Annular pressing equipment for brick tea

A ring-shaped, brick tea technology, applied in the field of black brick tea pressing equipment, can solve the problems of long operation cycle, high operation failure rate, high energy consumption, etc., and achieves faster equipment operation speed, simplified mechanical structure, equipment operation failure rate and The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

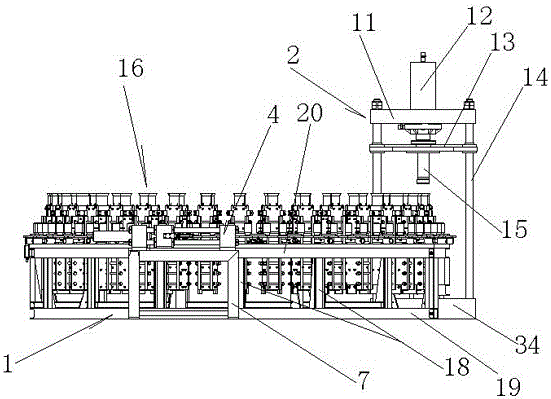

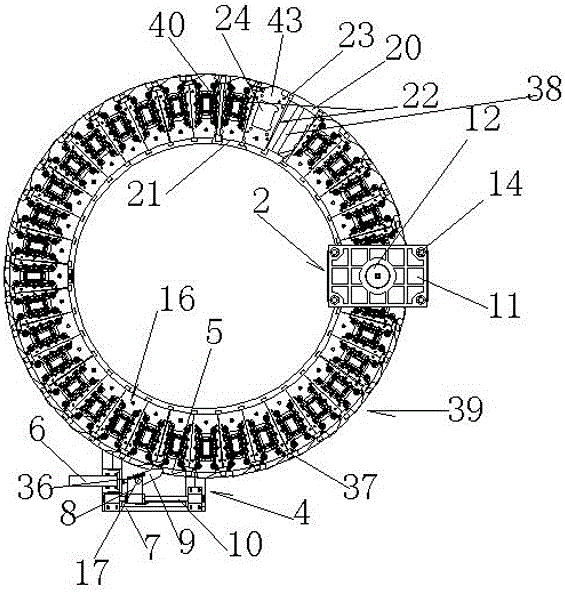

[0019] Embodiment 1: as figure 1 As shown in -2, the brick tea ring pressing equipment includes a ring track 1, a mold moving body 39 moving along the ring track 1 is arranged on the ring track 1, and a pusher for pushing the mold moving body 39 is provided on one side of the moving body 39. Mechanism 4, the press machine 2 is straddled above the mold moving body 39 .

Embodiment 2

[0020] Embodiment 2: as figure 1 As shown in -2, the annular pressing equipment for brick tea includes an annular track 1. The cross section of the annular track 1 can be designed to be U-shaped. Specifically, it can be fixed on the support column 18 by a base 19, a support column 18, and a bottom connecting rod 38. The upper inner track 21 and the outer track 20 are formed. On the circular track 1, there is a mold moving body 39 that moves along the circular track 1. The mold moving body 39 is composed of several roller bearing seats 22 that move along the circular track 1, and are arranged on two adjacent roller bearing seats 22. The mold supporting plate 43 on the upper surface is composed of the mold 16 fixedly supported in the mold supporting plate 43 by the connecting seat 30. The mold 16 can be a traditional machine press mold or a new mold, depending on the product needs, as long as its external structure can It can be combined and fixed with the mold supporting plate...

Embodiment 3

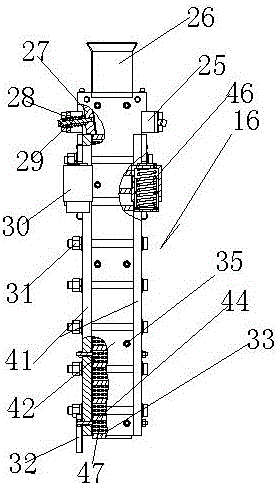

[0021] Embodiment 3: as figure 1 As shown in -4, the brick tea ring pressing equipment includes a ring track 1, and the ring track 1 can specifically be composed of a base 19, a support column 18, a bottom connecting rod 38, an inner track 21 fixed on the support main column 18, and an outer track. 20, its cross-section forms a U-shaped structure. The base 19 can be a polygonal structure formed by the connecting rods of the bottom columns, or a circular structure; the bottom connecting rods 38 are arranged in a triangle, so that the circular track 1 forms a stable U-shaped structure. On the circular track 1, there is a mold moving body 39 that moves along the circular track 1. The mold moving body 39 is composed of several roller bearing seats 22 that move along the circular track 1, and are arranged on two adjacent roller bearing seats 22. The upper mold supporting plate 43 is formed by the mold 16 fixedly supported in the mold supporting plate 43 by the connecting seat 30 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com