Patents

Literature

47results about How to "Less mechanical action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

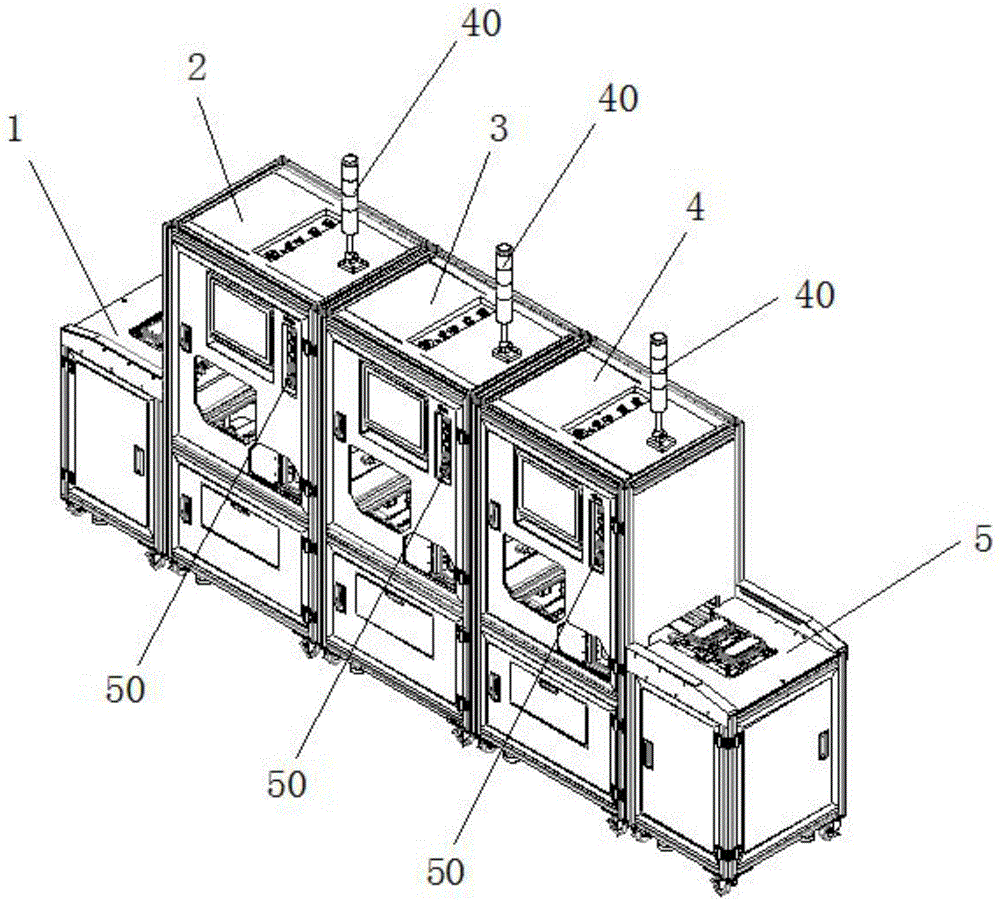

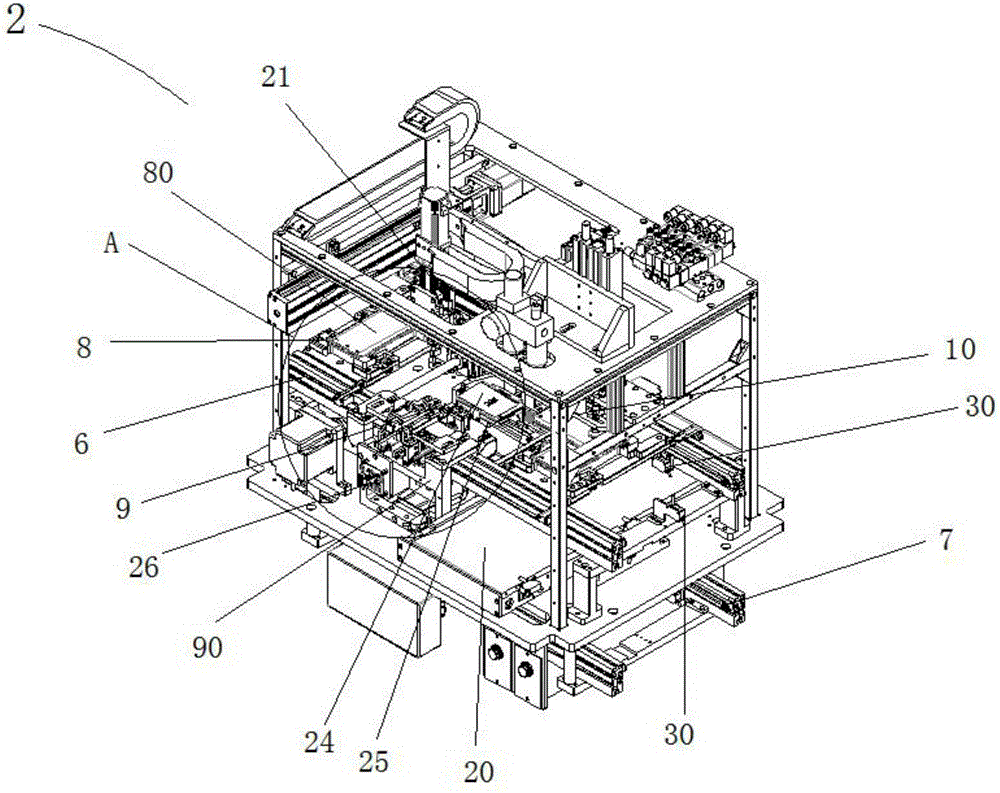

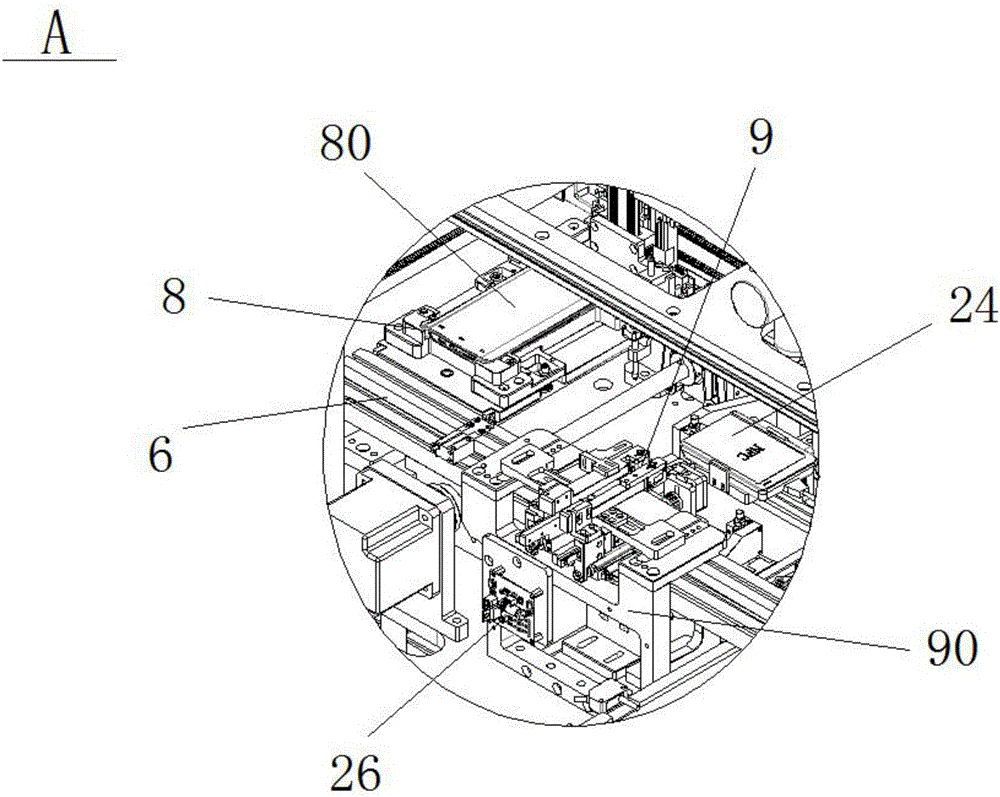

Automatic assembly line type cellphone online testing method and system

ActiveCN106092210AAccurate transmissionImprove accuracyMeasurement devicesSubstation equipmentTest efficiencyTestware

The invention discloses an automatic assembly line type cellphone online testing method, and the method comprises the following steps: (1), implanting testing software in a plurality of to-be-tested cellphones; (2), preparing an automatic assembly line type cellphone online testing system; (3), enabling the to-be-tested cellphones to be placed on a testing carrier, wherein the to-be-tested cellphones is driven by the upper conveying rail to move to a testing machine bench along with the testing carrier; (4), enabling a PC to transmit an AT instruction to built-in testing software in the to-be-tested cellphones through a testing communication model, enabling a PLC to drive the testing machine bench to carry out one operation for the to-be-tested cellphones according to the content of the AT instruction, and enabling the testing software to test the functions of the to-be-tested cellphones; (6), taking out the to-be-tested cellphones after the detection is finished, enabling the testing carrier to move to the lower end of a feeding bench along with a lower conveying rail, and enabling a front end lifting platform to lift the testing carrier back to the feeding bench. The method is quick and accurate in testing instruction transmission, improves the testing efficiency, is quick and precise in testing, and reduces the testing time.

Owner:广东每通测控科技股份有限公司

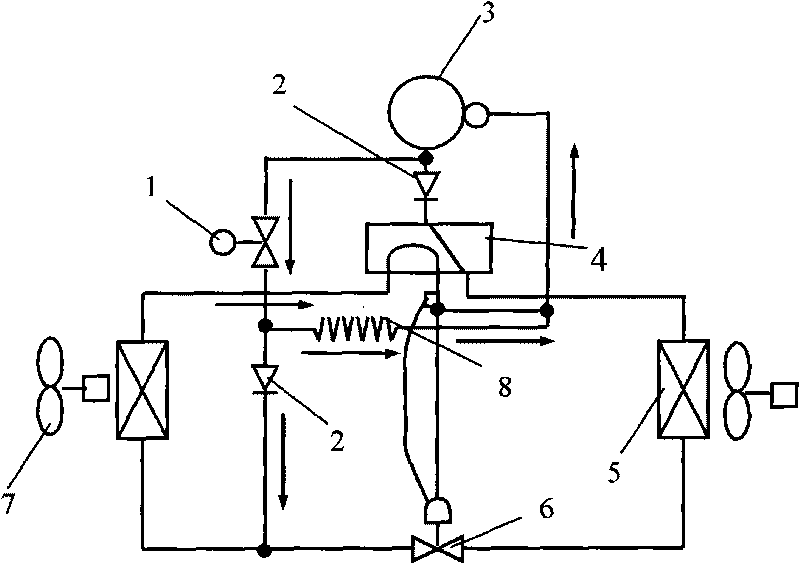

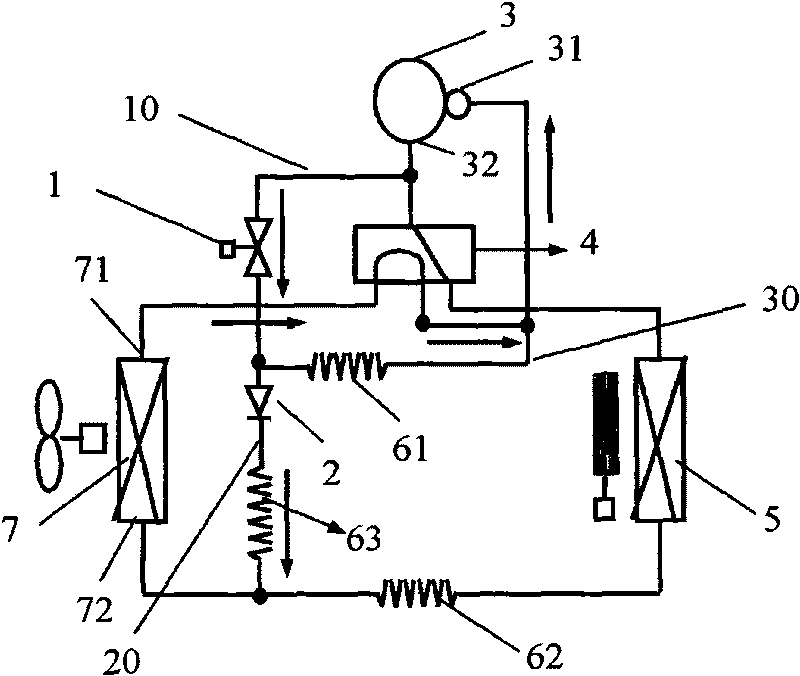

Hot air bypassing continuous heat-supply and defrost cycle structure of air conditioner

InactiveCN101749904AEasy to controlLess mechanical actionCorrosion preventionRefrigeration componentsAuto regulationSolenoid valve

The invention discloses a hot air bypassing continuous heat-supply and defrost cycle structure of an air conditioner, simple opening and closing of a capillary pipe and a solenoid valve are adopted to carry out the automatic adjustment of the refrigerant flow to realize the indoor continuous heat supply when the defrosting is carried out outside, the cycle structure has the advantages of simple control, less mechanical action and the like, thereby increasing the reliability of the air-conditioner system and having wide market application prospect.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

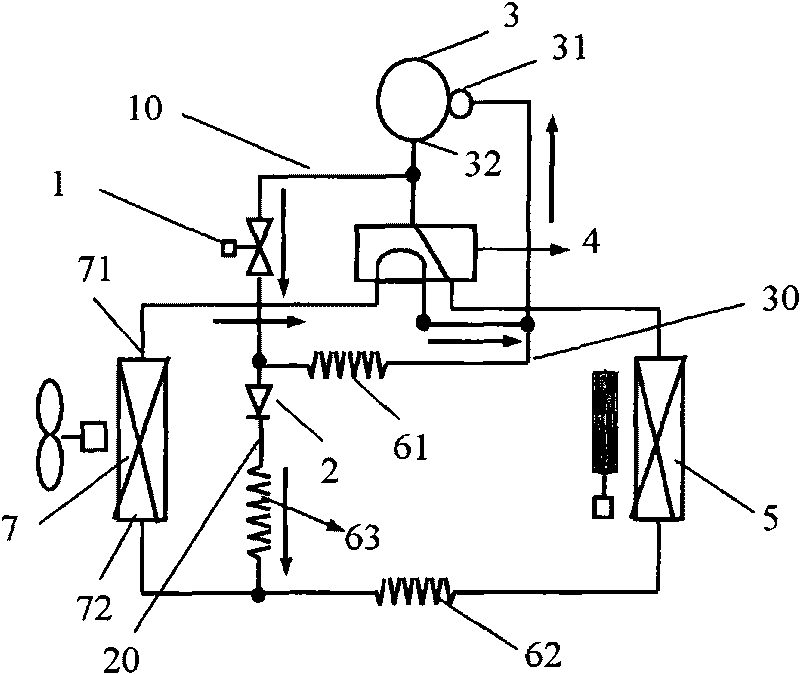

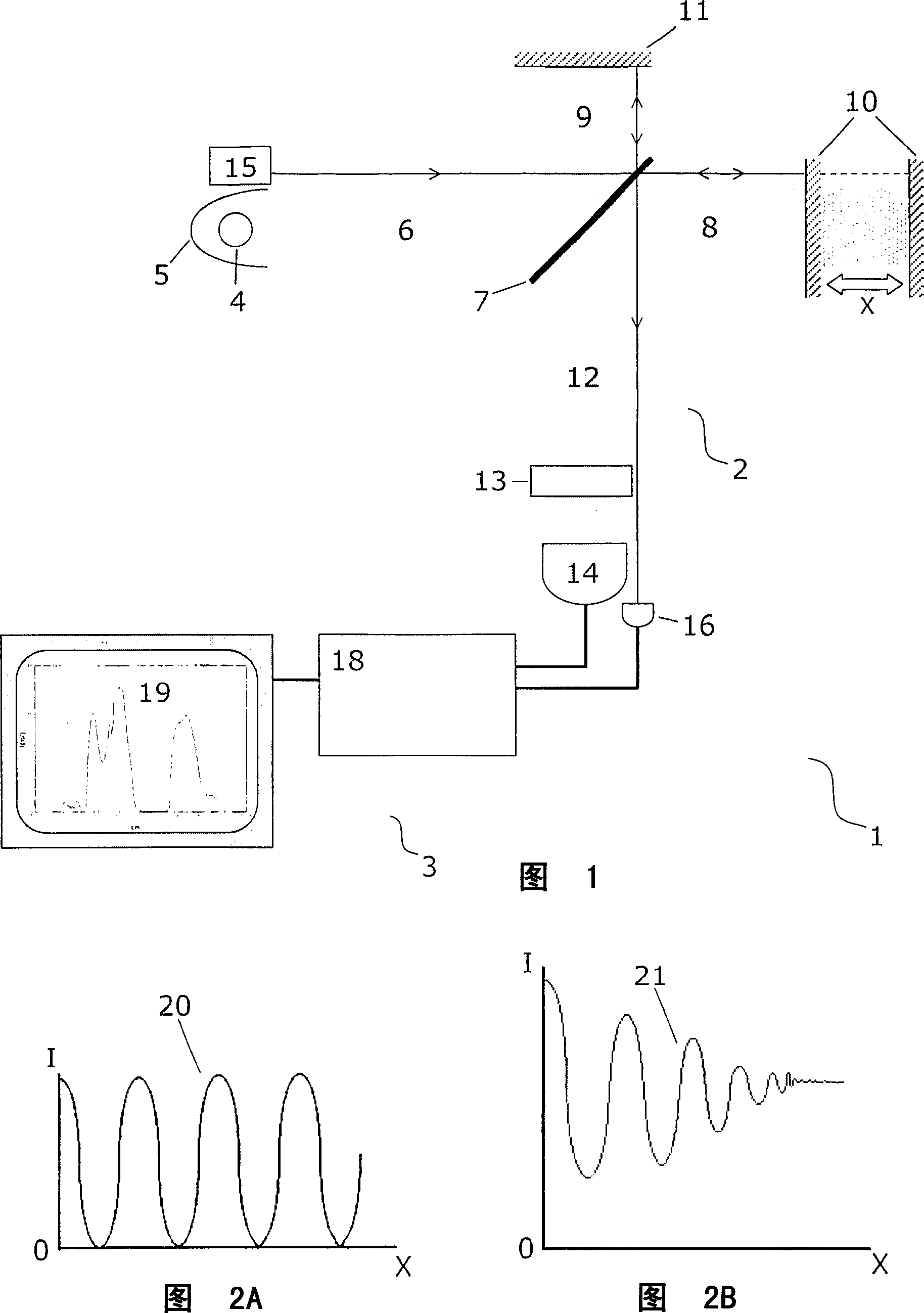

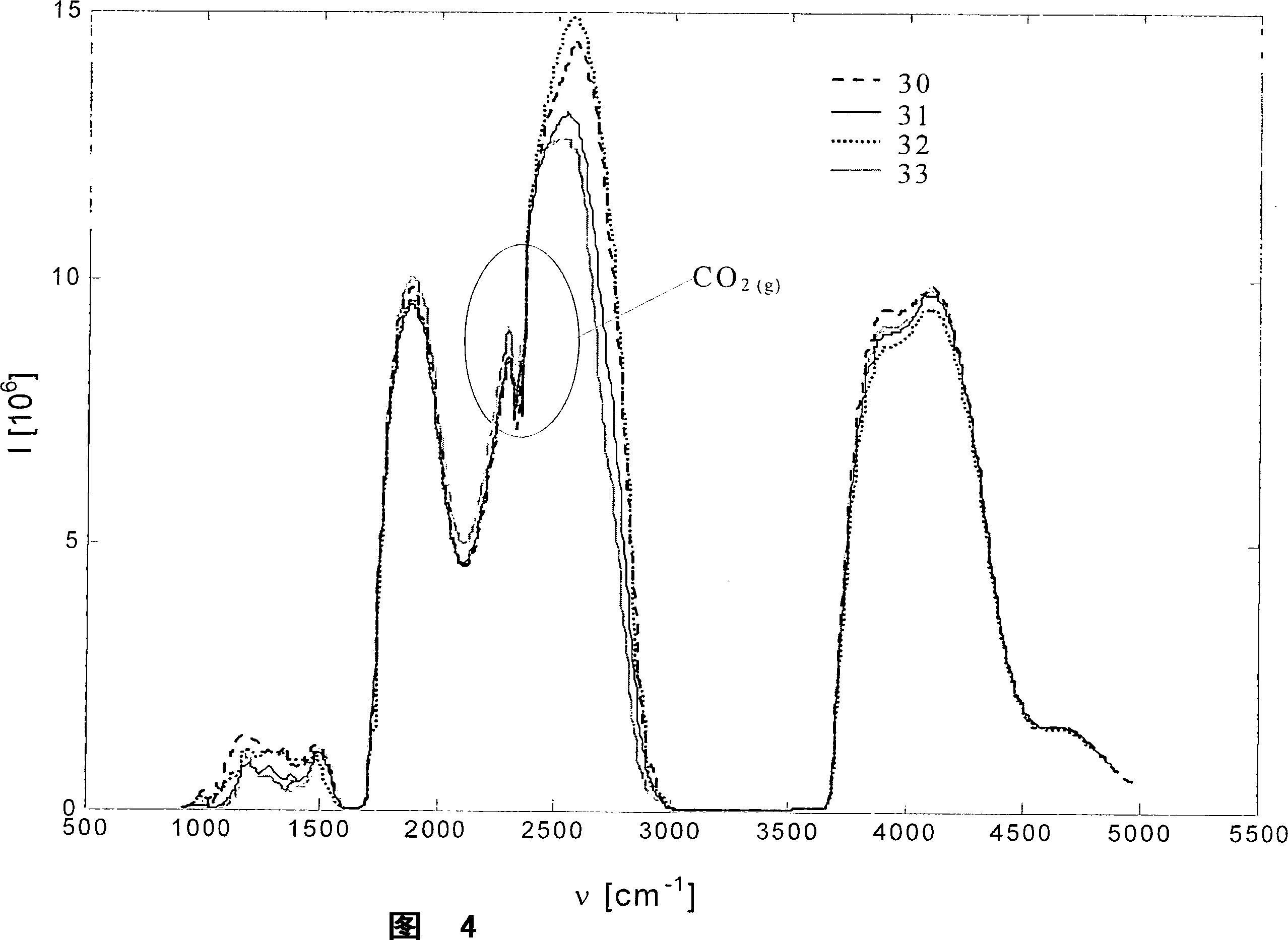

A method for standardising a spectrometer

InactiveCN101084419AAccurate CalibrationQuick calibrationRadiation pyrometrySpectrum investigationSpectral patternReference sample

The invention provides a method for standardising an infrared spectrometer based on spectral patterns of constituents of atmospheric air naturally occurring in the spectrometer. The invention also provides a spectrometer applying the method. The method selects a spectral pattern in a recorded spectrum and determines a wavelength dependent position value for a feature, such as the centre of the pattern. This value is compared to a reference value that may be obtained from a spectrum recorded by a master instrument, and a standardisation formula can be determined. The absorption peaks from CO2 (g)around 2350 cm<-1> are preferred as the selected pattern. The method renders the use of reference samples unnecessary and allows for the standardisation to be performed simultaneously with the recording of a spectrum of a sample of interest.

