Construction method of steel rib column beam-column joint

A construction method, column-beam-column technology, applied in the direction of construction, building construction, etc., can solve the problems of easy loose formwork, complicated construction technology, slow progress, etc., and achieve the effects of improving construction progress, easy operation for workers, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

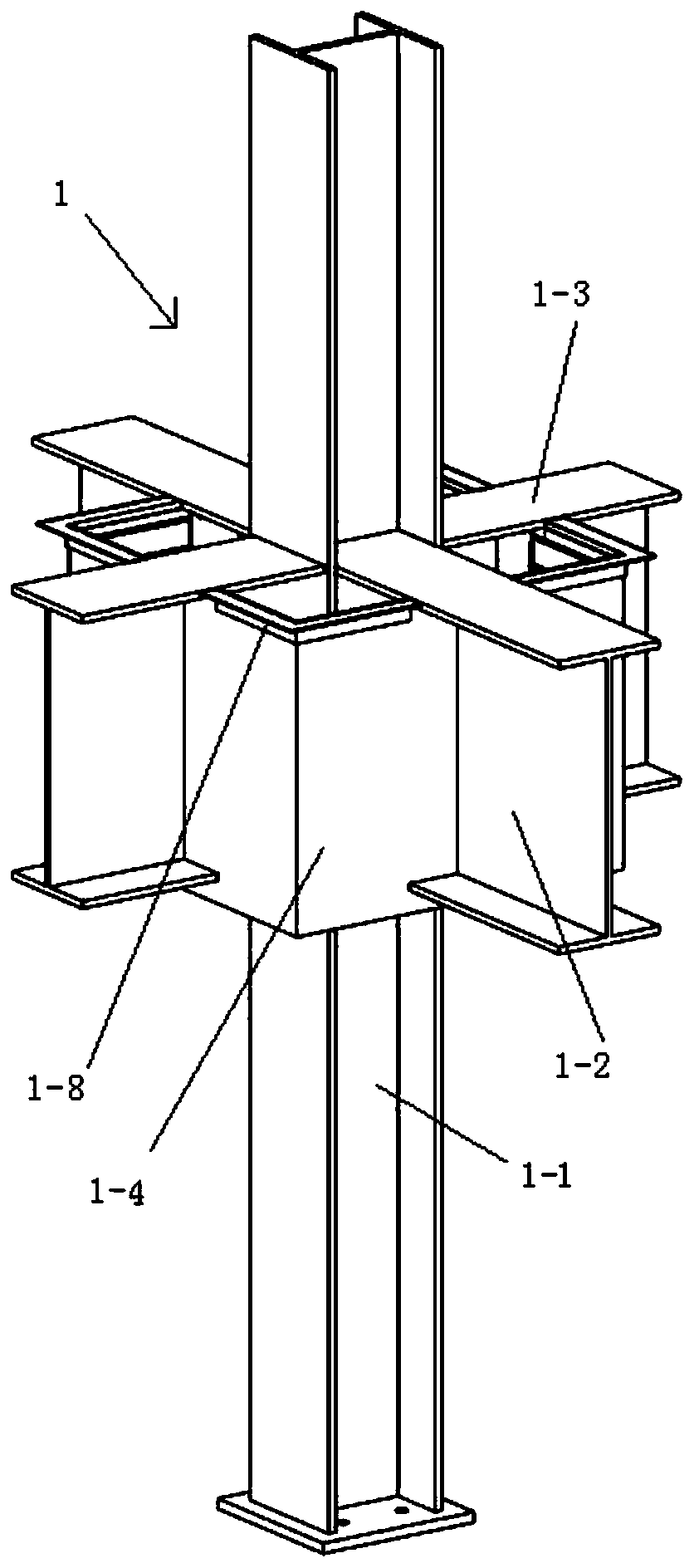

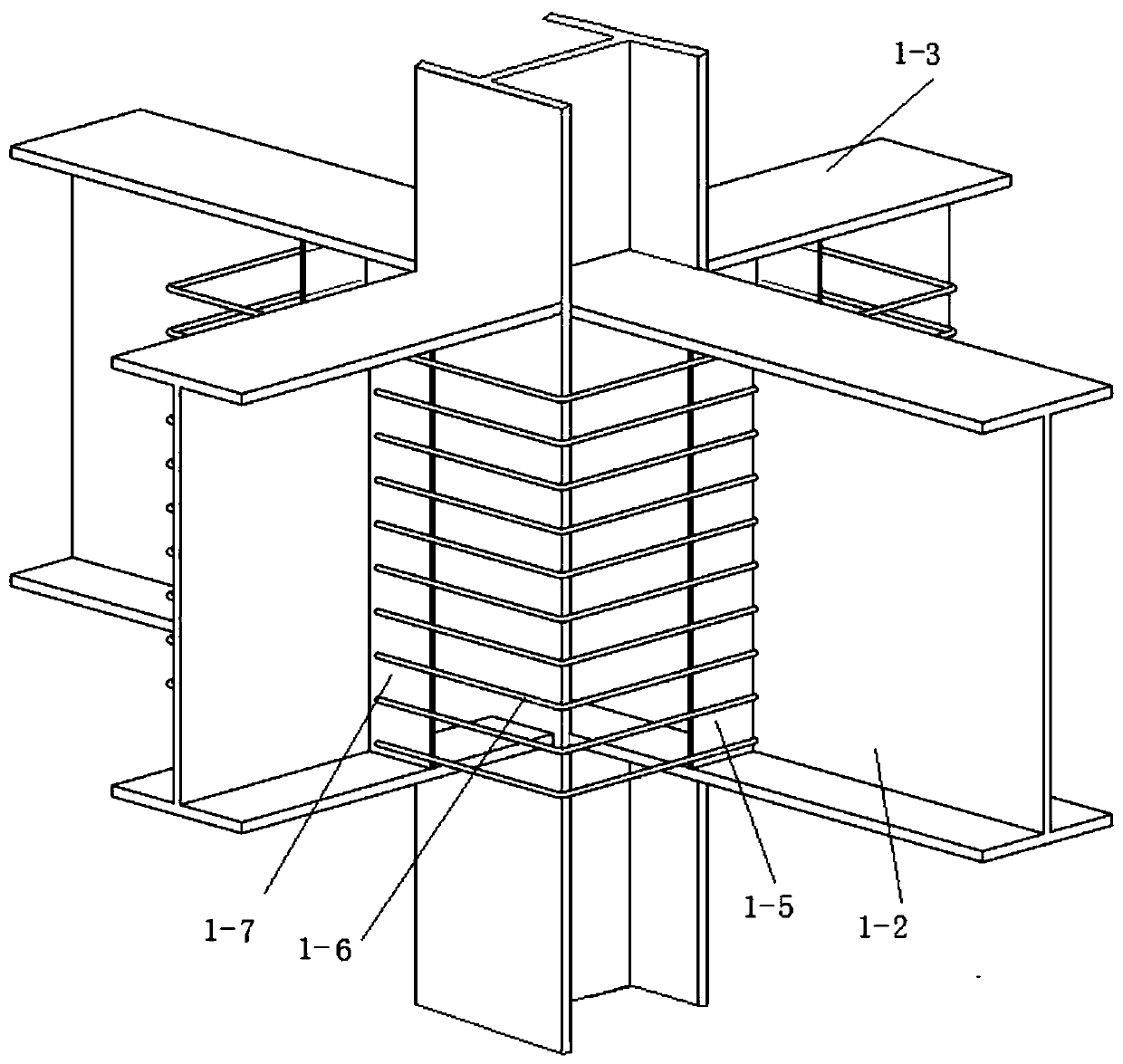

