Plant factory planting automation system and use method thereof

An automated system and factory technology, applied in planting methods, botanical equipment and methods, applications, etc., can solve problems such as difficulty in large-scale promotion, application and industrialization, increased production costs in plant factories, and plants do not have price advantages. Achieve the effect of automated operation, improved mobile efficiency, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

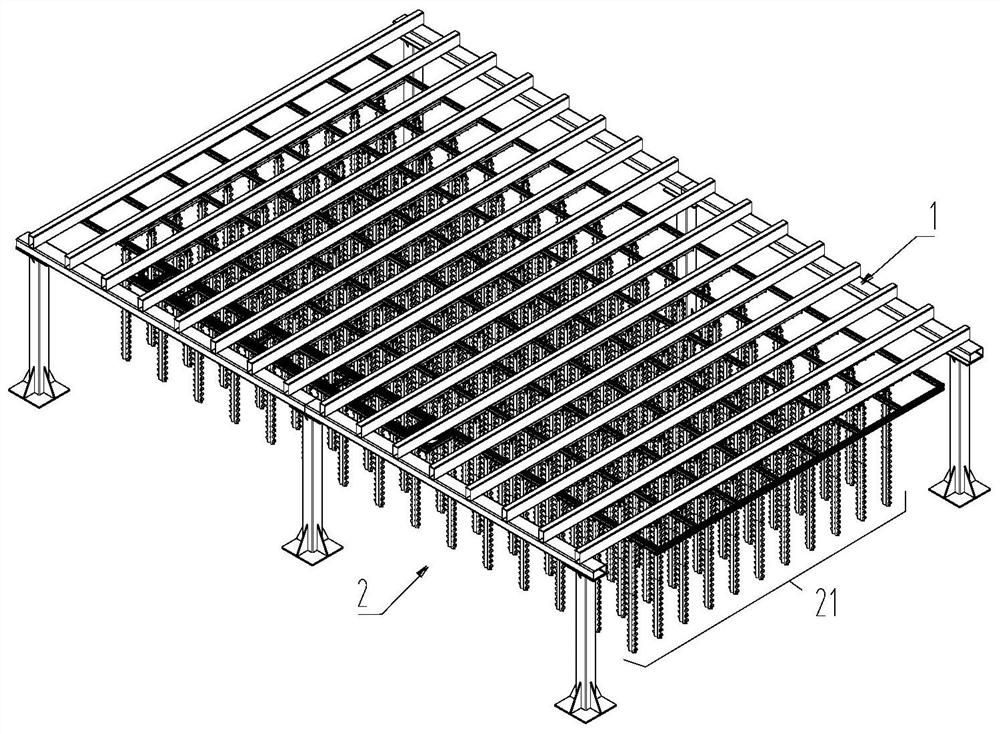

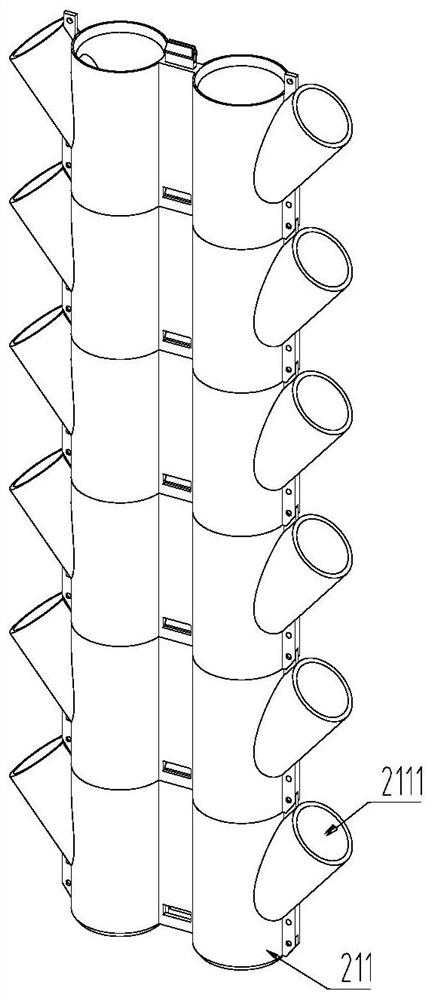

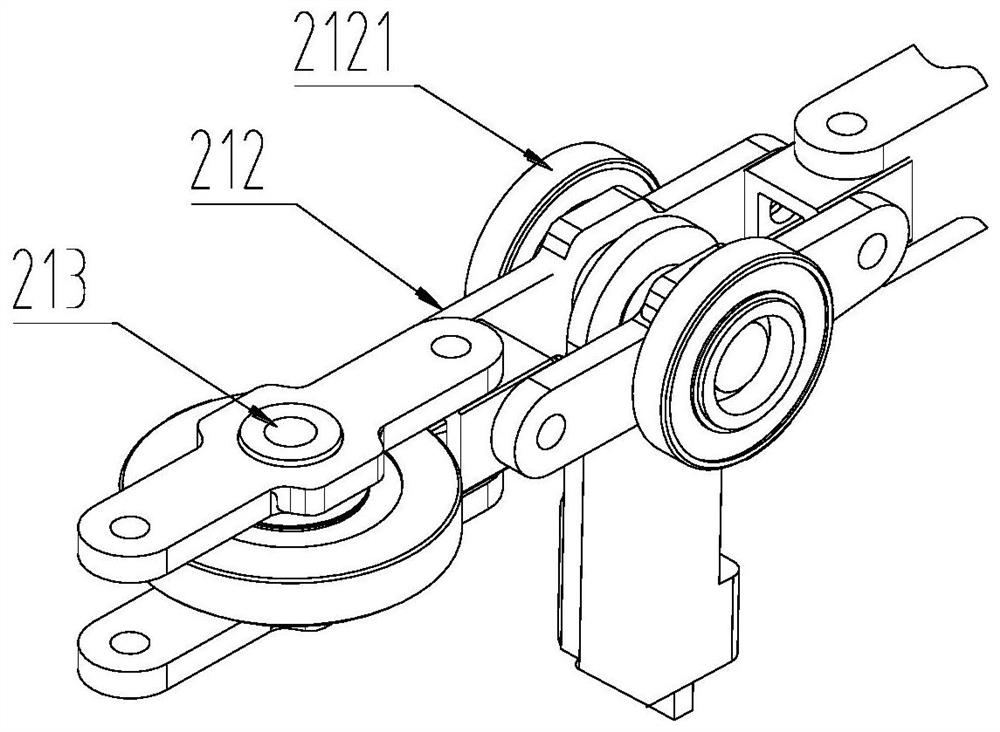

[0060] Embodiment 1: plant factory planting automation system, such as Figure 1 to Figure 9 As shown, it includes a frame body 1, a planting unit 2, a movable mobile unit 3, and a movable trolley 4. The planting unit 2 includes a plurality of planting rows 21 parallel to each other. The planting row 21 includes a connector 212 and a plurality of planting towers 211 suspended and fixed on the connecting member 212. The planting tower 211 is provided with a plurality of planting chambers 2111, and the plurality of planting chambers 2111 are distributed at intervals along the vertical direction, and plants are planted in the planting cavity 2111. The connecting piece 212 is a chain, and a plurality of first planting tracks 22 are installed on the frame body 1 , and each first planting track 22 corresponds to a row of planting rows 21 . The connecting piece 212 in each planting row 21 is located in the corresponding first planting track 22 . A plurality of planting load-bearing...

Embodiment 2

