River silt cleaning device and construction method

A technology for cleaning device and river silt, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of inability to clean the silt, large workload, etc., to reduce size, extend service life, improve stability and The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

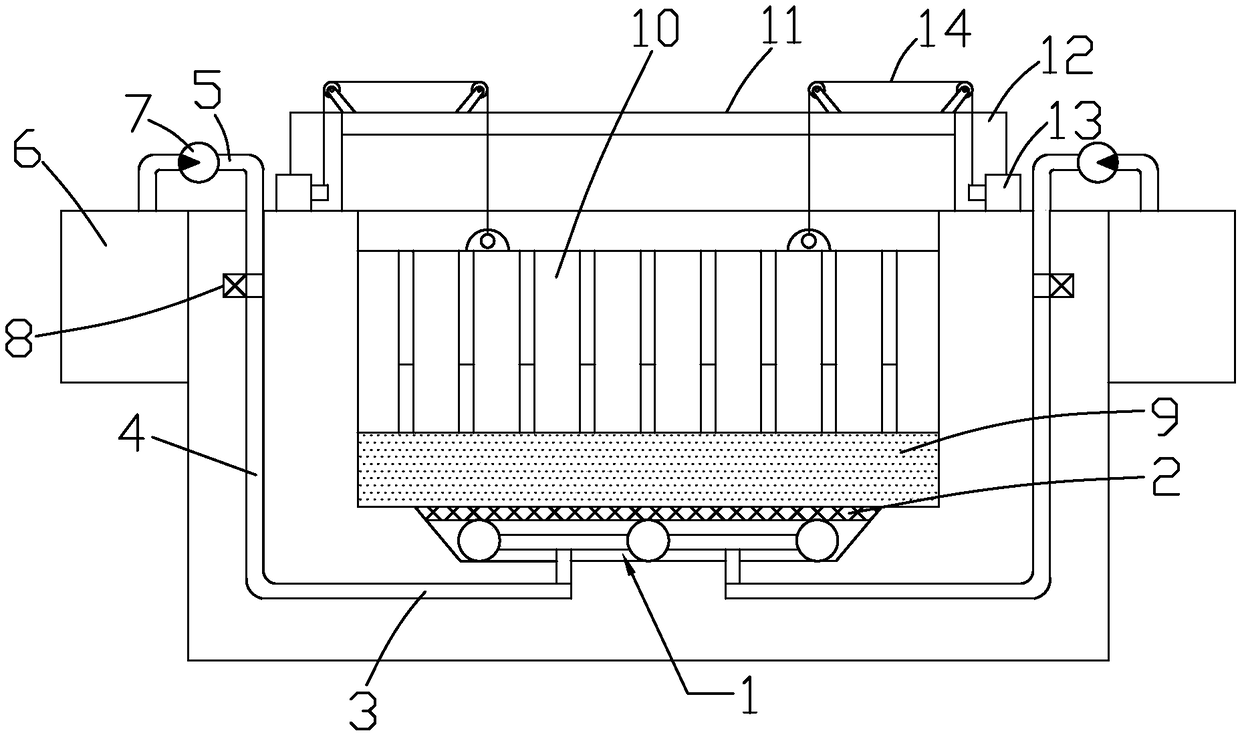

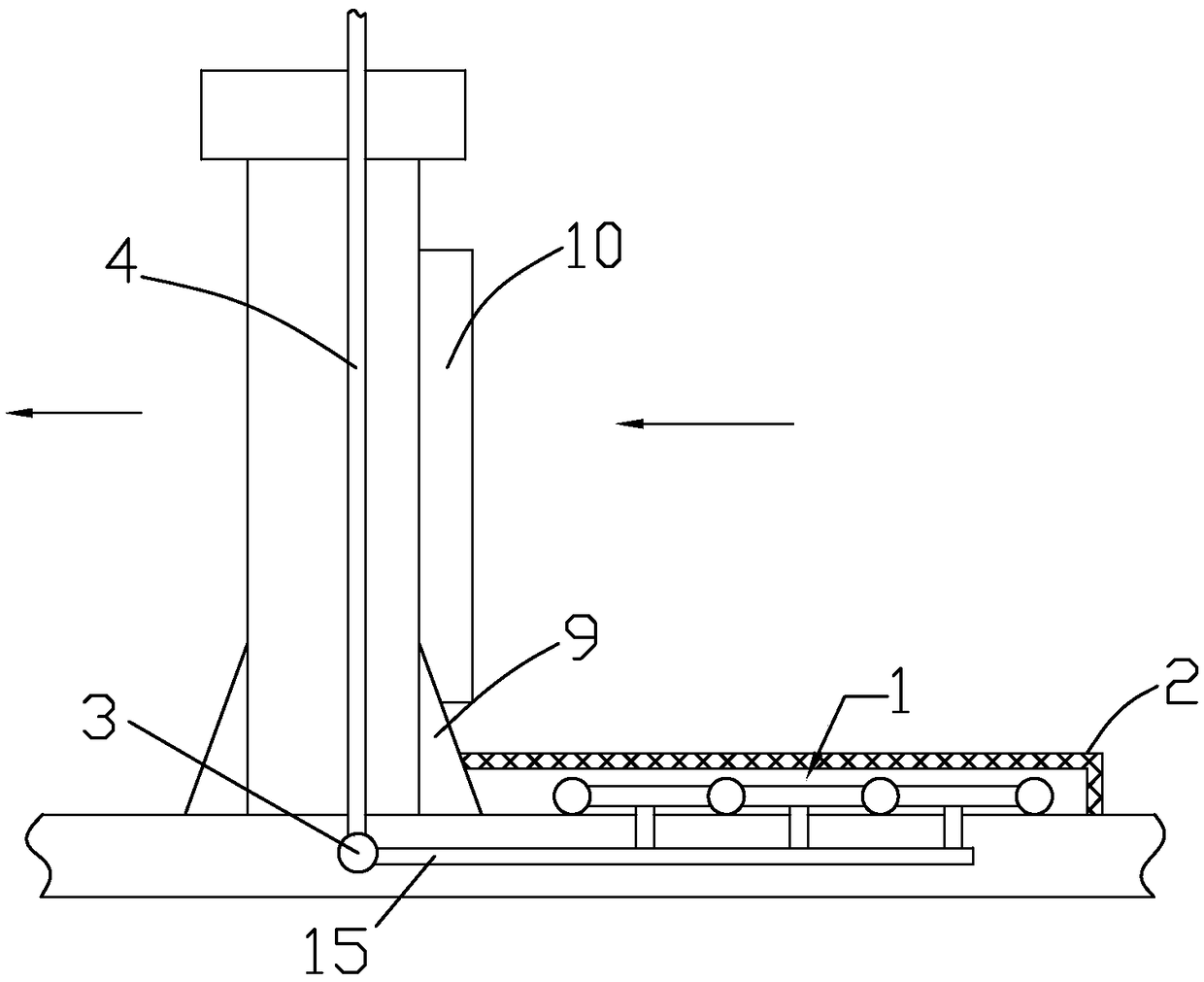

[0048] Such as Figure 1 to Figure 4 Shown here is a river silt cleaning device of the present invention, including a cleaning mechanism 1, a gate mechanism and a silt storage tank 6. The cleaning mechanism 1 is located at the bottom of the river, and the cleaning mechanism 1 is provided with a protective steel net 2 on the outside. 