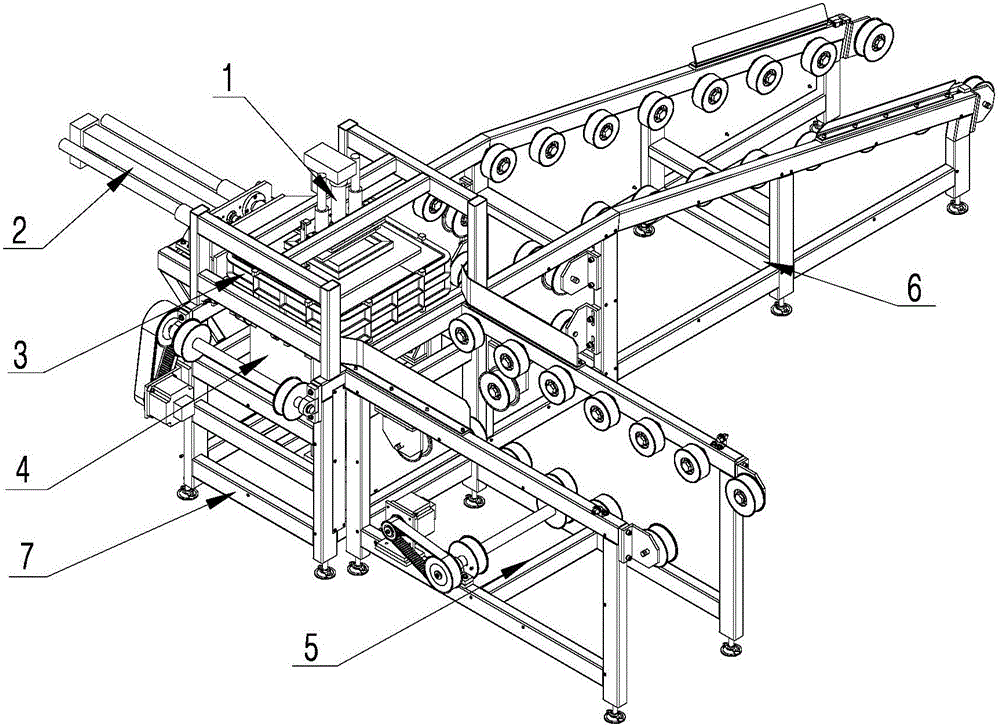

[0024] Such as Figure 1-11 As shown, the automatic demoulding device for donkey-hide gelatin lumps according to the present invention is used for the automatic demoulding of the mold 3, including: a pressurization pushing device 1 on the upper part of the mold, a glue lump pushing device 2, and a side frame pushing device for demoulding 4. Feeding conveying device 6, glue discharging conveying device 5, frame 7.