Owner:FOSS ANALYTICAL AS

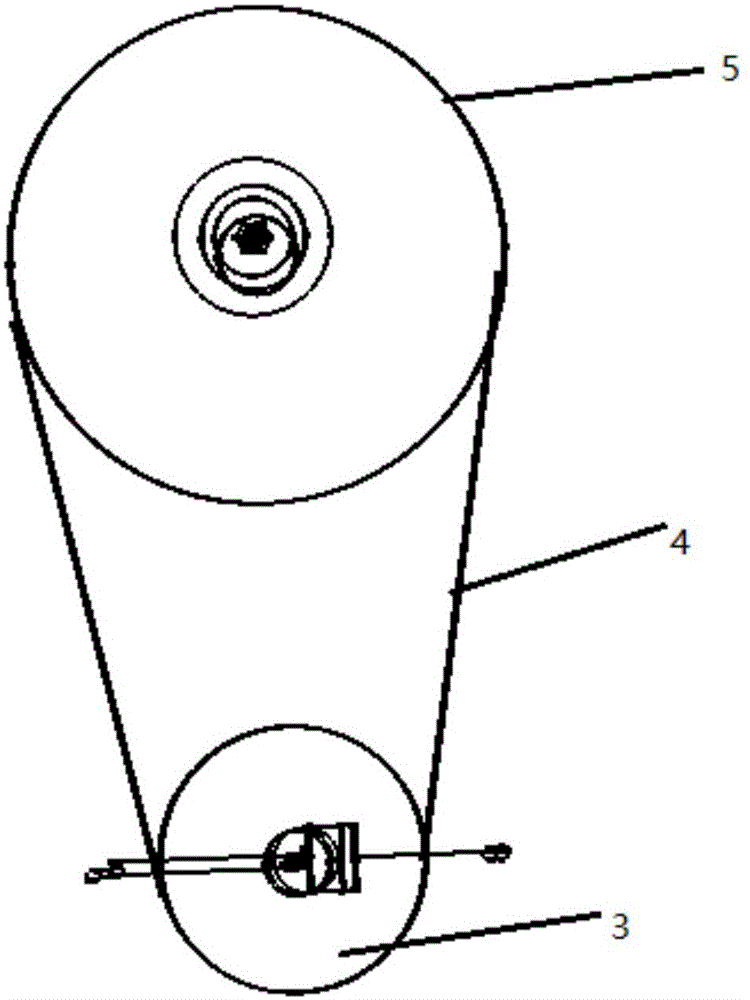

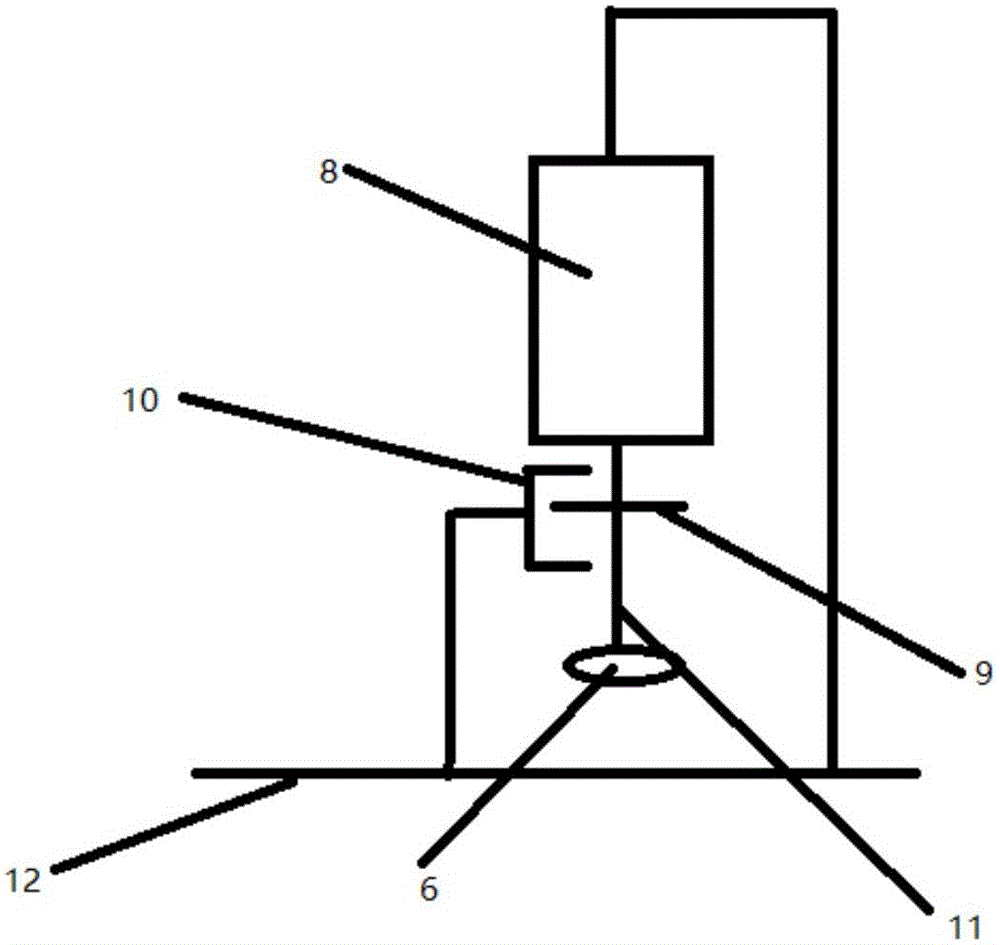

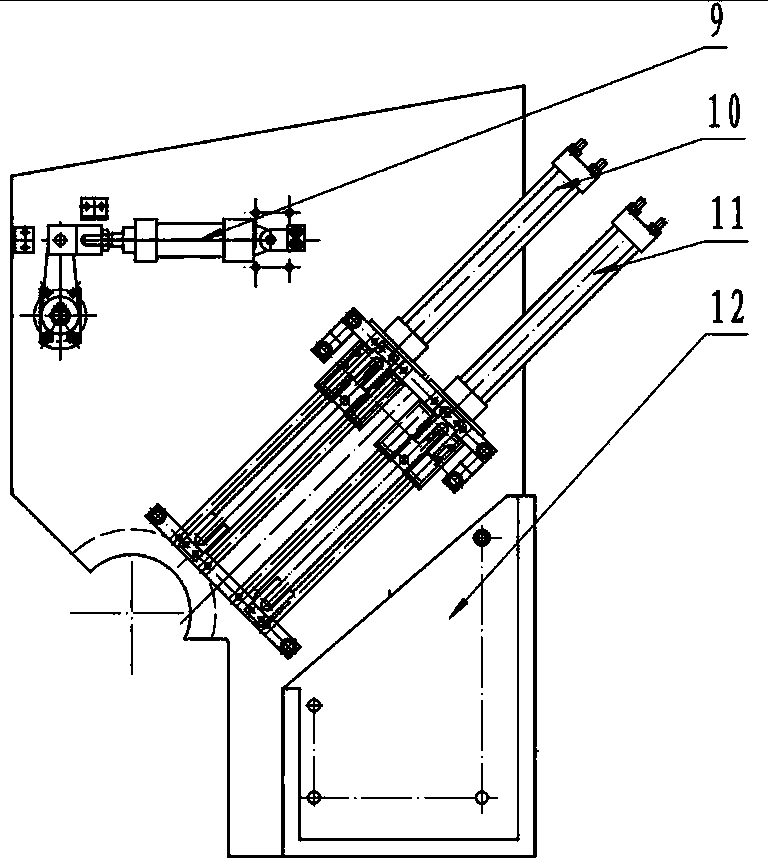

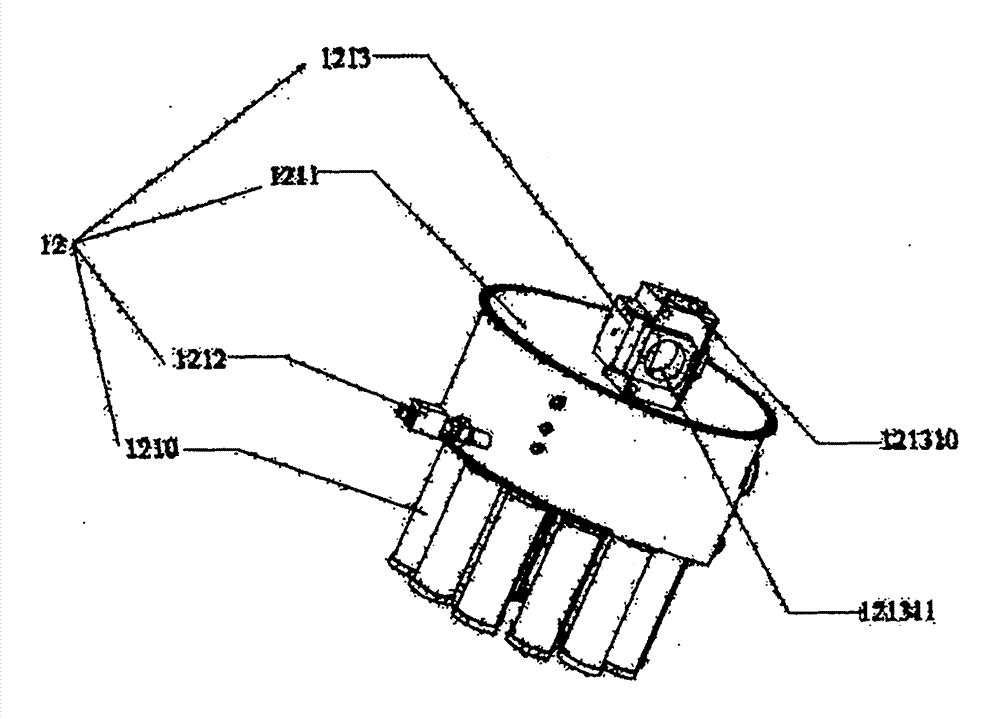

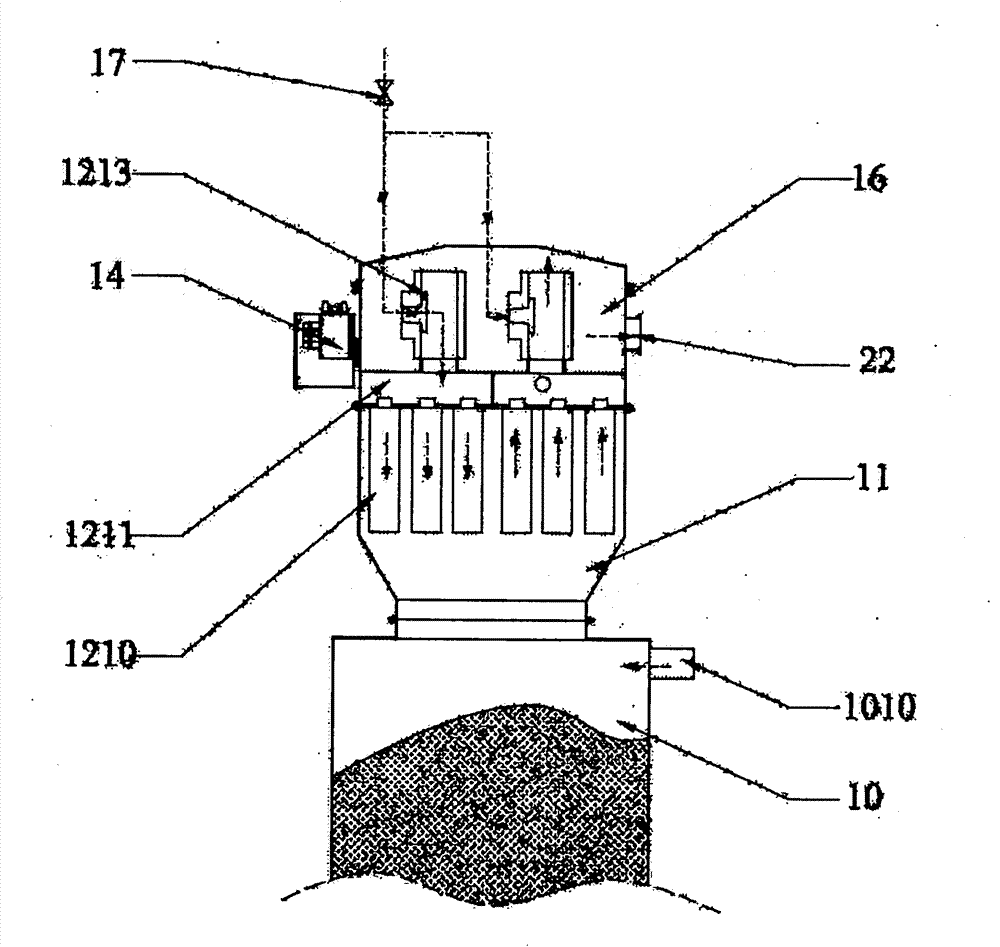

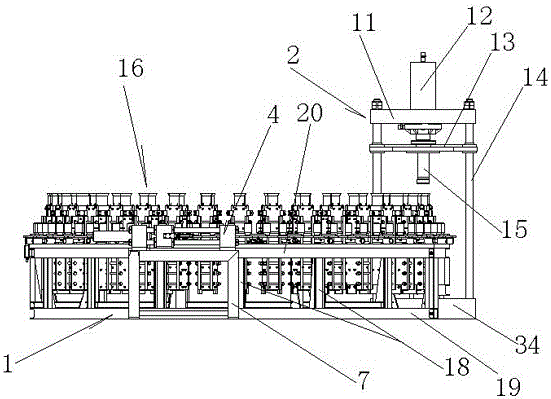

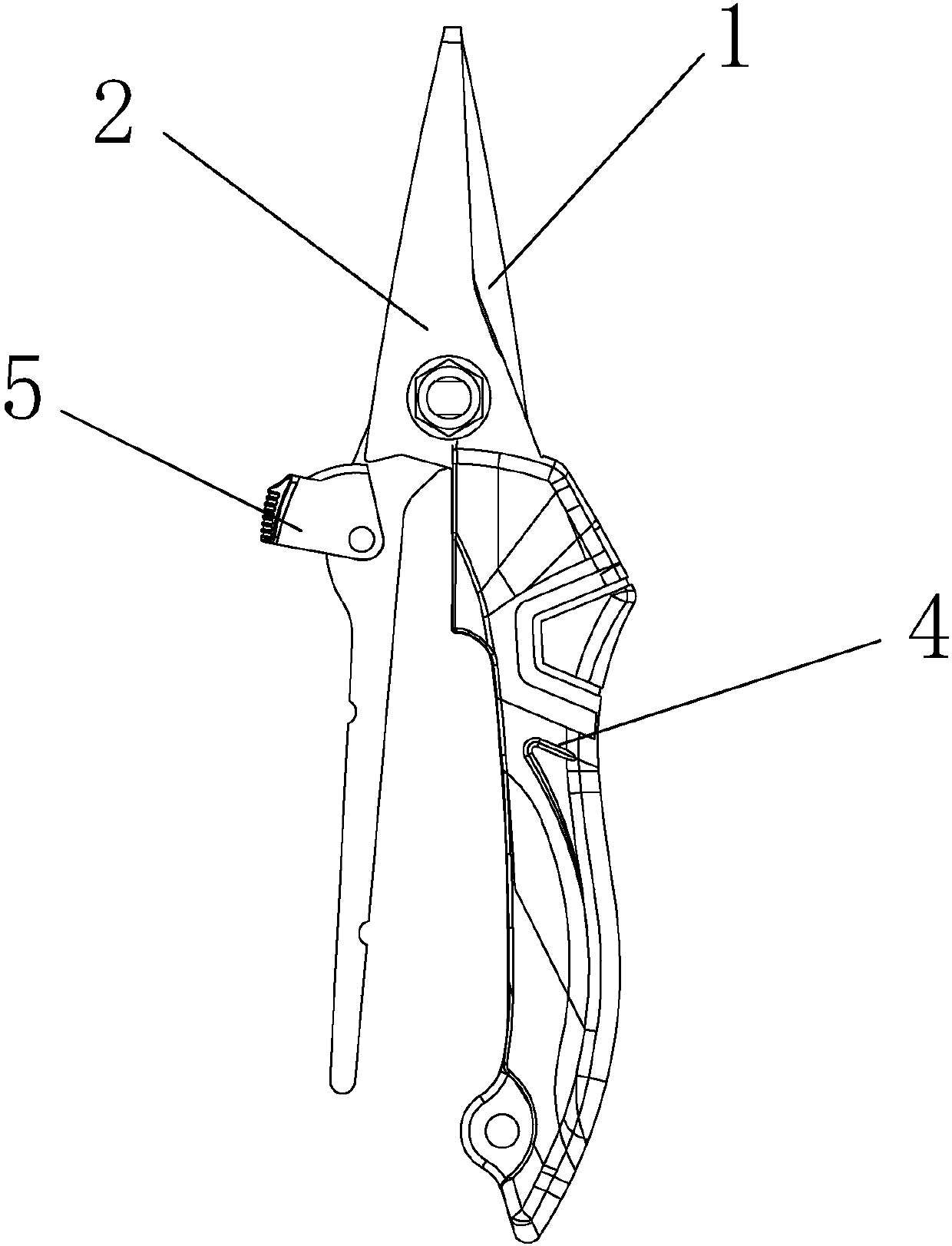

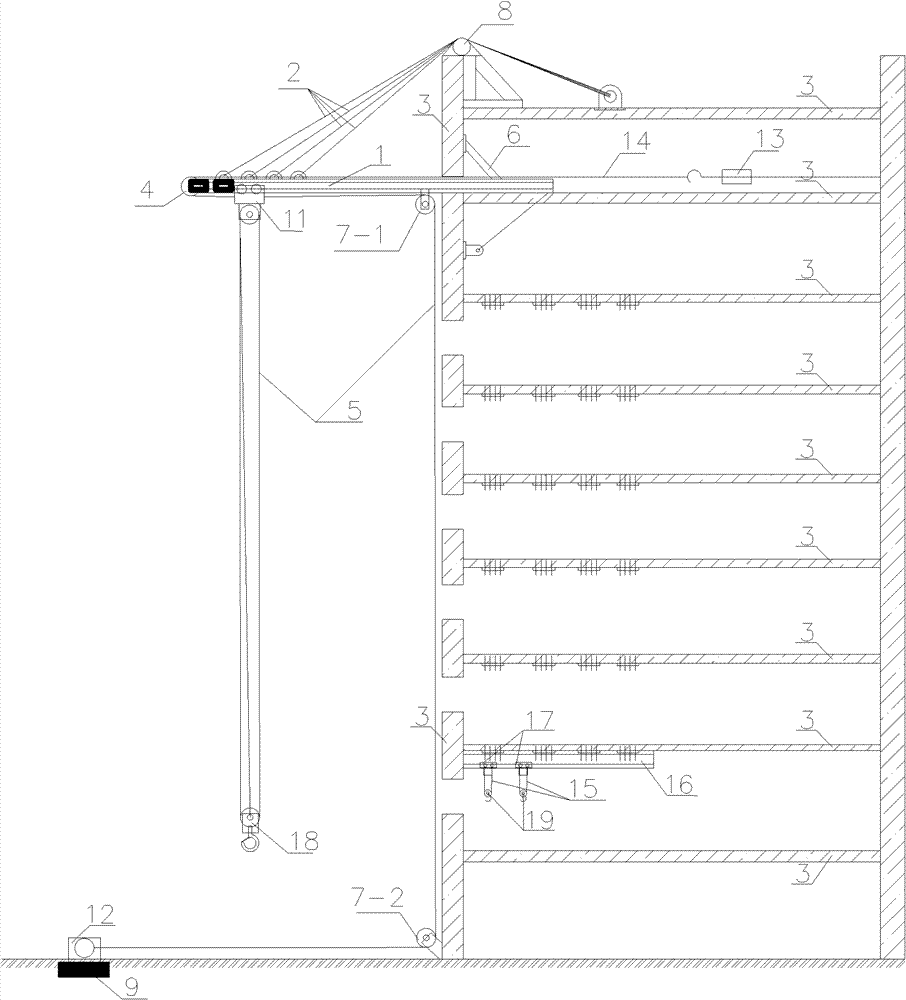

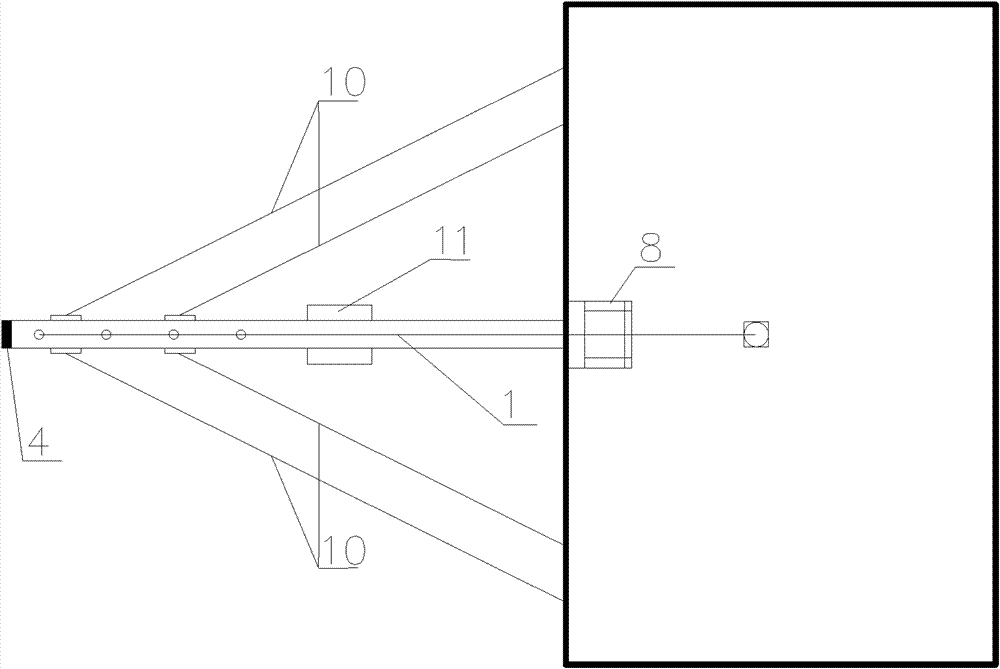

Process for charging and packing industrial powder explosive cartridge and vibratory charging machine

The invention relates to the technical field of explosives, in particular to a process for charging and packing an industrial powder explosive cartridge and a vibratory charging machine. The process for charging and packing the industrial powder explosive cartridge is characterized by comprising a cartridge finishing and fixed connecting process, a cartridge charging process and a cartridge sealing process. The vibratory charging machine is characterized by comprising a stander; the stander is provided with a frame conveying mechanism, a charging station and a sealing station; the charging station is provided with a charging ramming mechanism and a compaction mechanism; and the sealing station is provided with a sealing mechanism. The process has the advantages of short flow, high safety performance, high working efficiency, good charging quality, and the like; and the vibratory charging machine has the advantages of high essential safety level, high product quality qualification rate, high automation degree, large capacity, compact and reasonable structure, little occupied area, few operation personnel at a dangerous area, and the like.

Owner:蒙宝林

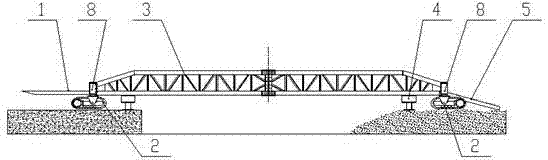

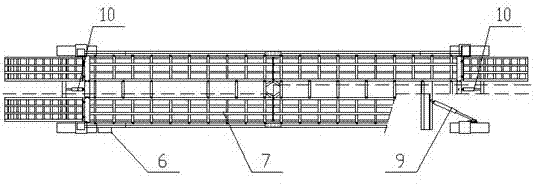

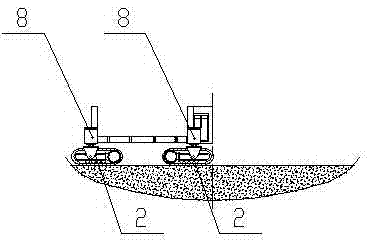

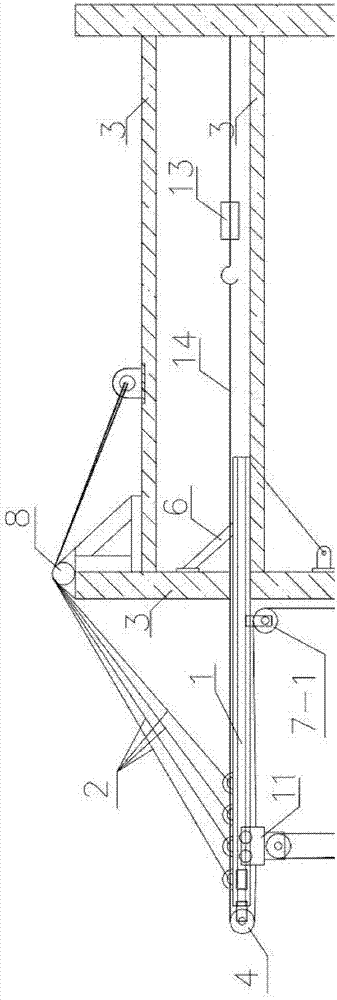

Full-hydraulic crawler-type self-moving trestle

InactiveCN104499416AHigh degree of automationEasy to operateBridge structural detailsTravelling bridgesControl engineeringHydraulic pump

A full-hydraulic crawler-type self-moving trestle comprises a main trestle body, a front end trestle approach, a pier, a rear end trestle approach, a hydraulic pump station, a trestle approach hydraulic oil cylinder and a hydraulic control system. The two ends of the main trestle body are each provided with a main lifting hydraulic oil cylinder, and a crawler-type walking device is arranged on the lower portions of the main lifting hydraulic oil cylinders, and a walking steering hydraulic oil cylinder is arranged on one side of the crawler-type walking device; and the other end of the walking steering hydraulic oil cylinder is fixed to the pier. The full-hydraulic control is adopted, automation degree is high, and operation is convenient and reliable; conversion between transverse moving and longitudinal moving is rapidly achieved through a walking steering system; investment of manpower and other auxiliary machines is small; labor intensity of a worker is reduced; the working efficiency is improved; truss type guardrails are designed on the two sides of the trestle; and safety of a vehicle in the passing process is ensured.