2Matching with cleaning mechanism 1, the protective steel mesh 2 can protect the cleaning mechanism 1, prevent larger stones from crushing the cleaning mechanism 1, extend the service life of the cleaning mechanism 1, and prevent the pipeline from being blocked.

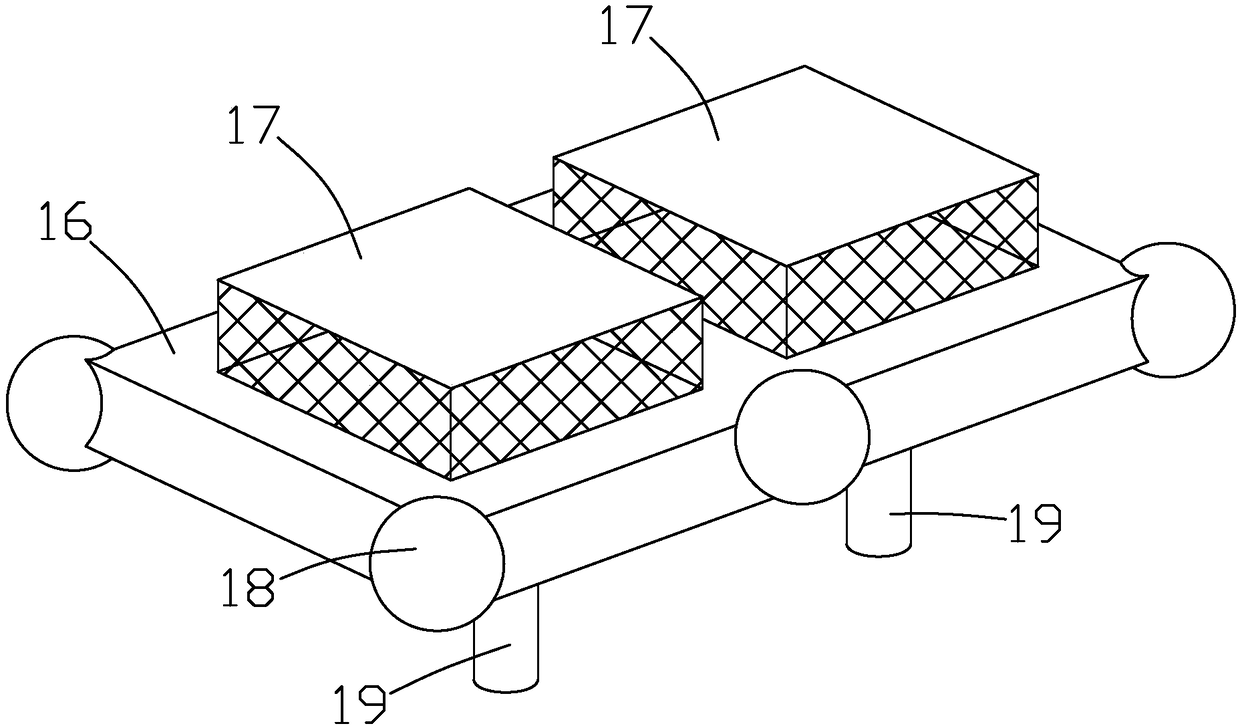

[0049] The cleaning mechanism 1 is formed by splicing at least three cleaning units. The cleaning units include a bottom plate 16 and a drainage device 17. The drainage device 17 is symmetrically arranged on the top surface of the bottom plate 16, and positioning blocks 18 are evenly arranged on the side surface of the bottom plate 16. The positioning block 18 is fixed at the bottom of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com