Image sensor wafer bonding method

A sensor and device wafer technology, applied in the field of image sensor wafer bonding, can solve problems such as difficult planarization, uneven surface, difficult chemical mechanical polishing, etc., to achieve the effect of achieving flatness and solving voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

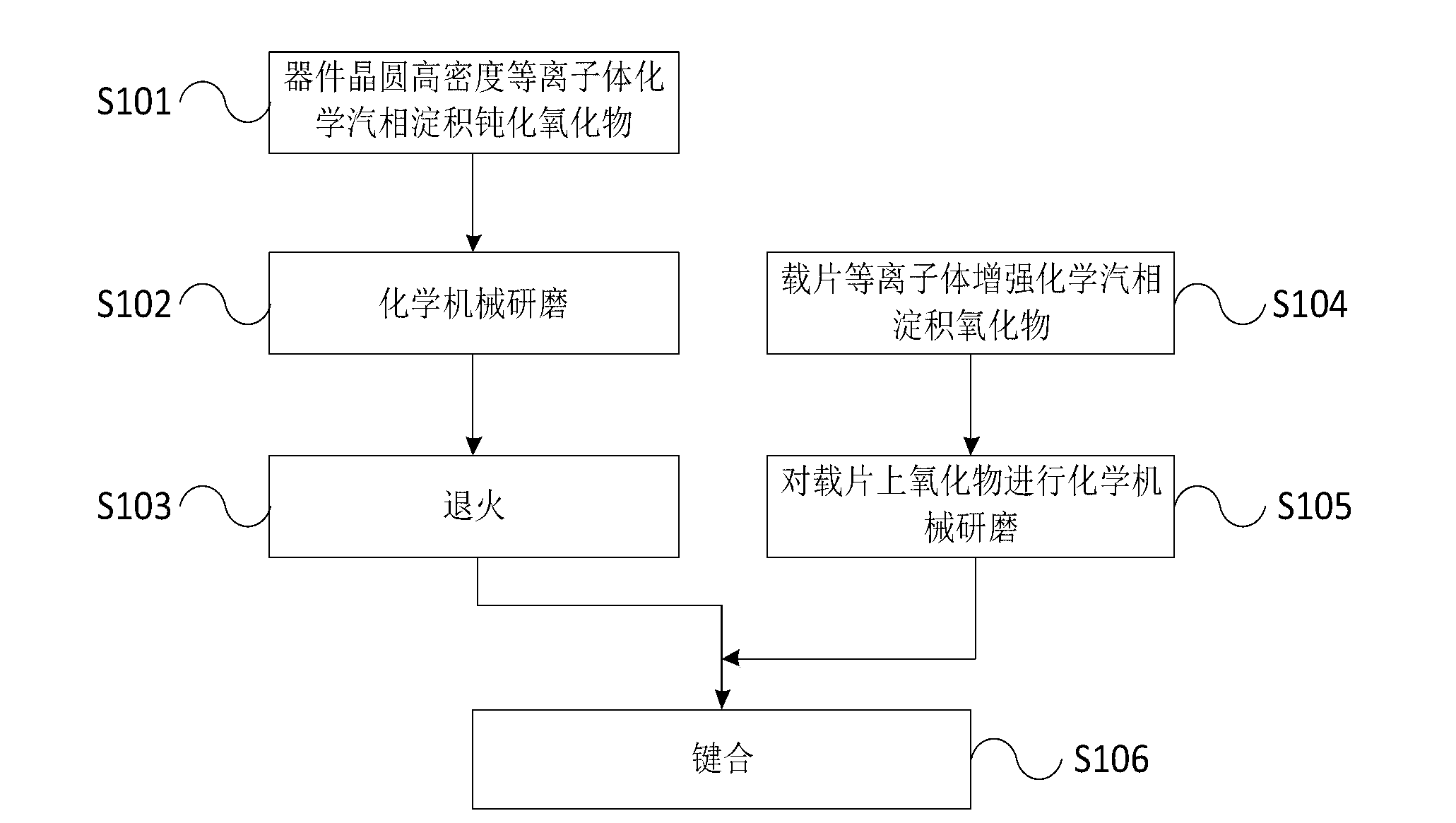

[0016] Such as figure 1 It is a flow chart of the existing image sensor wafer bonding process. It can be seen from the figure that the image sensor wafer bonding steps in the prior art, first, after step s101, the device wafer is deposited by high-density plasma chemical vapor deposition After passivating the oxide, step s102 grinds the oxide layer of the device wafer that has passed step s101, and then returns the device wafer through step s103, and step s104 is plasma-enhanced chemical vapor deposition of oxide on the carrier, Carrying out step s105 on the carrier that has passed step s104 to perform chemical mechanical polishing on the oxide on the carrier, and finally, bonding the treated and device wafer to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com