Owner:中铁隧道集团隧道设备制造有限公司

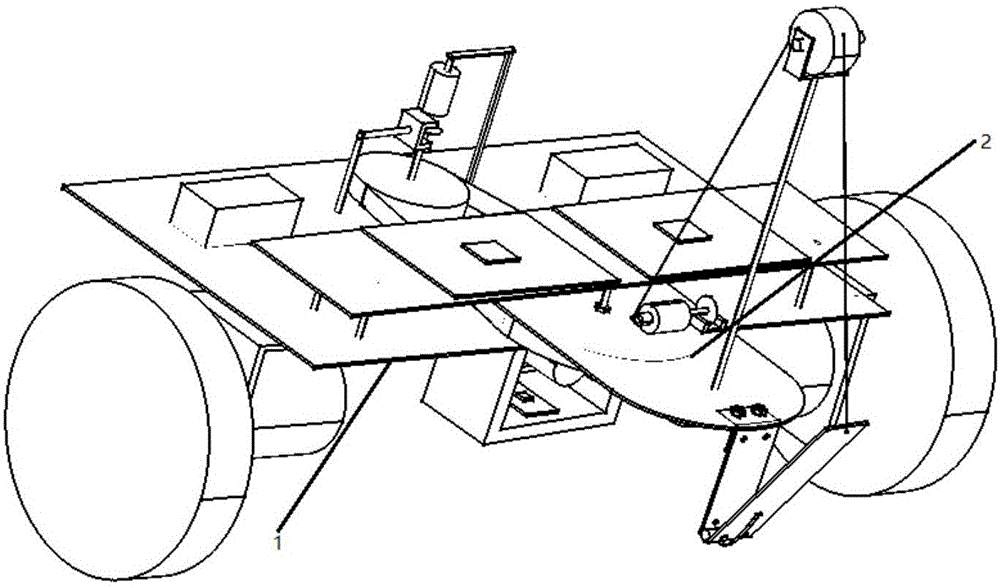

Two-wheeled balance car with bionic tail structure

The invention discloses a two-wheeled balance car with a bionic tail structure, and belongs to the technical field of automatic control. According to the two-wheeled balance car, the bionic principle is applied to modern life, a mechanical tail is abstracted from the great significance of tails in animal motion for self balance, an automatic control system is regulated and controlled through the mechanical tail, and therefore the overall stability of the system is improved, the two-wheeled balance car with the bionic tail structure is regulated and controlled under limiting conditions, and the response time needed by the system for restoring the balance state can be greatly shortened. According to implementation of the two-wheeled balance car, a body is kept balanced through the mechanical tail structure which is arranged on the rear portion of the two-wheeled balance car and utilizes the bionic principle via vertical and left-and-right motion, meanwhile, the two-wheeled balance car is controlled to be balanced by controlling independent rotation (speed and direction) of two wheels for cooperation, and therefore the obvious defects existing in automatic balance of the two-wheeled balance car are overcome through the design. In addition, the functions which cannot be achieved by other two-wheeled car platforms or are hard for other two-wheeled car platforms to achieve are shown.

Owner:JILIN UNIV

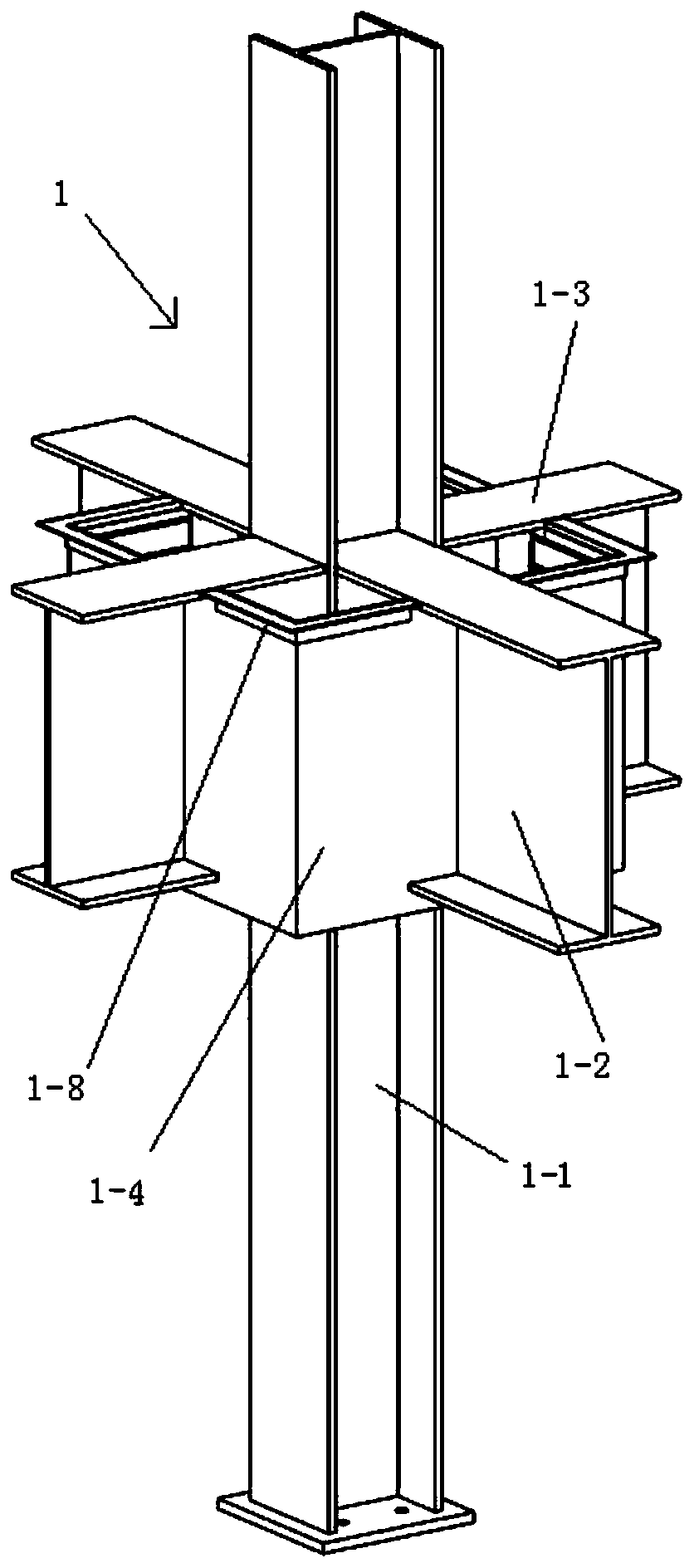

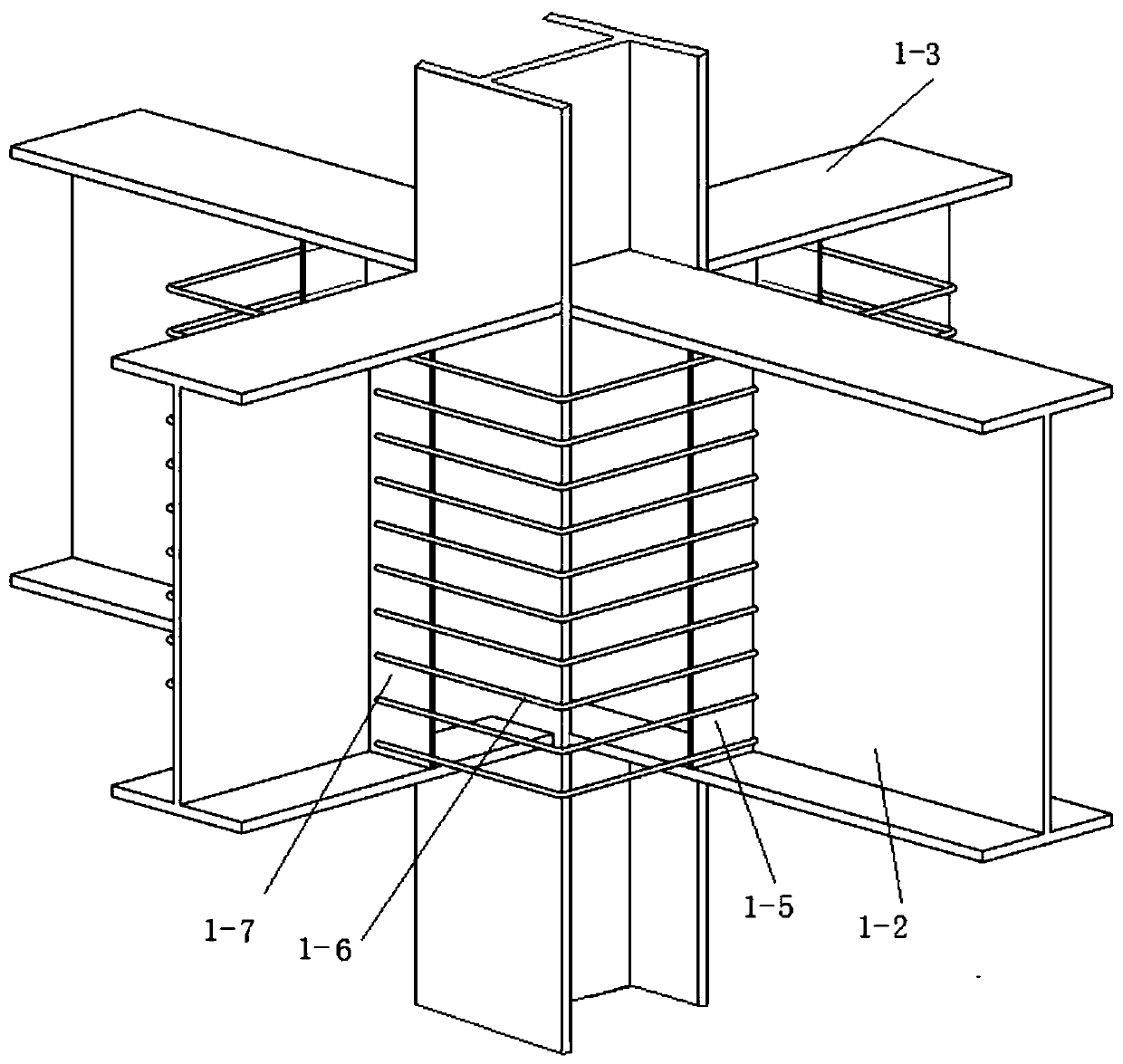

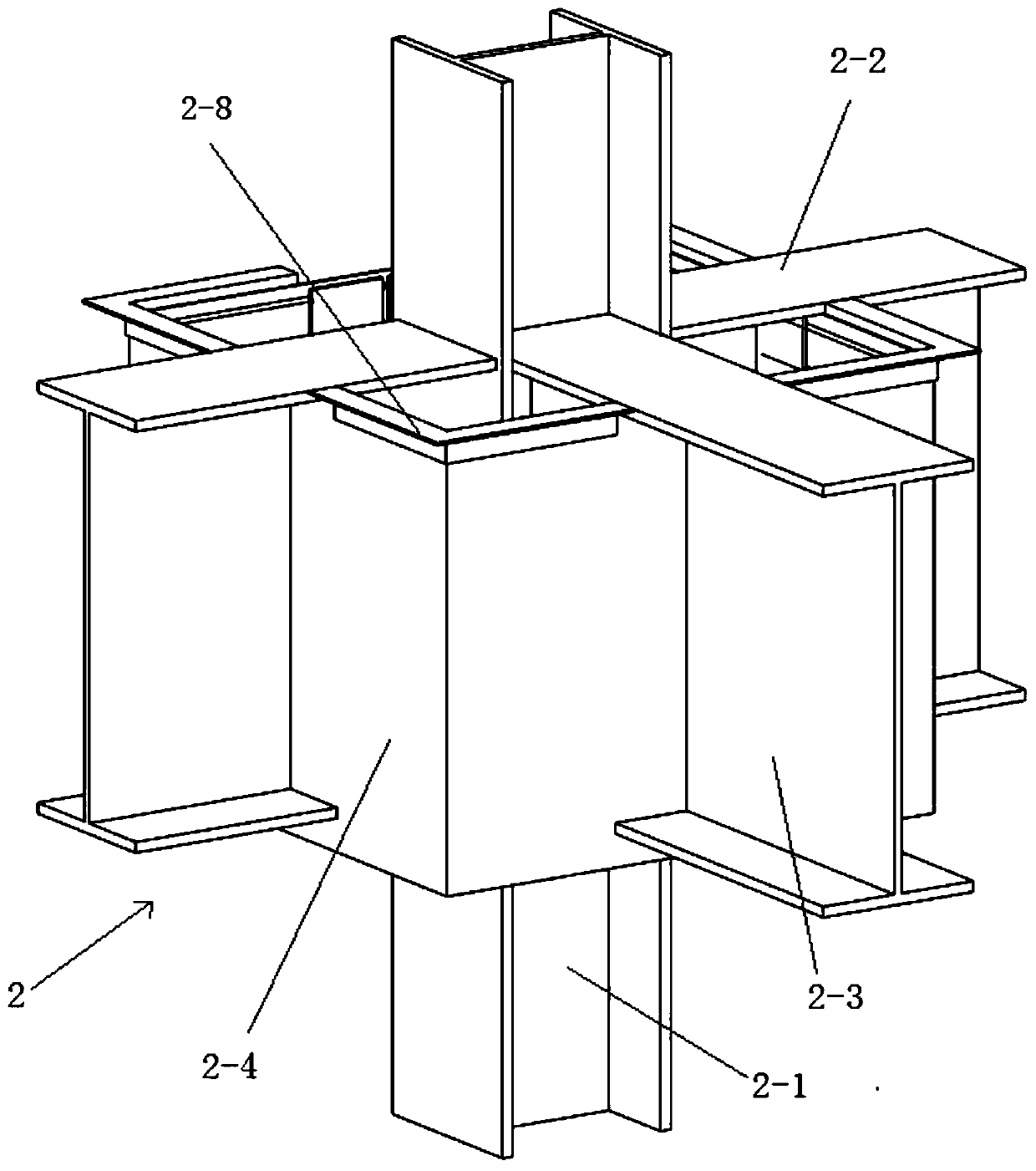

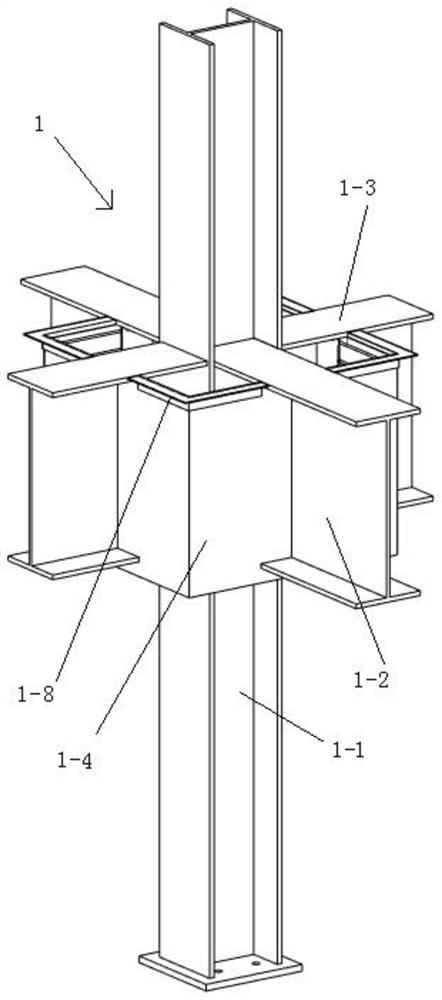

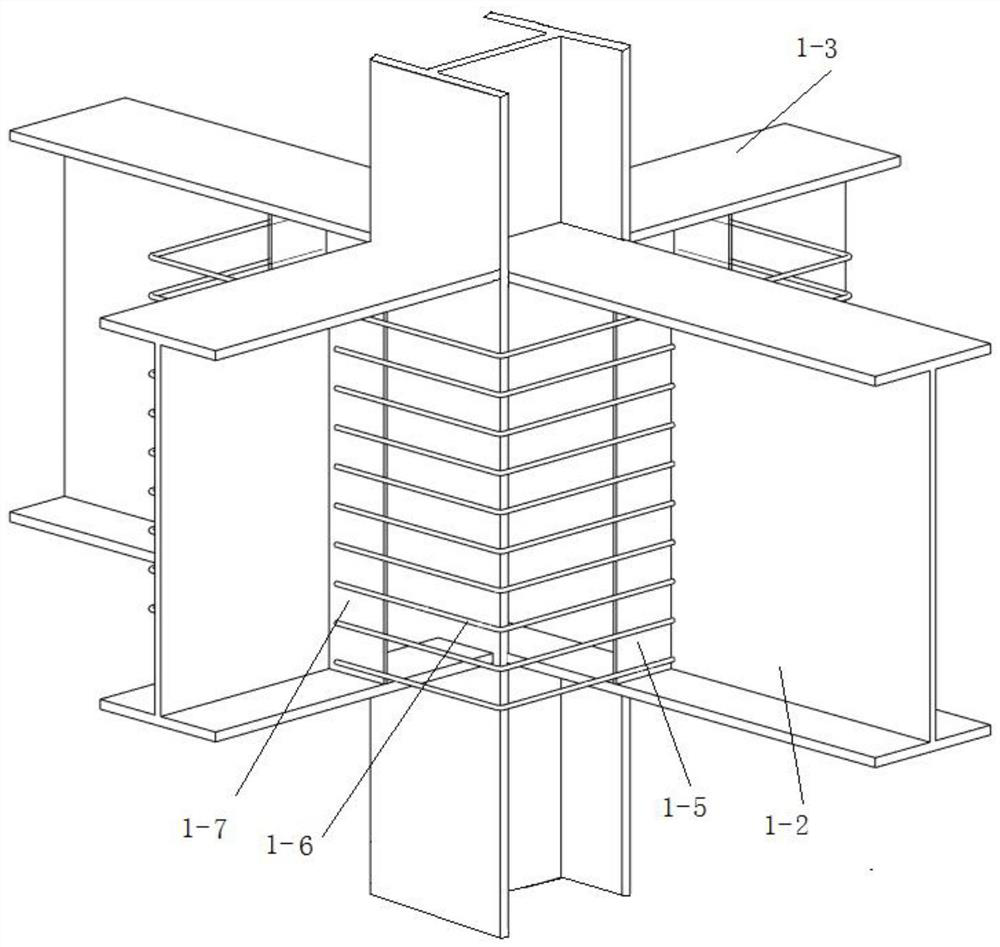

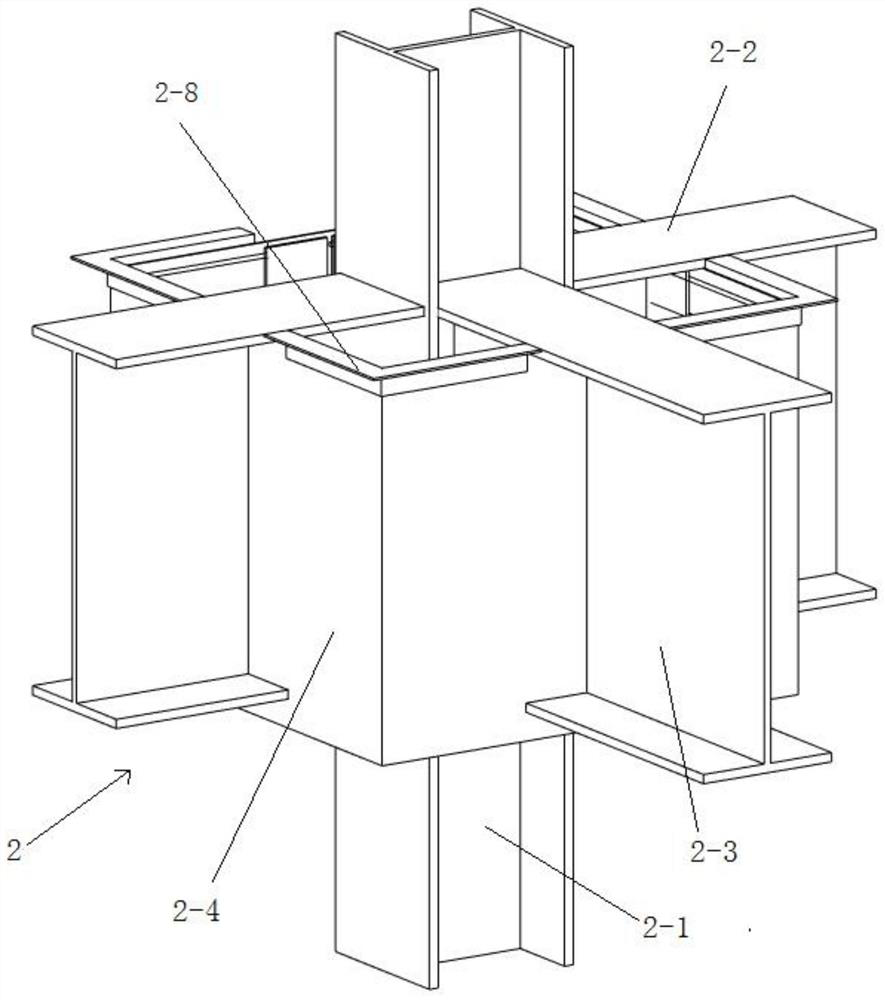

Construction method of steel rib column beam-column joint

ActiveCN110206144AThe construction method steps are simpleEasy constructionBuilding constructionsSteel barMechanical equipment

The invention discloses a construction method of a steel rib column beam-column joint. The construction method comprises the following steps: 1, machining of a steel rib column beam-column joint shaping protection barrel; 2, hoisting of a beam-column frame; 3, mounting of a steel bar truss floor bearing plate, and binding of vertical steel bars; and 4, erecting of a steel rib column formwork, andpouring of concrete. The construction method is simple in steps, convenient to construct and easy to operate, the beam-column joint does not need be supported by a wooden formwork, input labor force and mechanical equipment are less, and the construction effect is good; and after pouring, formwork removing is avoided, the problems of large formwork removing task and more labor force input are solved, and practicality is high.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

