Patents

Literature

220results about How to "Achieve flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

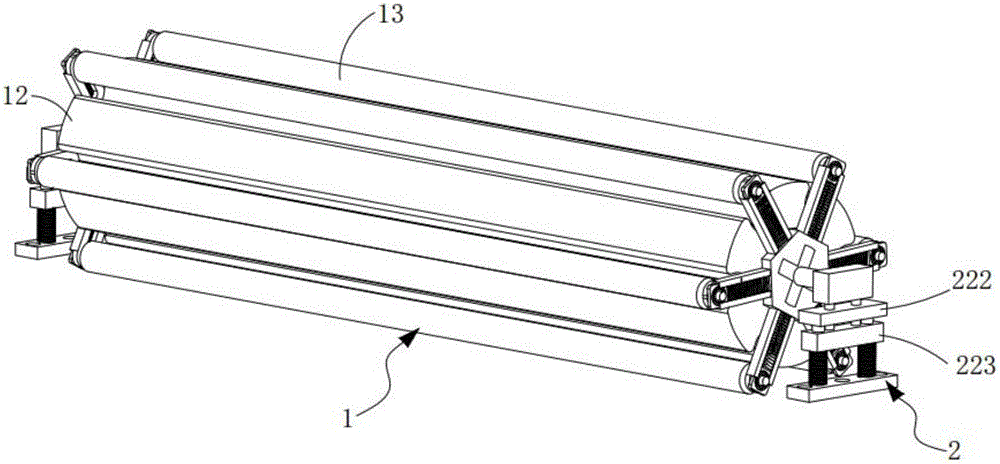

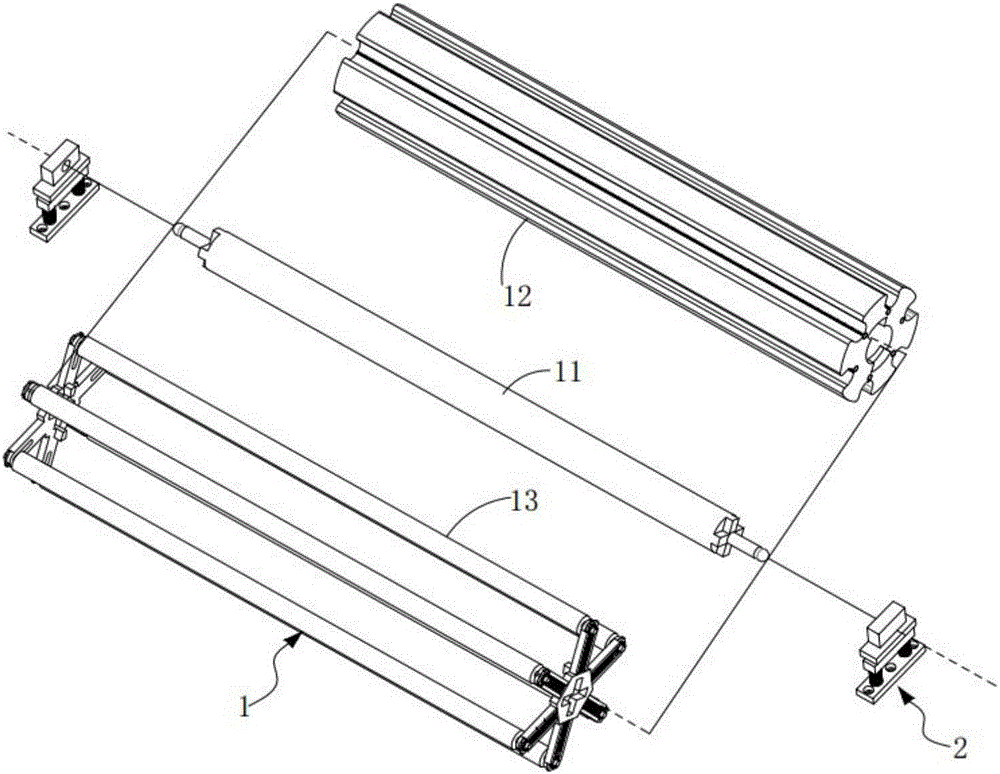

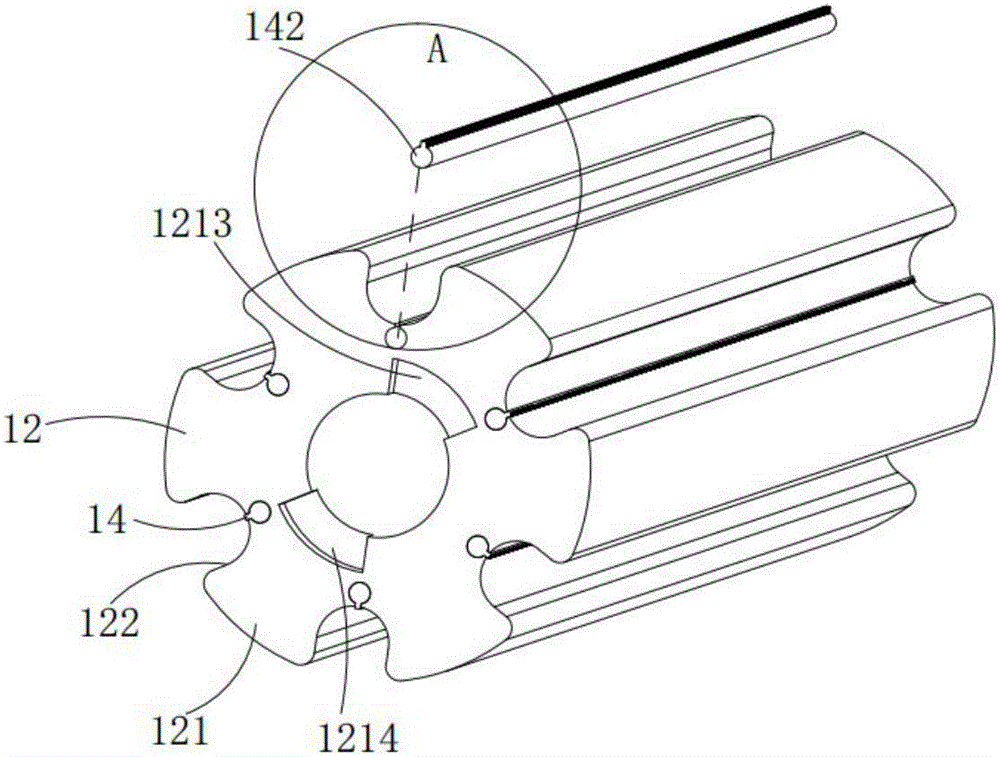

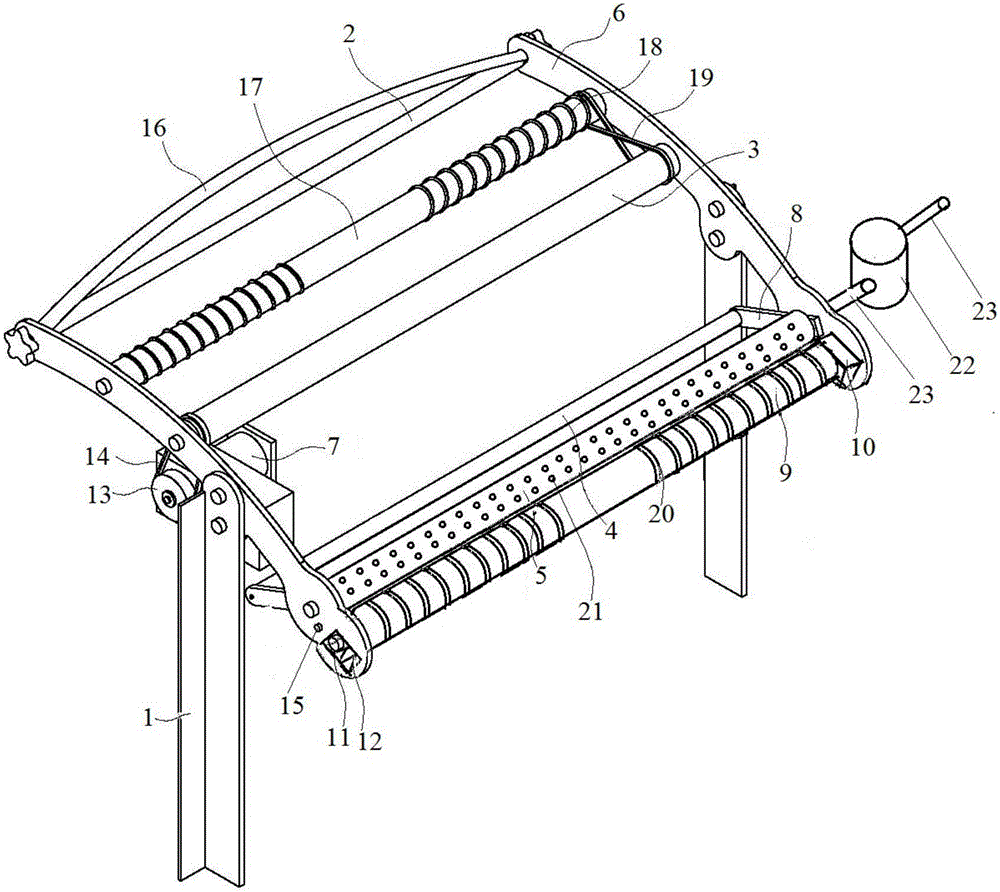

Flattening and dust-removing composite cloth roll

ActiveCN106809685AAchieve flatnessAchieve the effect of impurity removal combinationElectrostatic cleaningCleaning using toolsEngineeringTextile

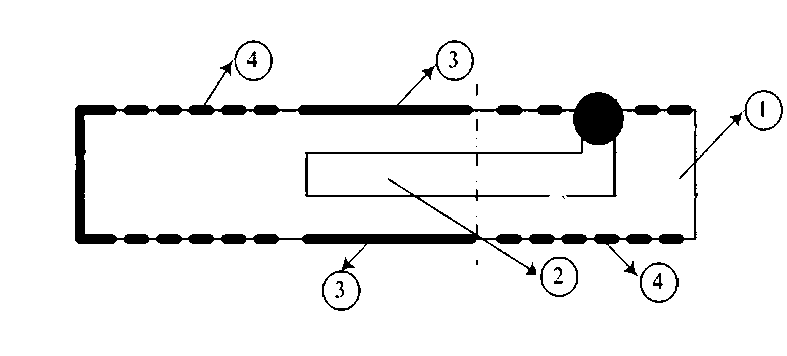

The invention provides a flattening and dust-removing composite cloth roll. The flattening and dust-removing composite cloth roll comprises a roll body and elastic supporting seats, wherein the elastic supporting seats are symmetrically arranged at the two ends of the roll body; the roll body comprises a main shaft unit, a rolling cloth-roll unit, a telescopic cloth-roll unit and a brushing-roll unit; the rolling cloth-roll unit is sheathed at the outer side of the main shaft unit; and the telescopic cloth-roll unit is positioned at the outer side of the rolling cloth-roll unit. The flattening and dust-removing composite cloth roll provided by the invention has the advantages that by combined use of the rolling cloth-roll unit and the telescopic cloth-roll unit, when textile fabrics are rolled and flattened by the rolling cloth-roll unit, simultaneously the telescopic cloth-roll unit is utilized for carrying out friction with the textile fabrics and generating static electricity, cloth dusts and impurities on the surfaces of the textile fabrics are absorbed by utilizing the electrostatic principle, simultaneously telescopic cloth rolls are cleaned by utilizing a roll brushing unit arranged on a rolling cloth roll, and the cloth dust and the impurities on the telescopic cloth rolls are collected, so that the compounding effect of rolling, flattening, and dust and impurity removal is achieved.

Owner:浙江玺爱纺织科技有限公司

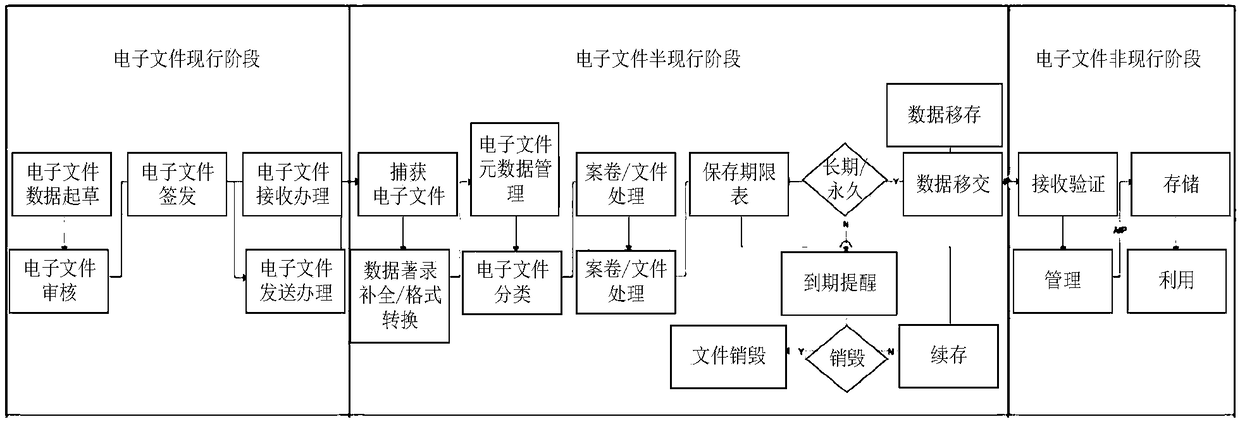

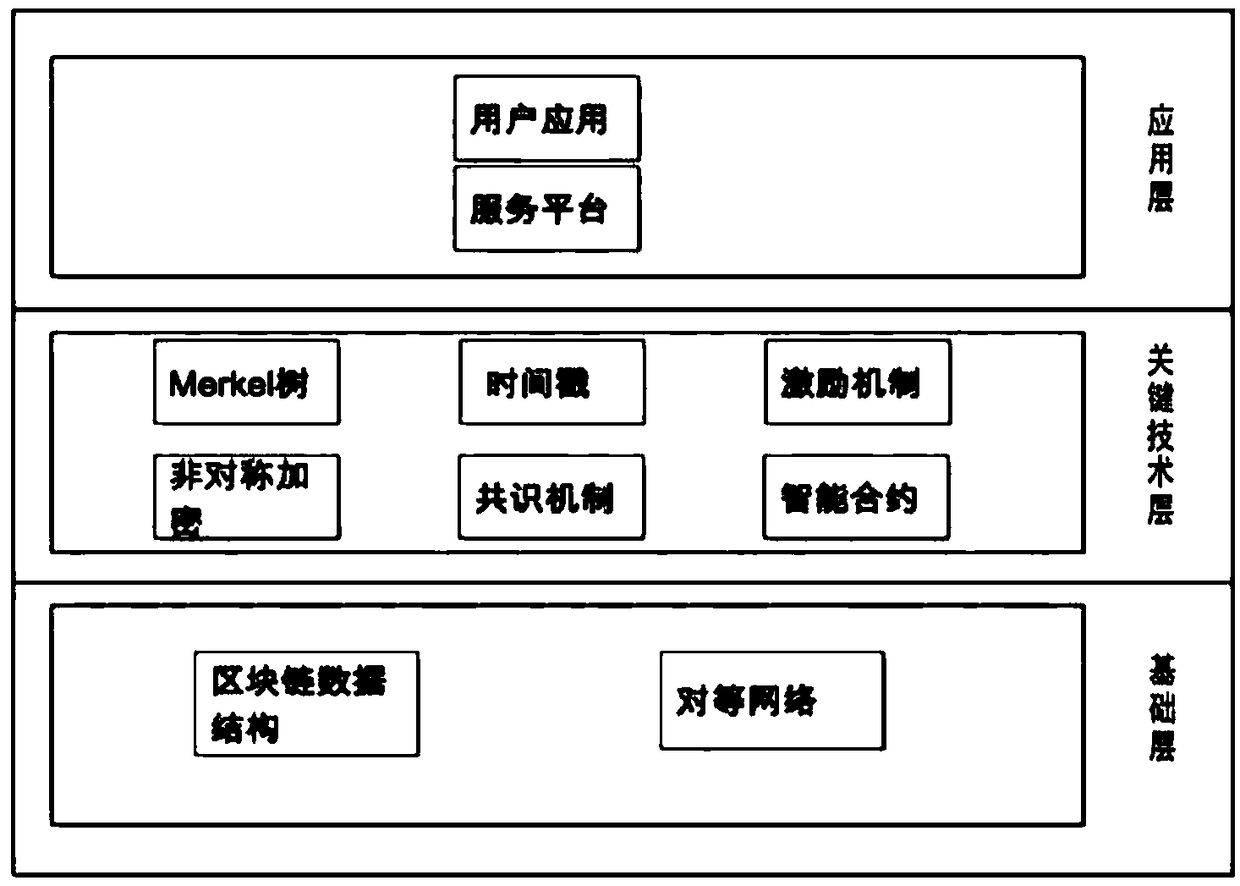

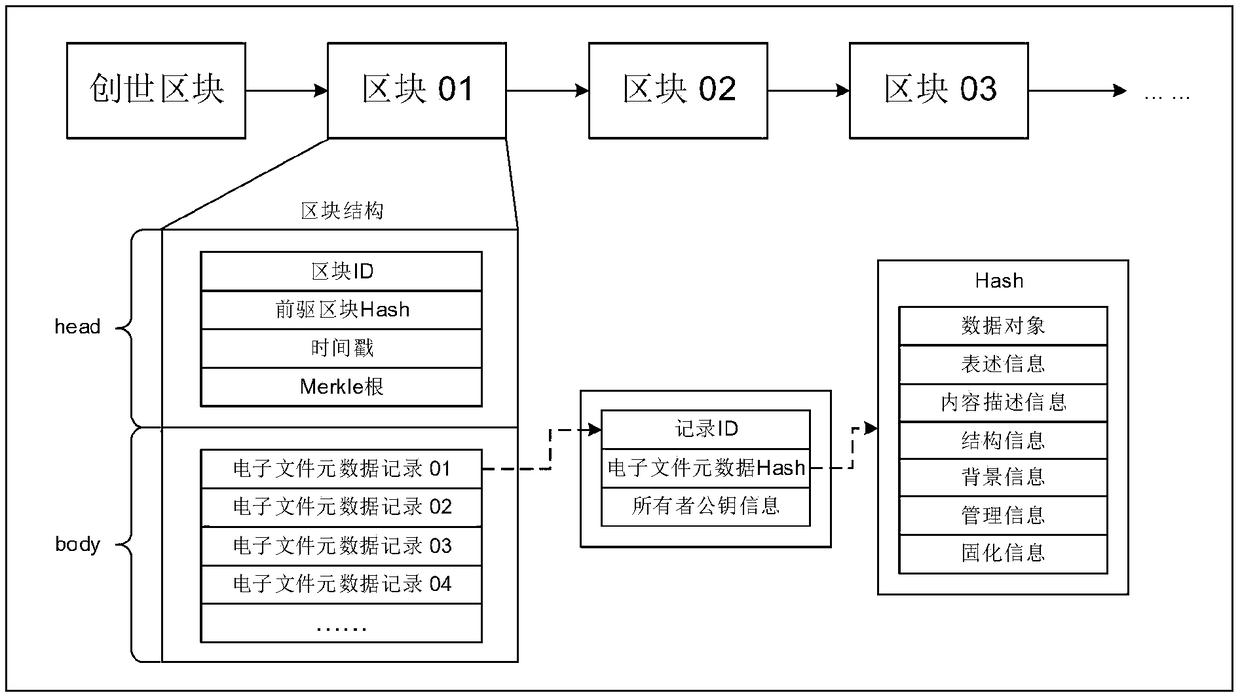

Electronic document authenticity assurance method based on block chain

ActiveCN109508563ACredential securityAchieve flatnessDigital data protectionCommerceService systemChain network

The invention provides a method for guaranteeing the authenticity of electronic files based on a block chain, which comprises the following steps: establishing a system overall structure, wherein thesystem overall structure comprises: each service system embedding, an access layer, a block chain network and a management platform; Establishing the system operation process, including: establishingthe business department, software development kit SDK, authentication center and the interaction between the block chain nodes running process; On the basis of the overall construction of the established system, combined with the operation process of the system, establishing the authenticity verification process of electronic documents. The invention utilizes the technical advantages of decentralization of the block chain and non-tampering of the process record, introduces the block chain technology into the electronic file authenticity research field and the application in practice, and realizes the functional advantages of flatness, credibility and security of the block chain.

Owner:NANJING UNIV

Anti-fold cloth feeding device for cloth spreading machine

InactiveCN106006163ASimple structureEasy to operateUnfolding thin materialsWebs handlingElectrostatic coatingMechanical engineering

The invention relates to an anti-wrinkle cloth feeding device of a spreading machine. The front end of the device is provided with a cloth pressing roller parallel to the cloth discharging roller. The two ends of the cloth pressing roller are embedded in the slider through bearings. The sliding block is slidingly matched with the chute arranged on the end of the cross bar of the frame, and a spring is arranged between the sliding block and the end of the chute; the cloth outlet roller and / or pressing roller are hollow rollers, and the hollow roller There are several ventilation holes evenly arranged on the wall, one end of the hollow roller is provided with a plugging head, and the other end of the hollow roller is connected to the steam source through an air pump and a pipeline; an antistatic coating is provided on the surface of the press roller, and the corresponding cloth passes through The cloth guide roller is driven by the cloth feed roller to convey to the tension roller, and is sent out from between the cloth outlet roller and the cloth pressure roller. The cloth adjusting device of the cloth spreader has the characteristics of relatively simple structure, convenient operation, smooth output cloth, can eliminate static electricity on the cloth surface, and is safe and reliable to use.

Owner:SHAGNHAI YIN SCI&TECH CO LTD

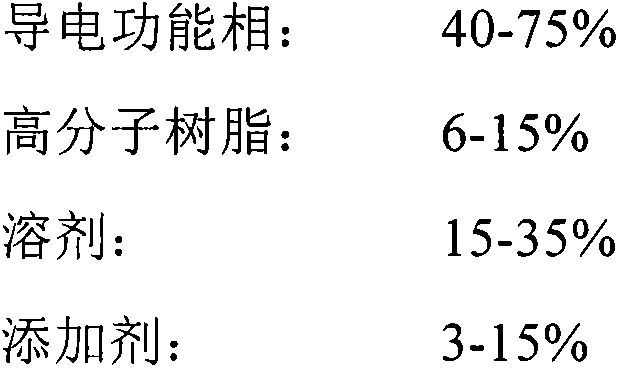

Special-purpose low temperature solidification silver migration resistance laser etching conductive silver paste for handset touch screen and preparation method thereof

InactiveCN106158065AStrong printabilityStable storageNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteLaser etching

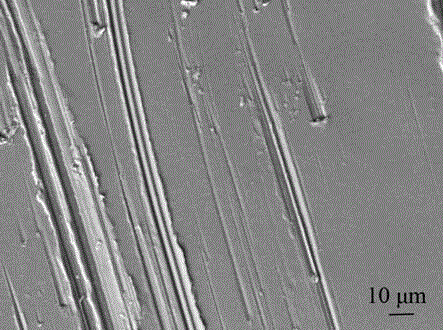

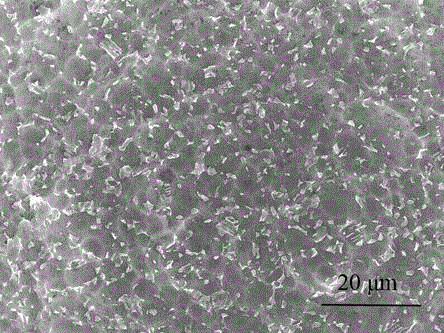

The invention relates to a special-purpose low temperature solidification silver migration resistance laser etching conductive silver paste for a handset touch screen and a preparation method thereof. The conductive silver paste mainly comprises silver powder content 40-75%, high-molecular carrier content 20-50% and additive content 3-15%. The preparation method of the conductive silver paste comprises steps of high-molecular resin carrier preparation, conductive silver paste preparation and conductive silver paste post-treatment. The conductive silver paste has excellent silver migration resistance capability, the silver migration rate under the wet environment is greatly reduced, the conductive silver paste has excellent laser etching performance, intelligible patterns with line-width / line-space of 30mum / 30mum can be acquired through etching, the silver paste has excellent adhesive force on PET, ITO films, ITO glass and common glass, pencil hardness is above 4H, a lowest block resistance value can reach 20mohm / square@1mil, and the silver paste has excellent compatibility with insulation oil ink and a peelable blue plastic protective layer. The conductive silver paste molded through sintering under the low temperature is advantaged in that production cost is low, energy resources are saved, and the conductive silver paste without halogen is further environmental friendly.