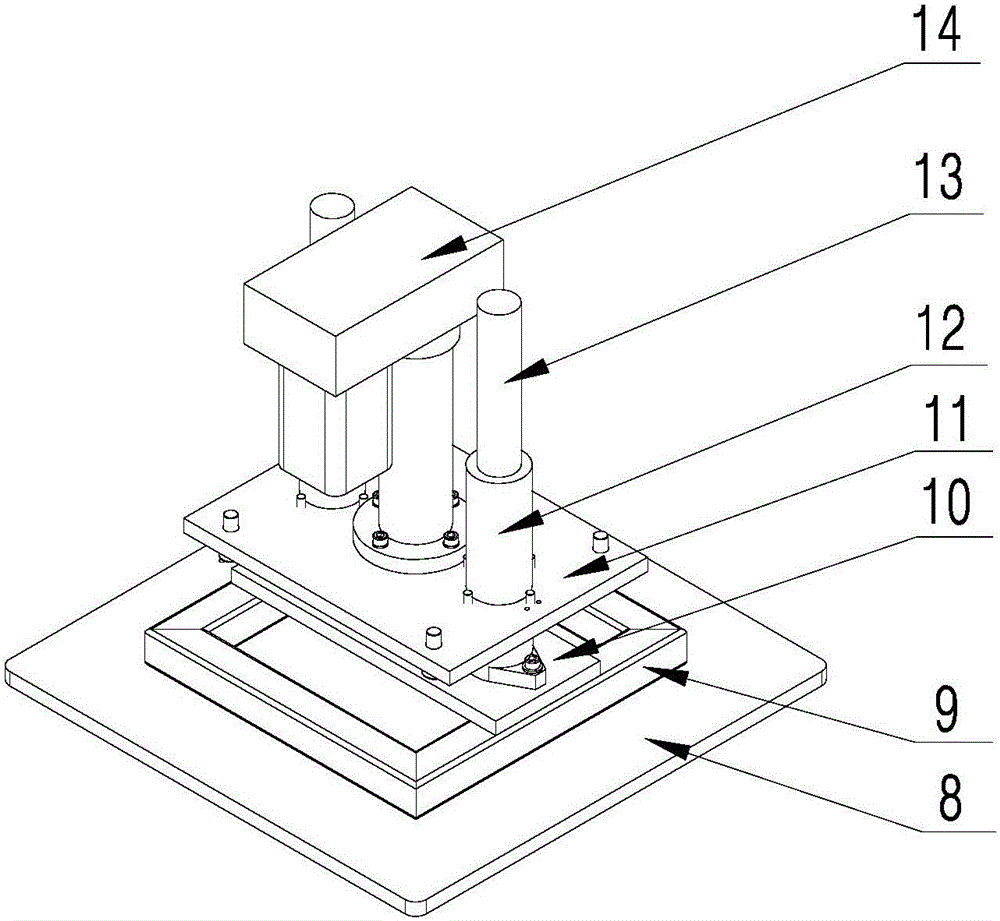

[0025] Wherein, the pressing and pushing device 1 on the upper part of the mold comprises: an upper push plate 8 , a push plate crossbeam 9 , a base plate 10 , an electric cylinder mounting plate 11 , an electric cylinder 14 , a slide block 12 , and a slide rail 13 .

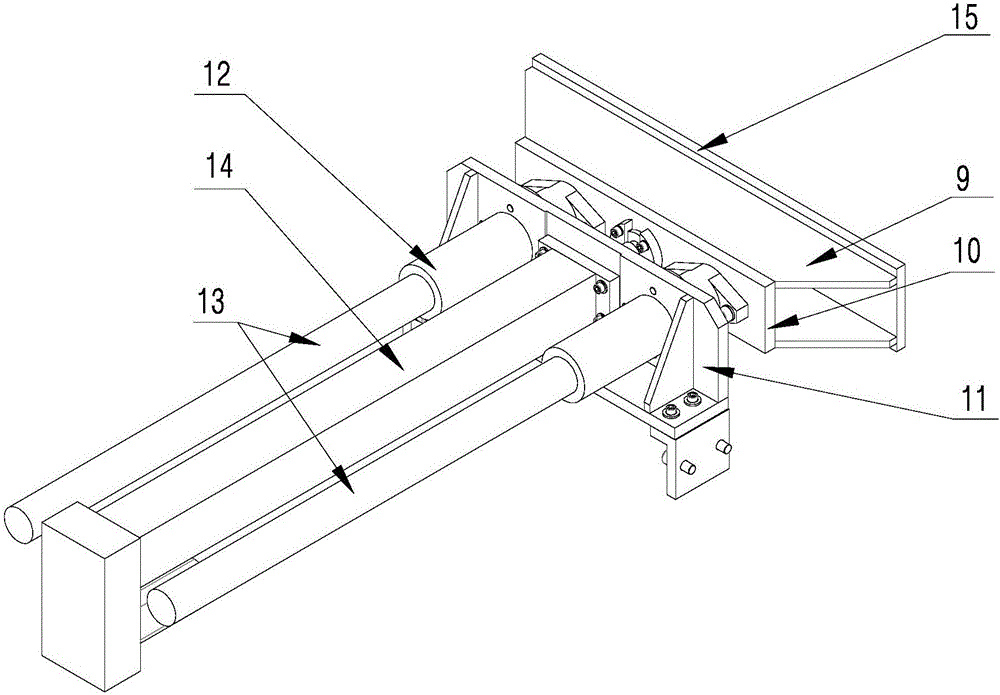

[0026] Glue pusher 2 comprises: push plate 15, push plate beam 9, base plate 9, electric cylinder 14, electric cylinder mounting plate 11, slide block 12, slide rail 13.

[0027] The demoulding side frame pushing device 4 includes: an upper push plate 16, a push plate crossbeam 9, a base plate 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com