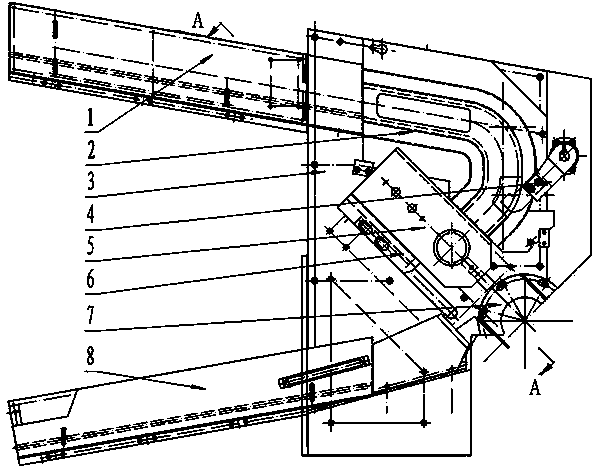

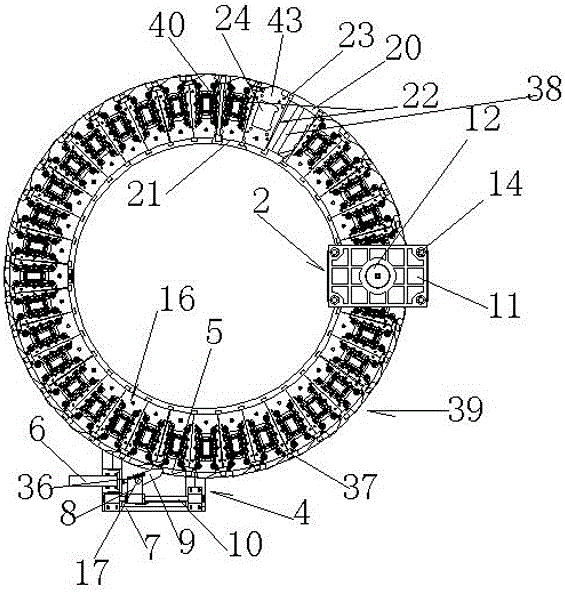

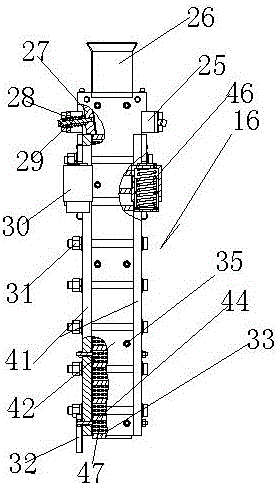

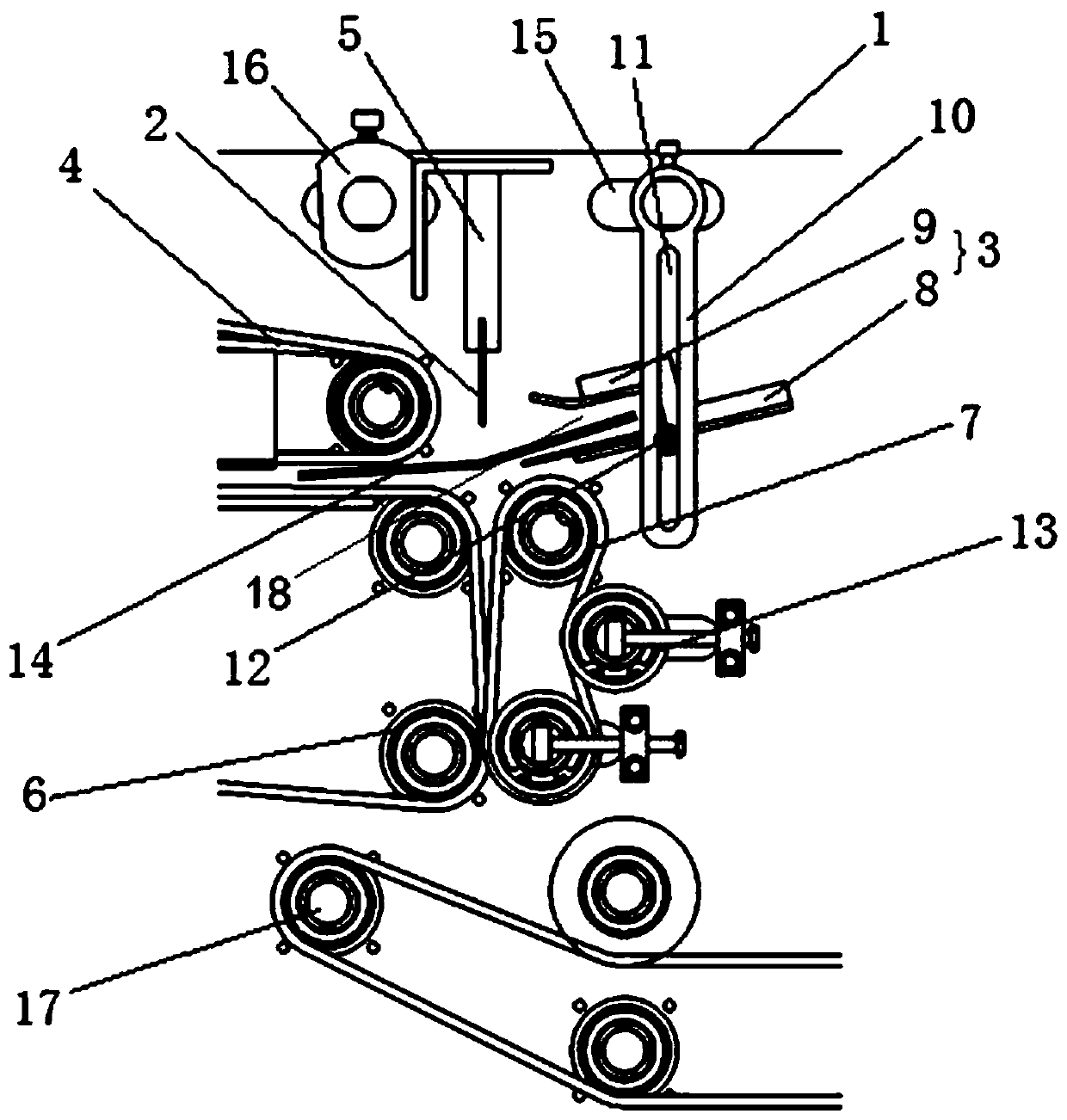

Charging and discharging device for outer circle groove grinder of automobile hub bearing unit, and application of device

ActiveCN103769977ALess mechanical actionFast loading and unloadingGrinding machinesGrinding feedersMachining timeBearing (mechanical)

The invention relates to a bearing grinder charging and discharging technology, in particular to a charging and discharging device for an outer circle groove grinder of an automobile hub bearing unit, and the application of the device. The charging and discharging device for the outer circle groove grinder of the automobile hub bearing unit comprises a panel, wherein a charging channel, a transitional material channel, a discharging channel, a material separation oil cylinder, a main manipulator oil cylinder and an auxiliary manipulator oil cylinder are fixedly arranged on the panel; the charging channel is connected with the transitional material channel; a material separation manipulator is arranged on one side of the transitional material channel and is connected with the material separation oil cylinder; the main manipulator oil cylinder and the auxiliary manipulator oil cylinder are positioned at the tail end of the transitional material channel; a main manipulator is connected with the main manipulator oil cylinder; an auxiliary manipulator is connected with the auxiliary manipulator oil cylinder; a fan-shaped plate is arranged at a grinding station on the panel; the discharging channel is arranged at a position corresponding to the fan-shaped plate. Compared with a common charging and discharging device, the charging and discharging device for the outer circle groove grinder of the automobile hub bearing unit has the advantages that waiting time for discharging and charging is not needed; the device is less in mechanical motion, high in charging and discharging speed and high in stability, the non-machining time is greatly shortened, and the efficiency is improved.

Owner:PUYANG BEAIN CNC MACHINERY & EQUIP

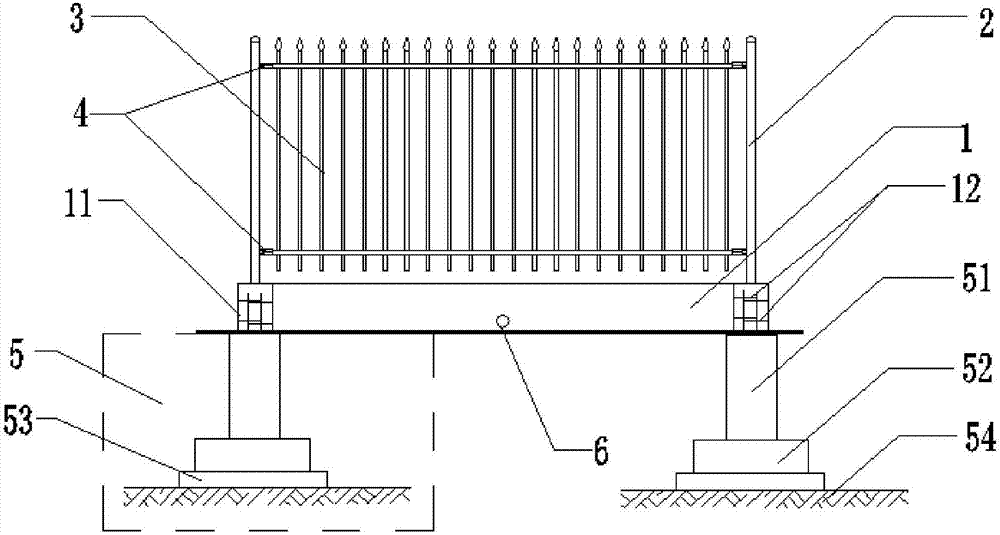

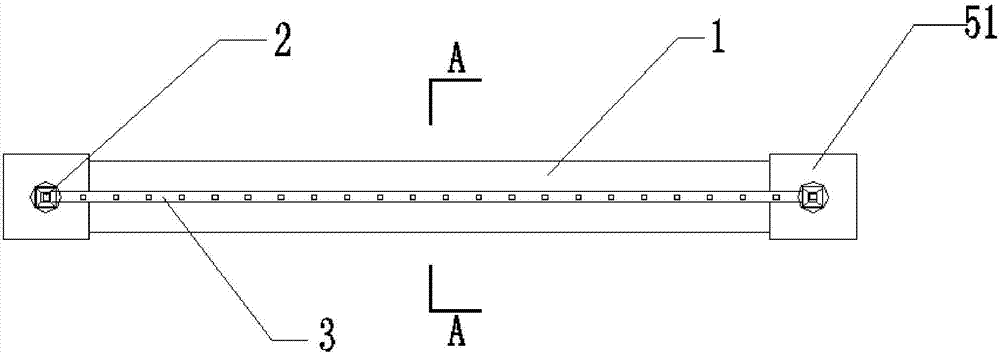

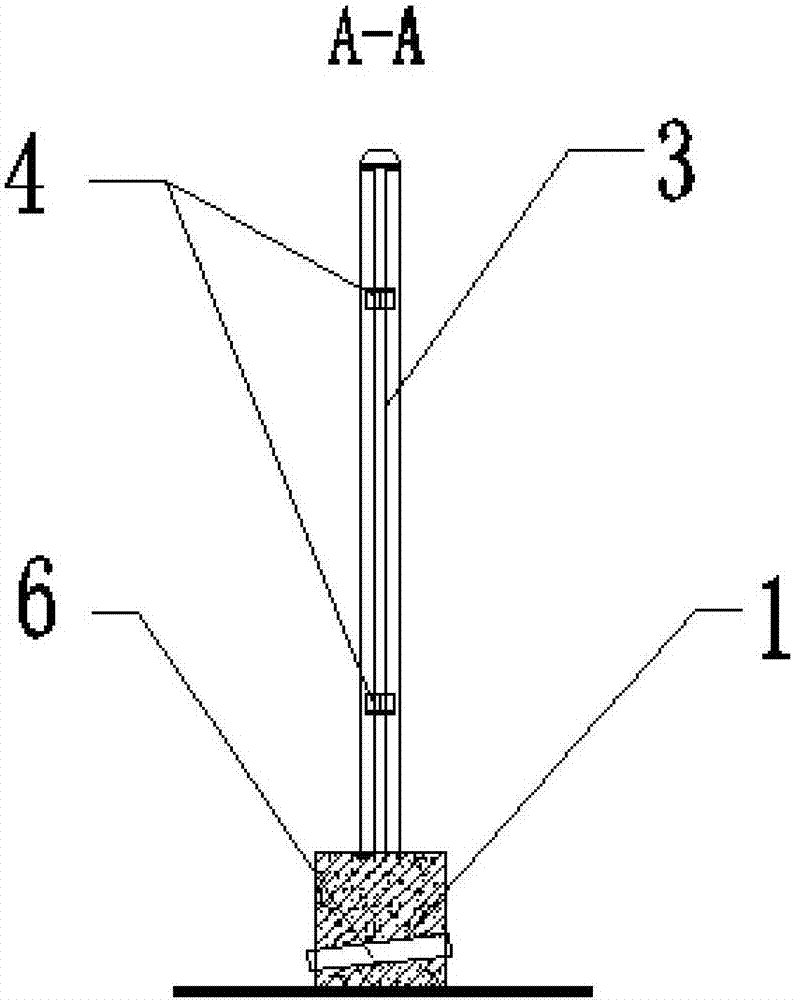

Fabricated enclosing wall and construction method thereof

The invention provides a fabricated enclosing wall. The fabricated enclosing wall comprises ground beams, supporting uprights and an underground foundation part. The ground beams are laid above the ground, a plurality of ground beam reinforcing bars are laid into the ground beams in the horizontal direction, and every two adjacent ground beams stretch out of the ground beam reinforcing bars at the two ends and are arranged at connecting nodes in a staggered and lap-joint mode. The underground foundation part comprises a foundation short column, a bearing table, a cushion layer and a plain soil punning layer. The foundation short column is of a hollow structure, and the bearing table, the cushion layer and the plain soil punning layer are sequentially arranged below the foundation short column from top to bottom. The hollow structure of the upper portion of the foundation short column is internally provided with vertical steel bars and a plurality of stirrups. The vertical steel bars extend into the connecting nodes of every two adjacent ground beams and are in perpendicular lap-joint connection with the ground beam reinforcing bars. The invention further provides a construction method of the fabricated enclosing wall. The fabricated enclosing wall is stable in structural stress, solid and durable; the construction method is high in construction speed and facilitates installation; and the product quality is good.

Owner:汤始建华建材(天津)有限公司

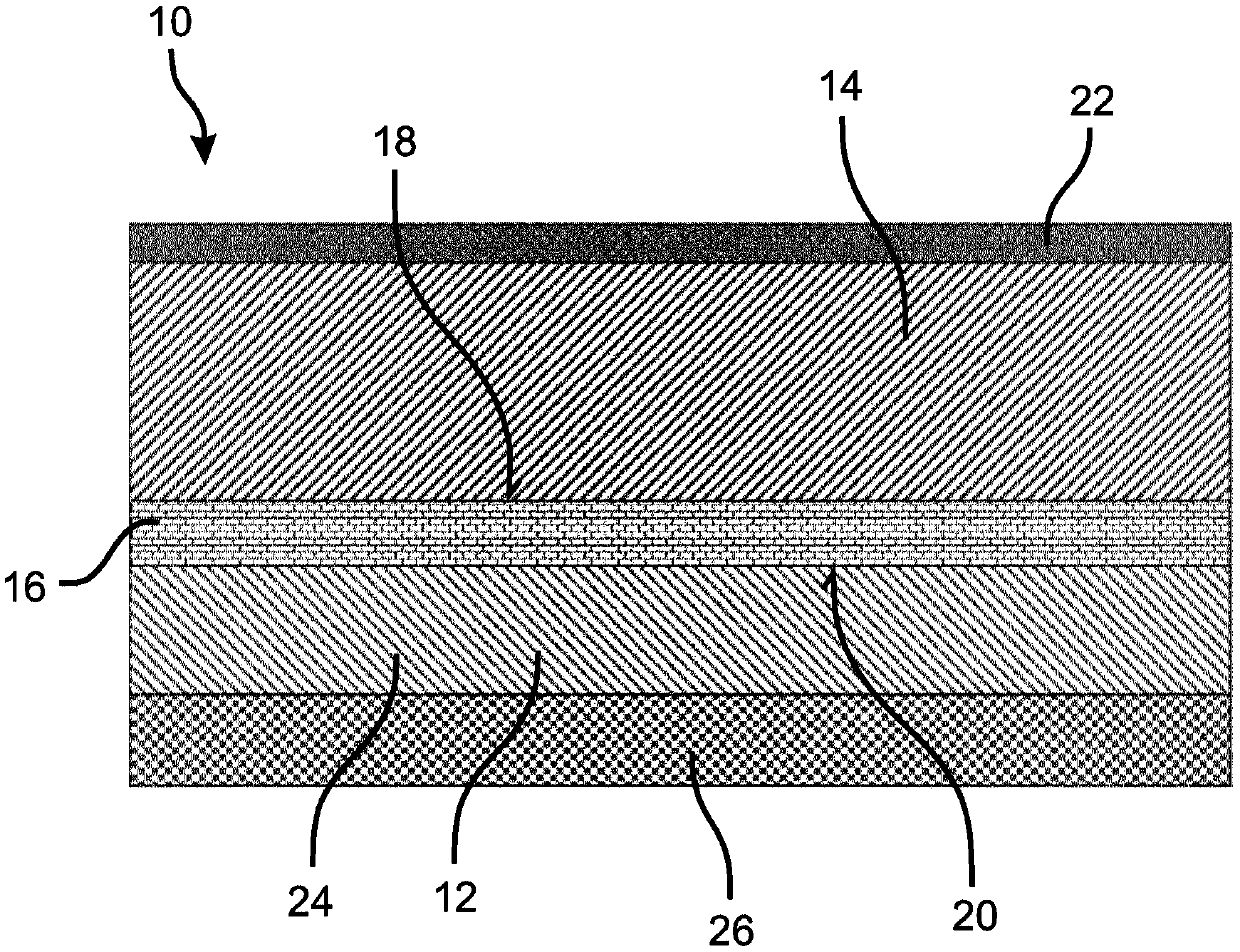

Method for Producing an Electrochemical Cell Comprising a Lithium Electrode, and Electrochemical Cell

ActiveCN109565028AHigh mechanical strengthEasy to operateElectrode rolling/calenderingElectrode thermal treatmentMetallic lithiumLithium metal

The invention relates to a method for producing an electrochemical cell (10) for a solid-state battery comprising a negative electrode (12), a positive electrode (14) and a lithium-ion-conducting solid electrolyte (16) arranged between the negative electrode and the positive electrode, wherein the negative electrode (12) comprises a layer of metallic lithium (24) which directly adjoins the solid electrolyte (16). In order to produce the electrochemical cell (10), the layer of metallic lithium (24) is heated until it softens before being joined together with the solid electrolyte (16). An electrochemical cell (10) according to the invention comprises the negative electrode (12) comprising a layer of metallic lithium (24) which directly adjoins the solid electrolyte (16), and a layer of a lithium-metal alloy (26) on the layer of metallic lithium.

Owner:BAYERISCHE MOTOREN WERKE AG

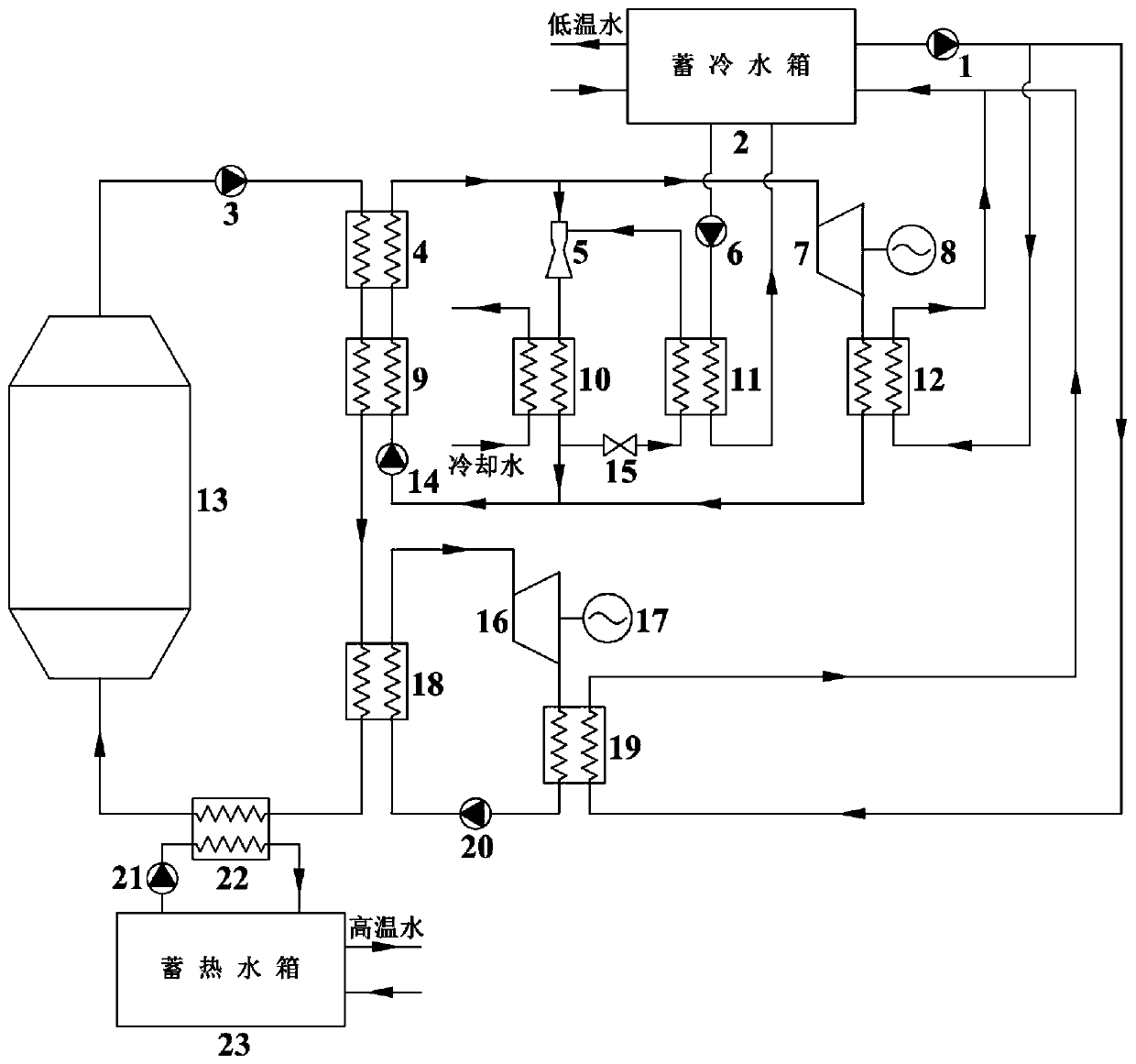

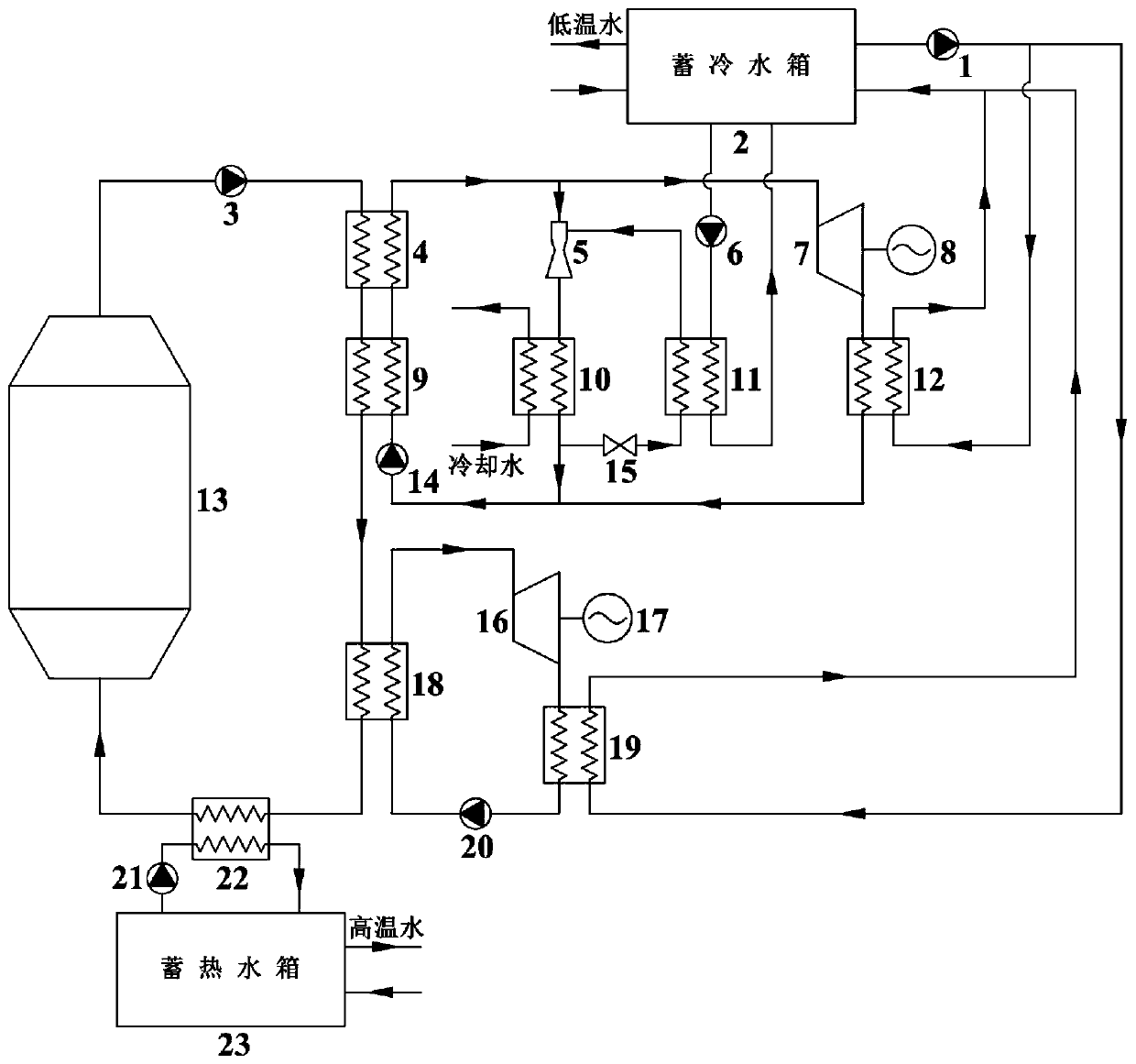

Distributed energy system utilizing dry quenching waste heat

ActiveCN109707472AEfficient use ofSimple structureCentral heating with accumulated heatCompression machinesWater vaporSuperheater

The invention discloses a distributed energy system utilizing dry quenching waste heat. The distributed energy system utilizing the dry quenching waste heat comprises a waste heat recovery subsystem,a water vapor refrigeration power generation subsystem, an organic working medium power generation subsystem and a heat supply subsystem, wherein the waste heat recovery subsystem and the water vaporrefrigeration power generation subsystem are mutually connected through a water vapor superheater and a first condensate water evaporator, the waste heat recovery subsystem and the organic working medium power generation subsystem are mutually connected through an organic working medium evaporator, and the waste heat recovery subsystem and the heat supply subsystem are mutually connected through arecycle gas-heat storage water heat exchanger. According to the distributed energy system utilizing the dry quenching waste heat, through efficient recycle of the dry quenching waste heat, combined generation and combined supply of multiple energy sources including cold energy, heat energy and electric energy are realized, the waste heat utilization efficiency of the system is improved, the energy consumption of the system operation is reduced, the stability and the reliability of the system operation are improved, the energy utilizing norm that 'suitable temperature, gradient utilization' ismet, and huge economic benefits and ecological benefits can be obtained.