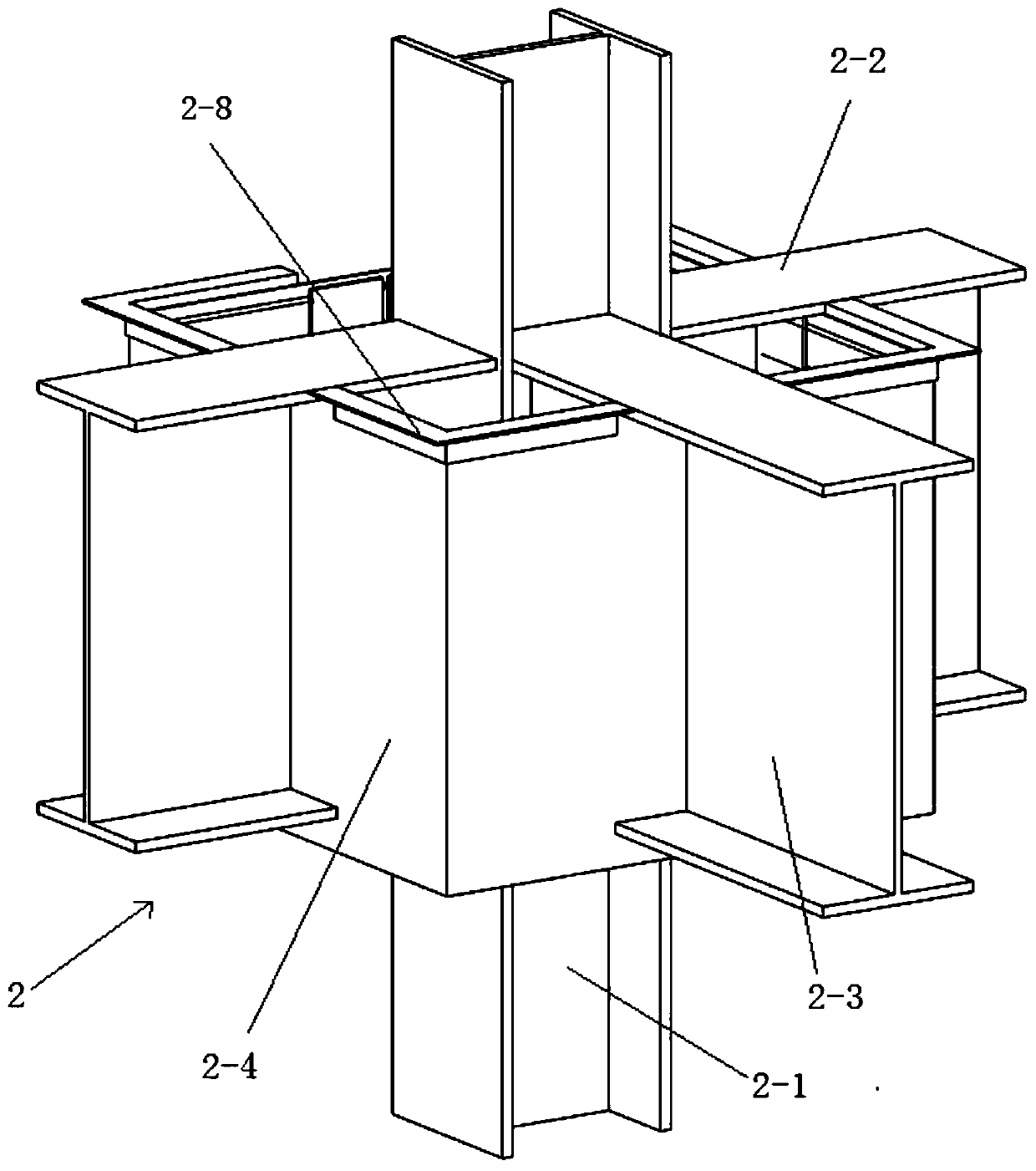

[0073] Such as Figure 1 to Figure 7 The construction method of a steel-framed column-beam-column joint includes step 1, processing the steel-framed column-beam-column joint shaped casing: the steel-framed column-beam-column joint shaped casing includes a cross-shaped beam-column shaped casing 1. T-shaped beam-column shaped casing 2 and L-shaped beam-column shaped casing 3. The specific processing process is as follows:

[0074] Step 101, the processing of the cross-shaped beam-column shaping casing 1, the specific processing process is as follows:

[0075] Step 1011: Weld two first connecting steel beams 1-2 symmetrically on one opposite side of the first steel column shaped steel 1-1, and weld two second connecting steel beams on the other opposite side of the first steel column shaped steel 1-1 Beams 1-3; wherein, two first connecting steel beams 1-2 and two second connecting steel beams 1-3 are arranged in a cross, and the first connecting steel beams 1-2 and the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com