Vehicle body top cover mounting and positioning control method and device, controller and storage medium

A technology of installation positioning and installation position, which is applied to the controller and storage medium, the installation and positioning control device of the roof of the vehicle body, and the installation and positioning control of the roof of the vehicle body. , increasing difficulty and other issues, to achieve the effect of improving the appearance quality level, reducing the difficulty of process planning, and widely using value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to further explain the present invention, a specific implementation of a method for controlling the installation and positioning of a vehicle body roof and a device for controlling the installation and positioning of a vehicle body roof according to the present invention will be described in detail below in conjunction with the accompanying drawings.

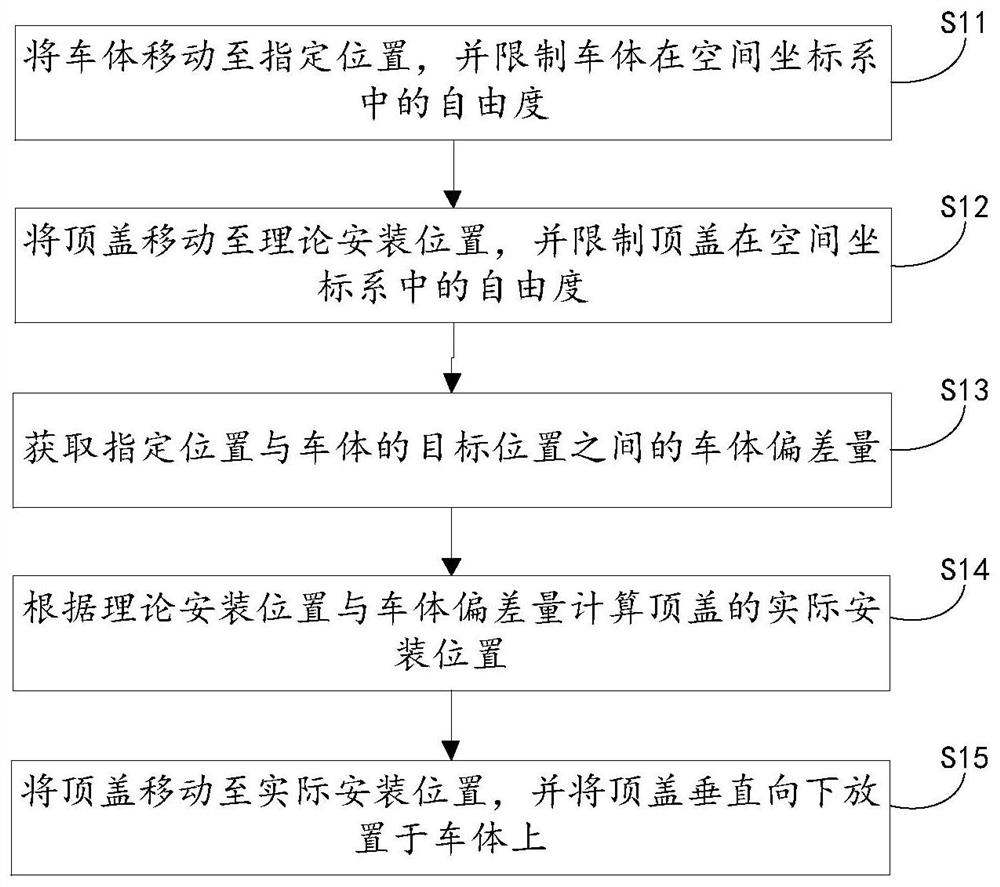

[0064] A method for controlling the installation and positioning of a car body roof according to an embodiment of the present invention, such as figure 1 As shown, the method includes:

[0065] Step S11: Move the car body to a designated position, and limit the degrees of freedom of the car body in the space coordinate system.

[0066] Specifically, such as Figure 6 As shown, the motorized equipment 61 is controlled to transport the car body 62 to a designated working position (namely a designated position), and the motorized device may be a transport roller bed. After the vehicle body moves to the specified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com