Owner:NORTHEASTERN UNIV

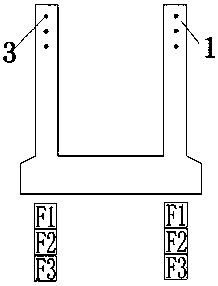

Construction technology for cantilever type U-shaped bent cap and precast beam component

PendingCN109591183AHigh precisionImprove protectionCeramic shaping apparatusBridge erection/assemblyShaped beamEngineering

The invention relates to a construction technology for a cantilever type U-shaped bent cap and a precast beam component. According to the construction technology for the cantilever type U-shaped bentcap, integral non-support construction of the cantilever type U-shaped bent cap is conducted through manners that staging prefabricated casting is adopted on the whole, and steel tendons are tensionedgradually in each state. The construction technology for the cantilever type U-shaped bent cap comprises the steps that a U-shaped beam component is prefabricated firstly; casting grooves with periphery totally-enclosed are formed in the U-shaped beam component; pre-buried casing pipes are installed at the bottom of the U-shaped beam component and the corresponding middle positions of bridge piers; the first batch of prestressed steel tendons are tensioned on the U-shaped beam component; the prefabricated U-shaped beam component is moved to the bridge piers; reserved steel bars in the bridgepiers penetrate through the pre-buried casing pipes in the beam component and stretch into the casting grooves; and hollow portions of the casting grooves of the beam component is cast in situ, the second batch of prestressed steel tendons are tensioned correspondingly, and pore channels are reserved for next-stage prestressed tensioning. By means of the construction technology for the cantilevertype U-shaped bent cap, higher efficiency of construction production, the lower cost and simple on-site transportation operation of the bent cap are achieved.

Owner:ZHENGZHOU COMM PLANNING SURVEY & DESIGN INST

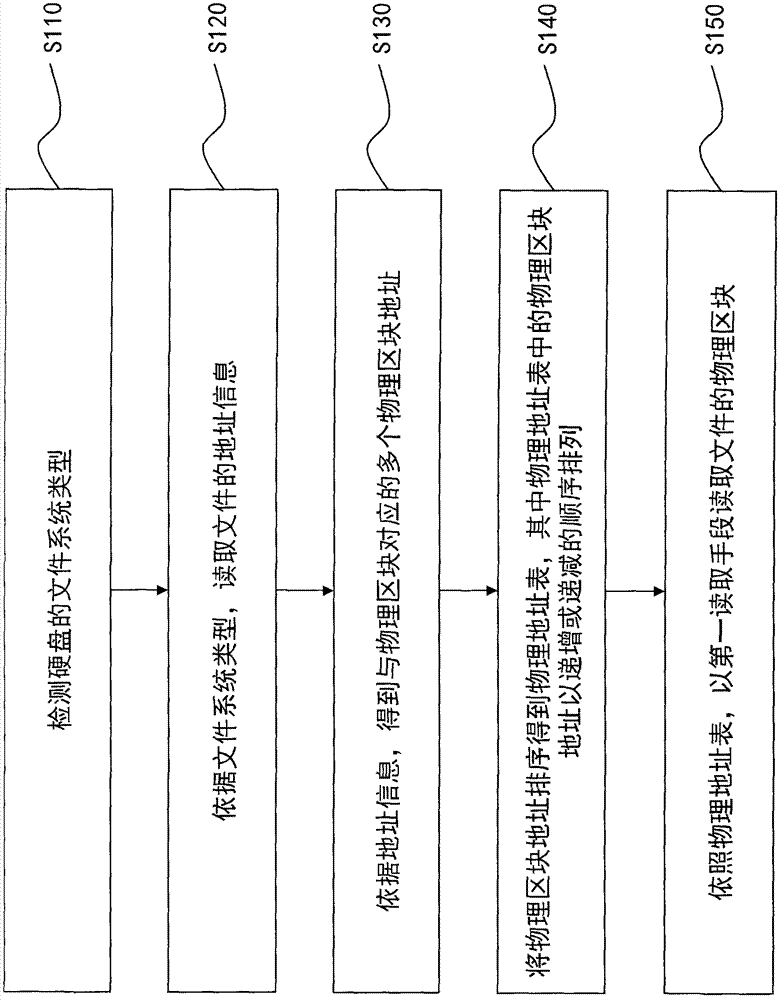

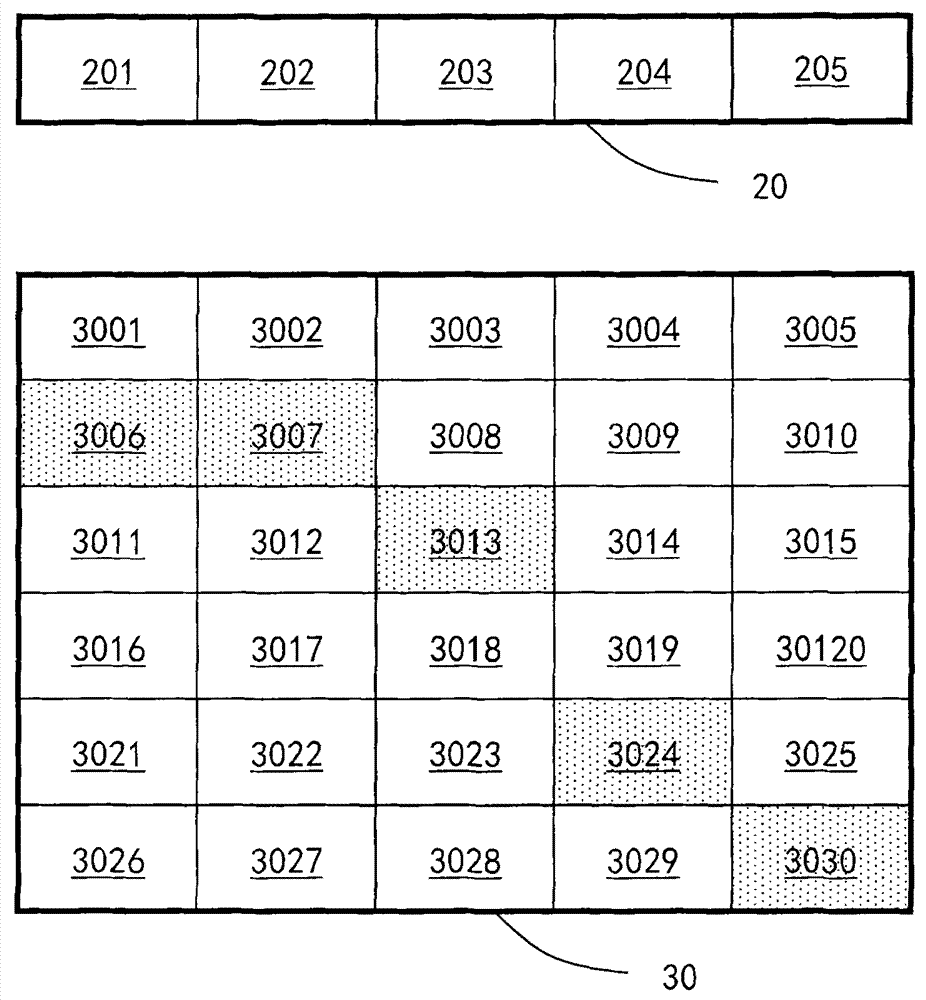

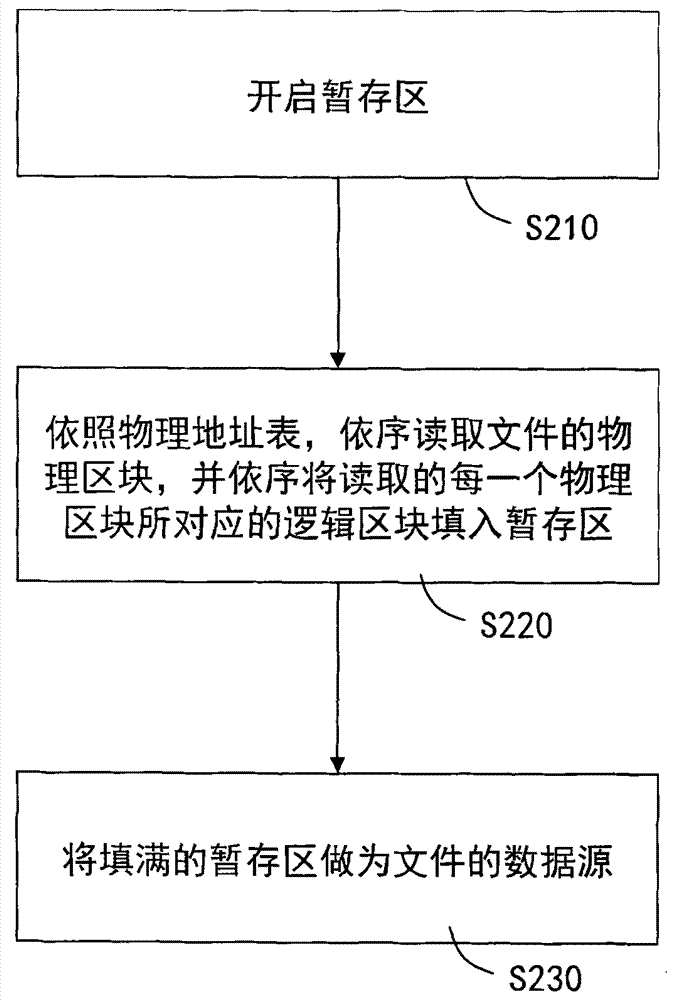

File reading method

InactiveCN103092896ALess mechanical actionImprove read rateMemory adressing/allocation/relocationSpecial data processing applicationsComputer hardwareFile system

A file reading method is used for reading files of hard disks. The files correspond to a plurality of physical blocks in hard disks. The file reading method comprises detecting file system types of hard disks; reading address information of the files according to the file system types; obtaining a plurality of physical block addresses corresponding to the physical blocks according to the address information; sequencing the physical block addresses to obtain a physical address table, wherein the physical block addresses in the physical address table are arranged in an increasing or decreasing sequence; and reading the physical blocks of the files through a first reading means according to the physical address table.

Owner:INVENTEC CORP

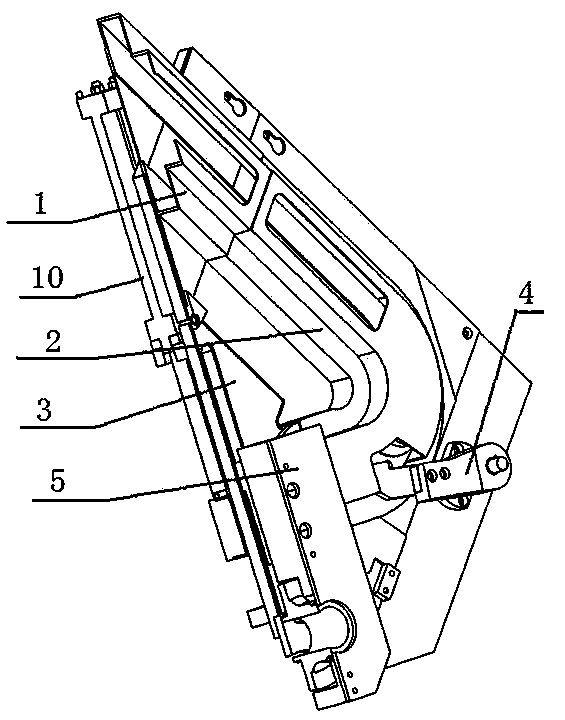

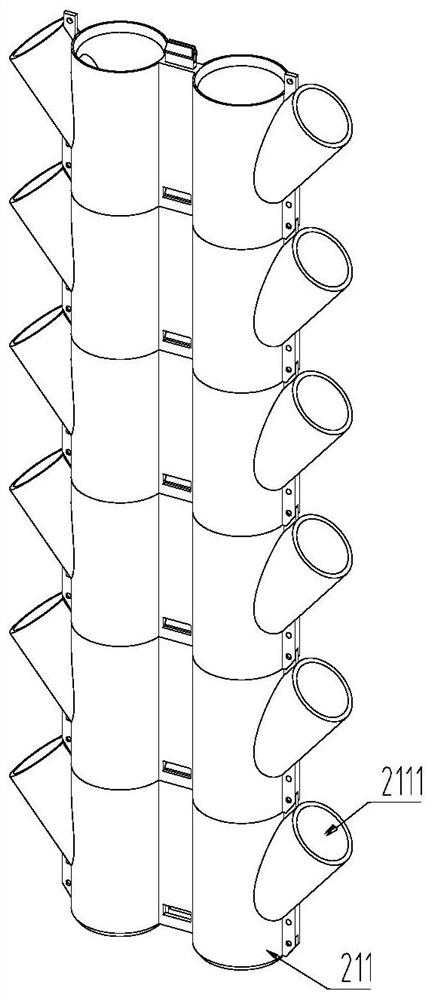

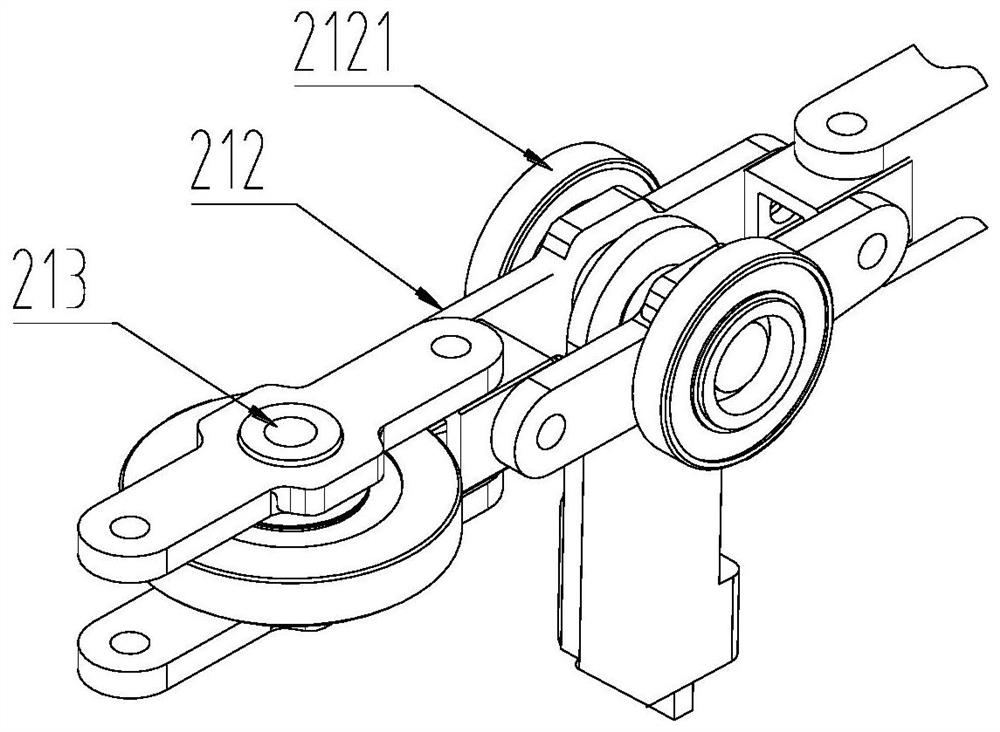

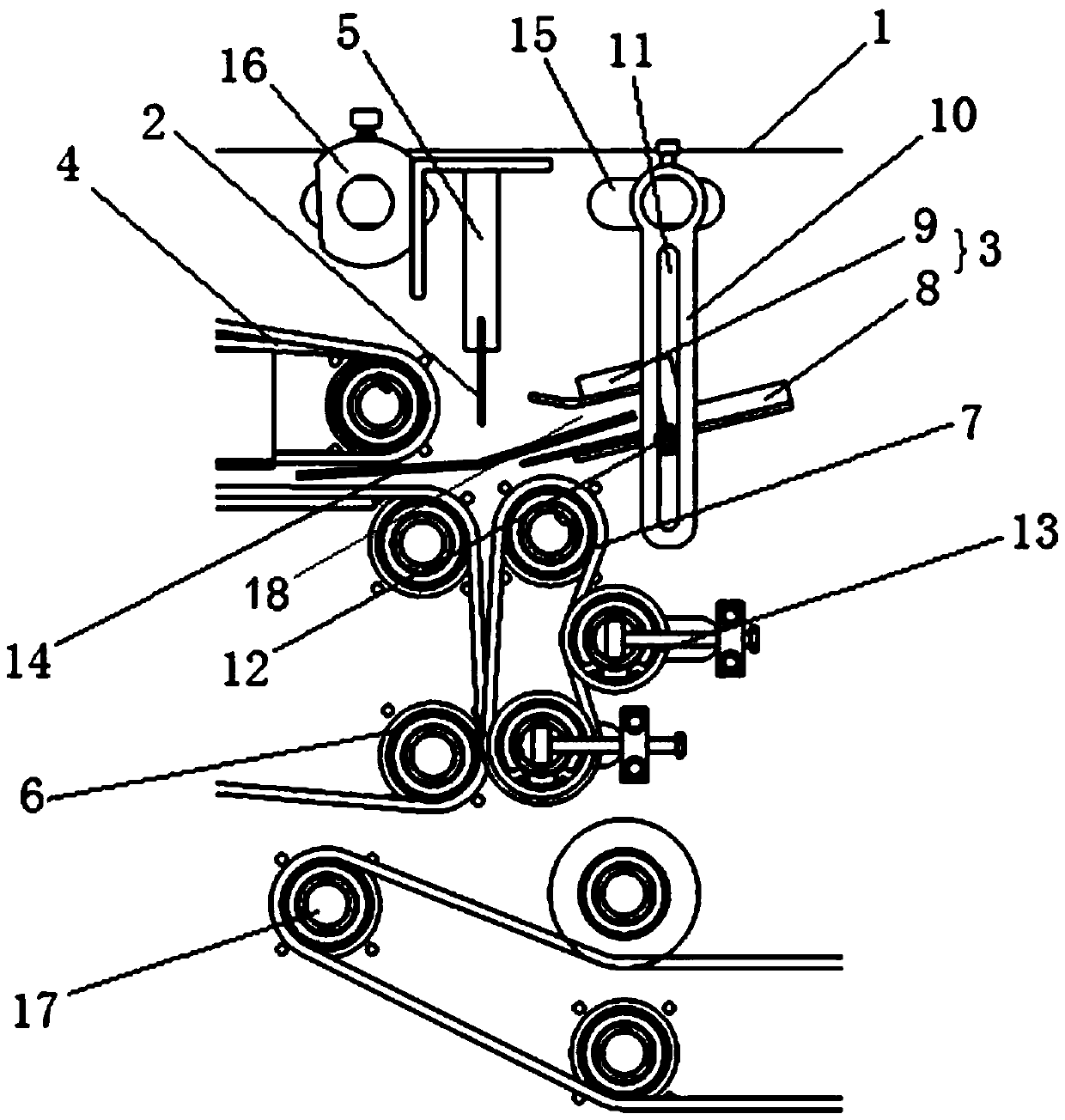

Automatic pipe feeding device of sealing machine

InactiveCN104609179AIncrease success rateHigh feed accuracyConveyor partsContinuous/uninterruptedEngineering

The invention relates to energy-saving lamp production equipment, in particular to an automatic pipe feeding device of a sealing machine. The automatic pipe feeding device of the sealing machine comprises a stem separating device, a first transfer device, a second transfer device and a stem guide device. The stem separating device comprises a first telescopic device, a piston rod of the first telescopic device is connected with a blocking rod, the blocking rod is divided into two vertical rods, transverse rods are connected with the top ends of the vertical rods, a plurality of blocking teeth are arranged on the transverse rods, and the blocking teeth on the two transverse rods are oppositely staggered. The stem guide device comprises a guide base, a guide clamp is arranged on the guide base and is in a funnel shape in the clamping state, and hydraulic drive, pneumatic drive, electrical drive and mechanical drive can be adopted for the guide clamp. By means of the automatic pipe feeding device of the sealing machine, the successful rate of clamping stems by a mechanical arm is high, the phenomenon that filaments of the stems cannot enter holes can be avoided, and the feeding accuracy is improved and is high; the stems can be continuously fed, mechanical movements are few, the feeding and discharging time is short, efficiency is high, and maintenance is convenient.

Owner:家雄灯饰(濮阳)有限公司

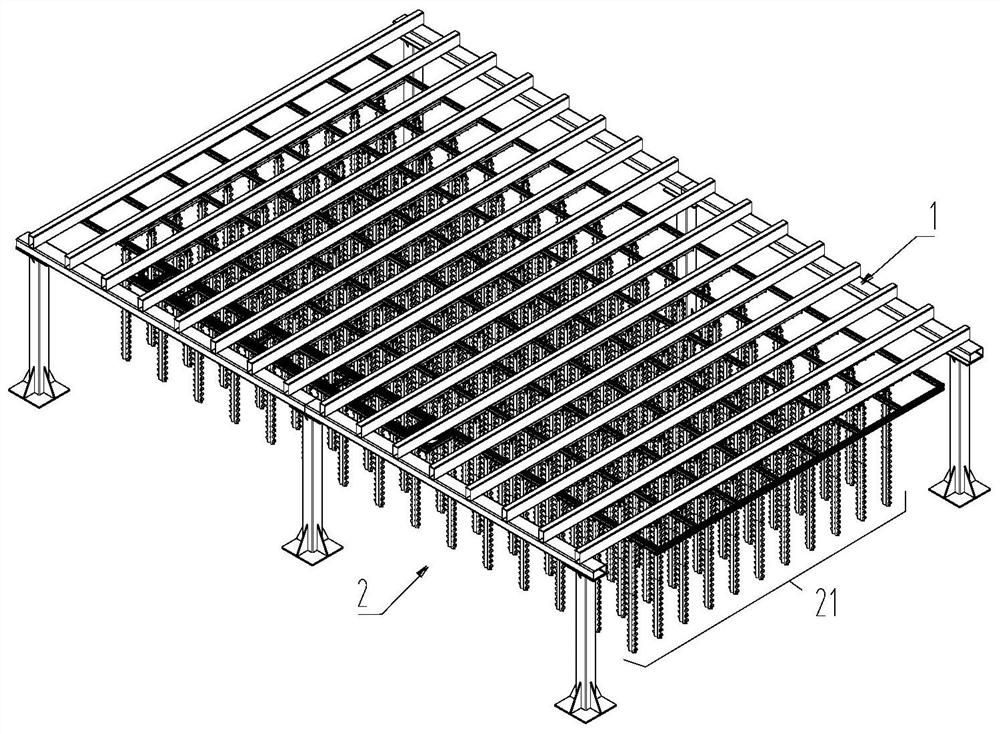

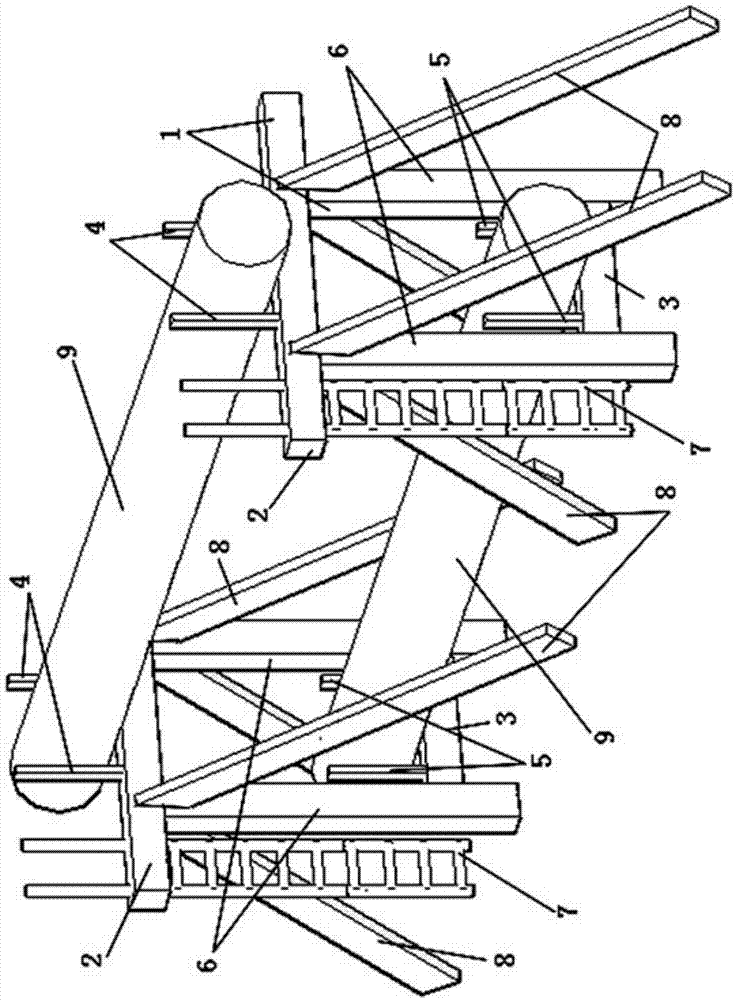

Plant factory planting automation system and use method thereof

ActiveCN113016421AIncrease productionTake advantage ofTransplantingGreenhouse cultivationPlant factoryAgricultural engineering

The invention relates to the technical field of plant factories and discloses a plant factory planting automation system. The plant factory planting automation system comprises a frame body, planting units, movable moving units and movable trolleys, the planting units comprises a plurality of planting columns movably arranged on the frame body, the trolleys comprise locking assemblies used for achieving locking or unlocking between the trolleys and the planting columns, and after the trolleys are locked with the planting columns, the trolleys are used for driving the planting columns to enter the moving units from the planting units or enter the planting units from the moving units. The plant factory planting automation system has the following advantages: automation in treatment processes of transporting, harvesting, transplanting and the like of planting towers of a plant factory is completed, an automation degree is greatly improved, production efficiency is high and production cost of the plant factory is reduced. The plant factory planting automation system solves technical problems of high automation realization difficulty and high automation cost during vertical planting in a plant factory, and has great significance in large-scale vertical planting and industrialization in the plant factory.

