Outer framework of post-poured belt of basement exterior wall and construction method of outer framework of post-poured belt of basement exterior wall

A technology for basement exterior walls and exterior formwork, applied in the field of construction engineering, can solve problems such as constraints, inability to isolate, and impact on the construction period of buildings, and achieve the effects of saving labor costs, concise steps, and easy to master.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

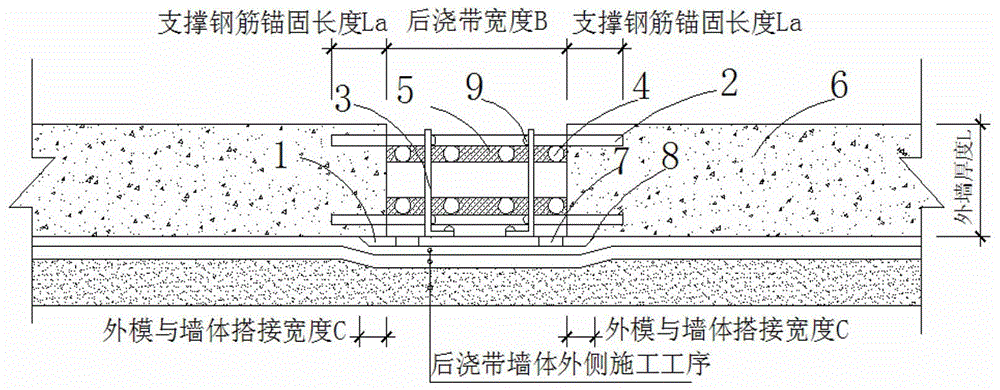

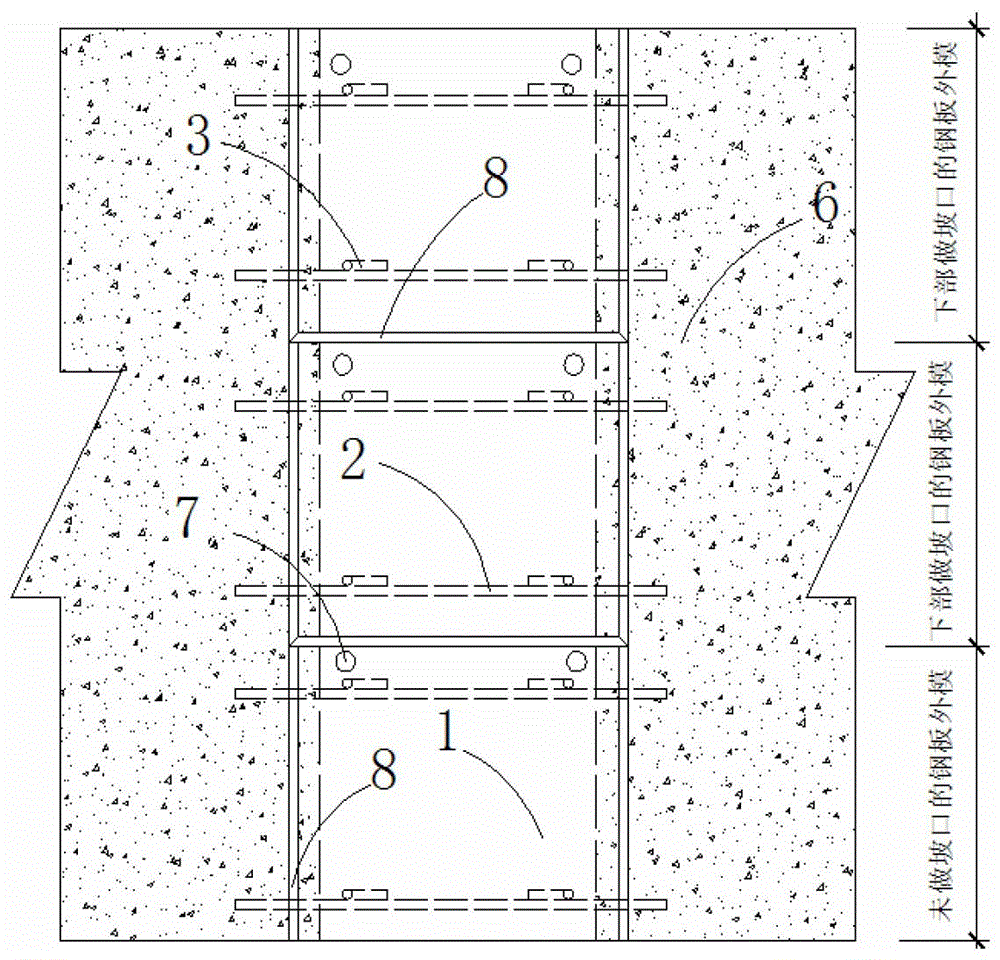

[0050] Such as figure 1 , 3 As shown in , 6 and 7, a basement outer wall post-casting outer formwork, the outer formwork 1 is composed of at least two steel plates spliced up and down sequentially, the upper and lower steel plates are fixed by welding, and the steel plates are provided with hoisting holes 7 . The outer formwork 1 is fixed by the L-shaped supporting steel bar 3 and the linear pre-embedded steel bar 2. It is connected with the outer formwork 1 by spot welding, and the other side of the L-shaped support reinforcement 3 is connected with the embedded reinforcement 2 by spot welding. The two sides of the steel plates are treated with 45° grooves, except for the bottom steel plate, the lower edges of the remaining steel plates are treated with 45° grooves, and groove welding is used between the upper and lower steel plates.

Embodiment 2

[0052] The construction method of the outer formwork of the basement exterior wall post-casting belt described in Example 1.

