Full-hydraulic crawler-type self-moving trestle

A crawler-type, full-hydraulic technology, applied in the direction of pedestrian bridges, bridges, bridge parts, etc., can solve the problems of simple trestles without safety protection, high labor intensity, and low work efficiency, so as to reduce the labor intensity of workers and achieve a high degree of automation , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples;

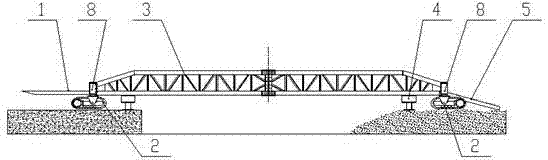

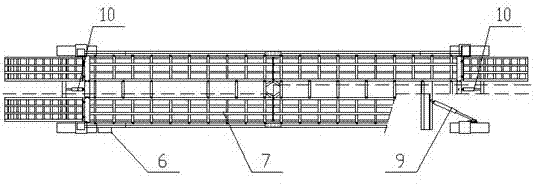

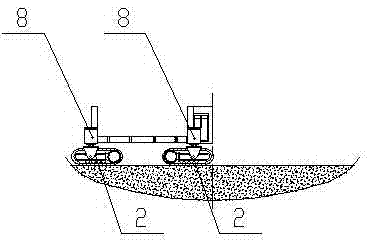

[0022] combined with figure 1 -4 shows a fully hydraulic crawler-type self-propelled trestle. When the fully hydraulic crawler-type self-propelled trestle is working, the front approach bridge 1 and the rear end approach bridge 5 are lifted to the horizontal position through the bridge approach hydraulic cylinder 10, and then the main lifting hydraulic cylinder is controlled. 8 Lift the crawler-type traveling device 2 to the position off the ground. At this time, the bridge pier 4 is under force on the ground, and then each crawler-type traveling device 2 is rotated 90° through the travel conversion cylinder. After completion, the crawler-type traveling device is lowered through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com