Timing chain assembling method and device

An assembly method and technology of an assembly device, which are applied to metal chains, metal processing, metal processing equipment, etc., can solve the problems of poor chain frame quality, reduced chain quality, and inability to install timing markers, so as to reduce waste of parts and shorten the The effect of job length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

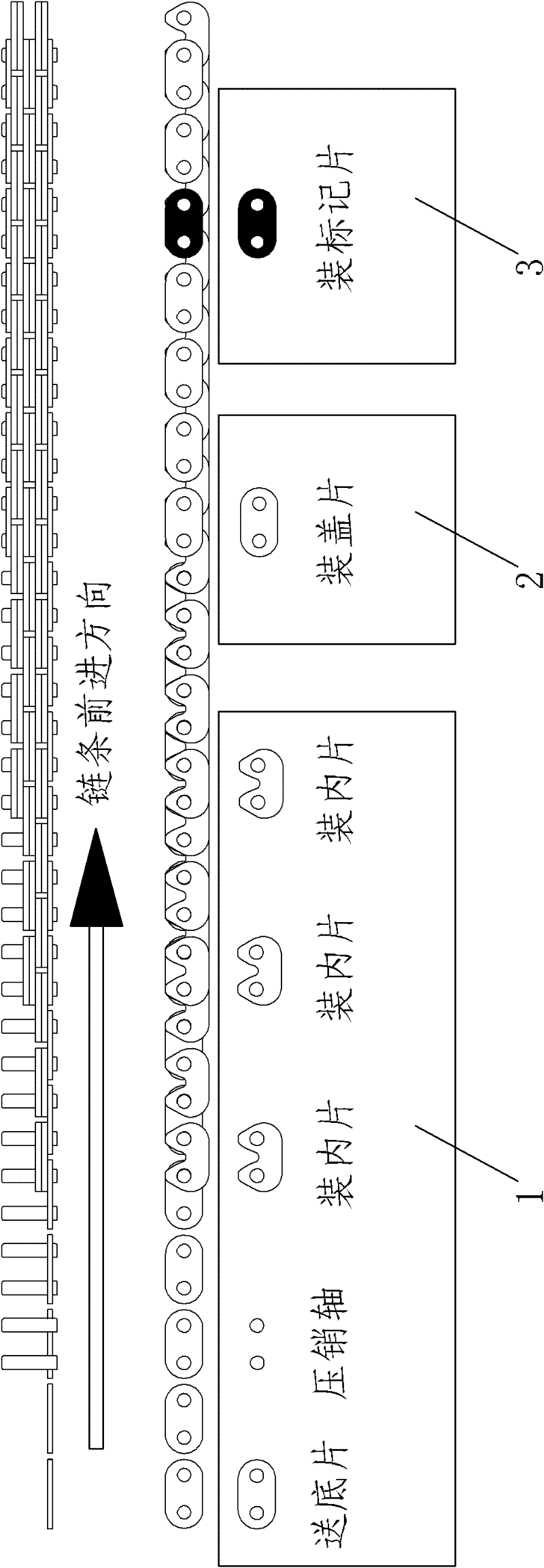

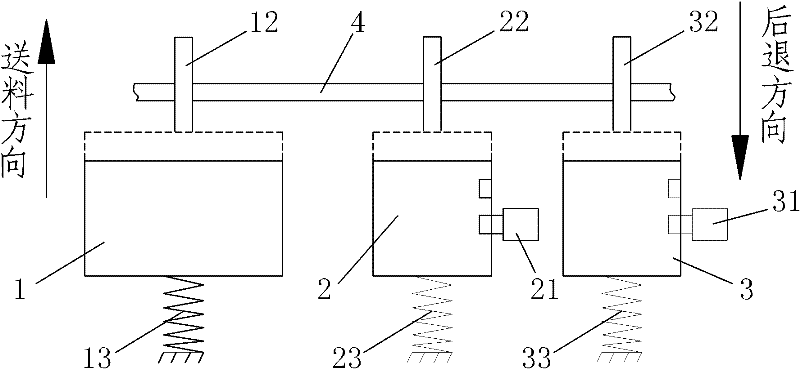

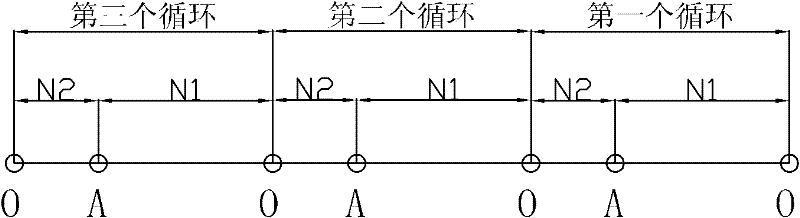

[0018] Such as figure 1 The shown assembly method of a timing chain includes: a first feeding tray 1 for pushing the negative film, a pin shaft and an inner film, a second feeding tray 2 for pushing the cover piece, and a third feeding tray 3 for pushing the marking piece; The chain link progressive assembly method is adopted, in which the first feeding tray 1 is always in the working state, pushing the negative film, pin shaft and inner film to the assembly station for pressing; the second feeding tray 2 and the third feeding tray 3 choose one to enter Working state; the second feeding tray 2 is in the working state when the marking sheet is not installed, and the cover sheet is pushed to the assembly station for pressing, and the second feeding tray 2 is in a vacant state when the marking sheet is loaded, and the cover sheet is not pushed; the third Feed tray 3 is in vacant state when not adorning marking sheet, does not push marking sheet, and the 3rd feeding tray 3 is in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com