[0053] Such as Figure 1-7 As shown, the outer formwork 1 is composed of more than two steel plates spliced up and down sequentially, and the upper and lower steel plates are fixed by welding, and the steel plates are provided with hoisting holes 7; The buried steel bar 2 is fixed, and the two ends of the pre-embedded steel bar 2 are anchored in the basement wall 6 on both sides of the post-casting belt. One side of the L-shaped support bar 3 is spot-welded to the outer formwork 1, and the L-shaped The other side of the type support steel bar 3 is spot-welded with the pre-embedded steel bar 2; the two sides of the steel plate are grooved, except for the bottom steel plate, the lower edges of the other steel plates are grooved, and the upper and lower steel plates are used Groove welding;

[0054] The construction method includes the following outsi...

Embodiment 3

[0083] Further concrete optimization on the basis of embodiment 2.

[0084] A method for constructing an outer formwork of a basement exterior wall after pouring, comprising the following steps:

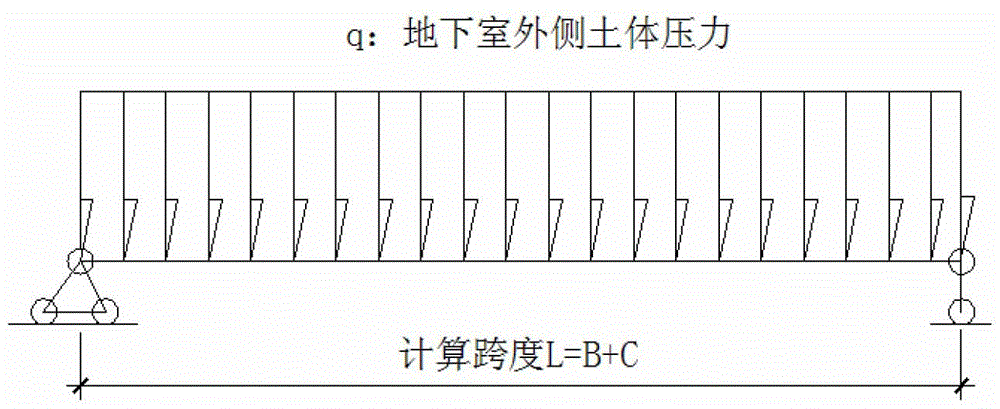

[0085] According to the simplified model of the steel plate formwork, check the calculation and determine the parameters of the steel plate;

[0086] Divide the steel formwork into blocks according to the height of the post-cast strip;

[0087] Manufacture the steel plate formwork according to the determined parameters;

[0088] According to the width of the post-casting strip of the basement exterior wall, the pre-embedded steel bars in the post-casting strip are processed and manufactured;

[0089] According to the thickness of the outer wall of the basement, the L-shaped supporting steel bars used to fix the outer formwork of the steel plate are processed and manufactured;

[0090] Install and fix the pre-embedded steel bars in the post-casting belt of the outdoor wall of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com