Owner:NANO TOP ELECTRONICS TECH

High-temperature ceramic pressure sensor for pressure test in high temperature environment and processing method thereof

ActiveCN103017945ARealize pressure measurementAvoid high temperature problemsFluid pressure measurement by electric/magnetic elementsForce measurementCapacitancePressure sense

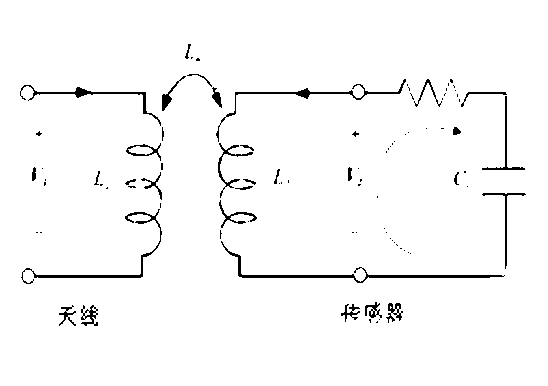

The invention relates to the field of a pressure sensor, particularly a high-temperature ceramic pressure sensor for a pressure test in a high temperature environment and a processing method of the high-temperature ceramic pressure sensor. The effective pressure test can be implemented in a special high temperature environment for a long time. The high-temperature ceramic pressure sensor comprises a pressure sensing ceramic element, wherein a closed chamber is arranged inside the pressure sensing ceramic element; the upper and lower planes of the pressure sensing ceramic element are respectively provided with an electrode layer and a planar spiral inductor; the two electrode layers form a capacitor; and the capacitor is connected in series with the two planar spiral inductors to form an LC loop. The processing steps are as follows: a, curtain coating; b, punching; c, stacking and filling; d, laminating and thermal cutting; e, high-temperature sintering; f, printing and low-temperature sintering; and g, cavity sealing. The sensor and the method disclosed by the invention can design and realize a concrete structure of sensitive elements of the sensor at a totally new angle; the structure is ingenious and reasonable; and a passive wireless high-temperature ceramic pressure sensor for the detection in a noncontact wireless manner based on an LC resonance theory is realized, so that the pressure test can be performed for a long time at a high temperature higher than 300 DEG C.

Owner:ZHONGBEI UNIV

Electrochemical polishing electrolyte and polishing method for titanium and titanium alloy

The invention discloses an electrochemical polishing electrolyte and polishing method for titanium and a titanium alloy. The electrolyte comprises, by mass percentage, 10%-90% of corrodent, 1%-5% of an additive, 1%-5% of a polynitrogen compound and the balance water. The electrochemical polishing method comprises the following steps of pretreatment, surface oil removal and acid pickling treatment, electrolyte compounding, electrochemical polishing treatment and aftertreatment. The electrochemical polishing electrolyte is simple in formula, stable in performance, long in service life, low in price and capable of being used cyclically for multiple times; reaction conditions such as the low temperature or the relatively high voltage or the large current are not needed; and the electrochemical polishing electrolyte is more suitable for large-scale industrialized production. The surface reflectivity of a finished workpiece obtained through the electrochemical polishing method ranges from 70% to 95%, and surface roughness Ra is smaller than 0.05 micron.

Owner:DABO MEDICAL TECH CO LTD +1

Method for preparing backside-polished PERC battery

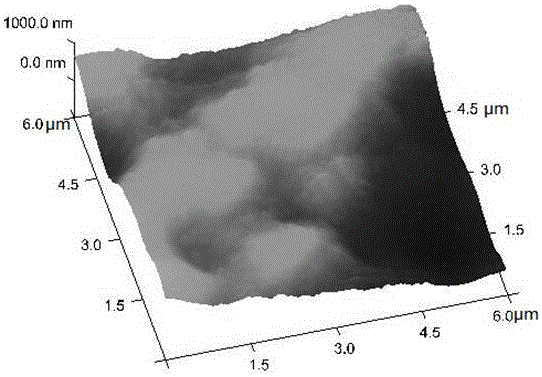

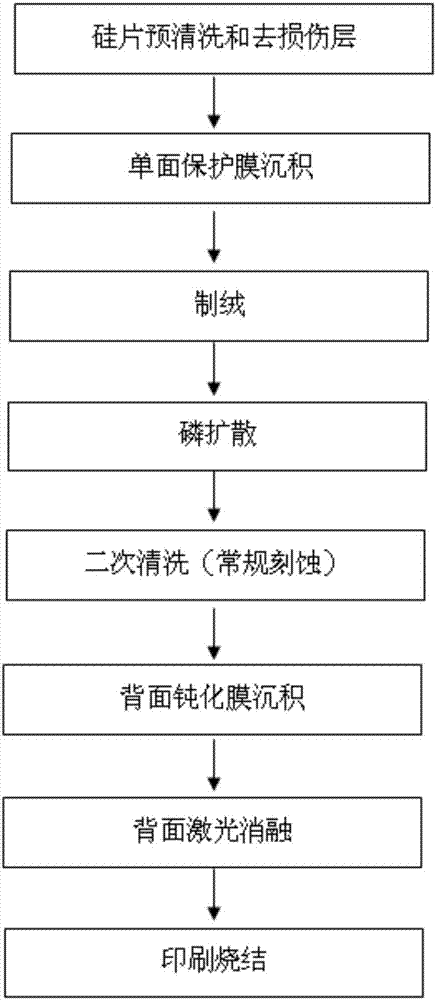

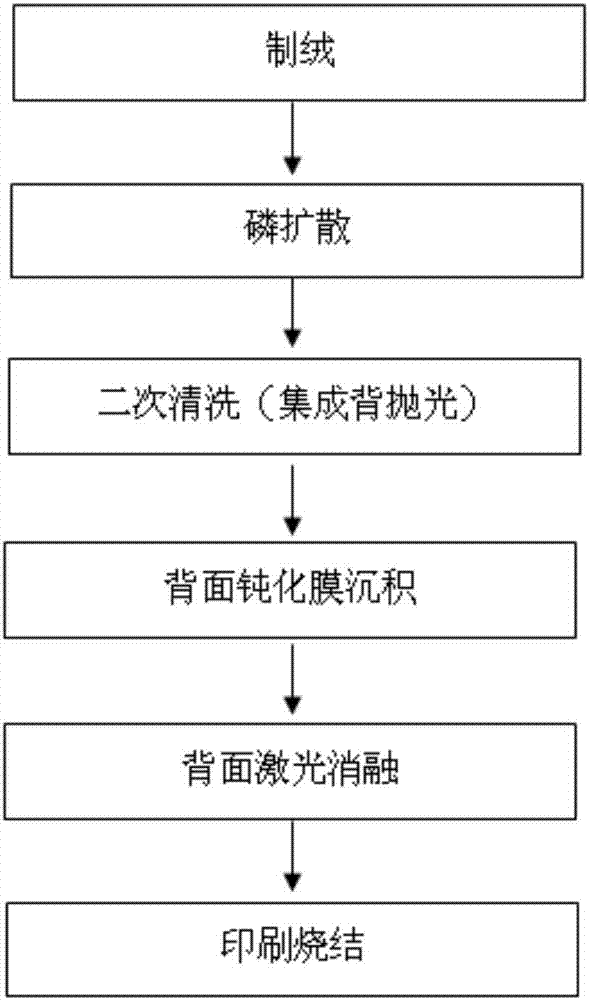

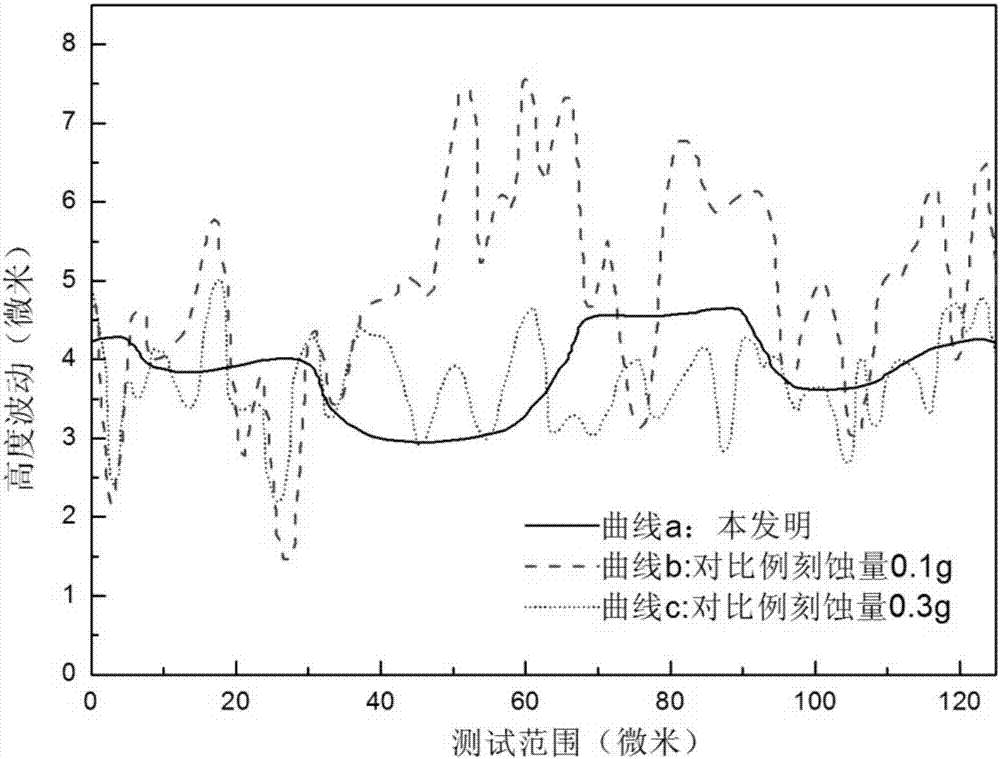

InactiveCN107123702ASmall amount of thinningAchieve flatnessFinal product manufacturePhotovoltaic energy generationMicro nanoScreen printing

The invention discloses a method for preparing a backside-polished PERC battery. The method comprises: (1), depositing a single-sided protective film on the backside of a silicon wafer; (2) carrying out texturing on the silicon wafer plated with the single-sided protective film and removing the single-sided protective film of the silicon wafer during a pickling process after texturing; (3), carrying out diffusion on the single-sided-textured silicon wafer; (4), carrying out conventional secondary cleaning; and (5), depositing aluminium oxide / silicon nitride laminated passivation film at the back side, carrying out laser grooving, screen printing and sintering, thereby obtaining a backside-polished PERC battery. According to the method disclosed by the invention, the volume production threshold is low; the operation cost is low; micro-nano flatness is realized; and the photoelectric conversion of the battery is improved.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

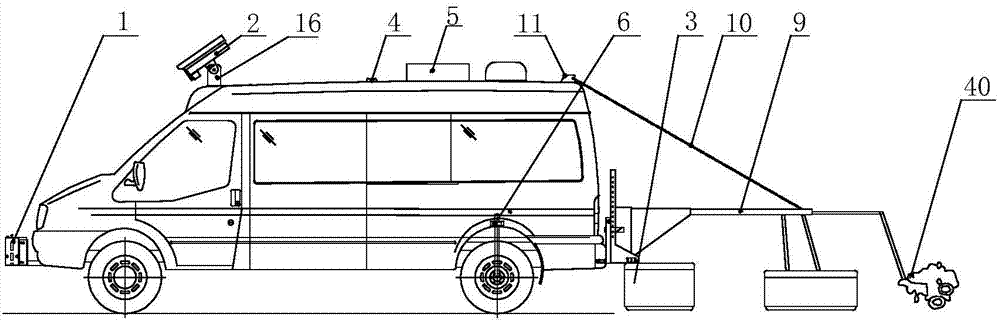

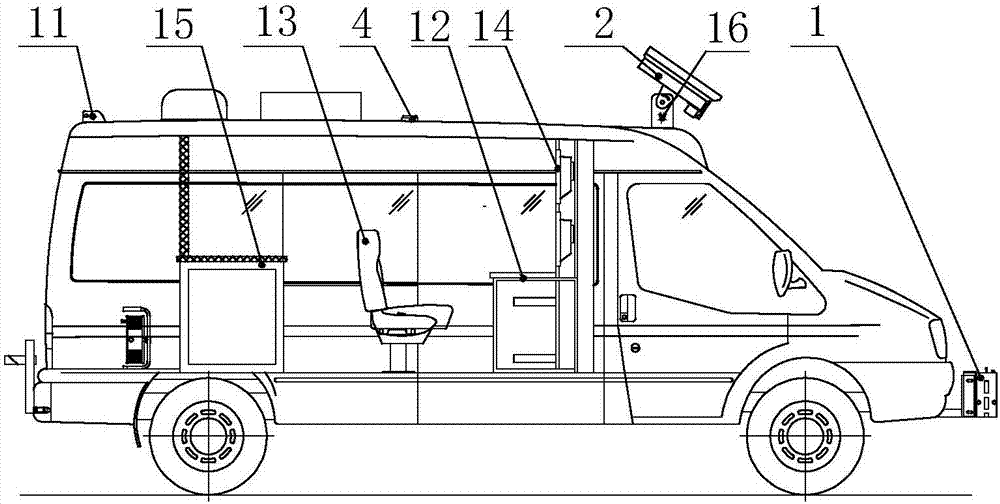

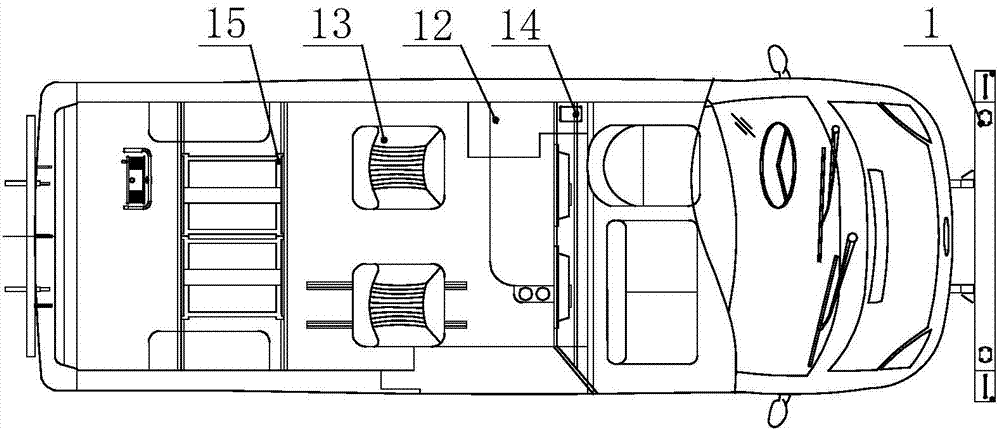

Multifunctional road CT comprehensive inspection vehicle

ActiveCN107059579AAchieve flatnessVersatile and versatileRoads maintainenceIlluminanceVisual inspection

The invention relates to the field of road detection equipment and provides a multifunctional road CT comprehensive inspection vehicle. A road CT comprehensive inspection system which integrates road surface visual inspection, laser inspection, ground penetrating radar inspection, illuminance inspection and friction coefficient inspection can be built. According to the technical scheme, the multifunctional road CT comprehensive inspection vehicle comprises a vehicle body and the inspection system carried on the vehicle body. The inspection system comprises a multifunctional laser profiler on the lower portion of the front end of the vehicle body, a road surface damage inspection camera on the upper portion of the front end of the vehicle body, a ground penetrating radar on the lower portion of the rear end of the vehicle body, a friction coefficient test device at the rear end of the vehicle body, a GPS antenna and an illuminance sensor which are arranged on the top of the vehicle body, and a rotary encoder disposed on the vehicle body. The road surface damage inspection camera inclines downwards to the front portion of the vehicle body. By means of the vehicle, nondestructive, efficient and continuous inspection can be achieved.

Owner:重庆亲禾智千科技有限公司

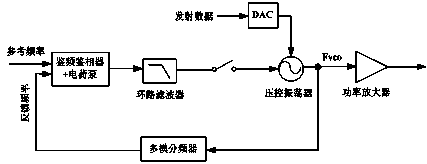

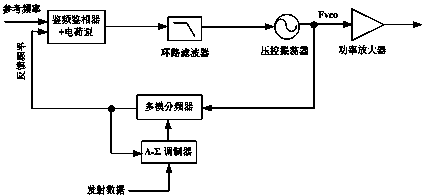

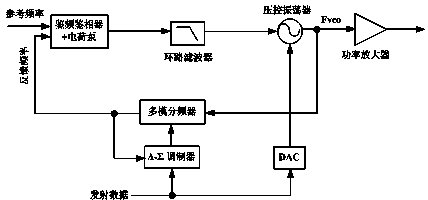

Two-point wireless transmitter and frequency offset correcting method thereof

InactiveCN104242961AReduce noise interferenceAchieve flatnessAngle modulation detailsTransmissionMicrocontrollerEngineering

The invention discloses a two-point wireless transmitter and a frequency offset correcting method of the two-point wireless transmitter. Improvement is conducted based on a circuit structure of a traditional two-point transmitter, and frequency offset correction is achieved by conducting data interaction by means of two wireless communication chips which have the complete functional design and are successfully taped out. During implementation, the two chips are respectively provided with a microcontroller, a register, a transmitting module, a receiving module, an antenna and a change-over switch; transmitted data are input to the wireless transmitter through two paths, one path of data are input to a voltage-controlled oscillator through a branch switch S2 of the first chip and a DAC to be transmitted in an out-band mode, and the other path of data are input to a multi-mode frequency divider through a branch switch S1 of the first chip and a delta-sigma modulator for modulation and frequency division and then are transmitted in an in-band mode. According to the two-point wireless transmitter and the frequency offset correcting method of the two-point wireless transmitter, through the data interaction between the two chips and software processing of the microcontroller of the first chip, the frequency offset of the transmitted data can be corrected effectively, and high-quality smooth transmission of data is achieved; the two-point wireless transmitter and the frequency offset correcting method of the two-point wireless transmitter have the advantages that energy consumption is low, the number of hardware resources is small, cost is low and stability is high.

Owner:SHANGHAI PANCHIP MICROELECTRONICS CO LTD

Differential spirally-wound type mirror surface polishing process and polishing equipment for metal zipper

ActiveCN101837561AReduce sharpness of sharp cornersDelicate feelEdge grinding machinesBelt grinding machinesSurface finishPolishing

The invention discloses a differential spirally-wound type mirror surface polishing process for a metal zipper, relating to the technical field of zippers. The zipper tooth surface of the metal zipper and a flexible abrasive band form surface contact; the zipper and the flexible abrasive band advance at uniform speed or variable speed and form a smoothly-advanced speed difference; a coarse surface layer of the zipper is cut and removed by the flexible abrasive band; the surface finish, the planeness and the dimensional tolerance of the zipper can be realized after plane polishing points with different thicknesses and polishing allowances are formed at various specific positions; and when Ra is less than 0.8, the surface of the zipper starts to show centralized light reflection similar to the mirror surface, and the centralized light reflection is vividly compared with the diffuse reflection of the traditional polishing process, so that remarkable qualities of high precision in size and high finish in the appearance of the metal zipper are improved.

Owner:JIANGSU CMZ ZIPPER SCI & TECH CO LTD

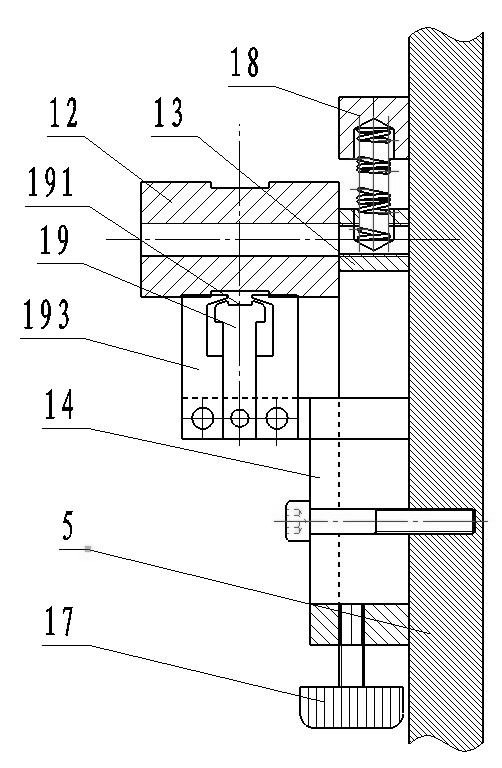

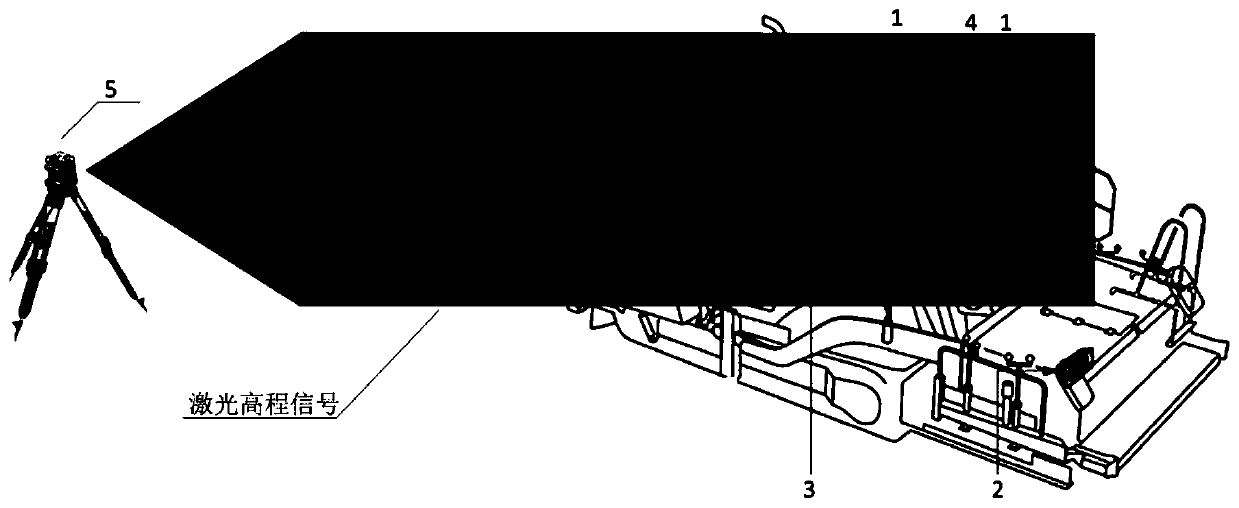

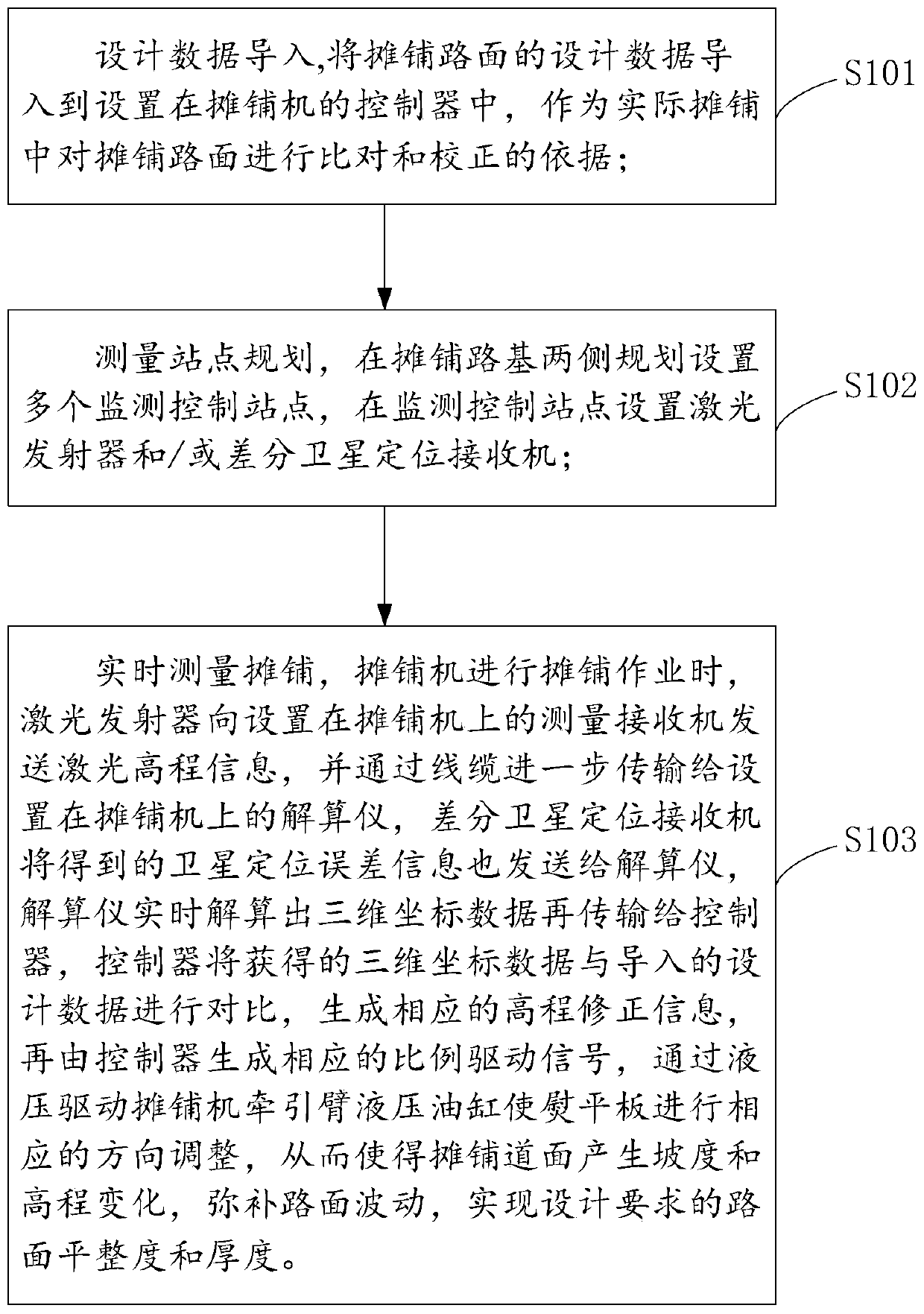

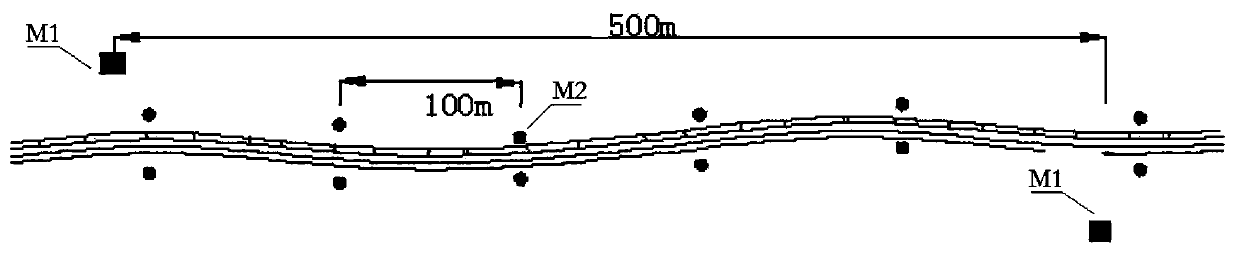

Automatic paving method based on laser scanning and satellite positioning

InactiveCN110983925AMake up for fluctuationsAchieve flatnessRoads maintainenceLaser transmitterAutomatic control

The invention discloses an automatic paving method based on laser scanning and satellite positioning. The method comprises the following steps: importing design data: importing the design data of a paving pavement into a controller of a paver, and taking the design data as a basis for the comparison and correction of the paving pavement in actual paving; planning measurement stations: planning a plurality of monitoring control stations at two sides of a paving roadbed, and arranging laser emitters and / or differential satellite positioning receivers at the monitoring control stations; and performing real-time measurement paving: when the paver is used for paving operation, sending information to a resolver by the laser emitters and the differential satellite positioning receivers, transmiting the information to the controller by the resolver, and adjusting the direction of a screed correspondingly by the controller, so that the paving pavement generates gradient and elevation changes, pavement fluctuation is made up, and the pavement flatness and thickness required by design are achieved. The automatic control level of pavement paving is improved, the control precision is high, andmulti-machine joint paving is realized.

