Rotary drum grille type packing device

A technology of drum and grid, which is applied in the field of drum grid type packing device, which can solve the problems of inability to finely control the amount and position of powder feeding, inconsistent powder density, and low production efficiency, so as to achieve smoothness and uniformity , No powder leakage, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

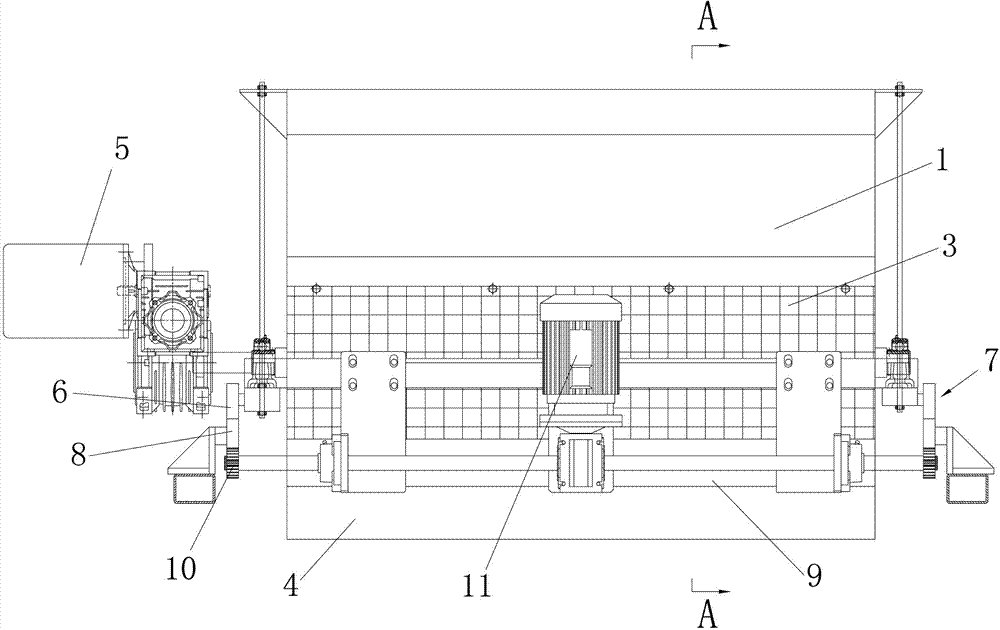

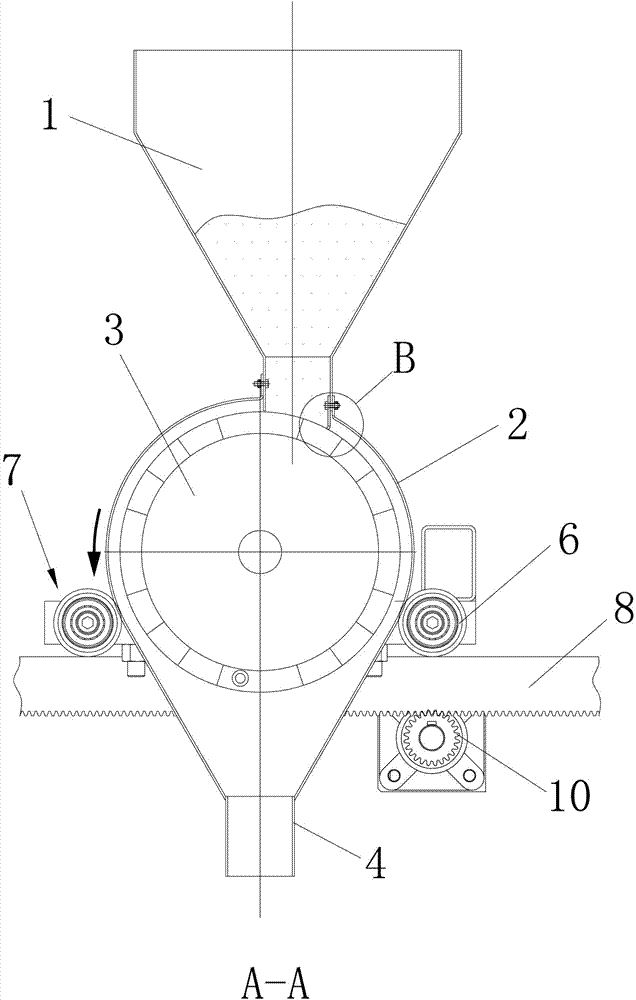

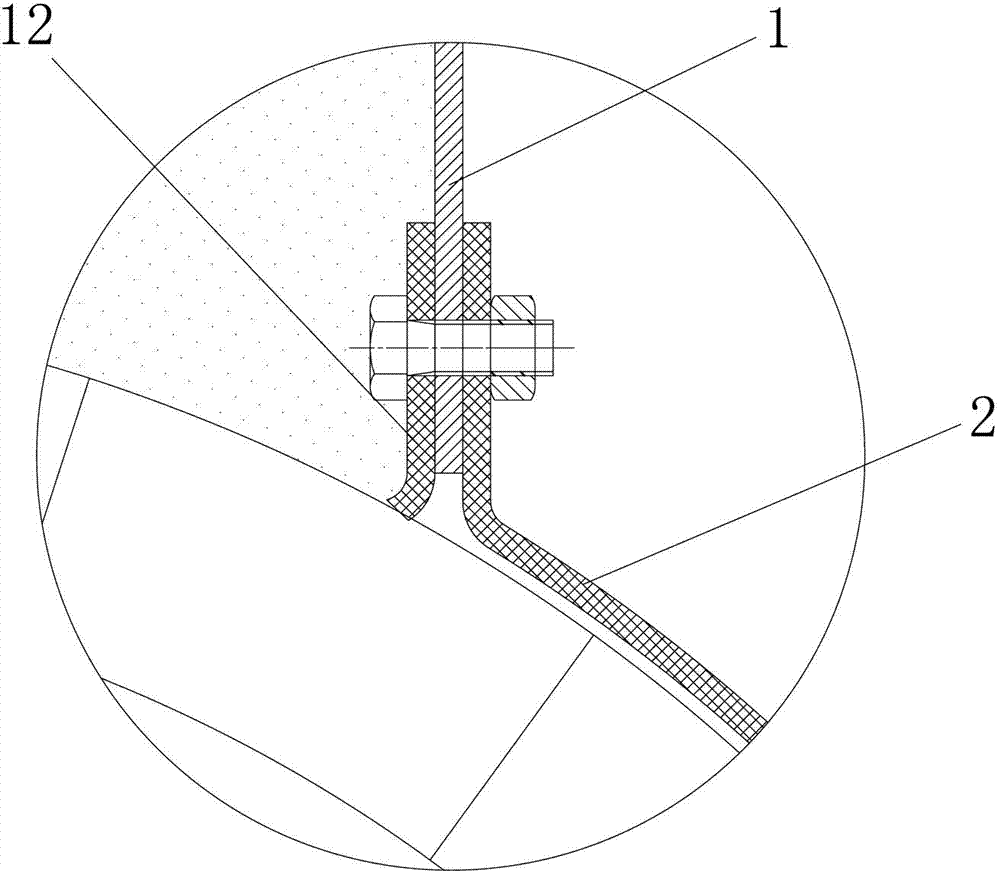

[0022] Embodiment 1: see attached figure 1 To attach Figure 4 As shown, the drum grid type filling device described in this embodiment includes a storage hopper 1, a dust cover 2, a drum 3 with a loading grid on the outer peripheral surface, a blanking hopper 4, and a drive unit 5 (specifically variable frequency motor), wherein, the drum 3 is horizontally arranged in the dust cover 2, and is driven to rotate by the drive unit 5 located on one side of its shaft end, and the grille 3 and the drive unit 5 are connected by a shaft or a sprocket chain The transmission is carried out, and at the same time, the grid shape of the loading grid on the outer peripheral surface of the drum 3 is rectangular; the storage hopper 1 is arranged adjacent to the top of the drum 3, and is fixedly connected with the dust cover 2, and the outlet of the storage hopper 1 The material opening is set on the side deviating from the axis of the drum 3 to ensure that there is no free fall of the powder...

Embodiment 2

[0023] Embodiment 2: see attached Figure 5 As shown, the difference from Embodiment 1 is that the grid shape of the loading grid in this embodiment is a regular hexagon.

Embodiment 3

[0024] Embodiment 3: see attached Figure 6 As shown, the difference from Embodiment 1 is that the grid shape of the loading grid in this embodiment is circular.

[0025] After adopting the above scheme, the present invention can ensure accurate, uniform, smooth and reliable powder filling action. Compared with the prior art, the present invention has a compact and simple structure, a small footprint, less mechanical action during the filling process, and high efficiency. , no powder leakage, easy to adjust the amount of powder input, wide application range, can greatly reduce manufacturing and maintenance costs, it is worth promoting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com