Point embedded Type heat preservation and sound insulation floor and construction method thereof

A construction method and sound insulation technology, applied in thermal insulation, floor slab, sound insulation and other directions, can solve problems such as incorrect placement of elevations, sloppy construction, user complaints, etc., to meet the dual needs of floor sound insulation and thermal insulation, and to solve noise interference and heat. Loss, effect with simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0039] In order to achieve the purpose of the present invention, in some embodiments of a point-embedded thermal insulation floor and its installation method,

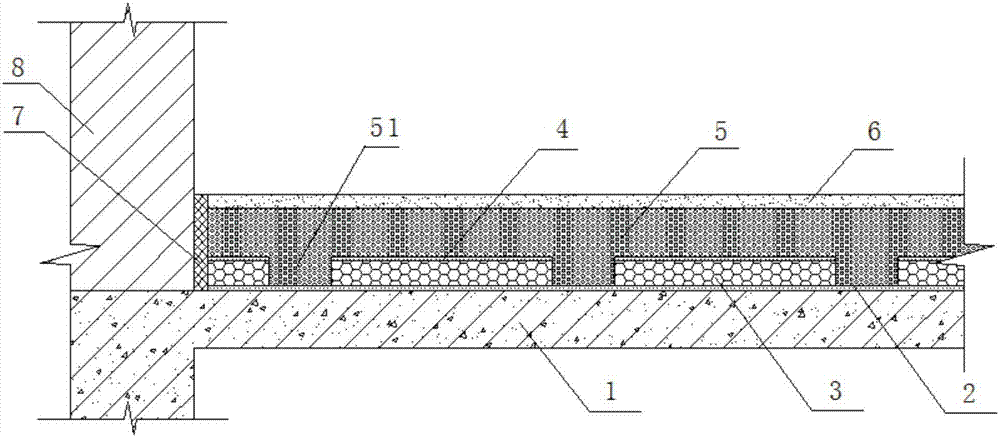

[0040] Such as figure 1 As shown, a point-embedded heat insulation and sound insulation floor includes from bottom to top: floor base 1, first interface layer 2, heat insulation and sound insulation net cushion layer 3, second interface layer 4, light mortar heat insulation and sound insulation layer 5 And cement mortar leveling layer 6.

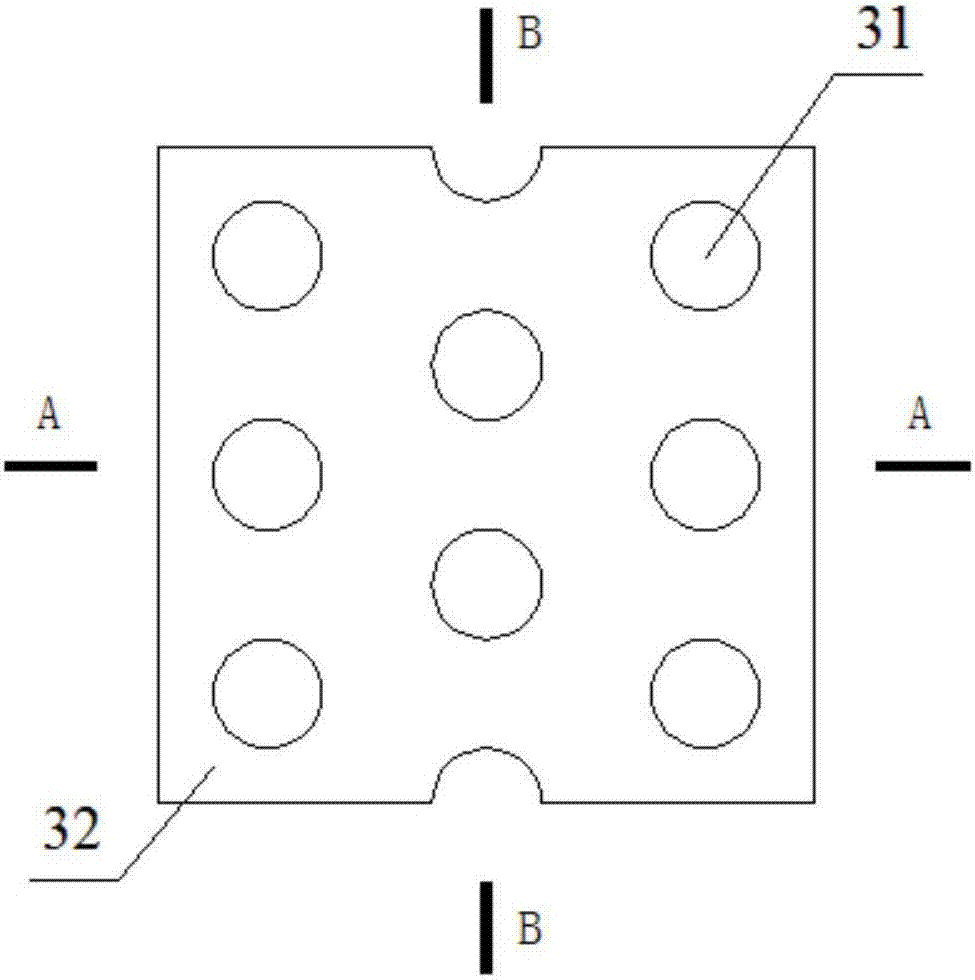

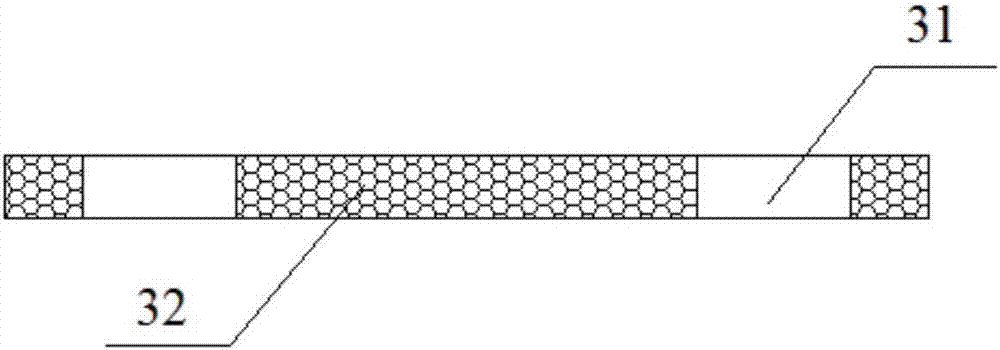

[0041] A plurality of through holes 31 are provided on the thermal insulation and sound insulation net cushion layer 3, and a plurality of protrusions 51 that match the through holes 31 and extend into the through holes are provided on the lightweight mortar thermal insulation and sound insulation layer 5, and the protrusions 51 The end surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com