Owner:HENAN HIGHWAY ENG GROUP

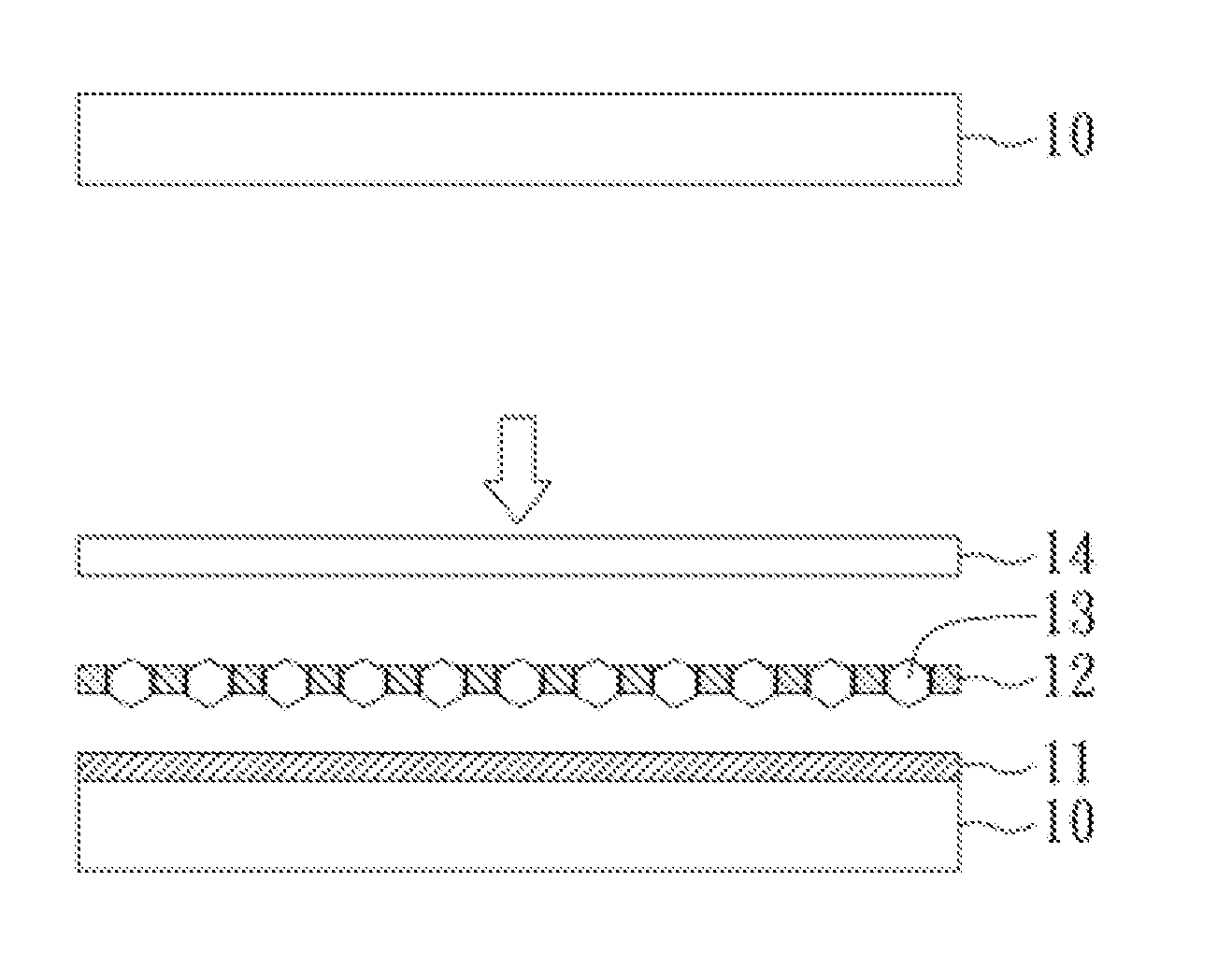

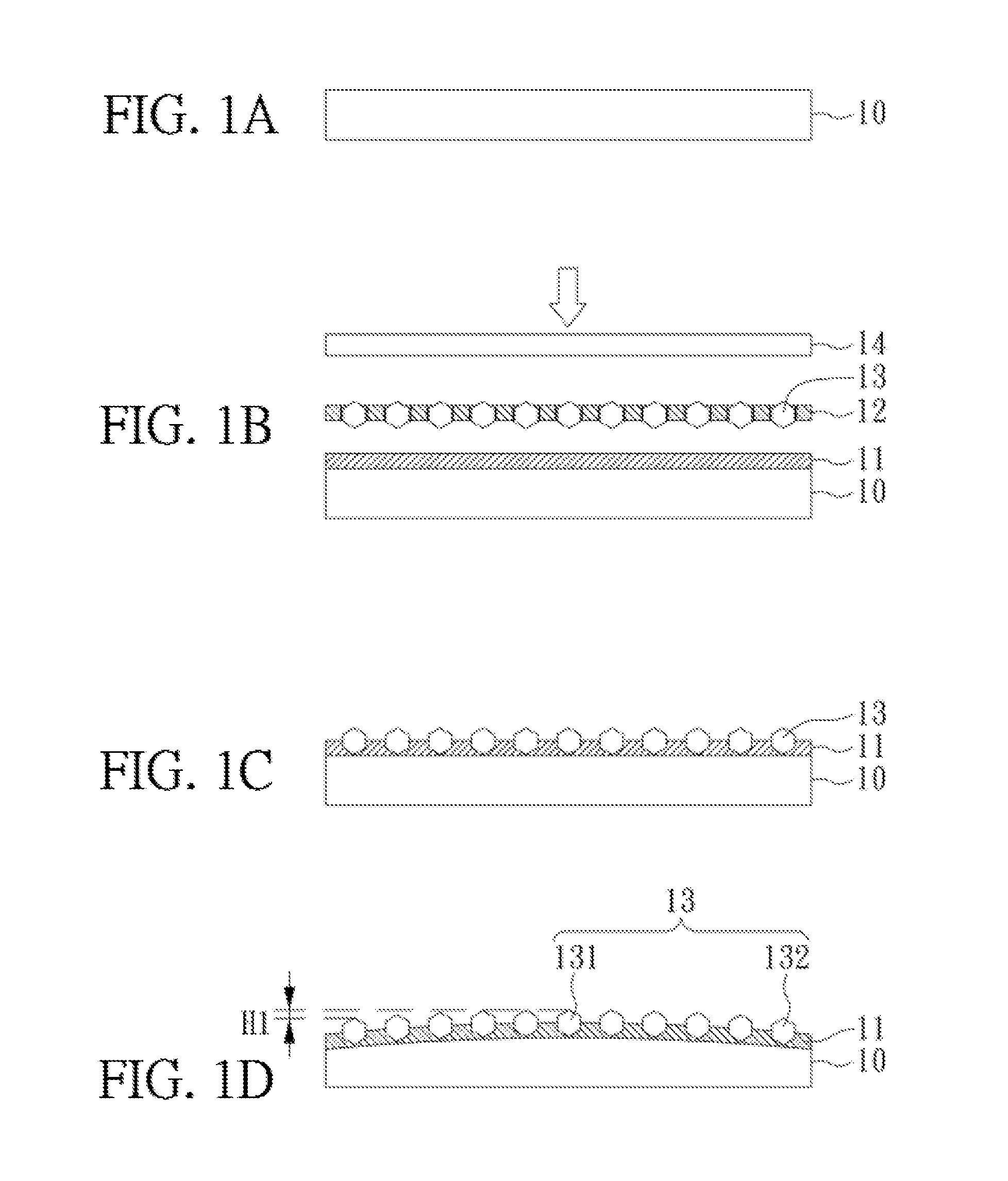

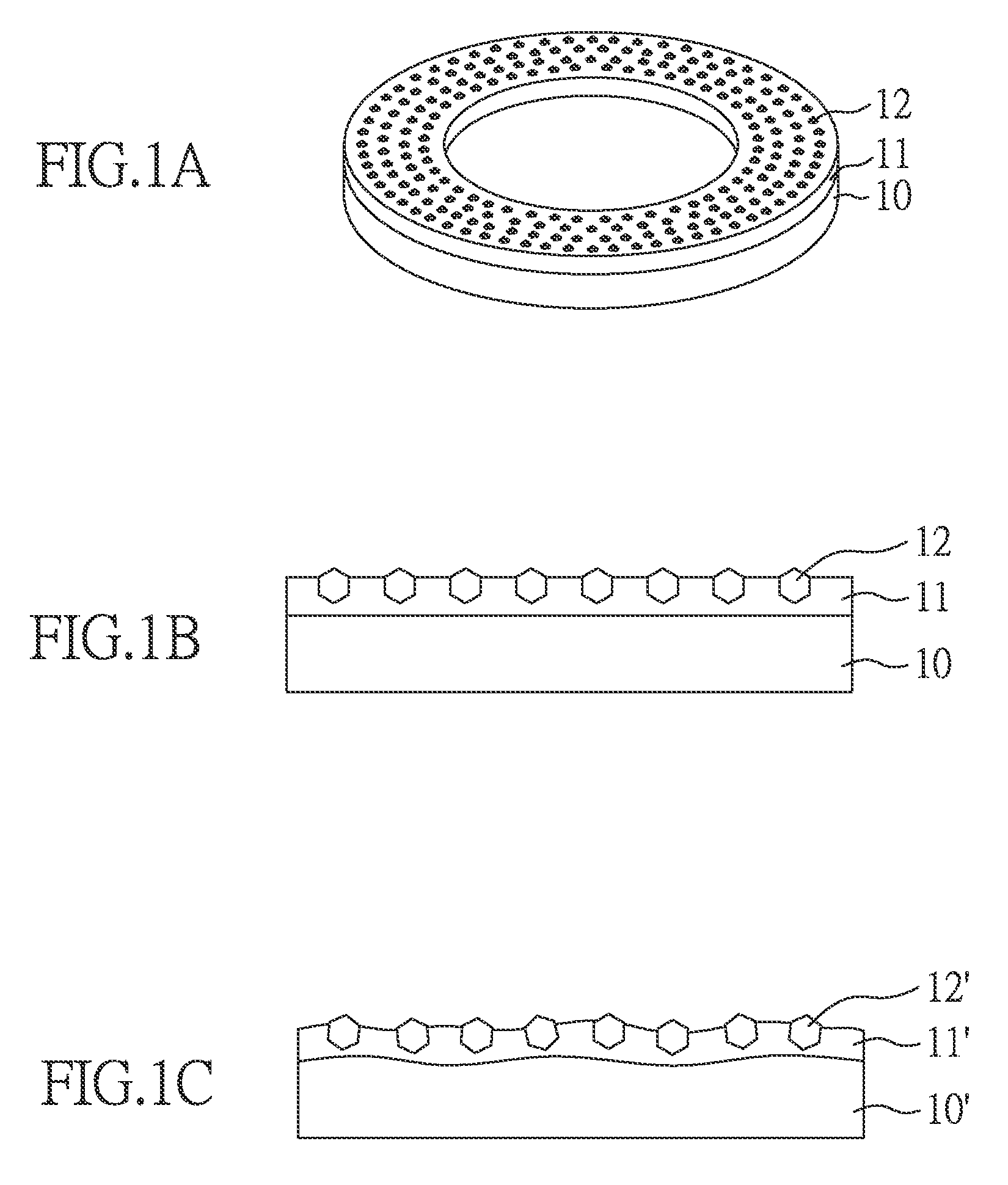

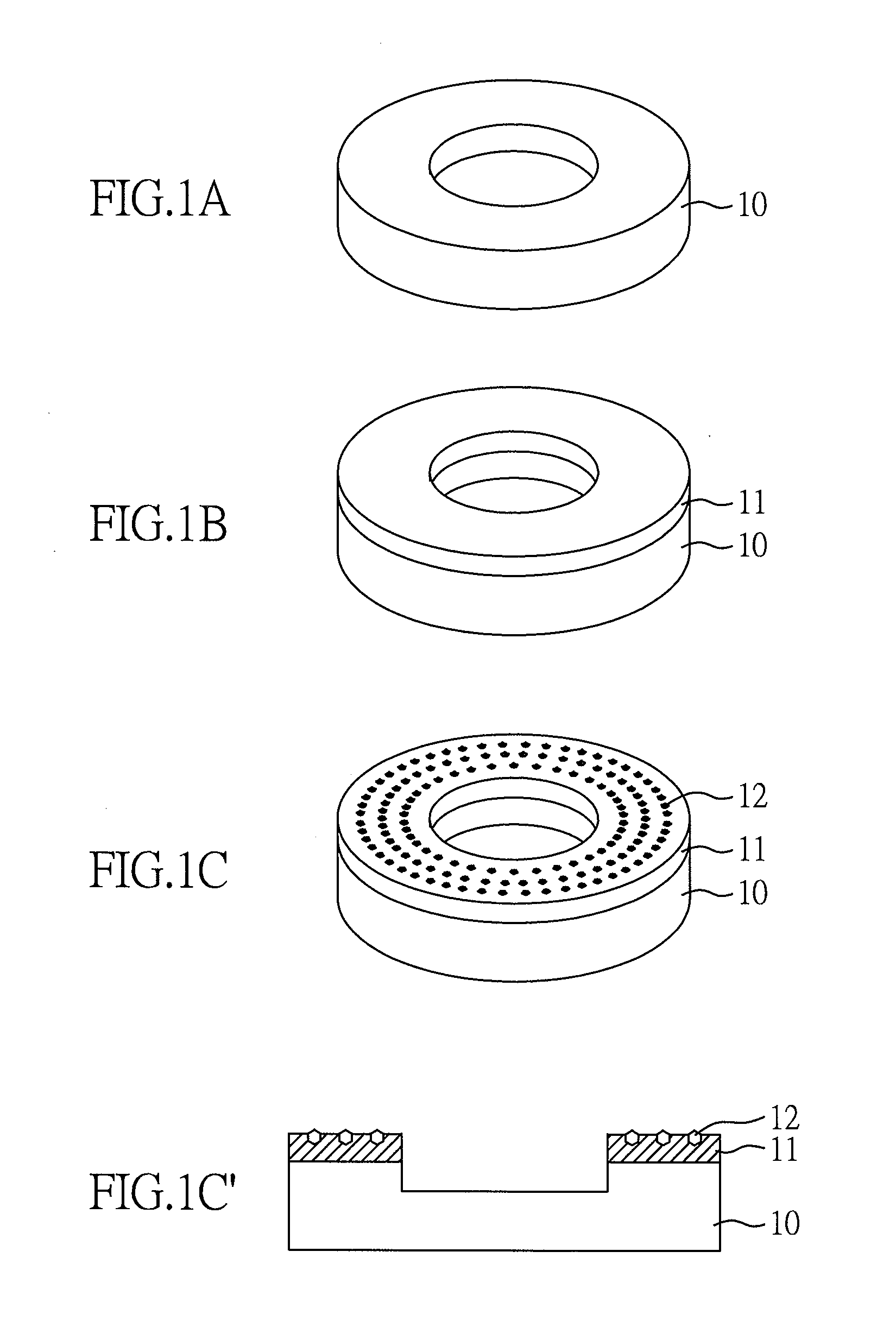

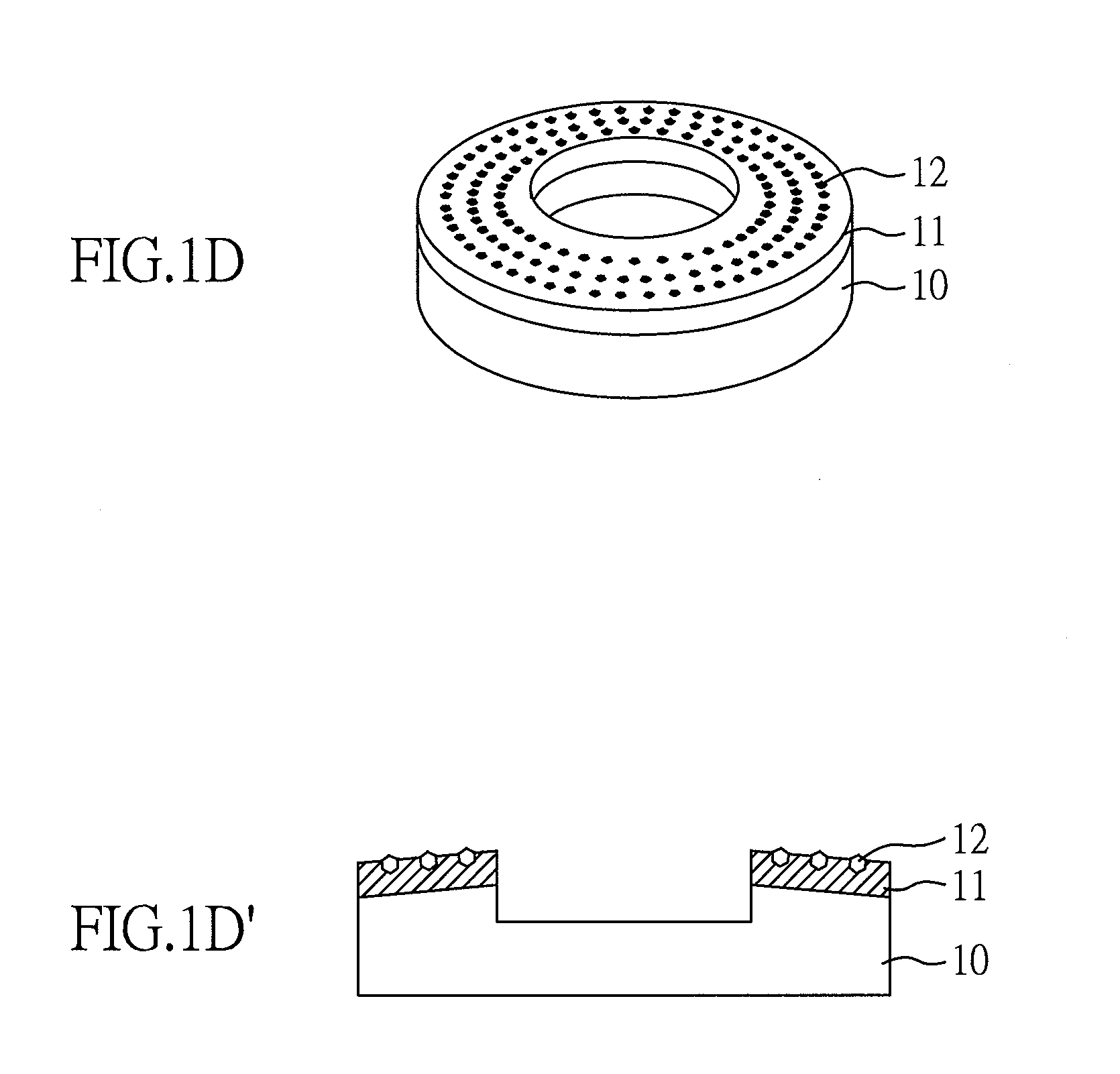

Chemical mechanical polishing conditioner and manufacturing methods thereof

ActiveUS20140127983A1Improve polishing efficiencyExtended service lifePigmenting treatmentOther chemical processesPlanar substrateThermal deformation

The present invention relates to a method for manufacturing a chemical mechanical polishing conditioner, comprising: (A) providing a non-planar substrate; (B) providing a binding layer disposed on the surface of the non-planar substrate; (C) providing a plurality of abrasive particles embedded in a surface of the binding layer, and (D) heat curing the binding layer, such that the non-planar substrate is deformed into a planar substrate during curing the binding layer, and the abrasive particles are fixed to a surface of the planar substrate by the binding layer; wherein, after step (D), tips of the abrasive particles have a leveled height. Therefore, the present can effectively improve the problem of thermal deformation of the substrate of the chemical mechanical polishing conditioner during a heat curing process, and enhance surface flatness of the chemical mechanical polishing conditioner.

