Filmy material stripping and bonding device and using method

A laminating device and film-like technology, which is applied in the directions of packaging, transportation and packaging, and unsealing of objects, can solve the problems of increasing operating area and production costs, extending the length of assembly line operations, and reducing production efficiency, so as to shorten the operation length, The effect of low cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

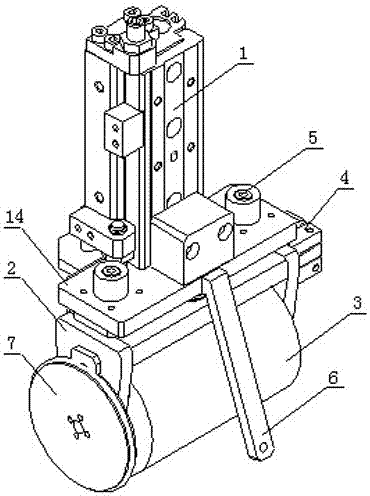

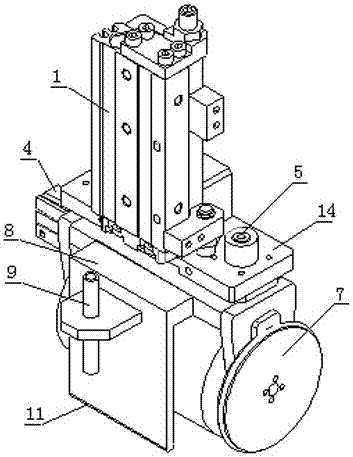

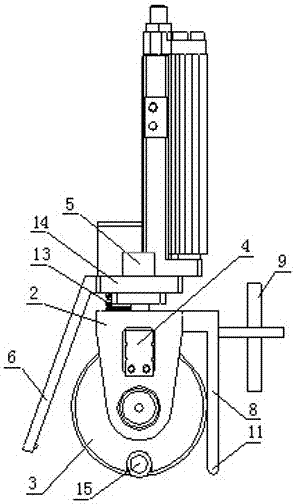

[0040] Attached below figure 1 , figure 2 , image 3 , Figure 4 Further detailed description of the film-like material stripping and bonding device of the present invention:

[0041] The film-like material peeling and laminating device of the present invention includes a vertical lifting mechanism 1, a support platform 14, a guiding mechanism, a spring 13 and a rolling film tearing mechanism. In this example, the vertical lifting mechanism 1 is a set of pneumatic sliding table, the sliding part is connected with the support platform 14, and drives the support platform 14 to move up and down. Of course, the vertical lifting mechanism 1 can also be a linear motion device driven by a motor and connected to the support platform 14 . The guiding mechanism is two linear bearings 5, and the two linear bearings 5 are evenly connected between the support platform 14 and the rolling film tearing mechanism. A spring 13 is installed between the rolling film tearing mechanism and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com