Owner:湖北火爆机器人科技有限公司 +1

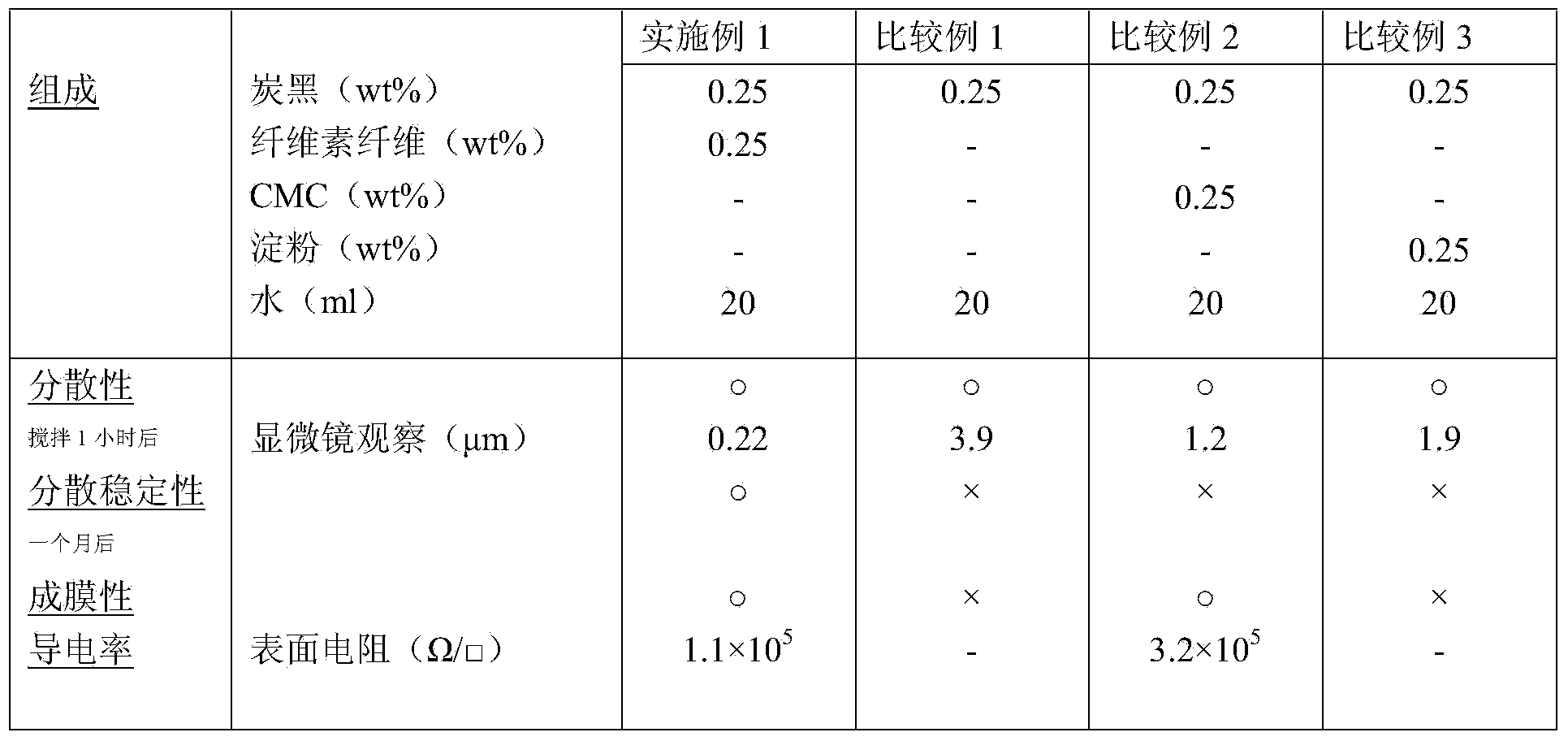

Carbon particle dispersion and method for producing same

InactiveCN103917613AGood dispersionImprove dispersion stabilityPigmenting treatmentInksDispersion stabilityPolymer science

Provided are: a carbon particle dispersion having favorable dispersion and dispersion stability; and a method for producing the carbon particle dispersion. The dispersion is characterized by containing at least carbon particles, a fibrous polysaccharide having a carboxyl group, and a dispersion medium. The method for producing the dispersion is characterized by including, in the given order: a step for dispersing a polysaccharide having a carboxyl group in the dispersion medium to prepare a preparation containing the fibrous polysaccharide and the dispersion medium; and a step for dispersing the carbon particles in the preparation, preparing a dispersion containing the fibrous polysaccharide, the carbon particles, and the dispersion medium.

Owner:TOPPAN PRINTING CO LTD

Vacuum feeding machine and automatic feeding system

ActiveCN103318658AReduce excessive adsorptionContinuous deliveryLoading/unloadingExhaust valveControl valves

The invention provides a vacuum feeding machine and an automatic feeding system. The vacuum feeding machine comprises a storage tank, a filter chamber, a controller, a top cover, an air regulating valve, an air cannon and at least two working groups, wherein each working group comprises a filter group, a control cavity, a tee pneumatic control valve and an exhaust valve; a feed opening is arranged on the storage tank, and the upper end of the storage tank is communicated with the filter chamber; the filter chambers are communicated with the filter groups; the top cover is fixedly connected with one end of each control cavity, so that a vacuum chamber is formed; the tee pneumatic control valve is accommodated in the vacuum chamber; the exhaust valves are communicated with the air cannon; the tee pneumatic control valves are further communicated with the air regulating valve; and the controller controls the on and off of the air cannon and the on and off of the tee pneumatic control valve of each working group respectively. According to the vacuum feeding machine, the feed opening is directly mounted on the storage tank of a material, so that the material can be prevented from being absorbed on filters excessively; a plurality of the working groups are arranged, and each working group can be independently controlled by the controller, so that the material can be conveyed continuously, and the conveying efficiency is improved greatly; and the mechanical device is optimized, mechanical faults are reduced, and the operation is convenient.

Owner:深圳市杰维工业设备有限公司

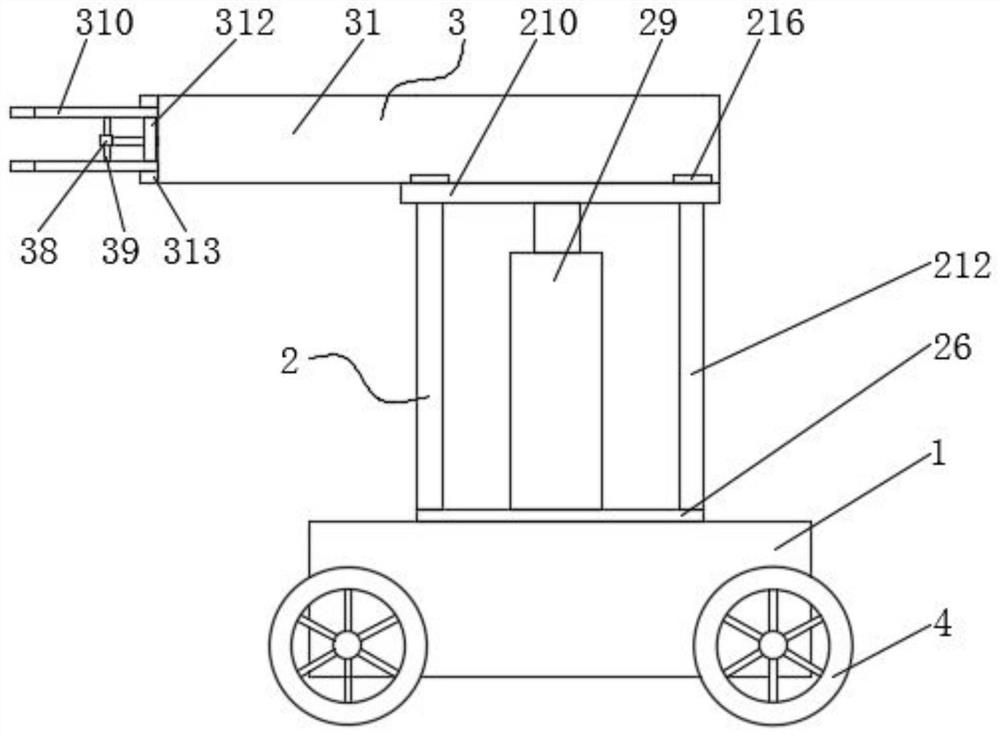

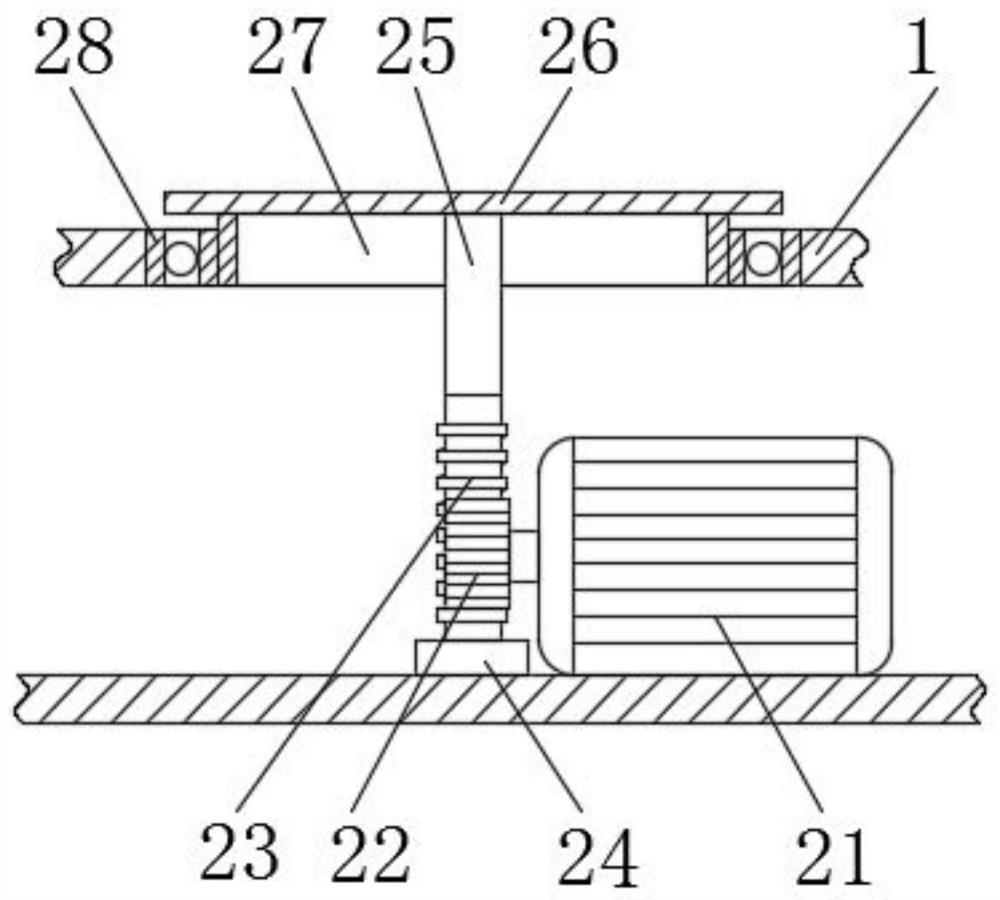

Intelligent material carrying mechanical arm

PendingCN111775133ALess mechanical actionImprove work efficiencyGripping headsHydraulic cylinderDrive wheel

The invention discloses an intelligent material carrying mechanical arm. The intelligent material carrying mechanical arm comprises a first machine shell, a lifting device, a clamping device and a drive wheel, the lifting device comprises a motor, a worm gear, a worm, a first bearing, a first connecting rod, a first supporting table, a first sleeve, a second bearing, a hydraulic cylinder, a secondsupporting table, a guide hole, a supporting rod, a limiting hole, a limiting block, a guide rod and a check block, and the clamping device comprises a second machine shell, an air cylinder, a secondconnecting rod, a connecting block, a first rotating shaft, a second sleeve, a third connecting rod, a third sleeve, a second rotating shaft, a clamping claw, a through hole, a third rotating shaft and a fixed block. Compared with an existing material carrying mechanical arm, the lifting device is designed, material carrying in the large range can be carried out, and the mechanical arm is more flexible compared with the existing material carrying mechanical arm. The clamping device can clamp different sizes and shapes of materials, the mechanical action is few, and the work efficiency of themechanical arm can be greatly improved.