Owner:KINIK

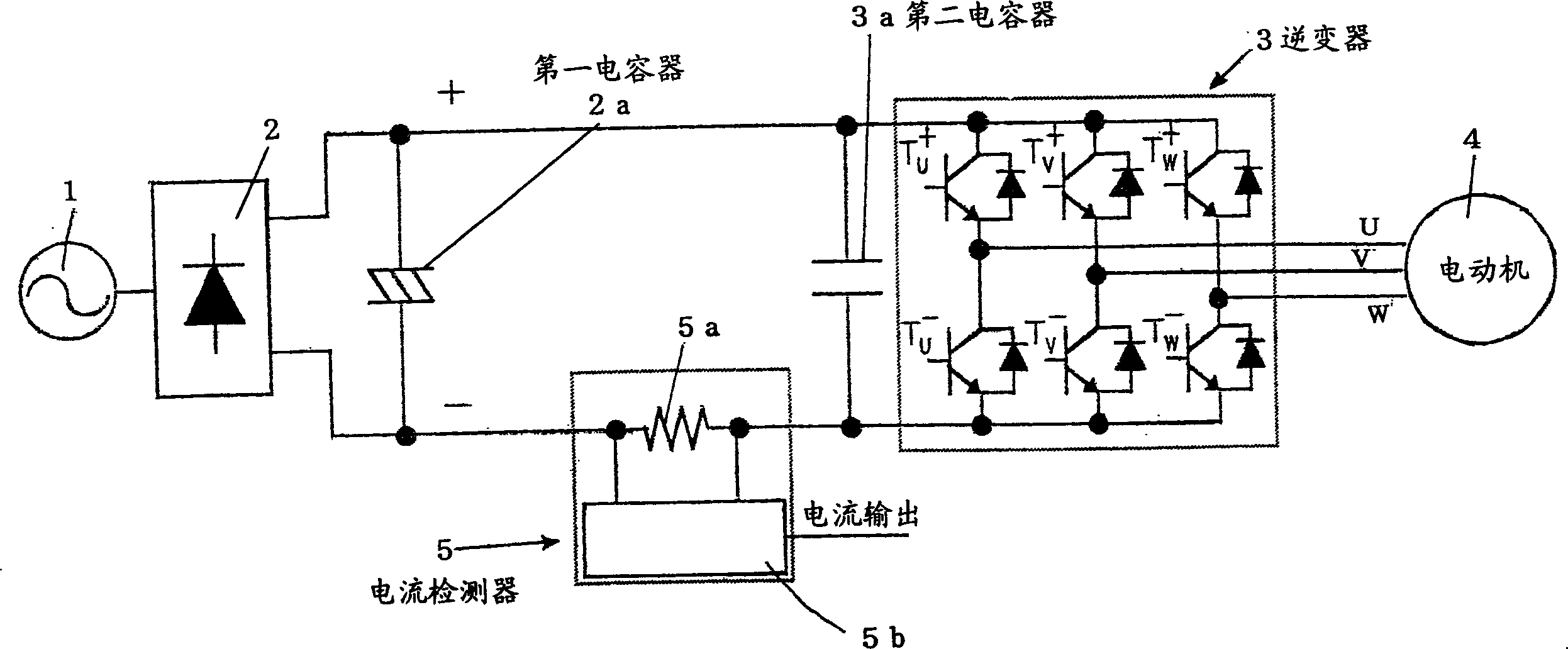

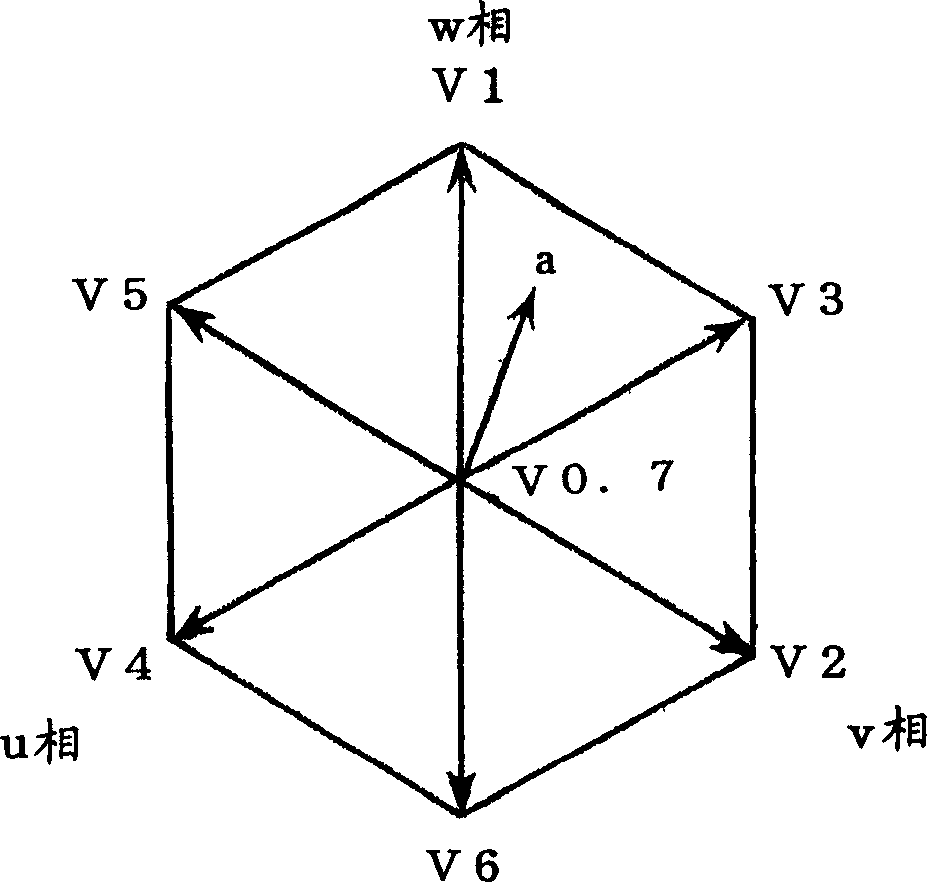

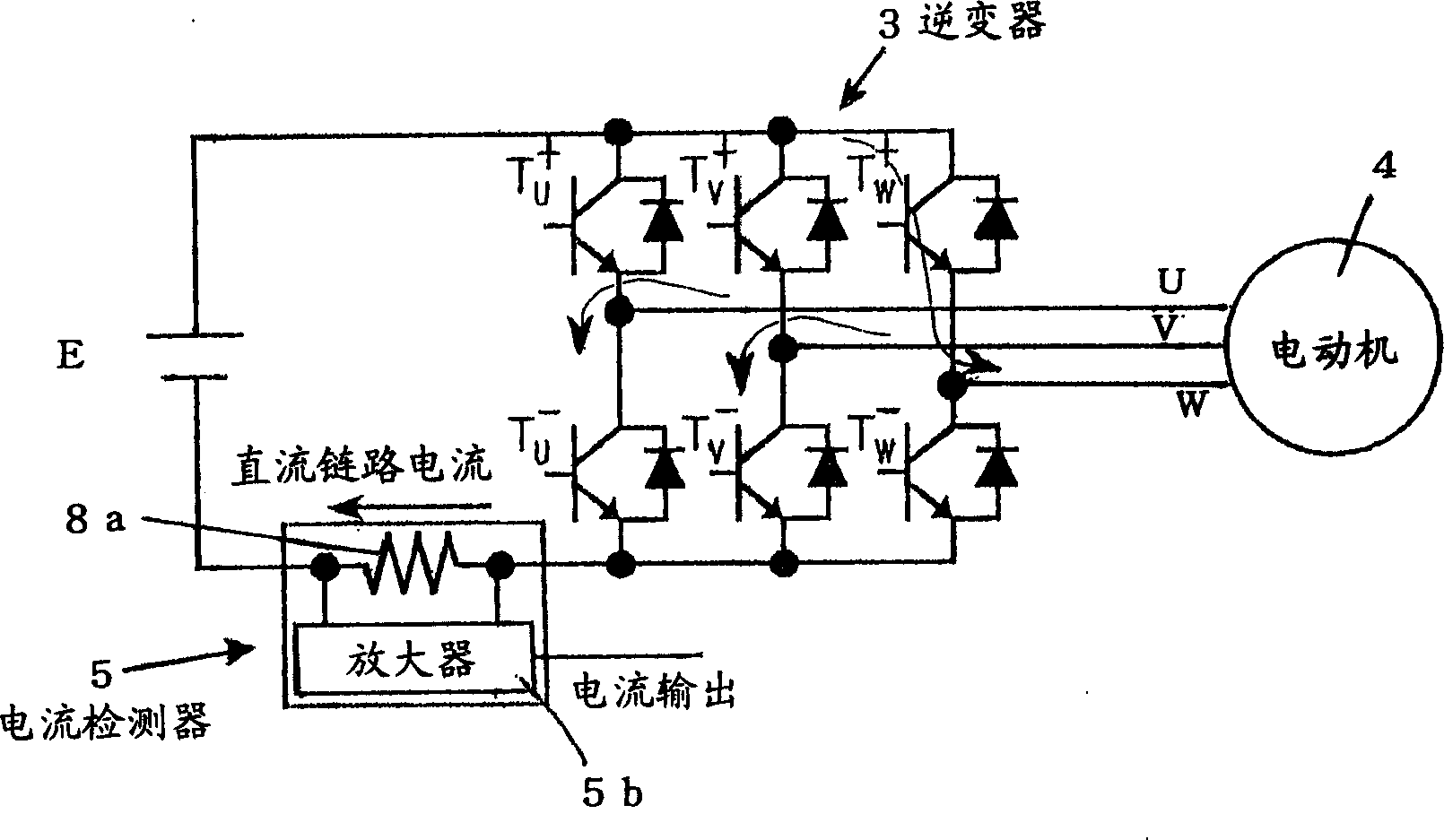

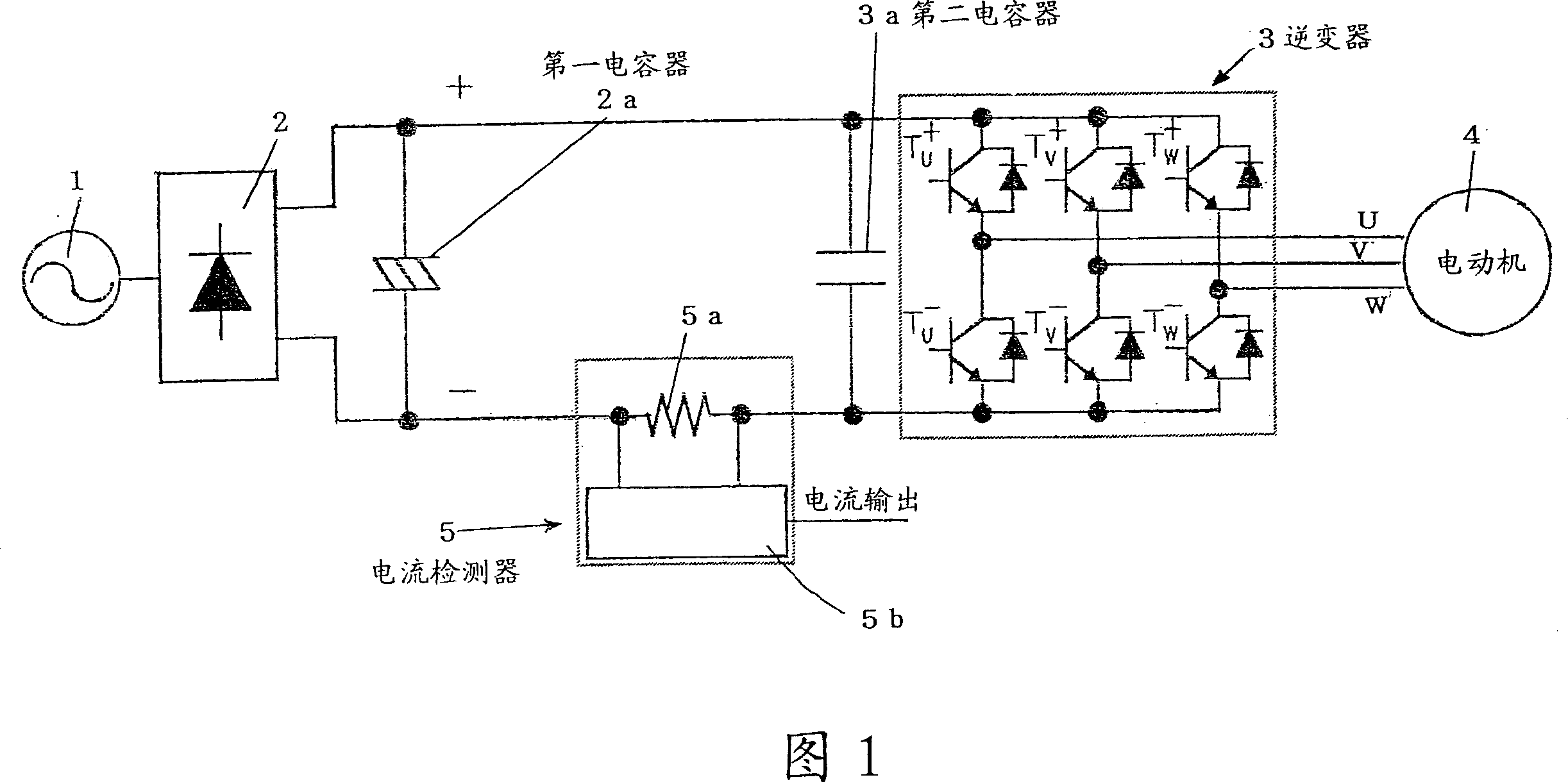

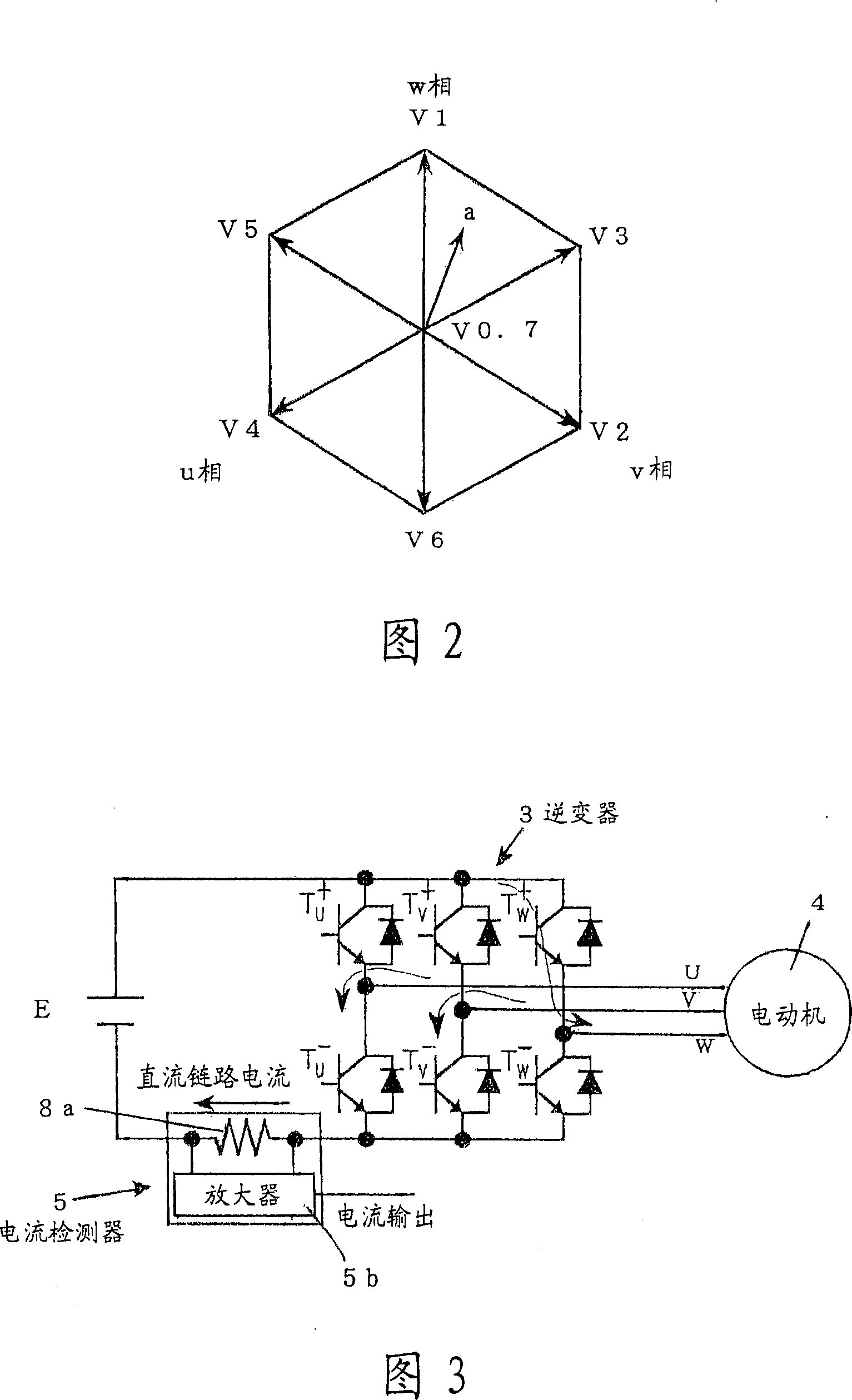

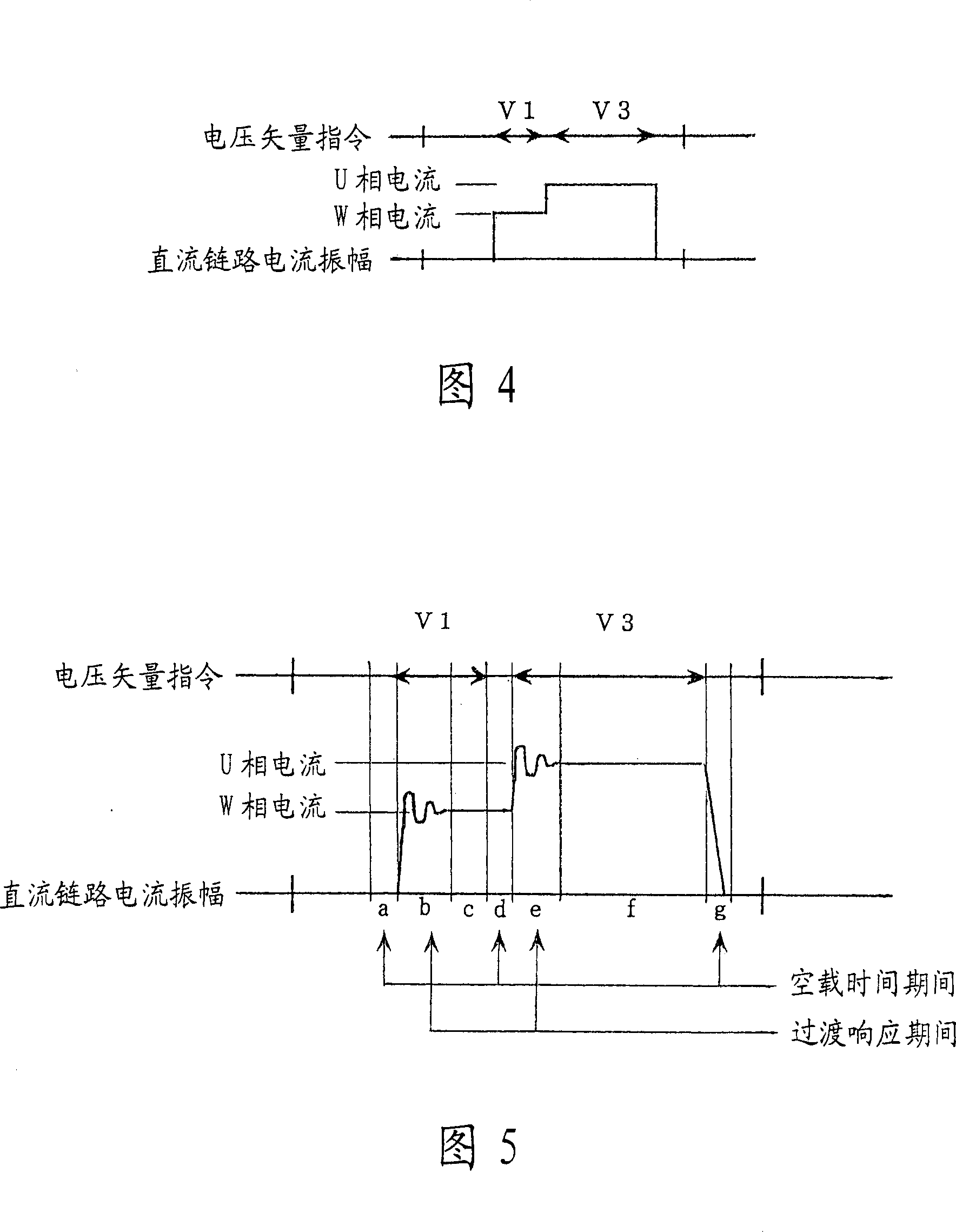

Phase current detector

InactiveCN1478319AReduce overshootReduce the effects of ringingElectronic commutation motor controlVector control systemsPhase currentsCapacitance

A first condenser (2a) is connected between output terminals of a rectifier circuit (2) which receives an AC power (1) as an input, and a three phase inverter (3) is connected in parallel with respect to the first condenser (2a), and output of the three phase inverter (3) is supplied to a motor (4), and a second condenser (3a) is connected in parallel to the input side of the three phase inverter (3), and a current detector (5) is connected between the first condenser (2a) and the second condenser (3a), and a third condenser is connected in parallel to the first condenser (2a) at a position slightly power side with respect to the current detector (5), and the capacitance of the second condenser (3a) is determined as small as possible within the range in which power devices are not destroyed by surge voltage due to switching, therefore, ringing is suppressed, and taking of current is performed rapidly and with high accuracy.

Owner:DAIKIN IND LTD

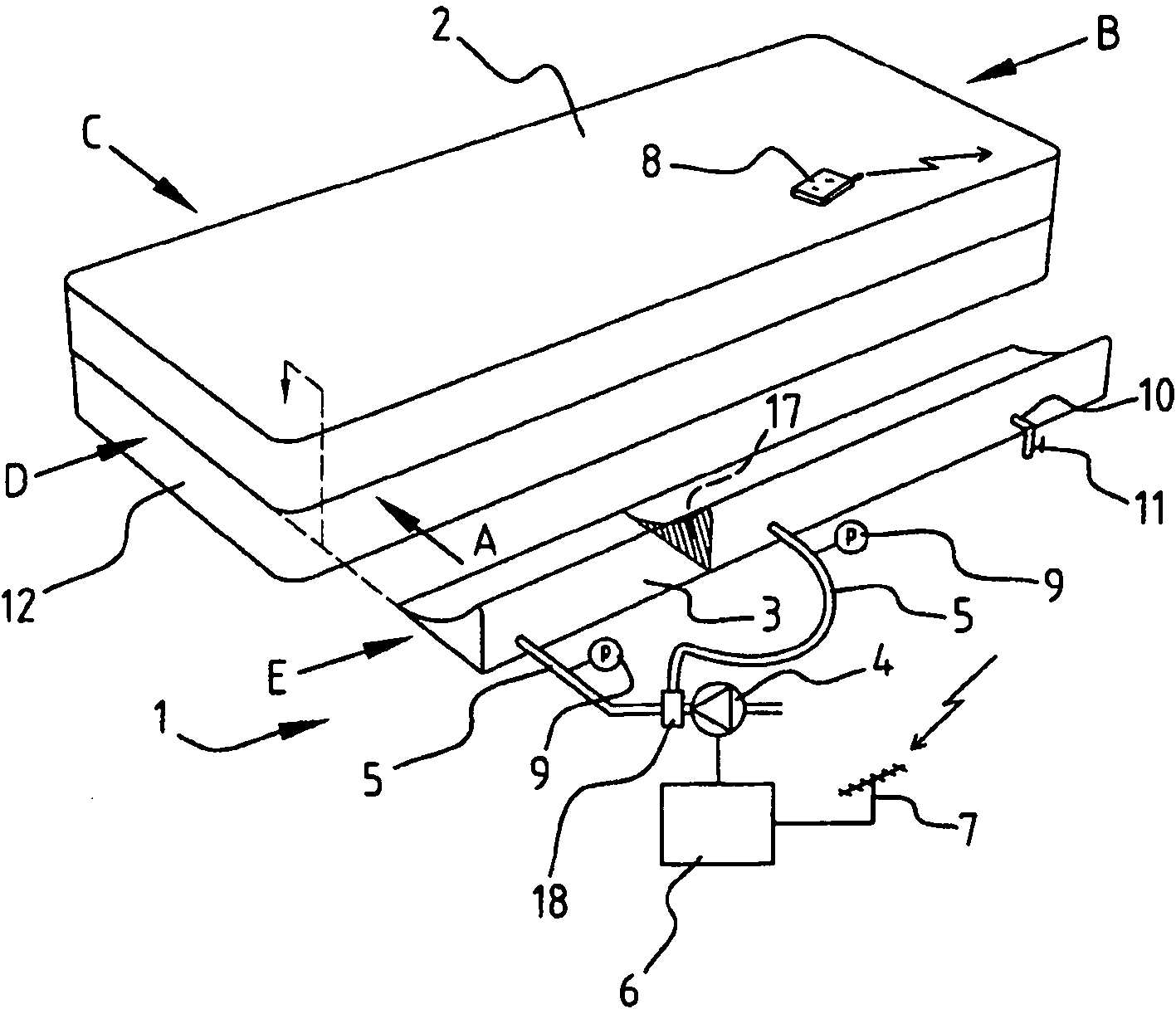

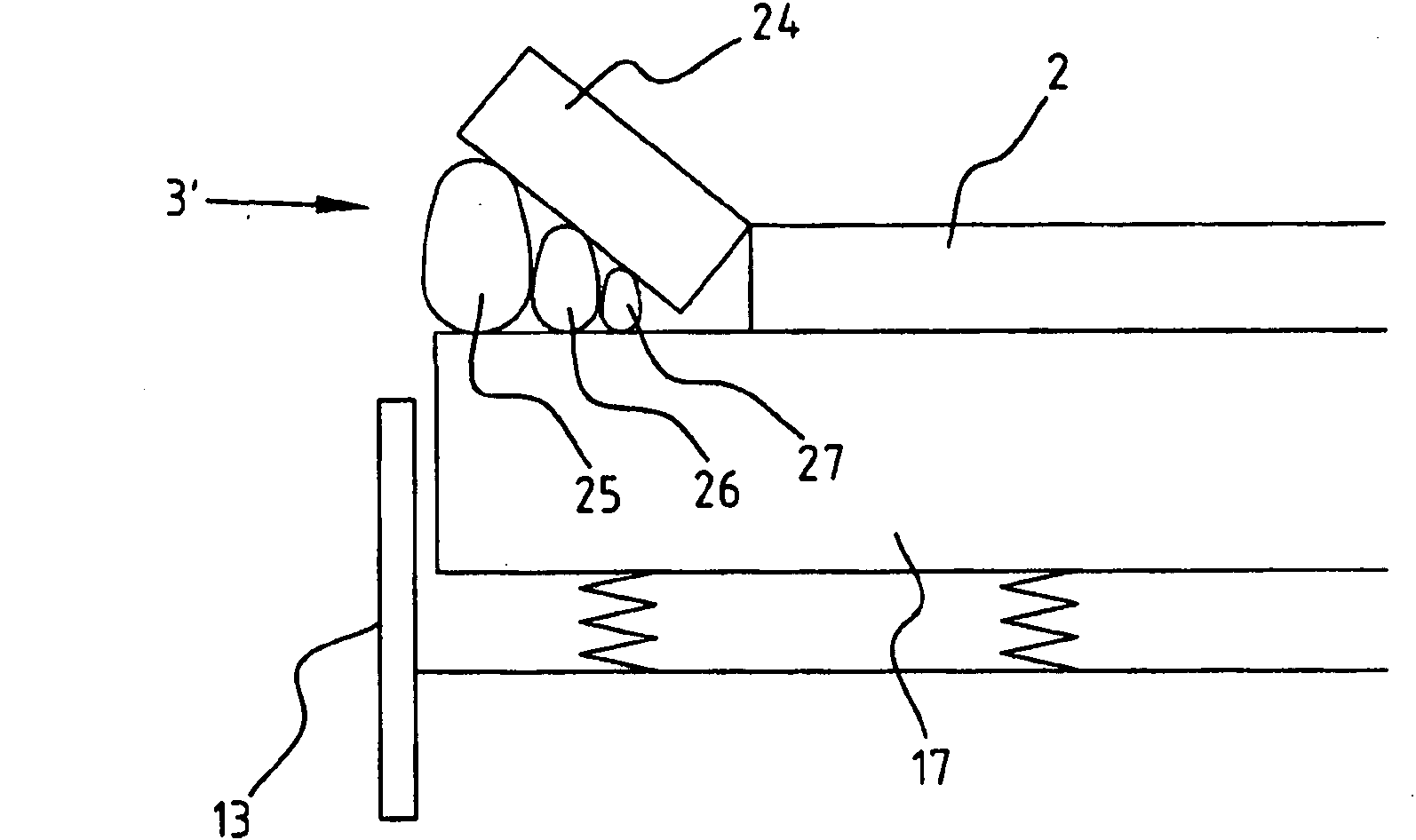

Assembly for adapting a support surface in a wave shape

InactiveCN102014700AAvoid hidden dangersSmooth mutual rocking motionSofasBedsWave shapeBiomedical engineering

The present invention relates to an assembly, comprising an element defining a lying or support surface, such as a foam layer forming a core of a mattress, and a device associated with the element for adapting the form of the lying or support surface in waves, wherein the device comprises at least one selectively expandable and / or compressible body. The body is further embedded in or arranged under a part of the element which is lower-lying during use and has above it at least a greater part of the thickness of the element. The body acts on a wave part of the element so as to selectively bring about waves in the lying or support surface, which wave part is connected via a hinged configuration to other parts of the element.