[0070] Embodiment 2: plant factory planting automation system, the difference with embodiment 1 is, as Figure 15 As shown, there are at least two planting units 2 and they are distributed on both sides of the mobile unit 3. The two turning planting tracks 322 in the second planting track 32 are distributed on both sides of the planting track 321 in the straight line section. A steering trolley 4 track 332 is distributed on both sides of the straight section trolley track 331. Frame body 1 is a split design, including frame body 1 and frame body 2. The first trolley track 23 and the first planting track 22 of planting unit 2 are all installed on frame body 1, and the mobile frame 31 is installed on frame body 2. The first planting track 22 is installed on the upper end and the lower end of the planting row 21 on the frame body, and the upper end and the lower end of the planting row 21 are provided with connecting pieces 212 . The first trolley track 23 is located under the f...

Embodiment 3

[0072] Embodiment 3: plant factory planting automation system, the difference with embodiment 1 is: as Figure 12 , Figure 13 , Figure 16 As shown, the mobile frame 31 is installed and fixed with a guide track 1, and track weighing rollers 1 are installed on both sides of the straight section trolley track 331, and the track weighing roller 1 is embedded in the guide track 1, so that the linear trolley track 331 can move along the guide track 1. Move on the mobile frame 31. The mobile frame 31 is installed and fixed with the guide track 2, and the track weighing roller 2 is installed on both sides of the straight section planting track 321, and the track load-bearing roller 2 is embedded in the guide track 2, so that the straight section planting track 321 can be placed on the mobile frame along the guide track 2. 31 on the move.

[0073] The moving frame 31 is equipped with a trolley track drive unit 311 for driving the straight section trolley track 331 to move, and a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com