Owner:吴慧平

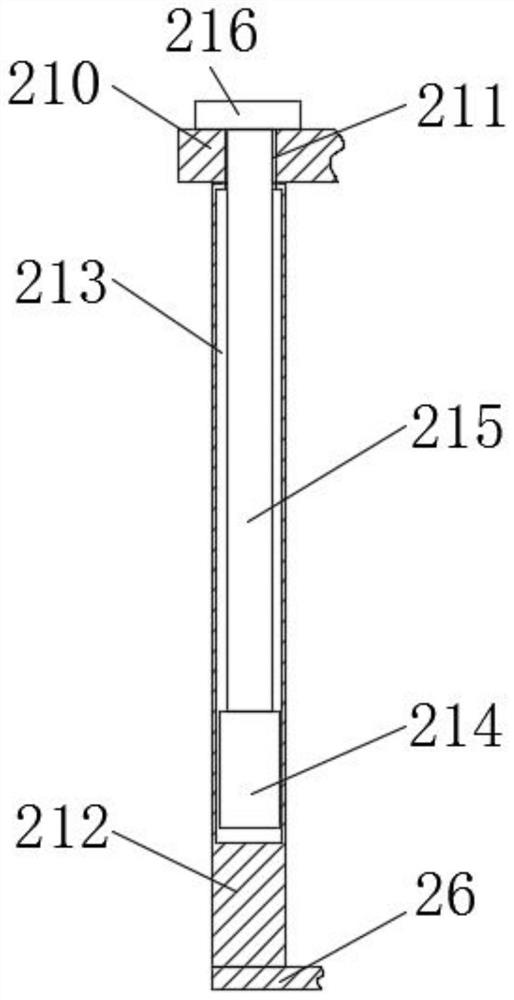

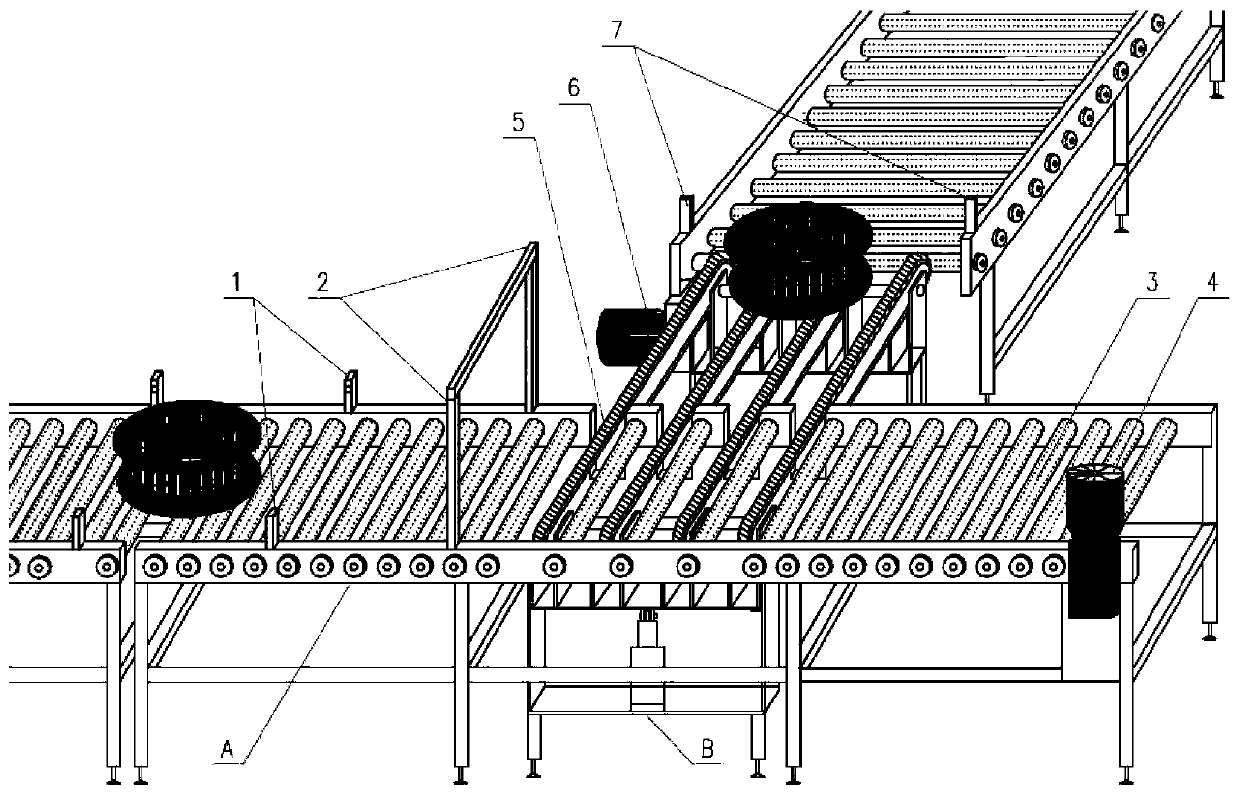

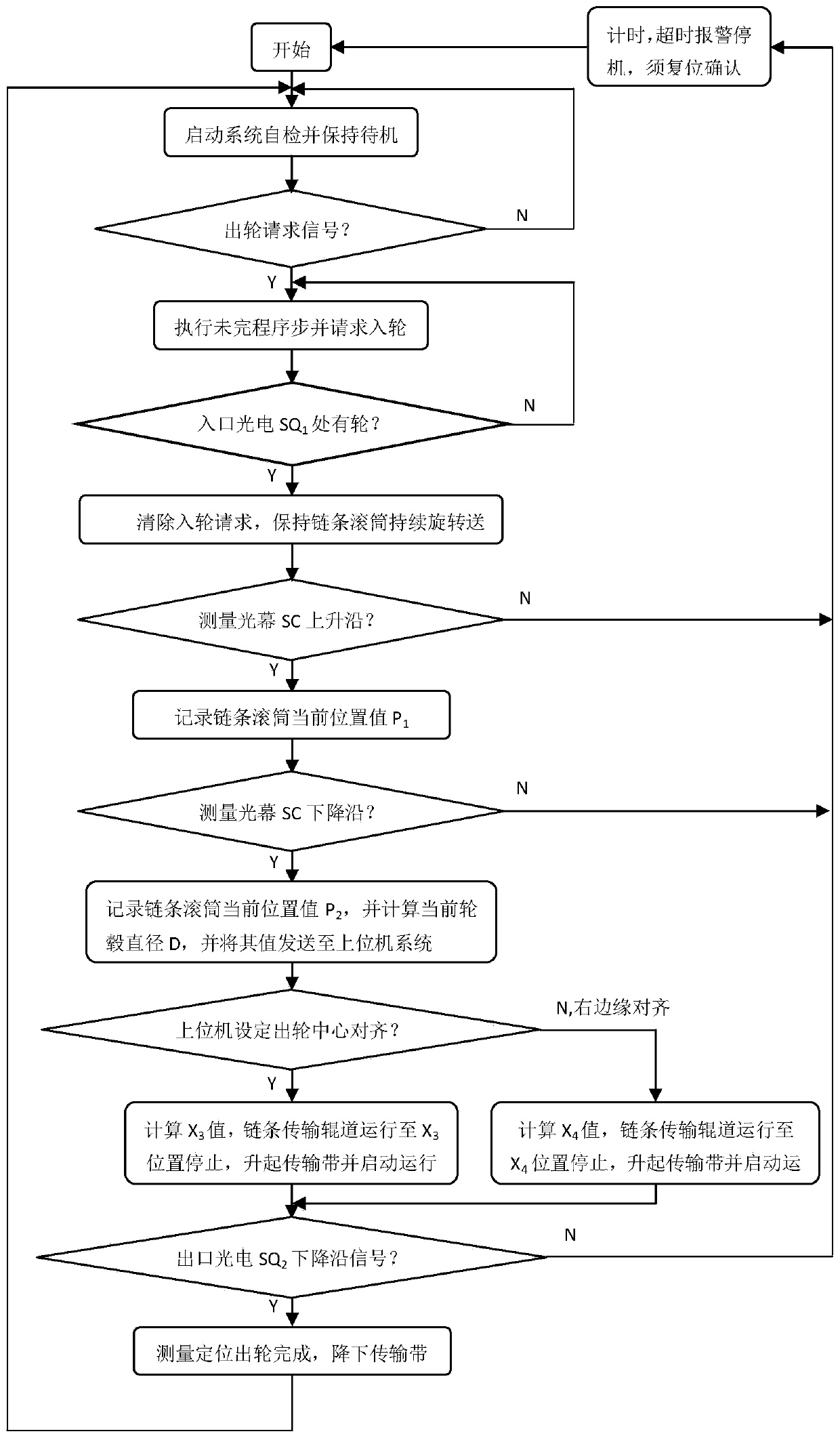

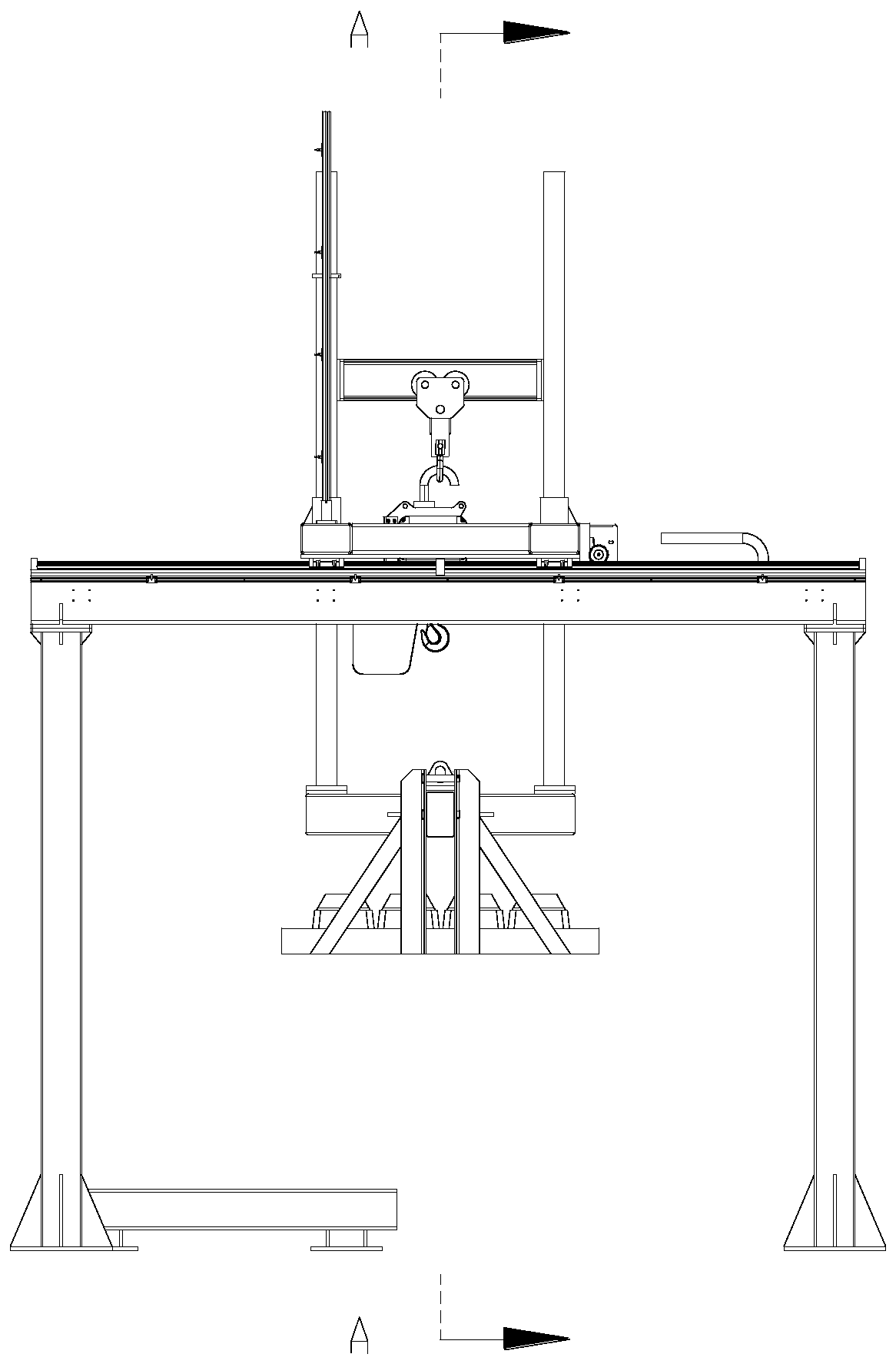

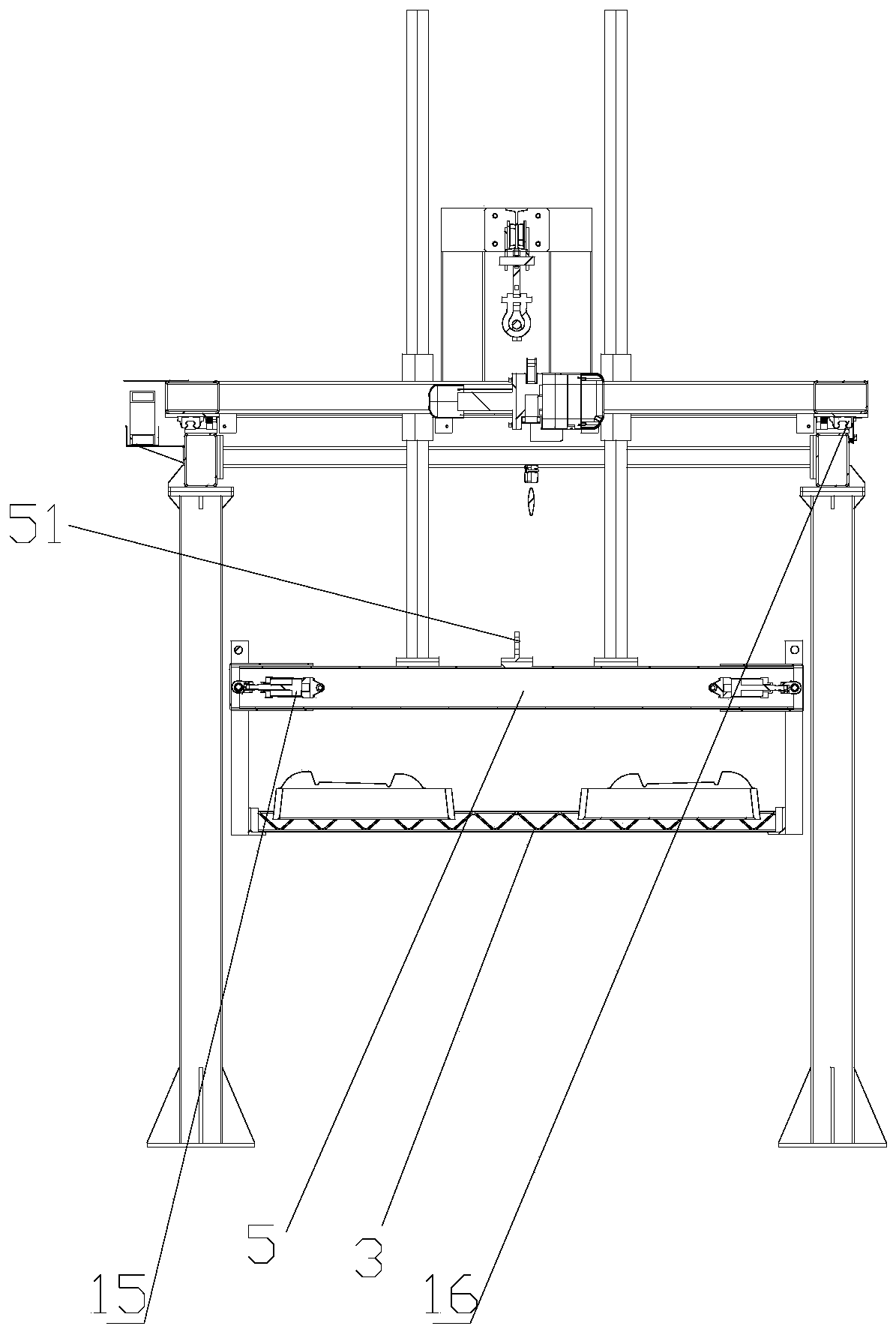

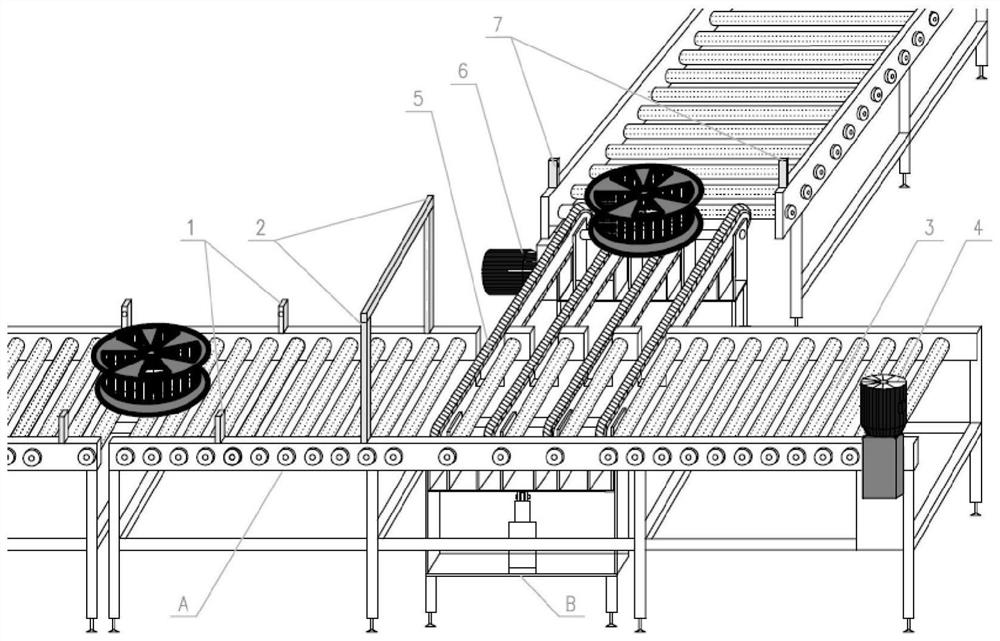

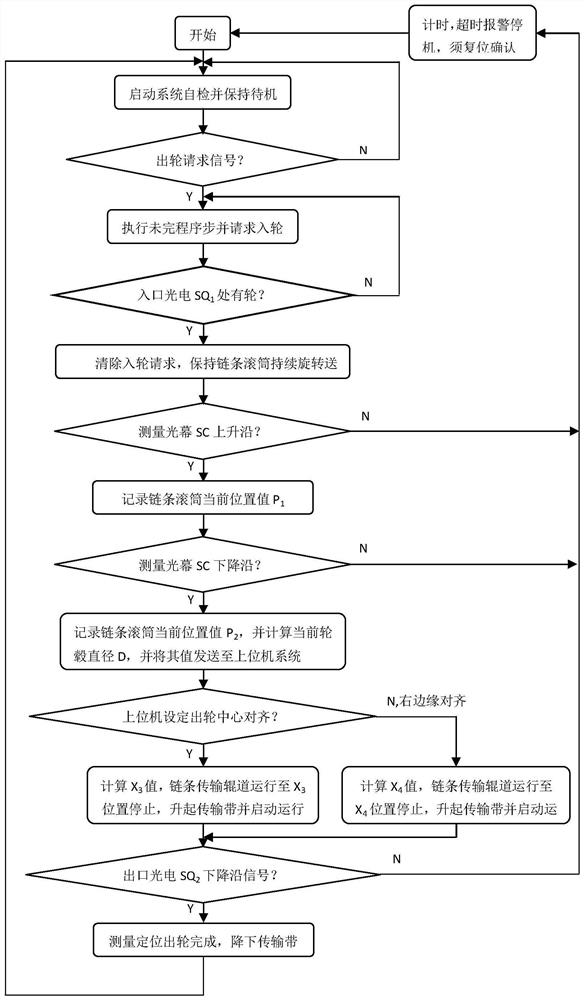

Automobile hub diameter measuring and positioning conveying device and control method thereof

ActiveCN111573128AReduce usageSimple structureConveyorsControl devices for conveyorsControl systemModularity

The invention discloses an automobile hub diameter measuring and positioning conveying device and a control method thereof. The device comprises a transverse conveying device, a longitudinal conveyingdevice, an upper computer and a control system. An inlet of the transverse conveying device is provided with an inlet photoelectric. The upper side of the transverse conveying device is provided witha measuring light curtain for diameter measuring and positioning for a hub. The transverse conveying device conveys the hub to a certain position. The longitudinal conveying device moves the hub out,and an outlet of the longitudinal conveying device is provided with an outlet photoelectric. The automobile hub diameter measuring and positioning conveying device has the advantages that hub diameter measuring precision is high, the measuring speed is high, hub positioning is accurate, the positioning position can be arbitrarily set according to the process, the control algorithm is modularized,intelligent and diversified, the control robustness is good, the mechanical structure is simple, the cost is low, and the efficiency of conveying the hub is high.

Owner:秦皇岛信能能源设备有限公司

Cable and plate dam

InactiveCN1680663ASuperiorLess material consumption for dam constructionBarrages/weirsWater flowEngineering

The invention consists of back guy and board. The back guy and board both are made of high tensile strength material. Both ends of back guy are anchored at the mountain body beside the river. The board is fixed on the back guy, and its bottom and broadside is building in riverbed and rock mass beside river by using cement concrete or mortar. With the invention, the dam can be built from top to bottom, and construction can not be influenced by water flow of river.

Owner:CHINA THREE GORGES UNIV +2

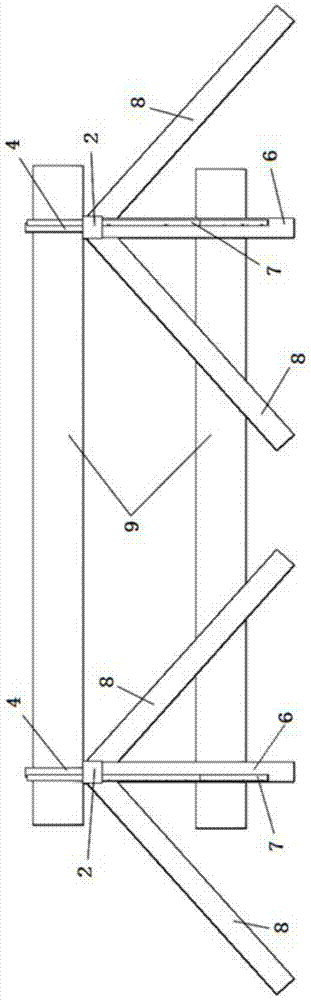

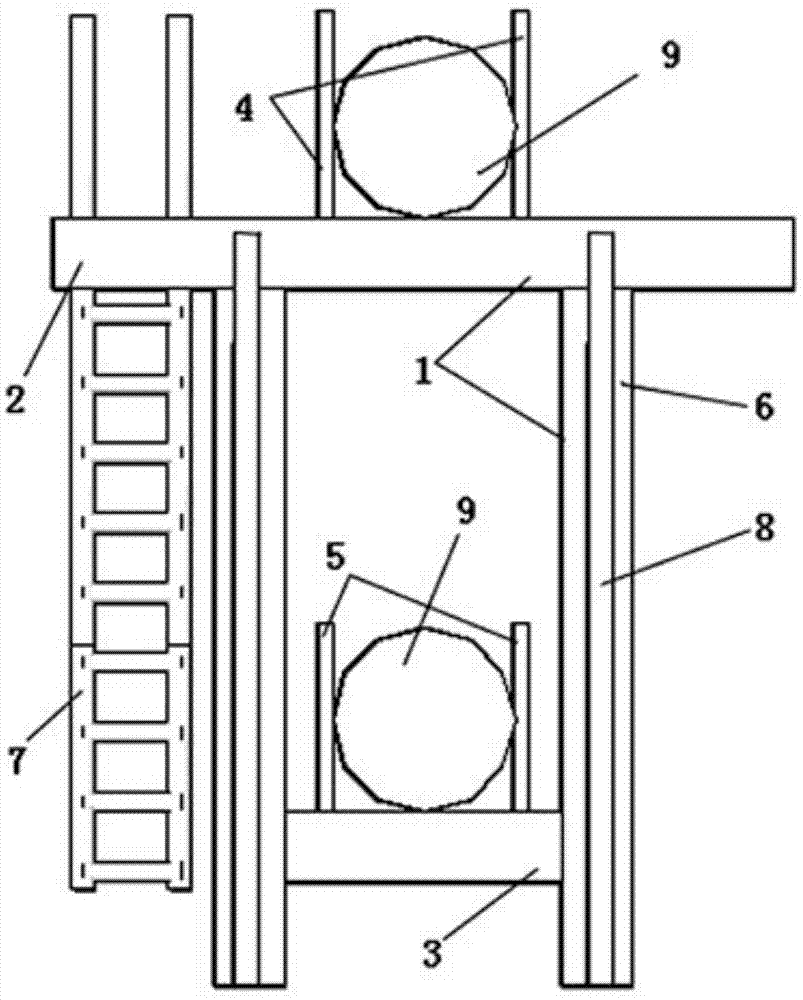

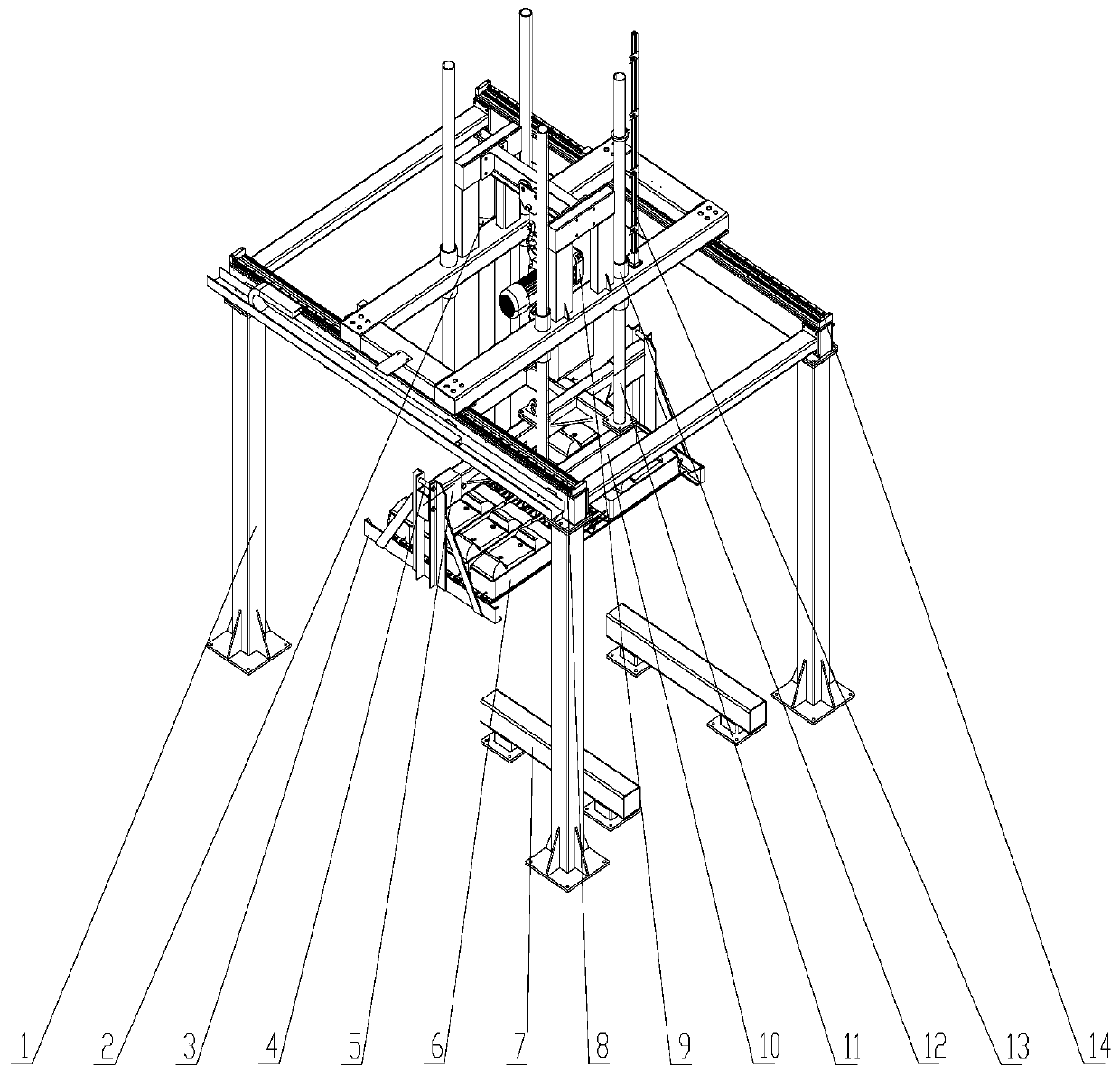

Tool used for fixing and installing boiler drum and use method thereof

The invention discloses a tool used for fixing and installing a boiler drum and a use method thereof. The tool comprises two symmetrically-arranged gantry fixing supports. Each gantry fixing support comprises two parallel stand columns, an upper transverse beam support arranged at the tops of the two stand columns and a lower transverse beam support arranged at the lower portions of the two stand columns. Two upper limiting devices are symmetrically arranged on each upper transverse beam support. Two lower limiting devices are symmetrically arranged on each lower transverse beam support. Slant supports are arranged on the two sides of each stand column, wherein the upper ends of the slant supports and the corresponding upper transverse beam support are fixed, and the lower ends of the slant supports are supported on the ground. The use method includes the steps of arranging, clamping and fixing the boiler drum on the two gantry fixing supports and the like. The tool and the use method have the advantages that the occupied area is small, the fixing state is stable, the super-large and super-heavy in-bulk boiler drum can be conveniently fixed, installed and constructed, and the good practicability is achieved.

Owner:中建六局第一建设有限公司 +1

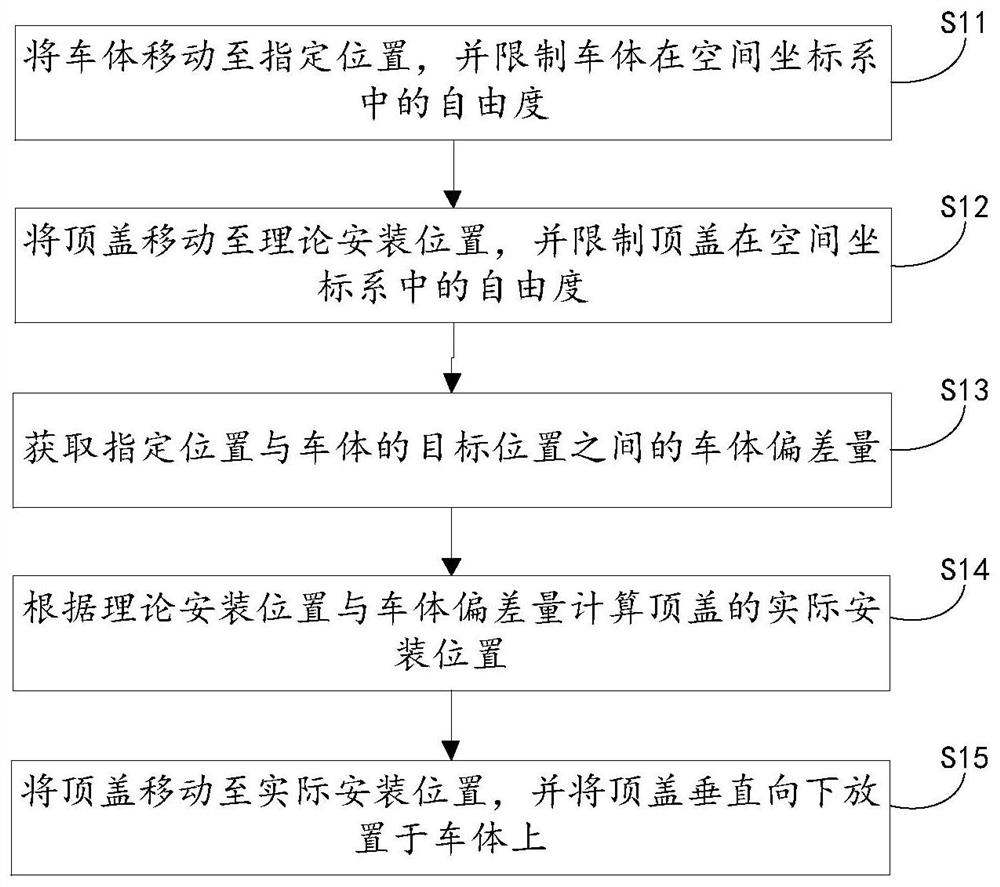

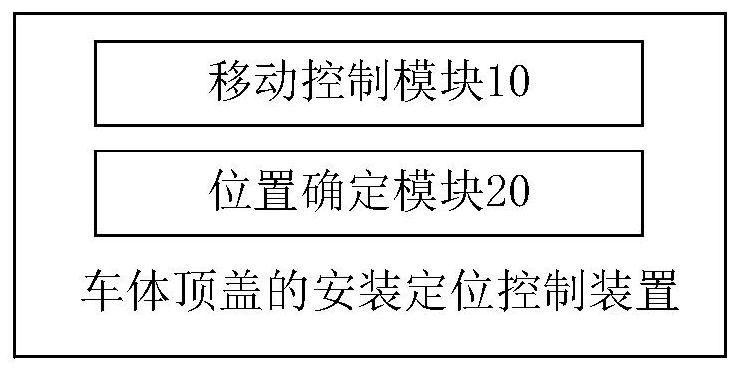

Vehicle body top cover mounting and positioning control method and device, controller and storage medium

PendingCN113182667AWidely used valueAvoid interferenceWelding/cutting auxillary devicesAuxillary welding devicesControl engineeringPosition control

The invention discloses a vehicle body top cover mounting and positioning control method and device, a controller and a medium. The method comprises the steps that a vehicle body is moved to a specified position, and the degree of freedom of the vehicle body in a space coordinate system is limited; a top cover is moved to a theoretical mounting position, and the degree of freedom of the top cover in the space coordinate system is limited; a vehicle body deviation value between the specified position and a target position of the vehicle body is acquired; the actual mounting position of the top cover is calculated according to the theoretical mounting position and the vehicle body deviation value; and the top cover is moved to the actual installation position, and the top cover is vertically and downwards placed on a vehicle body. The car body top cover mounting and positioning control method has the advantages of being high in flexibility, automatic and capable of saving process area while it is ensured that a car body top cover splicing process can meet the large-size design trend of the top cover.