Owner:约翰尼斯·科内利斯·玛丽亚·内杰斯

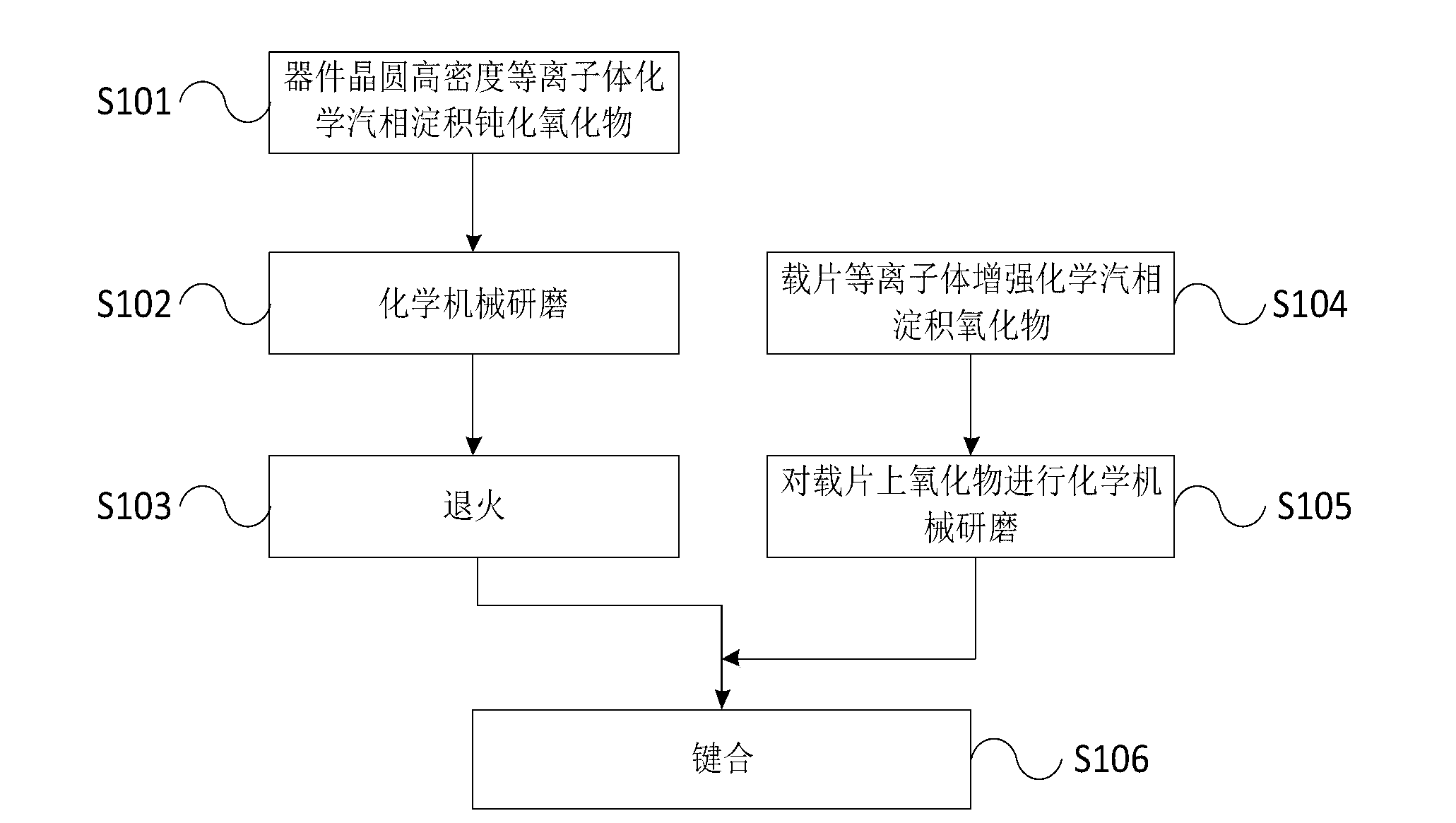

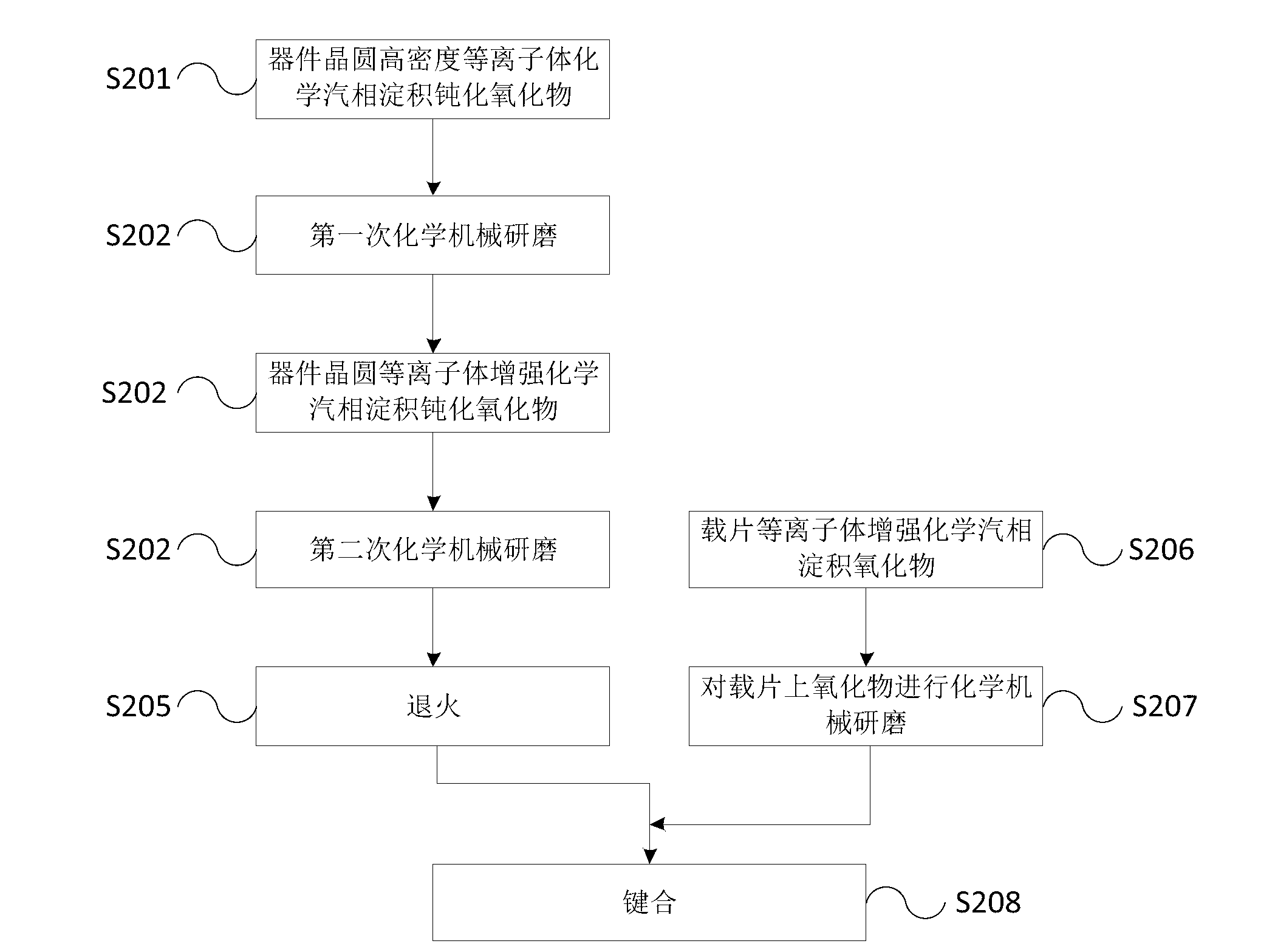

Image sensor wafer bonding method

ActiveCN103065945AAchieve flatnessSolve voidSemiconductor/solid-state device manufacturingHigh densityGas phase

The invention relates to the field of semiconductor manufacturing, in particular to an image sensor wafer bonding method. The image sensor wafer bonding method includes a first step of utilizing the high-density plasma chemistry vapor deposition technique to deposit passivation layer oxide on a device wafer, a second step of carrying out a first chemical mechanical lapping to the device wafer with the deposited passivation layer oxide, a third step of depositing the passivation layer oxide again on the original oxide of the device wafer through adoption of the plasma chemistry vapor deposition technique, a fourth step of carrying out a second chemical mechanical lapping to the device wafer, a fifth step of carrying out annealing treatment to the device wafer after the second chemical mechanical lapping, and a sixth step of bonding the treated device wafer and a ground slide which is subjected to the plasma enhanced chemistry vapor deposition oxide treatment and the chemical mechanical lapping. The image sensor wafer bonding method has the advantages that the plasma enhanced chemistry vapor deposition and the second chemical mechanical lapping are added to the device wafer after the original first chemical mechanical lapping, and consequently the plainness of the surface of the wafer is more effectively achieved, and the problem that holes are likely to generate after bonding is solved.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

