Construction technology for cantilever type U-shaped bent cap and precast beam component

A construction technology, horseshoe-shaped technology, applied in the direction of bridges, manufacturing tools, bridge construction, etc., can solve the problems of high cost, low efficiency, complicated on-site transportation operations, etc., achieve short construction period, improve accuracy, and be conducive to environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

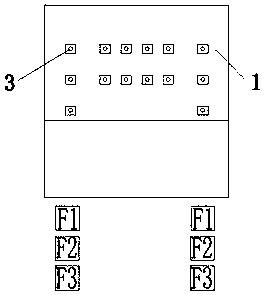

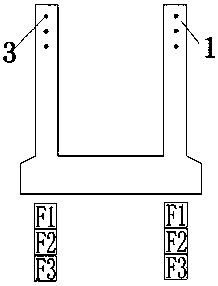

[0029] Embodiment one of the construction technology of the cantilevered horseshoe-shaped cap beam of the present invention, as Figure 1~9 As shown, this construction process is mainly used to produce cantilevered horseshoe-shaped cover beams. The process generally adopts prefabricated pouring in batches and gradually tensions steel strands at each stage to carry out the overall support-free construction of cantilevered horseshoe-shaped cover beams. Specifically, it includes the following four steps:

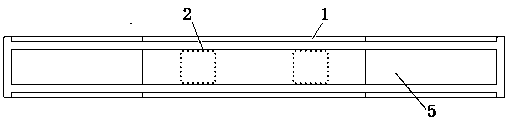

[0030] Step (1): If Figure 1~4 As shown: the prefabricated beam component is used as the bottom form and side formwork of the overall construction without support in the subsequent stage. 5 is a trapezoidal groove, and at the same time, a pre-embedded casing 2 is installed at the middle position corresponding to the bottom of the beam member and the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com