Owner:NIO TECH ANHUI CO LTD

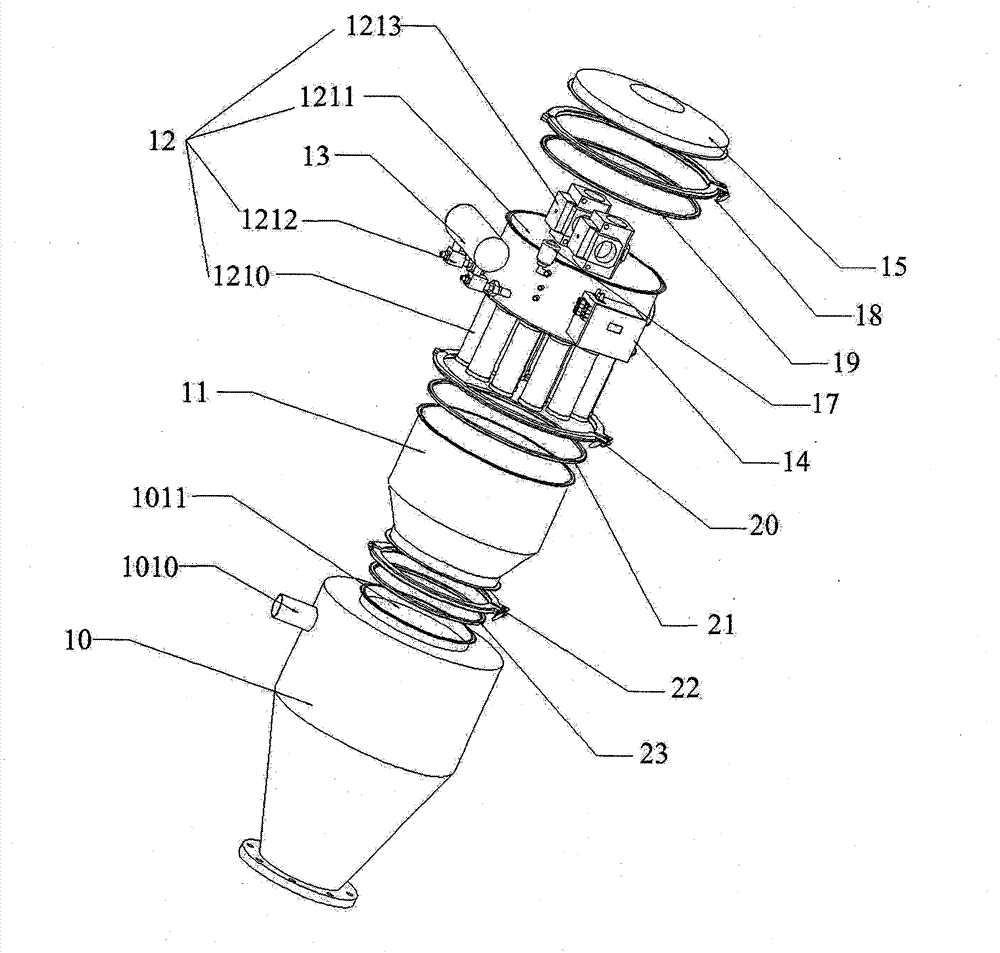

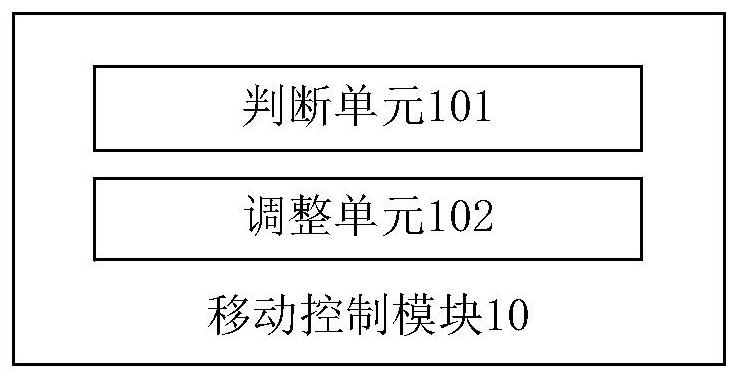

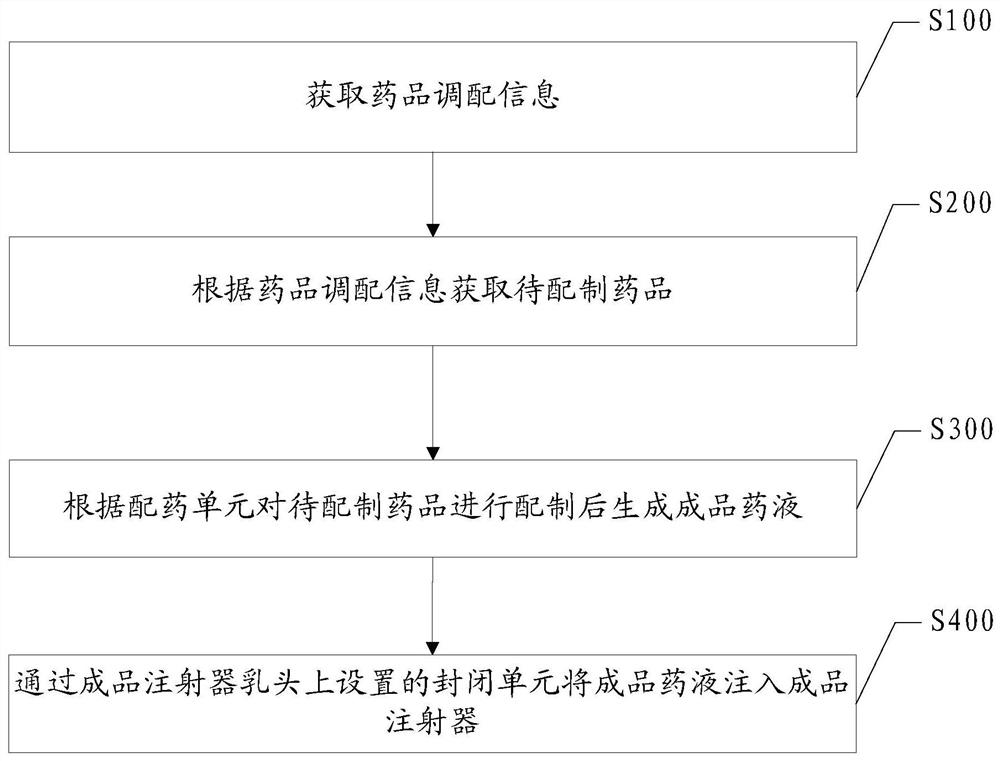

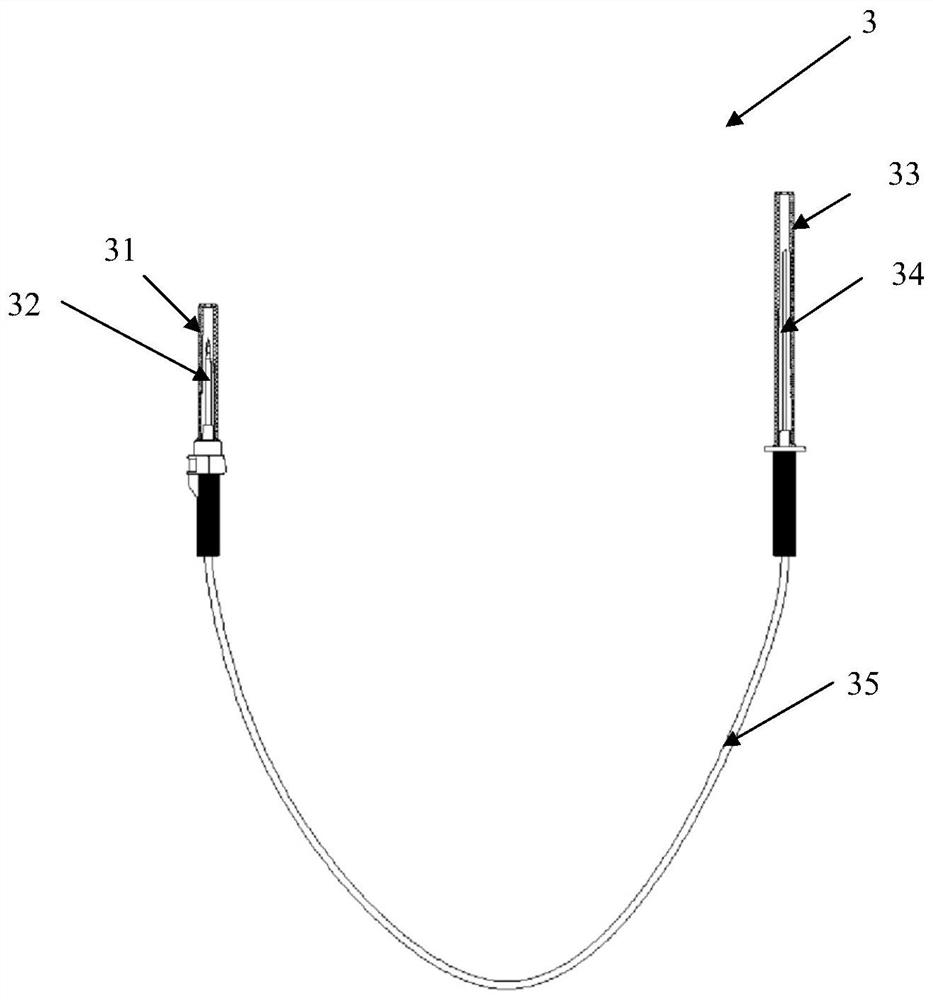

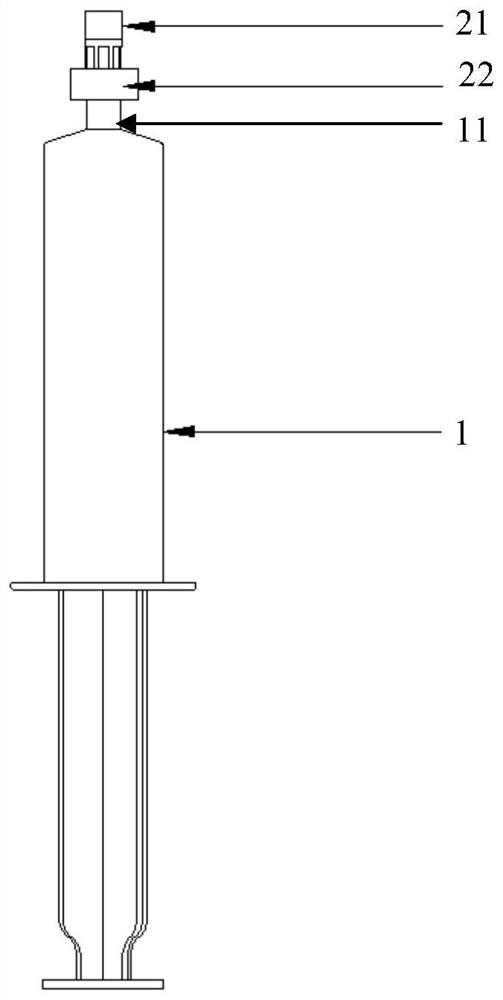

A medicine dispensing method and dispensing robot

ActiveCN109360627BLess mechanical actionImprove dispensing efficiencyDrug and medicationsPharmaceutical containersDrugs solutionBiochemical engineering

The invention discloses a medicine dispensing method and a medicine dispensing robot. The method comprises: obtaining medicine dispensing information; obtaining medicines to be prepared according to the medicine dispensing information; preparing medicines to be prepared according to the dispensing unit to generate a finished medicine liquid; The closed unit injects the finished drug solution into the finished syringe. In the embodiment of the present invention, the syringe or dispensing device for dispensing is separated from the final finished syringe. During the preparation process, the syringe or dispensing device for dispensing is first prepared for drug preparation, and after the preparation, the liquid medicine is transferred to the finished syringe. , reduce the complex mechanical actions of the dispensing robot, and improve the dispensing efficiency of the dispensing robot.

Owner:SHENZHEN CITY WEIBANG TECH

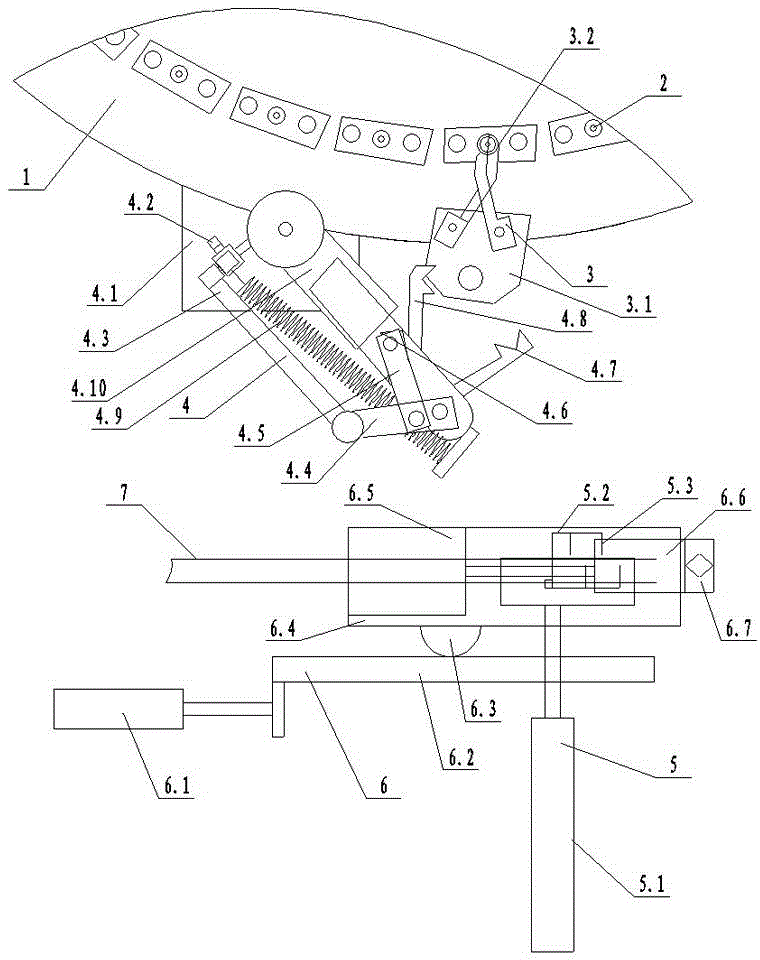

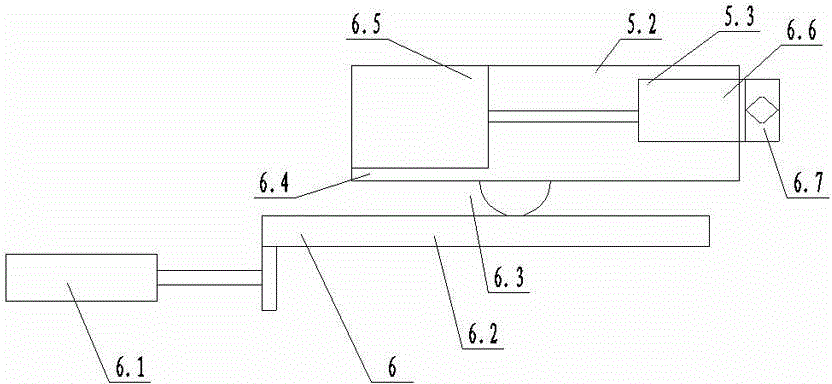

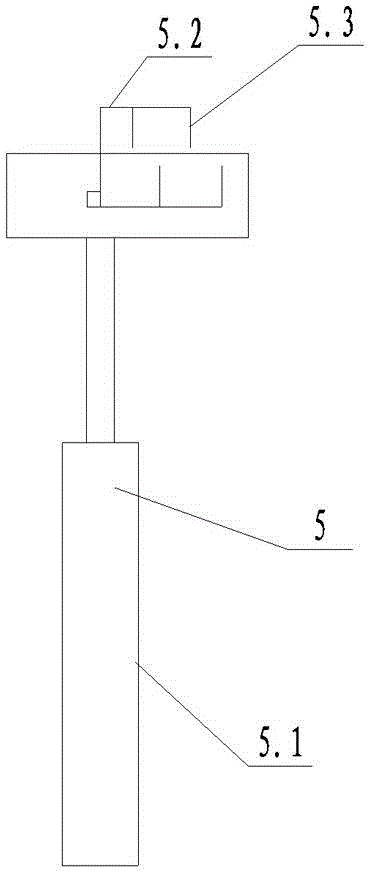

Annular pressing equipment for brick tea

The invention relates to annular pressing equipment of brick tea, and relates to a black brick tea mechanism. The annular pressing equipment comprises an annular track frame (1), wherein a mold moving body (39) which moves on the annular track frame (1) is arranged on the annular track frame (1); a pushing mechanism (4) for pushing the mold moving body (39) to move is arranged on one side of the mold moving body (39); and a pressing machine (2) is arranged on the mold moving body (39) in a crossing manner. The annular pressing equipment disclosed by the invention is compact in structure; compared with the floor space of a rectangular pressing machine, the floor space of the annular pressing equipment is reduced to 1 / 4-to 1 / 2; the mechanical structure is simplified; the mechanical movements are reduced; the running fault rate of the equipment and the energy consumption of the equipment are obviously reduced; the running speed of the equipment is accelerated; and the production efficiency is obviously improved.

Owner:湖南省白沙溪茶厂股份有限公司

Sleeper stacking machine capable of realizing telescoping-clamping for sleepers

PendingCN111115283AOvercome instabilityImprove efficiencyConveyorsStacking articlesPalletizerElectric machinery

The invention discloses a sleeper stacking machine capable of realizing telescoping-clamping for sleepers. The sleeper stacking machine capable of realizing telescoping-clamping for the sleepers comprises a main body truss, and a stacking base below the main body truss, wherein a travelling rack and a linear slide rail are arranged at the two sides of the upper part of the main body truss separately, and the travelling rack and the linear slide rail are connected with a stacking rail moving mechanism which moves in parallel; a lifting mechanism is slidably connected to the stacking rail movingmechanism; a telescoping-clamping mechanism for the sleepers is installed on the lower part of the lifting mechanism, the telescoping-clamping mechanism for the sleepers comprises a bracket telescoping arm, as well as a lifting hanger ring and sleeper brackets which are connected to the bracket telescoping arm; the bracket telescoping arm is connected to a stable frame, and the lifting hanger ring is arranged at the middle part of the bracket telescoping arm; an output end of a lifting drive motor is connected with the lifting hanger ring; at least two sleeper brackets are welded to the end part of the bracket telescoping arm; and a telescopic driver is installed at the two ends of the bracket telescoping arm separately.

Owner:北京智创赋能技术开发中心(有限合伙)

Automobile hub diameter measuring positioning conveying device and its control method

ActiveCN111573128BReduce usageSimple structureConveyorsControl devices for conveyorsFast measurementControl system

Owner:秦皇岛信能能源设备有限公司

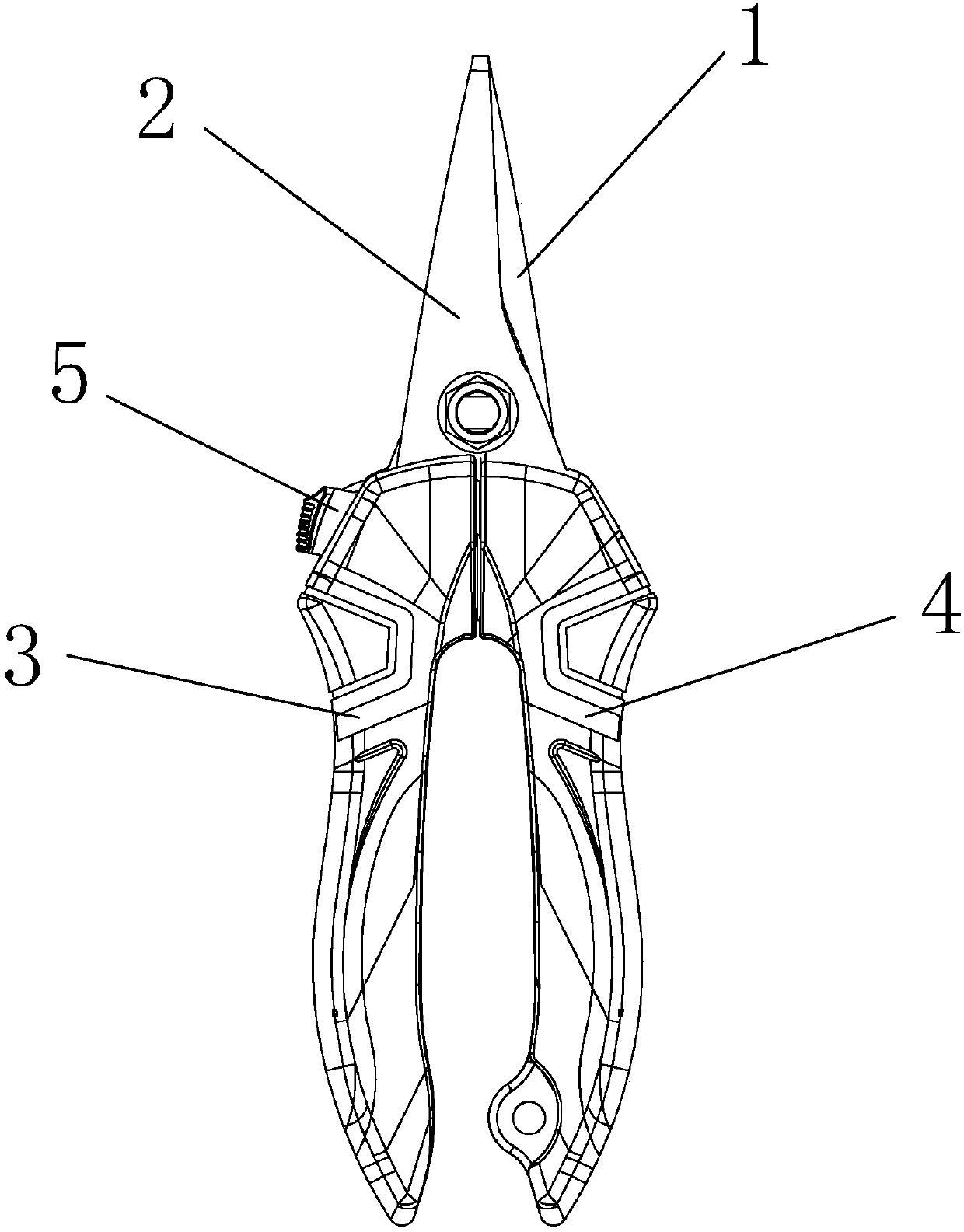

Closed locking device for cutting hipper

InactiveCN107718056AReduce the risk of accidentally injuring yourselfLess mechanical actionMetal working apparatusMetal-working hand toolsClosed lockKnife handles

The invention discloses a closed locking device for a cutting hipper. The closed locking device comprises a first cutter body, a second cutter body, a first knife handle and a second knife handle. Thefirst cutter body and the second cutter body are hinged; the first knife handle and the first cutter body are connected; the second knife handle and the second cutter body are connected; a locking block which pushes the first cutter body to eject the second cutter body to be closed and locked when the first cutter body and the second cutter body are closed is arranged on the first cutter body, sothat the danger of injuring a child holding the closed locking device for the cutting hipper accidentally is reduced, the mechanical action of repeatedly opening and closing the closed locking devicefor the cutting hipper for many times can be also reduced effectively, wear is reduced, and meanwhile, the danger of holding the cutting edge to be injured is reduced when a worker transfer the tool.

Owner:陈永

Hoisting in-place method for allowing large equipment to pass through ultrahigh hole

The invention discloses a hoisting in-place method for allowing large equipment to pass through an ultrahigh hole. Hoisting equipment of a high-altitude monorail combined cantilever crane is adopted in the method, and the high-altitude monorail combined cantilever crane comprises a main crane positioned at the outer side of a building structure and a secondary crane positioned at the inner side of the building structure. The method adopting the hoisting equipment of the high-altitude monorail combined cantilever crane comprises the following steps of: (1) hoisting the equipment to a reserved hole by using the main crane, and effectively butting the equipment and the edge of the reserved hole: 1) positively starting a winch, hoisting the equipment above the reserved hole, and braking the winch; 2) loosening a balance chain block, lowering the equipment at the same time of horizontal movement, and gradually moving the equipment to the reserved hole; 3) repeating the steps 1) and 2), starting and stopping the winch and loosening and tightening the position of balance chain block adjusting equipment till the equipment body is effectively butted with the edge of the reserved hole; and (2) drawing the equipment to the interior of the building structure by using the secondary crane, loosening a hook of the main crane, and hoisting the equipment in place by using the secondary crane. The method is convenient for operation and short in hoisting time.

Owner:中建六局第一建设有限公司

A longitudinal folding device for glove lining paper

ActiveCN106144049BSimple structureLess mechanical actionWrapper folding/bending apparatusEngineeringMechanical engineering

Owner:BEIJING ZEYUXING IND & TRADE CO LTD

A construction method of a steel frame column-beam-column joint

ActiveCN110206144BThe construction method steps are simpleEasy constructionBuilding constructionsMechanical equipmentSteel frame

The invention discloses a construction method of a steel rib column beam-column joint. The construction method comprises the following steps: 1, machining of a steel rib column beam-column joint shaping protection barrel; 2, hoisting of a beam-column frame; 3, mounting of a steel bar truss floor bearing plate, and binding of vertical steel bars; and 4, erecting of a steel rib column formwork, andpouring of concrete. The construction method is simple in steps, convenient to construct and easy to operate, the beam-column joint does not need be supported by a wooden formwork, input labor force and mechanical equipment are less, and the construction effect is good; and after pouring, formwork removing is avoided, the problems of large formwork removing task and more labor force input are solved, and practicality is high.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com