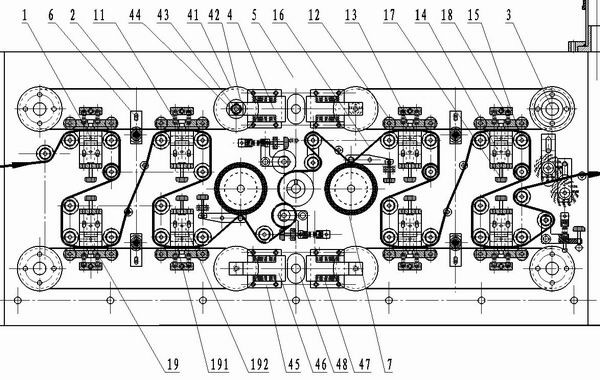

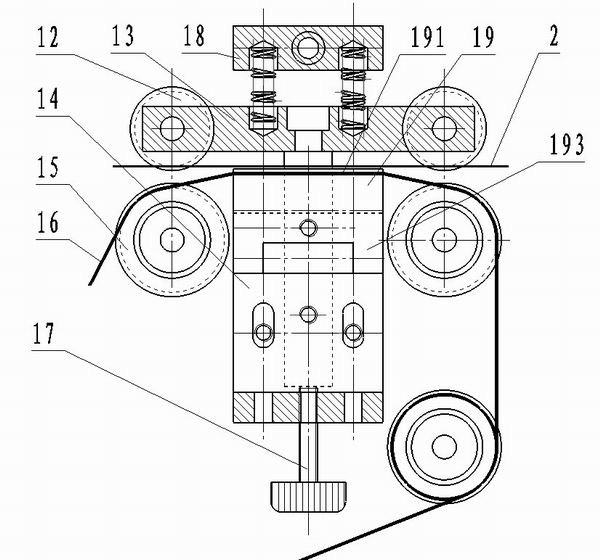

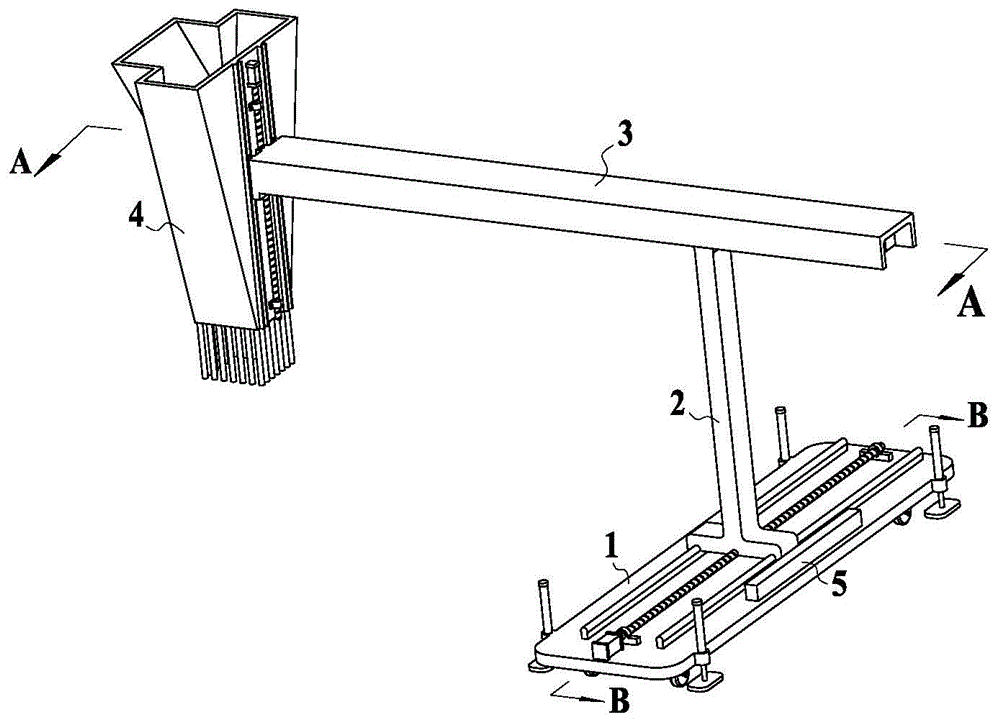

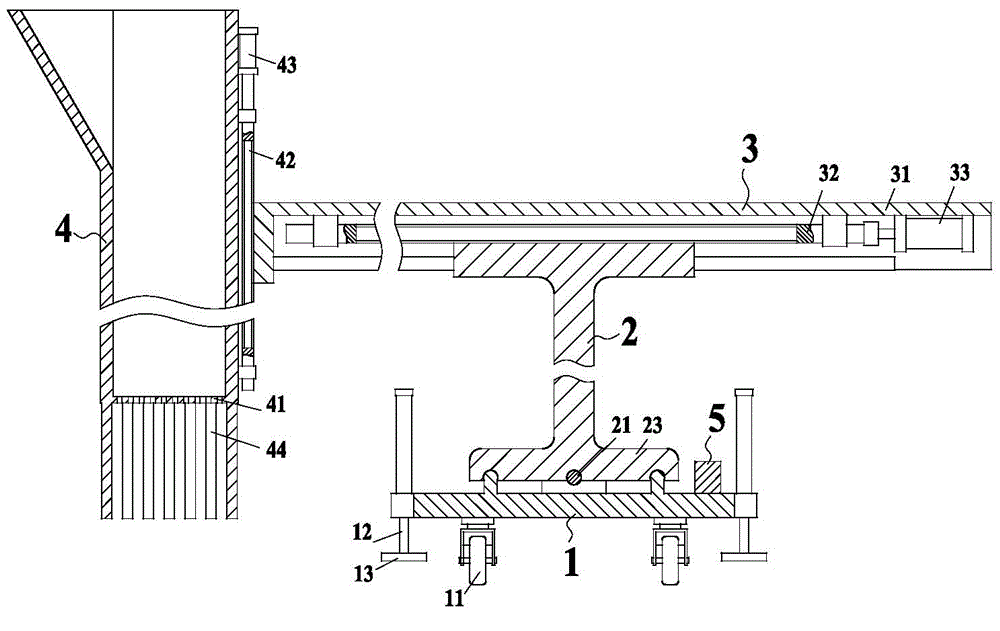

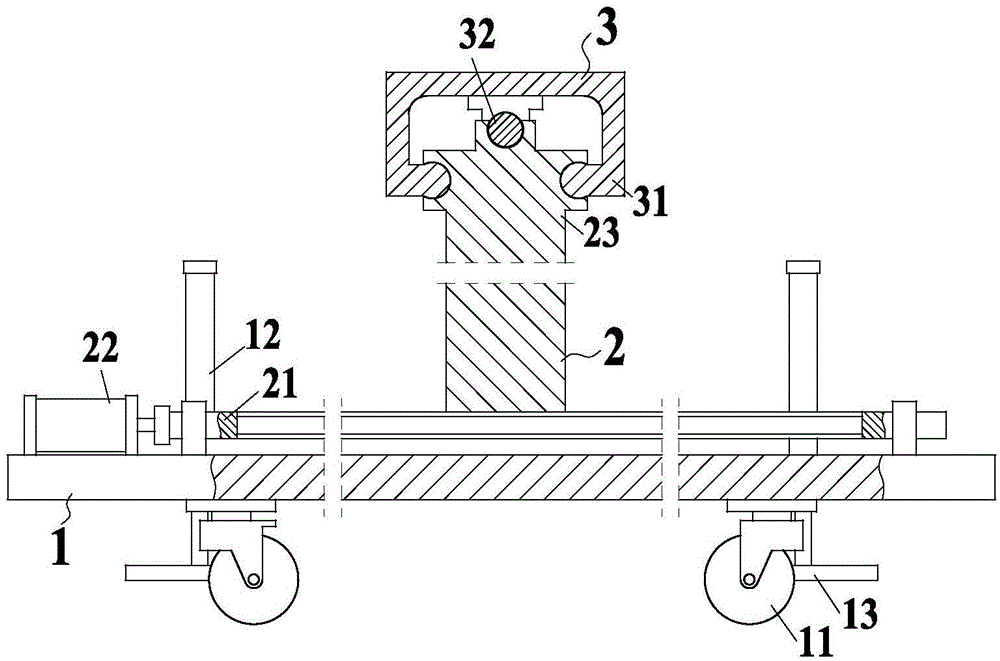

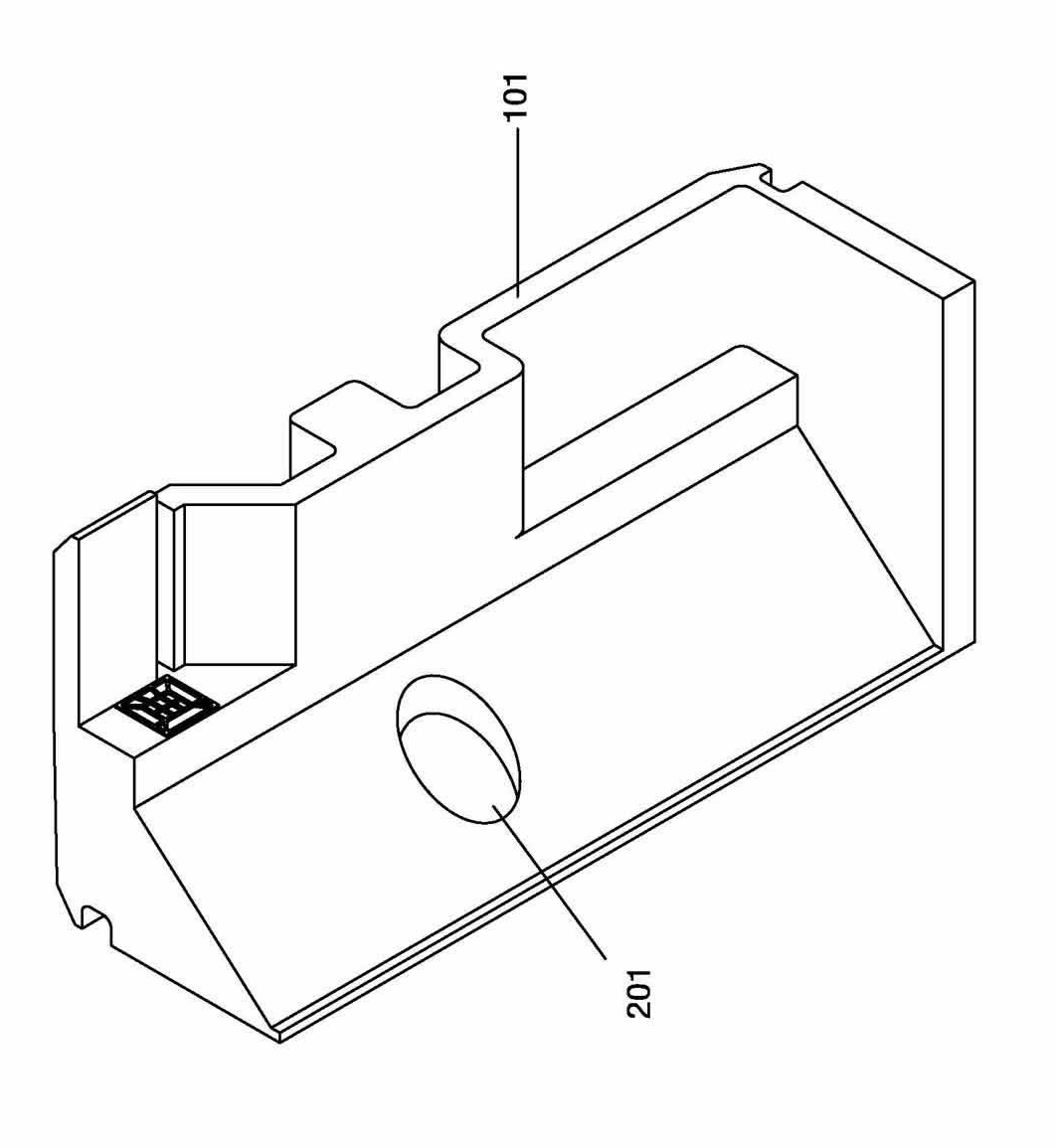

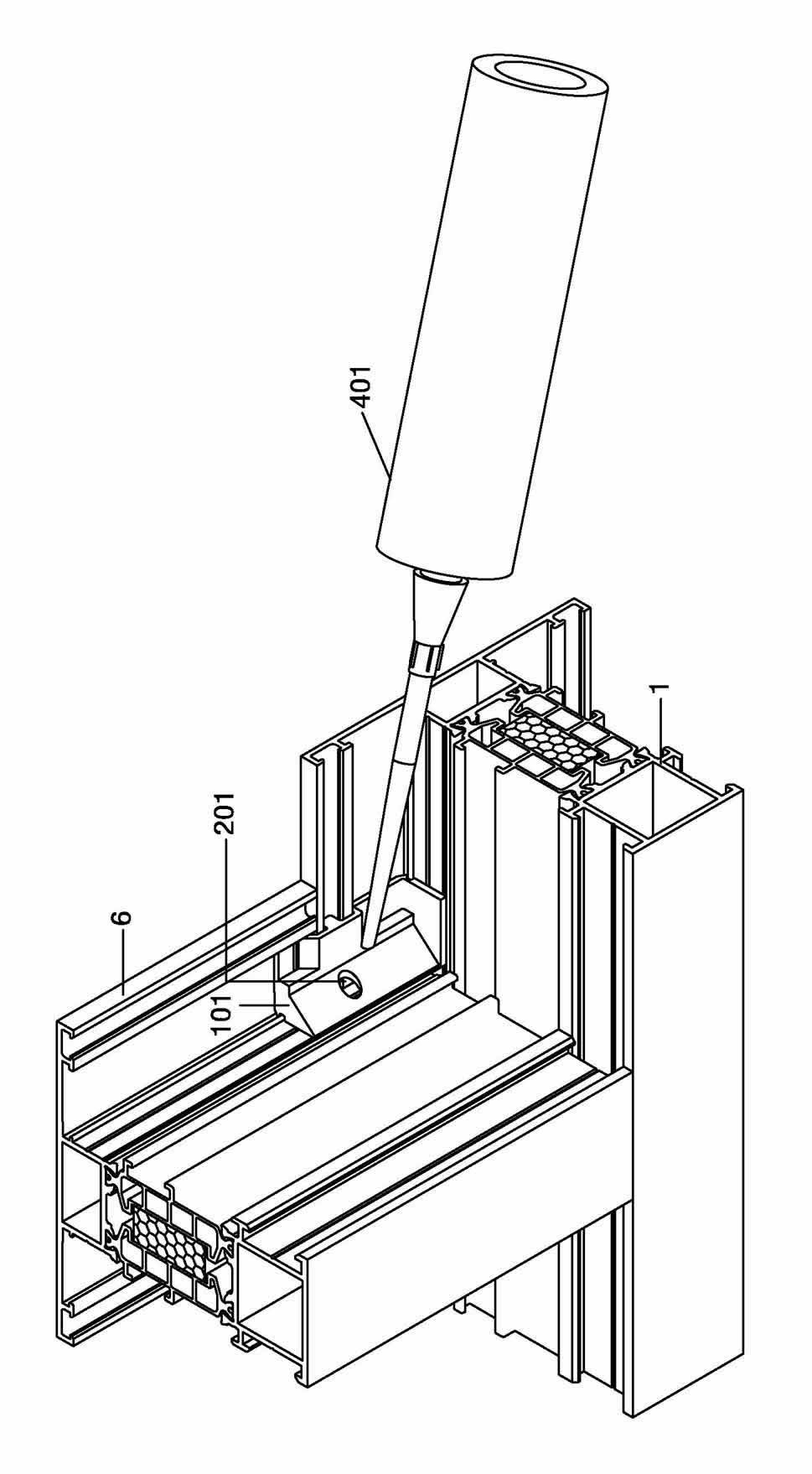

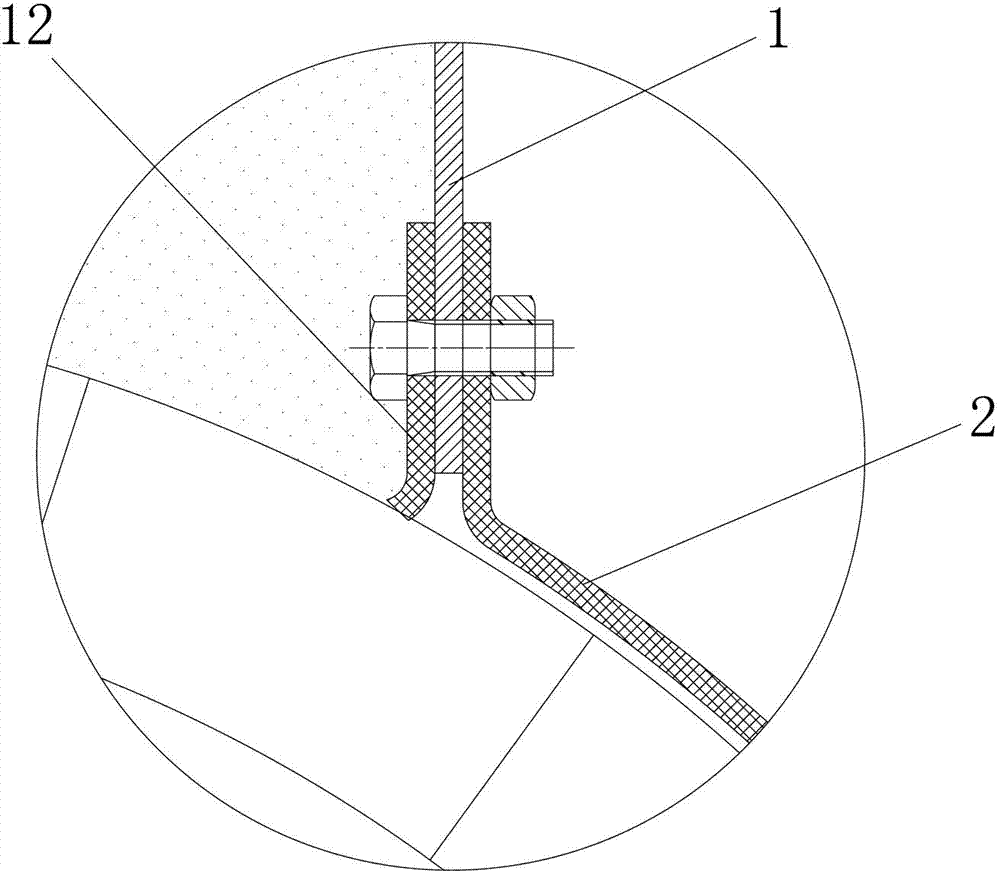

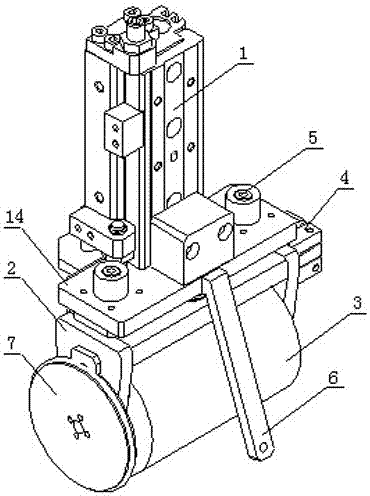

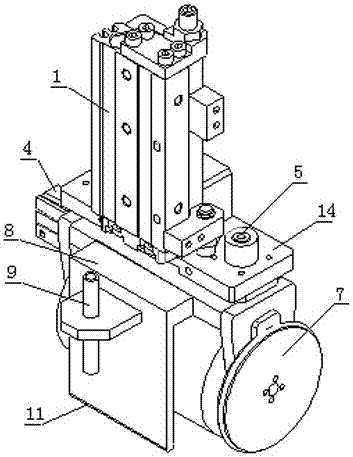

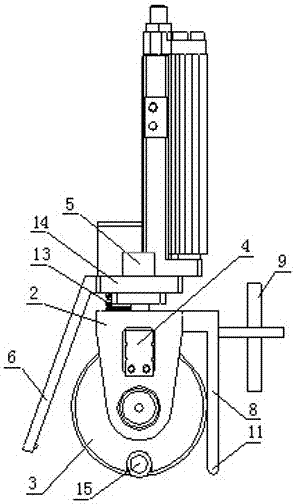

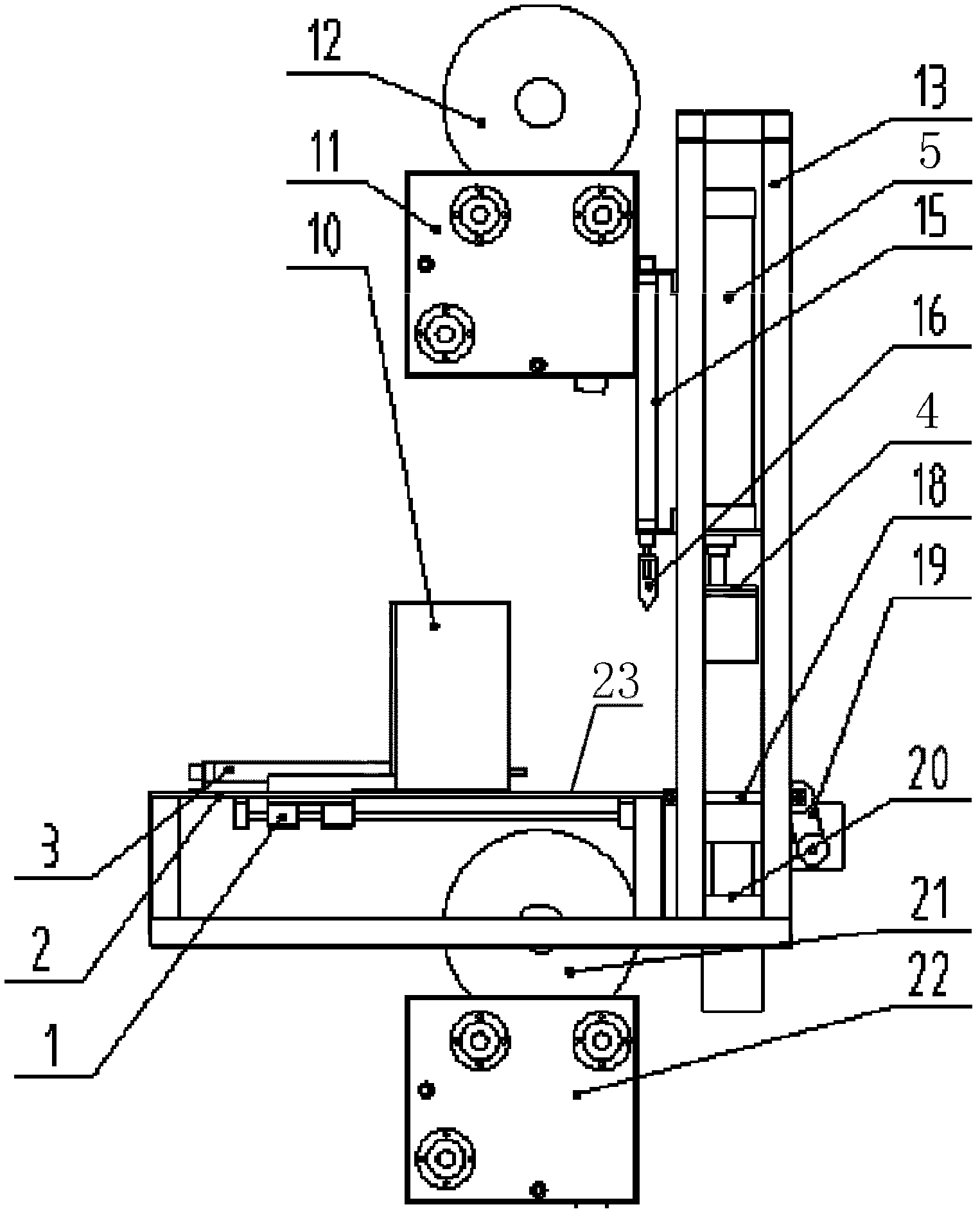

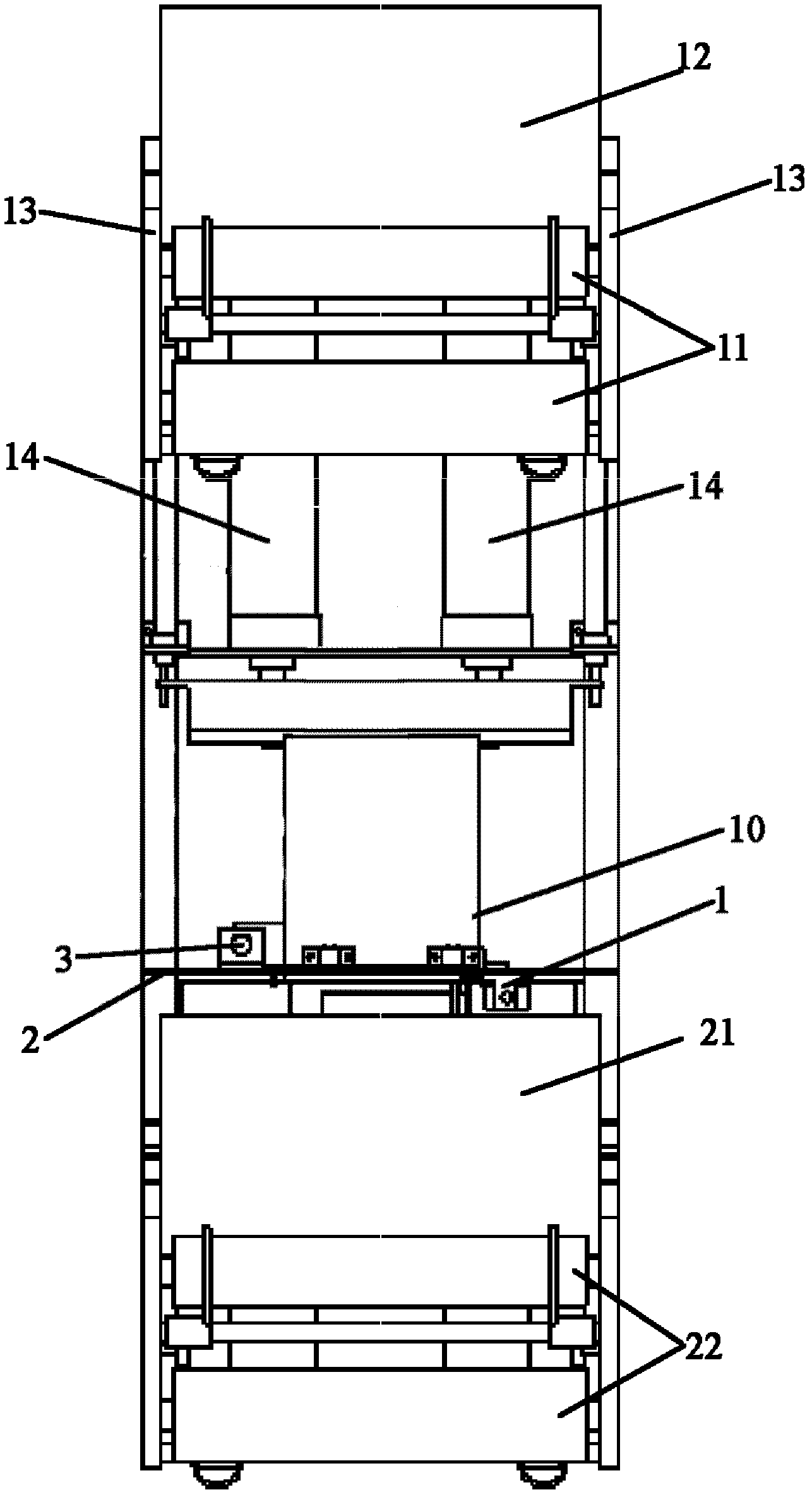

White spirit brewing retort loading dispersing machine suitable for multiple types of liquor retorts

ActiveCN104911053AAchieve flatnessImprove wine qualityAlcoholic beverage preparationLarge containersMechanical engineeringBrewing

The invention relates to the field of white spirit brewing equipment and specifically relates to a white spirit brewing retort loading dispersing machine suitable for multiple types of liquor retorts. The white spirit brewing retort loading dispersing machine comprises a base, a left-right moving device, a front-back moving device, a dispersing hopper and a counterweight iron block; the base is entirely of a flat cuboid structure; the left-right moving device is located above the base; the left-right moving device is used for pushing the dispersing hopper to move left and right; the front-back moving device is located above the left-right moving device and used for pushing the dispersing hopper to move forwards and backwards; the dispersing hopper is located in front of the front-back moving device; the polishing hopper is capable of moving up and down. The white spirit brewing retort loading dispersing machine is used for overcoming the defects of the existing retort loader that the materials below are compacted in the gradual stacking process of the materials to affect liquor quality and the existing retort loader fails to be adapted to the retorts different in volume.

Owner:罗定市丰智酒业有限公司

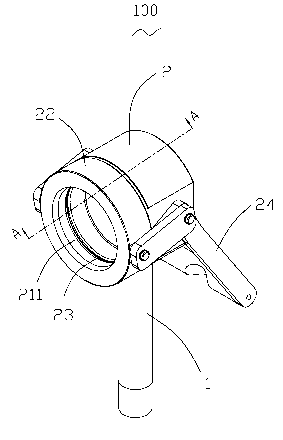

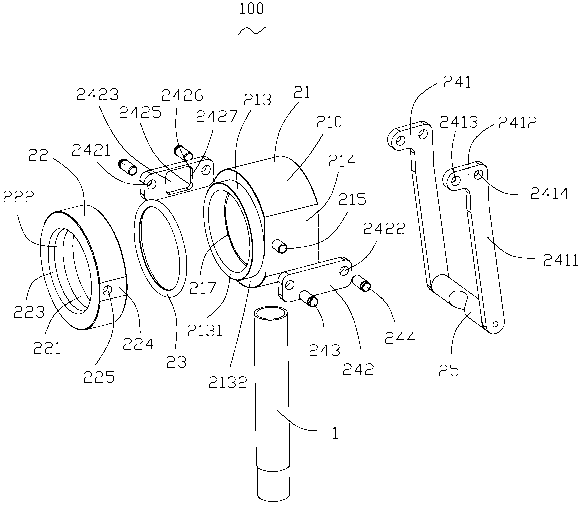

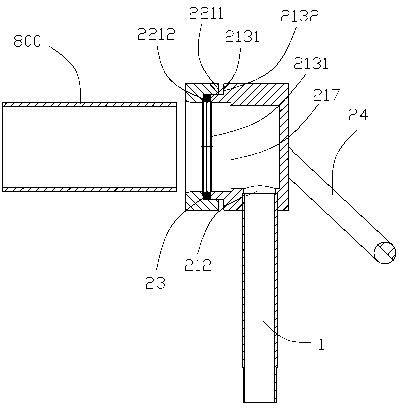

Welding shielding gas device and pipe fitting connecting piece thereof

InactiveCN102699581AAchieve connectionAchieve flatnessSleeve/socket jointsWelding/cutting auxillary devicesPipe fittingShielding gas

The invention provides a welding shielding gas device, which comprises a cleaning gas pipe for conveying shielding gas and a pipe fitting connecting piece fixed at the tail end of the cleaning gas pipe to be connected to a welding pipe fitting, wherein the pipe fitting connecting piece comprises a base connected to the cleaning gas pipe, a lantern ring movably positioned at one end of the base and a sealing ring which is inlayed between the base and the lantern ring and is extruded inwards in the radial direction along the lantern ring to abut against the periphery of the welding pipe fitting when the lantern ring moves along the axial direction of the welding pipe fitting. Therefore, the welding shielding gas device and the welding pipe fitting are connected with each other in a sealing manner, and foreign gas can be prevented from being guided into the welding pipe fitting to influence a welding effect.

Owner:HUAHENG WELDING

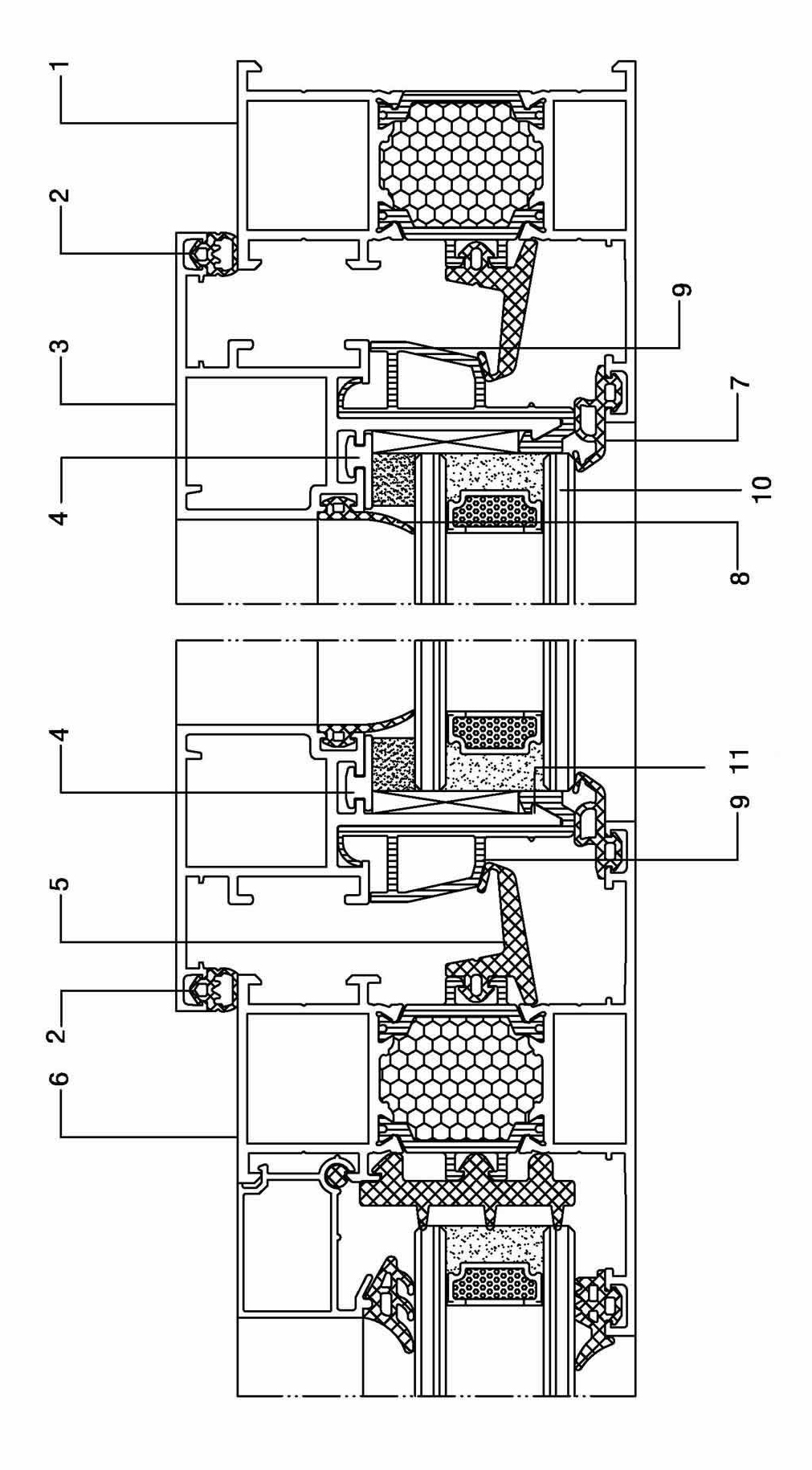

Energy-saving environment-friendly door/window system

ActiveCN102409925ASatisfy the requirement of dissipated energy indexImprove sealing performanceSills/thresholdSealing arrangementsSash windowArchitectural engineering

The invention belongs to the field of building door / window curtain walls, and particularly relates to an energy-saving environment-friendly door / window system. The system comprises a border (1), a mullion (6) and a leaf-hidden window sash (3) arranged therein, wherein an outdoor sealing rubber strip (7) is fixed between the border (1) and the leaf-hidden window sash (3) on the border (1); an indoor sealing rubber strip (2) is fixed between the leaf-hidden window sash (3) and the the border (1) on the leaf-hidden window sash (3); a T-shaped connection glue injection sheet is fixed at the joint between the mullion (6) and the border (1); the T-shaped connection glue injection sheet is clamped and fixed with a notch of the mullion (6); and a glue injection port is formed on the T-shaped connection glue injection sheet. The energy-saving environment-friendly door / window system provided by the invention has good sealing and heat insulation performance, a firm structure and high generality, and can effectively meet the requirements on the lost energy index of the building door / window.

Owner:LIAONING JOYDON ALUMINUM BUILDING SYST

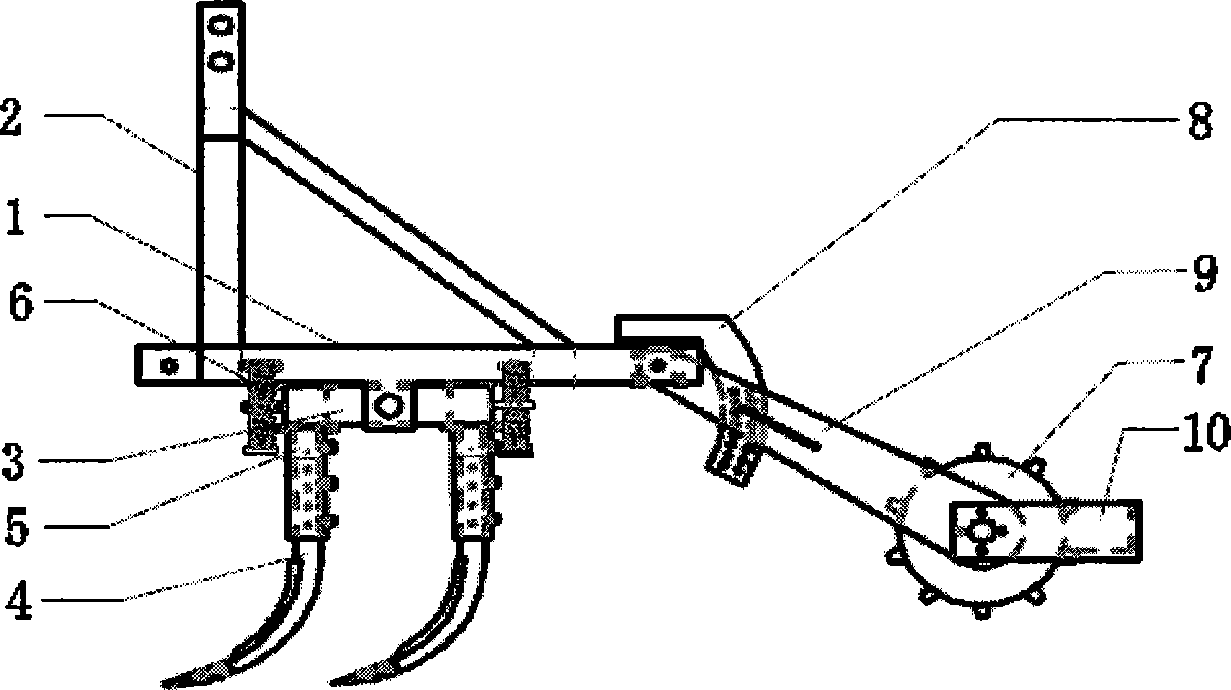

Novel deep scarification and soil preparation combined machine

InactiveCN104186045AReduce the impactReduce energy consumptionSpadesSaving energy measuresAgricultural engineeringScarification

The invention discloses a novel deep scarification and soil preparation combined machine. The novel deep scarification and soil preparation combined machine comprises a machine frame, wherein a three-point suspension frame, a subsoiler frame, subsoilers, subsoiler fixing elements, a self-excited vibration elastic assembly, a suppression roller, a suppression roller adjusting plate, a suppression roller connecting plate and a soil scraping plate are connected to the front end of the machine frame. The subsoiler frame is hinged into a lifting lug under a left-right edge beam of the machine frame and is connected with the machine frame through the elastic assembly. The elastic assembly is arranged in the mode the front end is provided with an upper tension spring and a lower compression spring, and the rear end is provided with an upper compression spring and a lower tension spring, so the front portion and the rear portion of the subsoiler frame can vibrate in the direction perpendicular to the machine frame. The subsoilers are arranged in a W shape, and the tops of the subsoilers are connected with subsoiler frame bolts through the subsoiler fixing elements. The space between the subsoilers and the tilling depth can be adjusted. The suppression roller and the soil scraping plate are hinged to the rear end of the machine frame through the suppression roller connecting plate, and height adjustment is achieved through the suppression roller adjusting plate. The novel deep scarification and soil preparation combined machine is applied to deep scarification and soil preparation of farmland and has the advantages of being simple in structure and capable of reducing resistance and saving energy.

Owner:NORTHWEST A & F UNIV

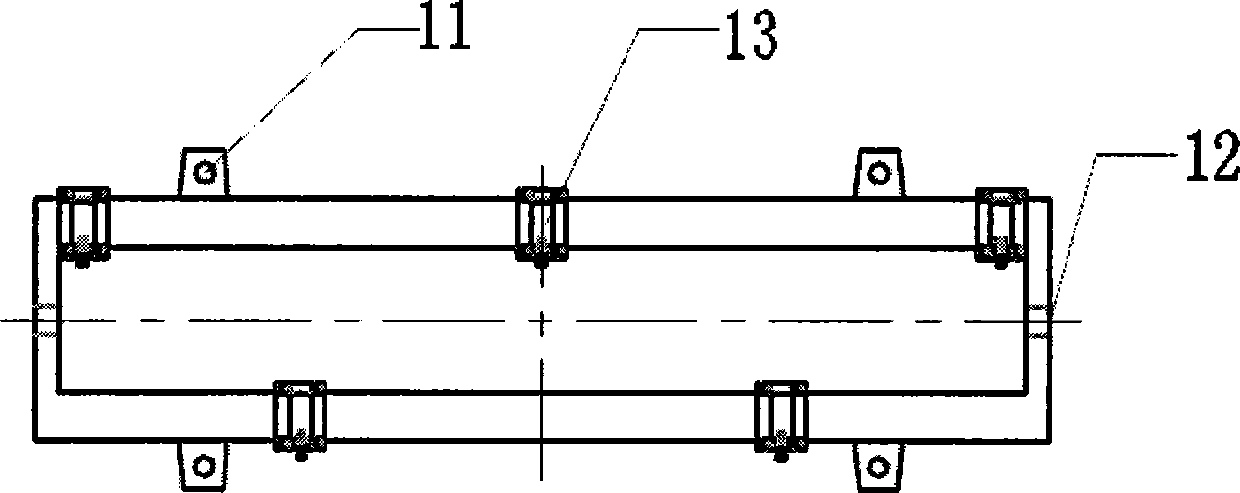

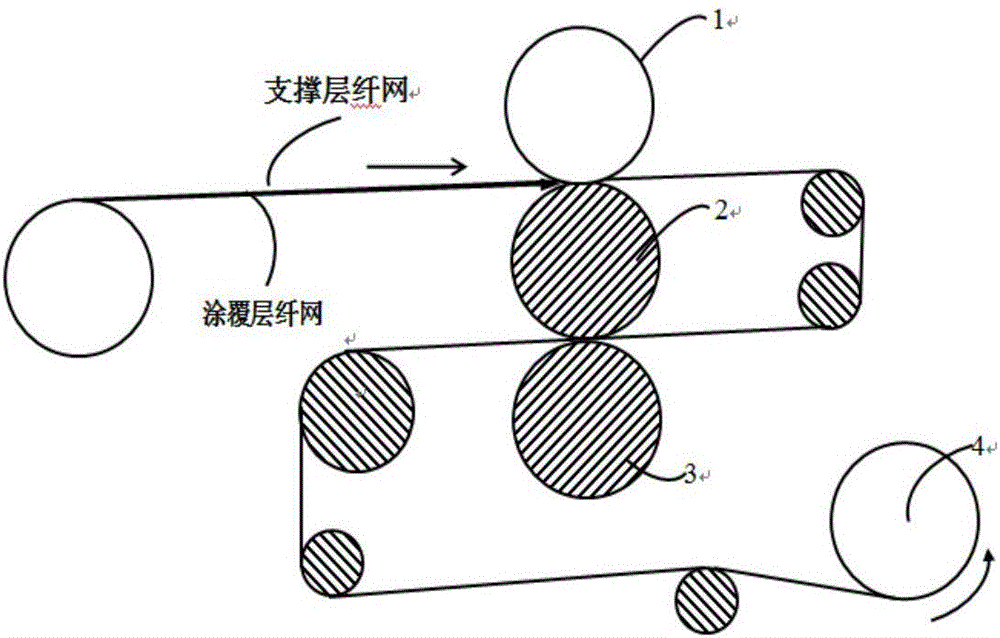

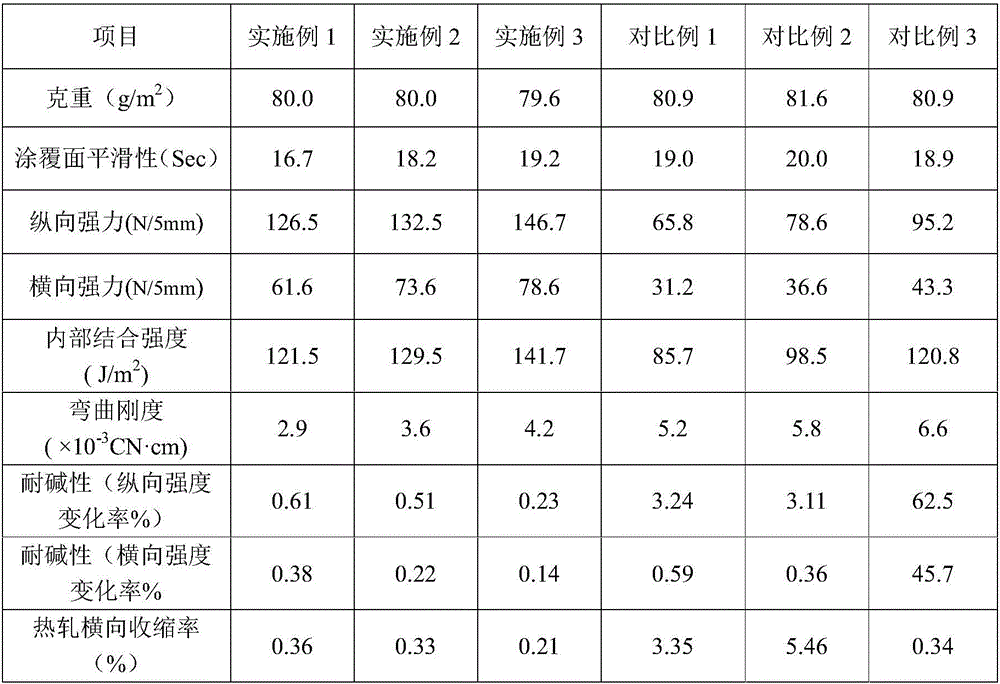

Double-layer alkali-resisting separation membrane support material and preparing method thereof

ActiveCN106582313ASolve the problem that it cannot be used in an alkaline environment for a long timeEffective tangleSemi-permeable membranesFibre typesHardnessSupport materials

The invention discloses a double-layer alkali-resisting separation membrane support material and a preparing method thereof. The double-layer alkali-resisting separation membrane support material comprises a coating layer and a support layer, and is prepared by spunlace and hot rolling calendaring. A thin diameter polypropylene fiber and a meldable fiber are adopted as raw materials by the coating layer, a thick diameter polypropylene fiber and a certain amount of meldable fiber are adopted as the raw materials by the support layer, through the steps of beating, pulp forming and the like, the raw materials are conveyed by different pulp supply systems to double-layer forming wet method equipment to prepare the pulp into a net respectively, and the double-layer alkali-resisting separation membrane support material is formed after spunlace and hot rolling calendarin. The double-layer alkali-resisting separation membrane support material adopts the technology, solves the problem that the double-layer separation membrane support body is poor in alkali resistance, prone to separated layers, low in strength, poor in flexibility and the like, and the double-layer separation membrane support material with an excellent alkaline resistant property, good interlayer binding force, a stable shape and state and moderate hardness and softness is prepared at low hot rolling pressure and temperature.

Owner:FOSHAN S L P SPECIAL MATERIALS +1

Phase current detector

InactiveCN1953312AHigh measurement accuracyReduce measurement errorAc-dc conversionPhase currentsCapacitance

A first capacitor (2a) is connected between the output terminals of a rectification circuit (2) the input of which is an AC power source (1), and a three-phase inverter (3) in parallel with the first capacitor (2a), and the output of the three-phase inverter (3) is supplied to a motor (4). A second capacitor (3a) is connected in parallel with the input side of the three-phase inverter (3), a current detector (5) between the first capacitor (2a) and second capacitor (3a), and a third capacitor in parallel with the first capacitor (2a) slightly closer to the power source than to the current detector (5). Thus, the capacitance of the second capacitor (3a) is set as small as possible in such a range that a power device is not broken down by a surge voltage attributed to switching to suppress ringing, so that current is incorporated at a high speed with a high precision.

Owner:DAIKIN IND LTD

Computer case flatness inspection device based on electromagnetic induction principle

ActiveCN111649666AAchieve flatnessImprove inspection efficiencyElectric/magnetic roughness/irregularity measurementsUsing optical meansEngineeringAssembly line

The invention relates to the technical field of computer cases. The invention further discloses a computer case flatness inspection device based on the electromagnetic induction principle. The devicecomprises a base and a shell, a telescopic rod is movably connected to the exterior of the base, a supporting plate is movably connected to the top of the telescopic rod, a limiting plate is movably connected to the exterior of the base, a rotating shaft is movably connected into the shell, rollers are movably connected to the exterior of the rotating shaft, and a movable plate is movably connected to the exterior of the rotating shaft. Under the interaction of the base, the shell, the telescopic rod, the supporting plate, the limiting plate, the rotating shaft, the rollers, a movable plate, the movable rod, a lead screw, a sliding block, an N pole, an S pole and a connecting rod, the case flatness inspection device can be suitable for detecting cases with different thicknesses, can be suitable for assembly line work of factories, can sense the flatness of the cases under the transmission of structures, and further gives a prompt to an operator through the alarm, so that the flatness of the cases can be detected.

Owner:长春财经学院

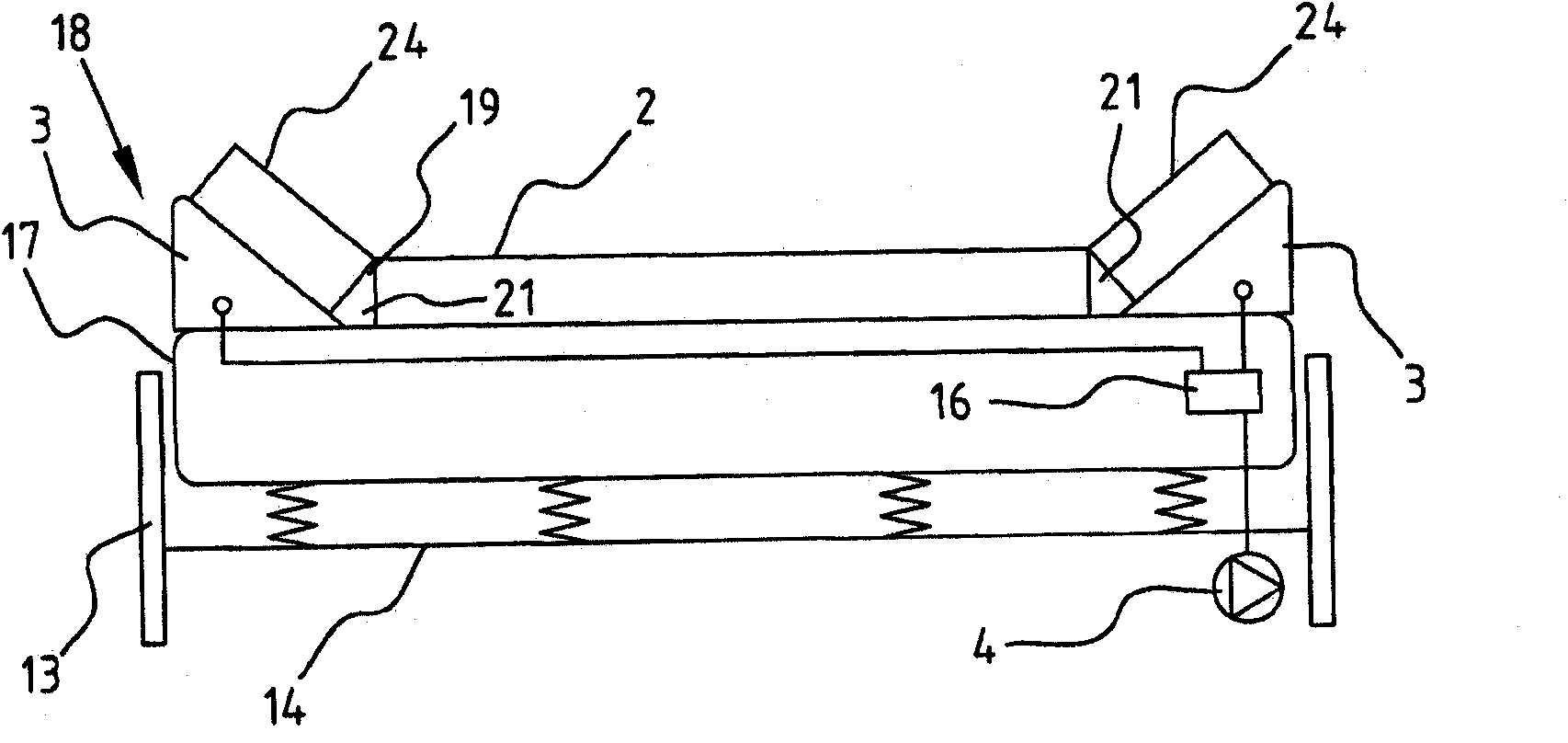

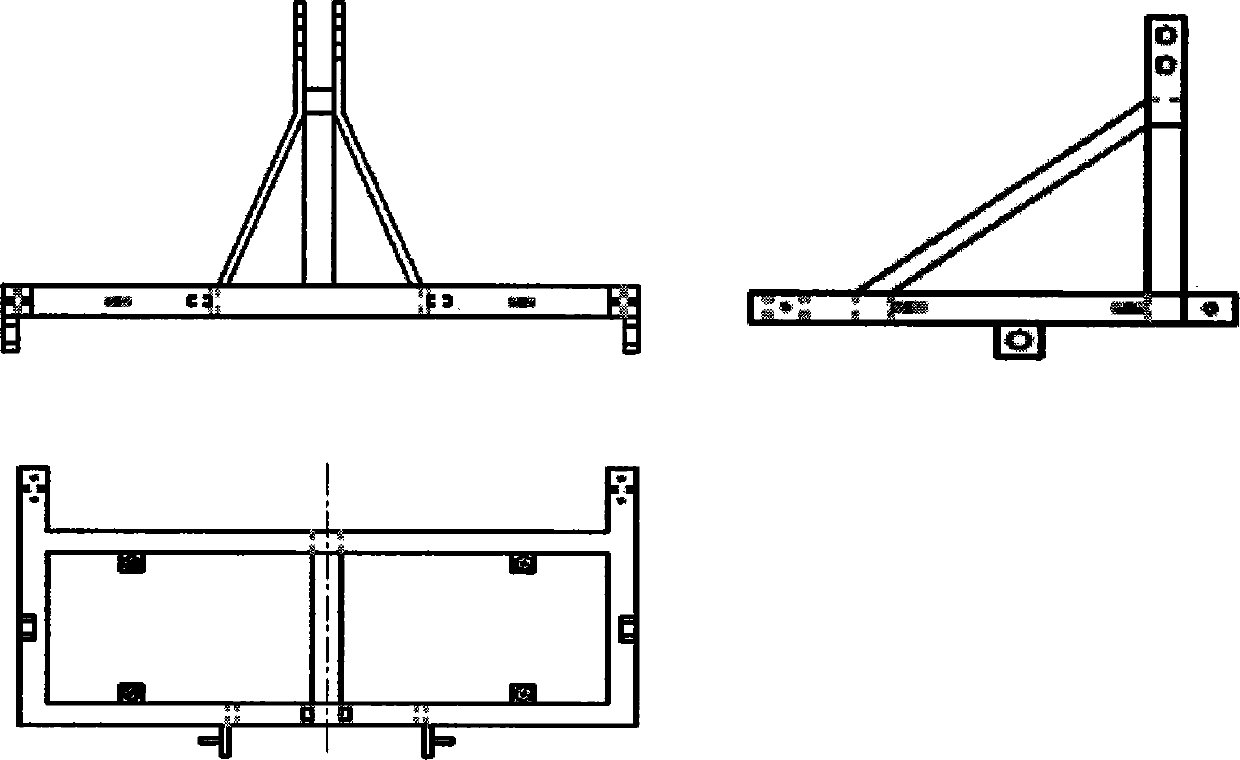

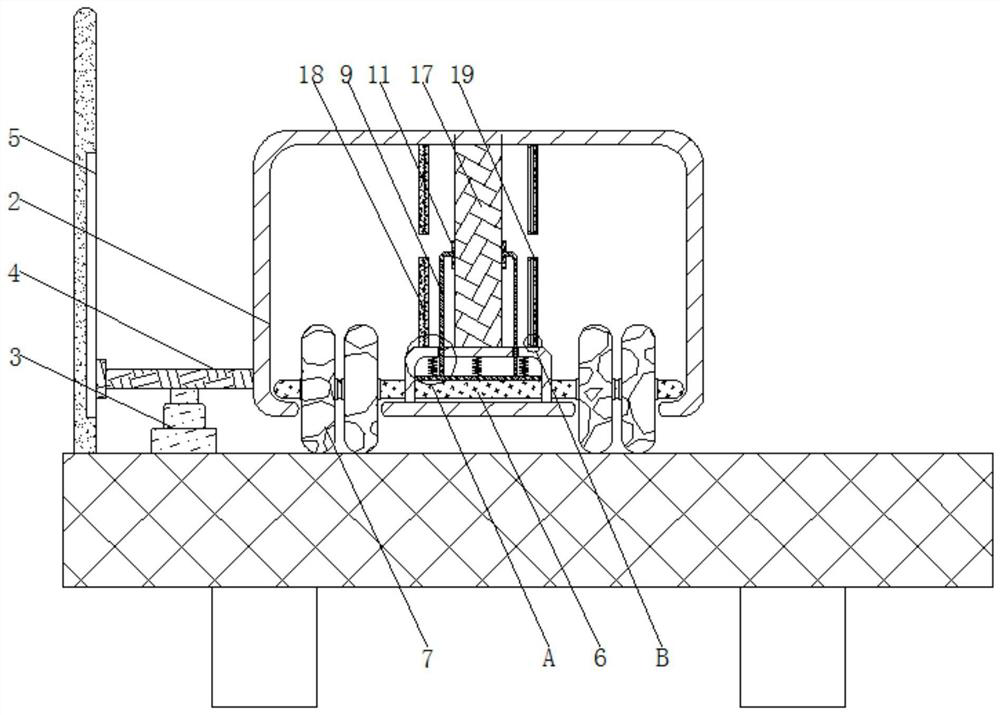

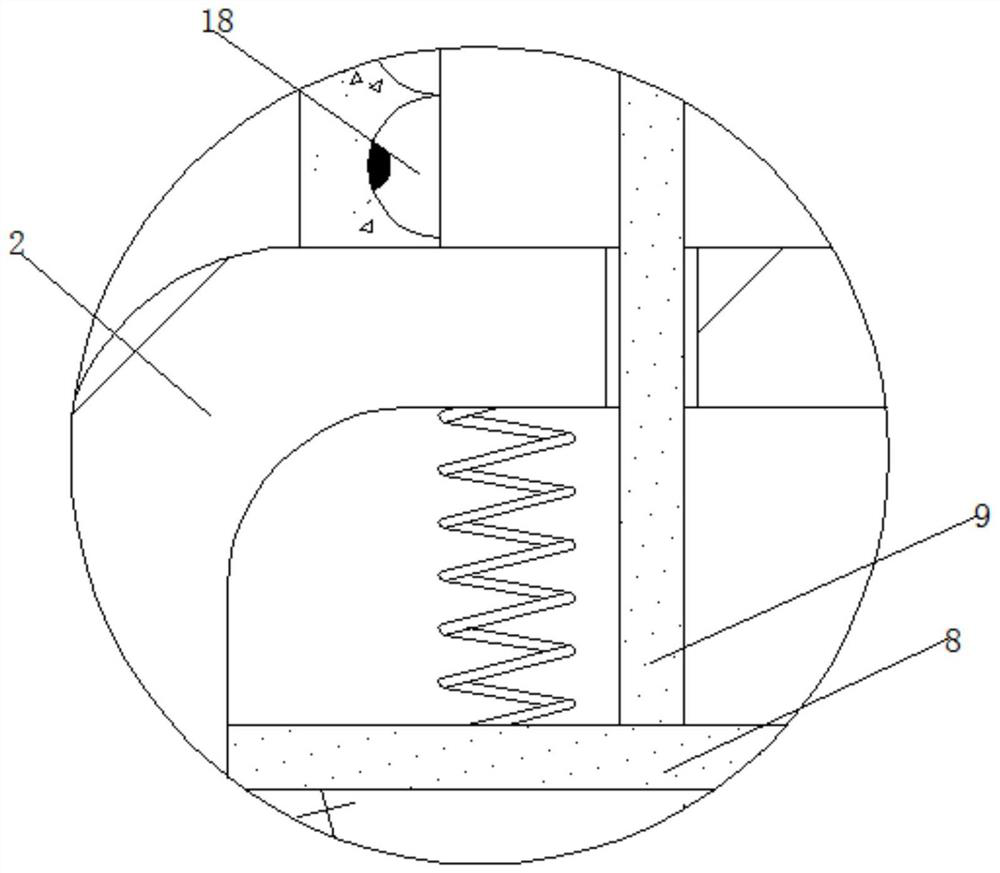

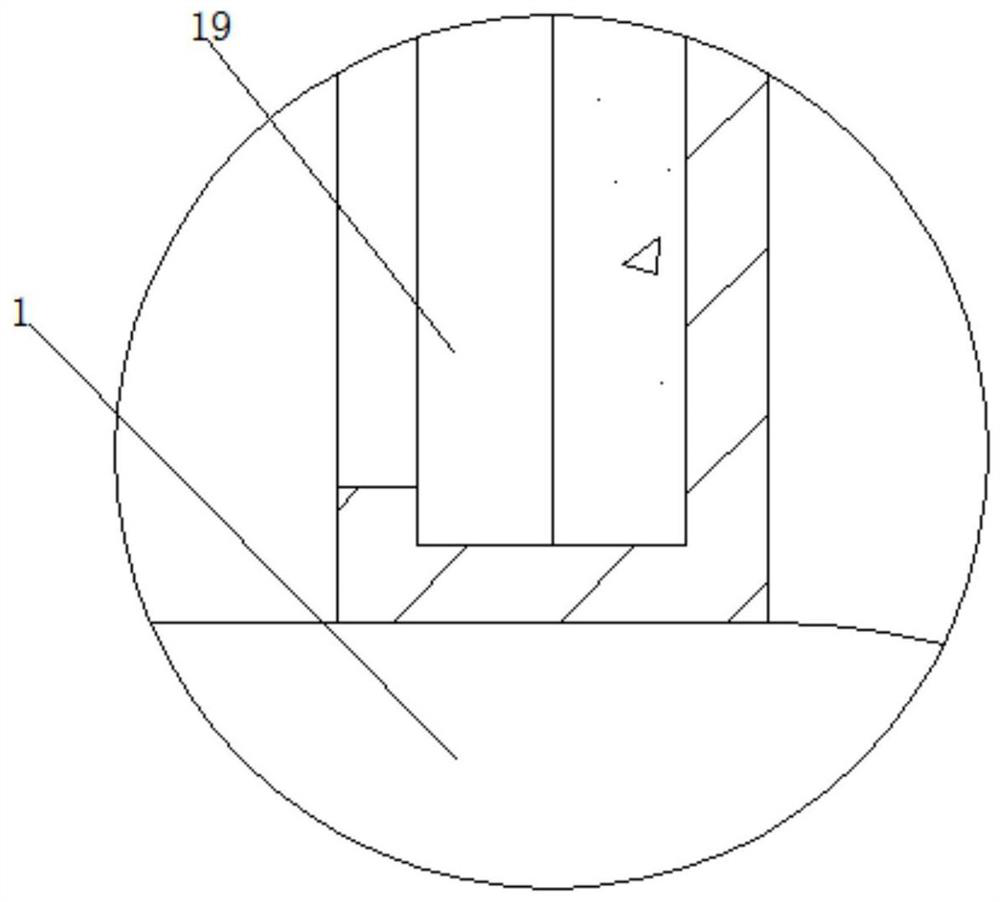

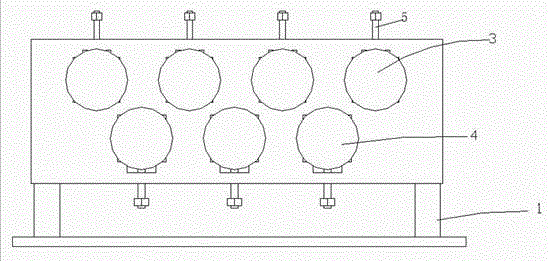

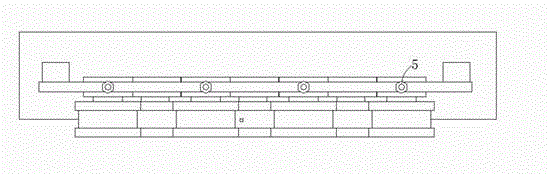

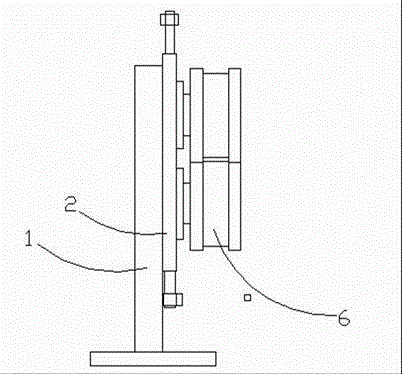

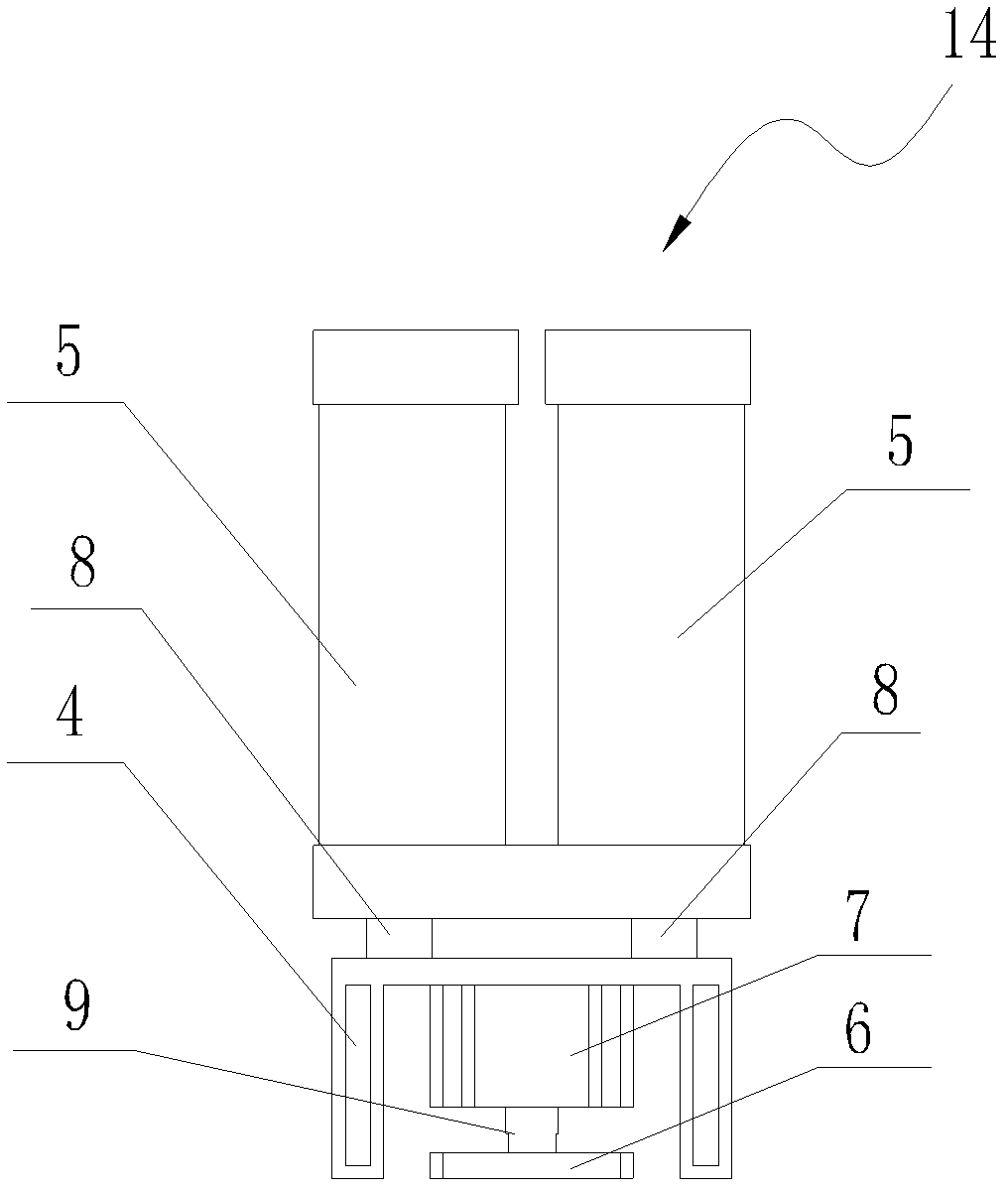

Vertical flattening straightening device for copper belt

The invention discloses a vertical flattening straightening device for a copper belt, which comprises a frame 1, a bracket 2, upper shaft rollers 3 and lower shaft rollers 4, wherein the bracket 2 is mounted on the frame 1; the upper shaft rollers 3 are mounted on the bracket 2; the lower shaft rollers 4 are mounted on the bracket 2; adjusting bolts 5 for adjusting the height of the shaft rollers are mounted on the shaft rollers; the quantity of the upper shaft rollers 3 is four; and the quantity of the lower shaft rollers 4 is three. The height of the upper and lower shaft rollers can be adjusted by the adjusting bolts 5; the quantity of the shaft rollers participating in work is confirmed by the adjusting bolts 5; a copper belt 7 passes through clearances between the upper and lower shaft rollers; and the copper belt is straightened and flattened by rolling the upper and lower shaft rollers.

Owner:芜湖鑫泰铜业有限公司

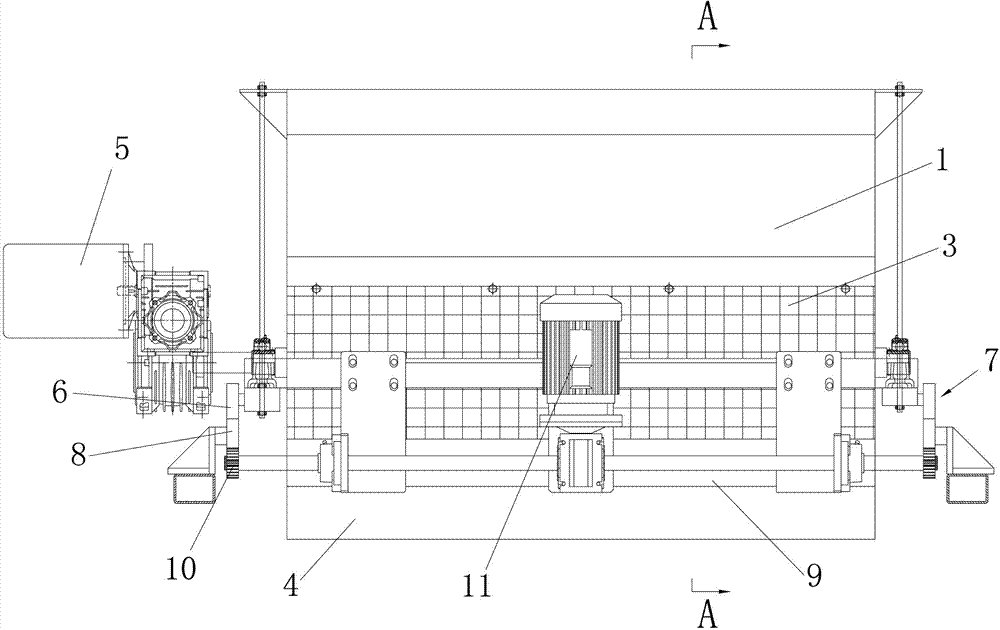

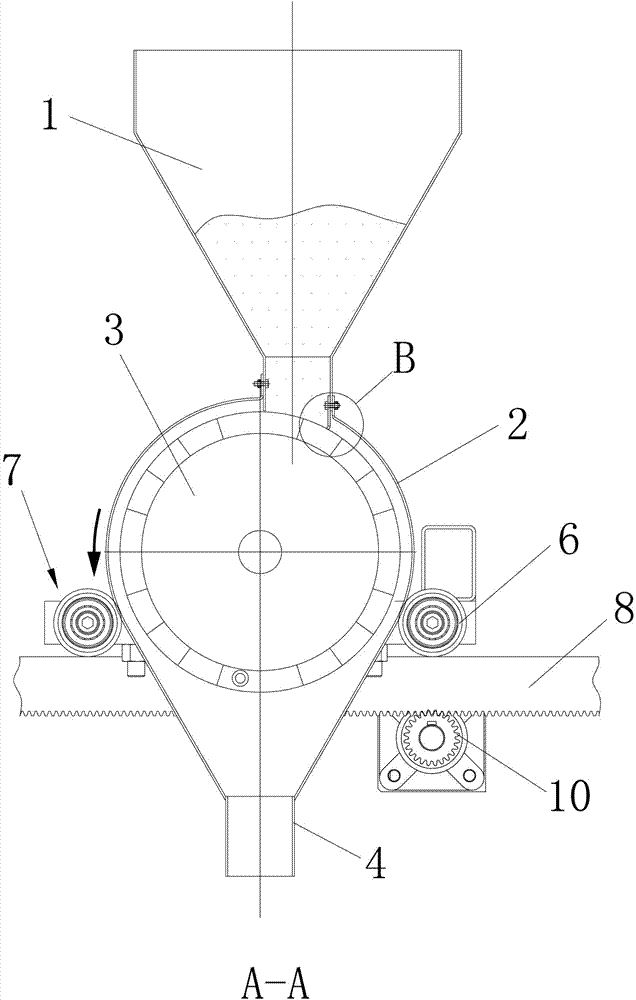

Rotary drum grille type packing device

ActiveCN103029210AAchieve flatness and uniformityCompact structureFeeding arrangmentsEngineeringMechanical engineering

The invention provides a rotary drum grille type packing device, which comprises a storage hopper, a dust cover, a rotary drum, a blanking hopper and a driving unit, wherein a material loading grille is arranged on the peripheral surface of the rotary drum; the rotary drum is transversely arranged in a dust cover and is driven by the driving unit positioned on one side of the shaft end of the rotary drum to rotate; the storage hopper is closely arranged above the rotary drum and is fixedly connected with the dust cover, and meanwhile, the discharge port of the the storage hopper is in clearance fit with the material loading grille on the peripheral surface of the rotary drum; the blanking hopper is arranged below the rotary drum, and the feed port of the blanking hopper corresponds to the rotary drum; and meanwhile, the blanking hopper is fixedly connected with the dust cover. After the rotary drum grille type packing device adopts the scheme, the material loading grille on the peripheral surface of the rotary drum is utilized to convey power and fix the powder in a set position, then the rotary drum puts the constant weight of powder on a die cavity or other powder carriers at a constant rotation speed, and therefore the smoothness and the uniformity of powder putting are realized.

Owner:佛山市光华智能设备有限公司

Formula of clay sand

The invention discloses a formula of clay sand, which comprises the following raw materials in percentage: 15 percent to 20 percent of yellow sand, 8 percent to 15 percent of green sand, 3.5 percent to 5 percent of high-temperature cement, 3 percent to 6 percent of quartz sand, 50 percent to 60 percent of secondary return sand, 3 percent to 5 percent of coal dust, 3 percent to 6 percent of bentonite and 0.5 percent of base powder. The water content of the formula is measured by 100 percent of each group of components and values, six measuring units of water are added, therefore, the formula of clay sand solves the defects of air holes, sand holes, roughness, unclear angular edges and the like caused by the problem of formula of the clay sand, and achieves the purpose of having complete condition of the whole surface appearance of the casting piece so as to improve finished product ratio and economic benefit.

Owner:俞保平

Filmy material stripping and bonding device and using method

ActiveCN106965999AShorten job lengthReduce manufacturing costArticle unpackingBonding processEngineering

The invention discloses a filmy material stripping and bonding device and a using method. The device comprises a vertical lifting mechanism, a supporting platform, a guide mechanism, a spring and a rolling film stripping and coating mechanism. The supporting platform is connected to the lifting end of the vertical lifting mechanism. The rolling film stripping and coating mechanism and the guide mechanism are connected to the bottom face of the supporting platform through the spring. According to the filmy material stripping and bonding device and the using method, stripping and bonding processes of a to-be-processed screen protective film are automatically completed on one machine, waste of stripped-away protection film is avoided, the production cost is reduced, and the space occupied by the production line is shortened. The filmy material stripping and bonding device has the advantages of being simple and practical in structure, low in cost, high in working efficiency and suitable for being used in the production process of various LED screens, liquid crystal screens and mobile phone screens.

Owner:泰姆瑞(北京)精密技术有限公司

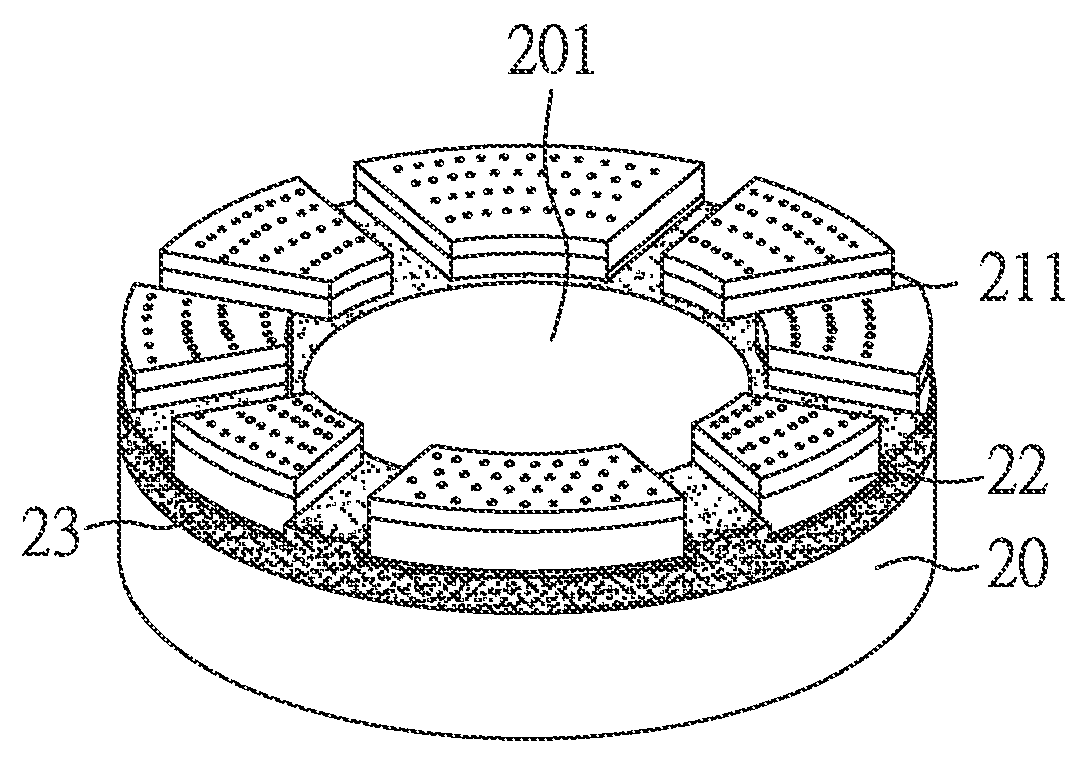

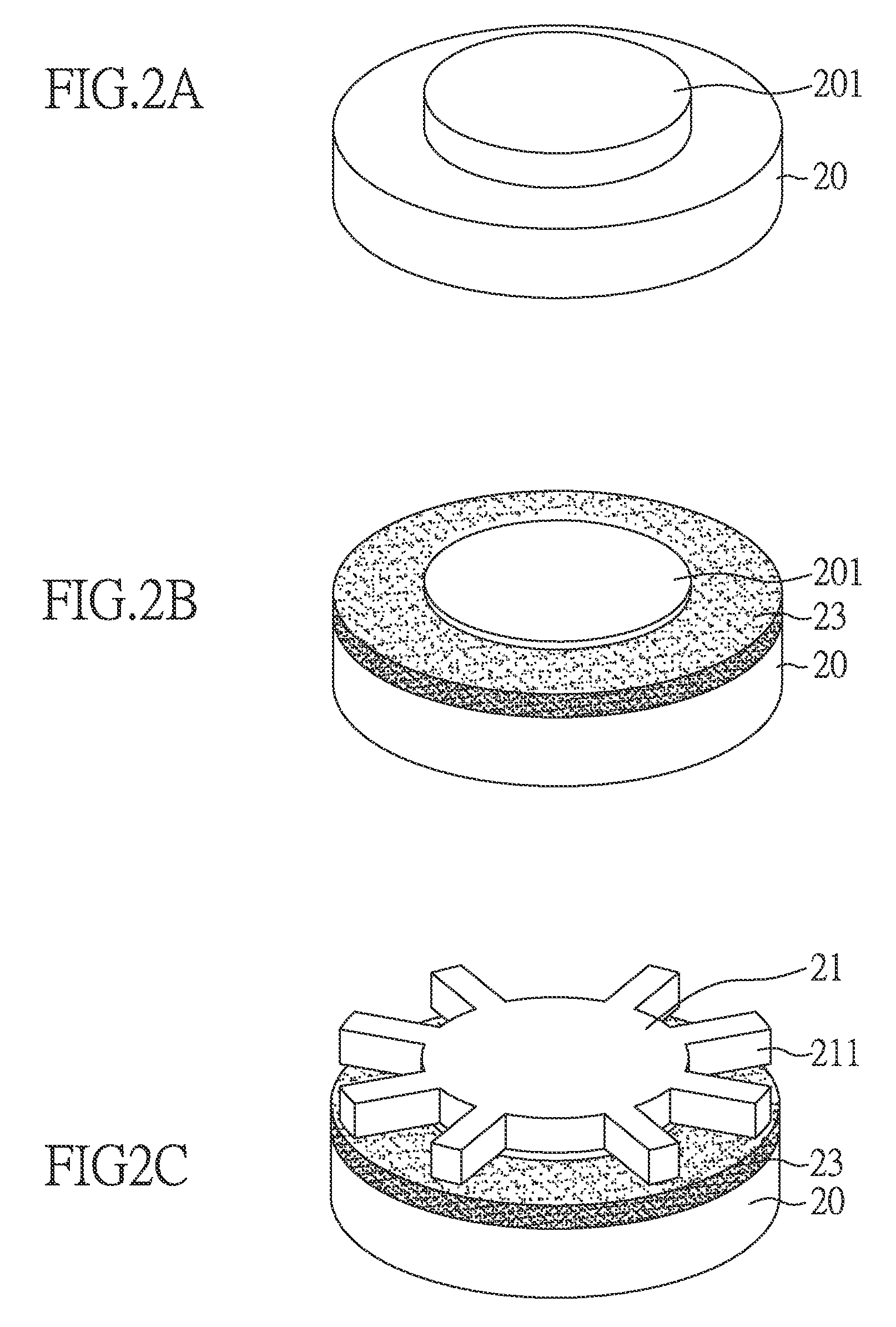

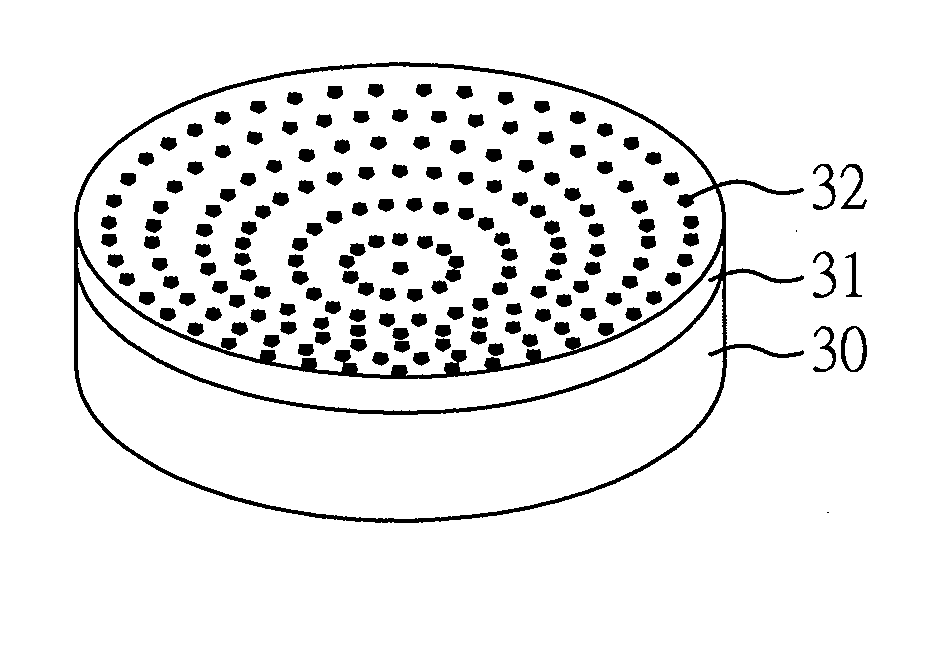

Segment-type chemical mechanical polishing conditioner and method for manufacturing thereof

ActiveUS9067302B2Achieve flatnessUniform effectGrinding devicesAbrasive surface conditioning devicesMetallurgyThermal deformation

The present invention relates to a segment-type chemical mechanical polishing conditioner and a method for manufacturing thereof. The segment-type chemical mechanical polishing conditioner comprises: a bottom substrate having a center protrusion; an abrasive unit binding layer disposed on the outside of the surface of the bottom substrate; and a plurality of abrasive units placed on the abrasive unit binding layer; wherein the abrasive units have a fan-shaped contour and are arrange along the center protrusion of the bottom substrate to form a discontinuous circular contour. Therefore, the present invention can utilize the center protrusion of the bottom substrate to adjust the arrangements of the abrasive units, and effectively improve the problem of thermal deformation of the surface of the chemical mechanical polishing conditioner during heat-hardening process, thereby enhancing the surface flatness of chemical mechanical polishing conditioner.

Owner:KINIK

Making method of elastic copper alloy sheet used for spectacle frame

ActiveCN103173647ABright surfaceReduce the degree of oxidationMetal rolling arrangementsEyewearIngot

The invention discloses a making method of an elastic copper alloy sheet used for a spectacle frame. A component qualified alloy ingot is used to continuously process in the invention. The above alloy comprises 8.5-9.5% by mass of Ni, 5.5-6.5% by mass of Sn, and the balance Cu. The method comprises the following steps: heating to 345-355DEG C, carrying out heat insulation of the ingot in an inert atmosphere for 20-40min, carrying out hot rolling deformation by 15-25%, and covering with carbon at a temperature of 795-805DEG C or homogeneously annealing in an inert gas; carrying out hot rolling cogging of the ingot, wherein the total machining rate is 55-70%; carrying out intermediate destressing annealing in a vacuum annealing furnace in 645-655DEGC / 2h; carrying out cold rolling until the thickness of the sheet is 1.2-1.4mm, wherein the total machining rate is 70-80%, and the pass machining rate is 10-15%; and carrying out solid solution and water quenching in the inert atmosphere, and carrying out cold rolling to the thickness of the finished sheet. The finished sheet is straightened, and the surface of the sheet is pickled. The performances of the elastic sheet used for the spectacle frame, which is made through using the method, can reach the performances of elastic CuNi9Sn6 alloy sheets reaching the levels of foreign products.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Pressing mechanism and note packaging device with same

The invention discloses a pressing mechanism, which is used for a note packaging device and leads a packaging film to wrap on packaged notes tightly. The pressing mechanism comprises at least one note pressing submechanism and at least one film-pressing submechanism, wherein the note pressing submechanism comprises a note pressing plate and a note pressing plate driving module for driving the note pressing plate to move up and down; the film-pressing submechanism comprises a film pressing plate and a film pressing plate driving module for driving the film pressing plate to move up and down; the film pressing plate is arranged on an area covered with the packaging film on the packaged note in a pressing manner; and the note pressing plate is arranged on an area uncovered with the packagingfilm on the packaged note, and can move up and down relative to the note pressing plate. The invention also provides a note packaging device with the pressing mechanism. According to the invention, the tightening of the packaging film and the surface flattening of the packaged notes are realized, the packing quality of the notes is improved, the safety for storage and transportation of the notes is improved, the economic and social benefits are obvious, the manufacturing cost is saved and the damage caused to the notes is avoided.

Owner:ZHEJIANG ZHONGDA PACKAGING EQUIP

Chemical mechanical polishing conditioner and manufacturing methods thereof

ActiveUS20140273772A1Efficient solutionAchieve flatnessPigmenting treatmentOther chemical processesPlanar substrateThermal deformation

The present invention relates to a chemical mechanical polishing conditioner and manufacturing methods thereof. The chemical mechanical polishing conditioner comprises: a planar substrate having a leveling surface; a bonding layer disposed on the surface of the planar substrate; and a plurality of abrasive particles embedded in the surface of the bonding layer and fixed to the surface of the planar substrate by the binding layer; wherein the planar substrate is formed by a deformation compensation for the non-planar substrate during curing the binding layer, and thus the tips of the abrasive particles have a leveled height. Therefore, the present invention can effectively improve the problem of thermal deformation of the substrate of the chemical mechanical polishing conditioner during heating and curing process, and thereby enhancing the surface flatness of chemical mechanical polishing conditioner.

Owner:KINIK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com