Distributed energy system utilizing dry quenching waste heat

A technology of distributed energy and dry quenching, which is applied in the heating system, steam generation method using heat carrier, heating method, etc., can solve the problems of reducing system economy and increasing initial investment of the system, and achieves cascade utilization, The effect of simple equipment structure and low electrical and mechanical power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

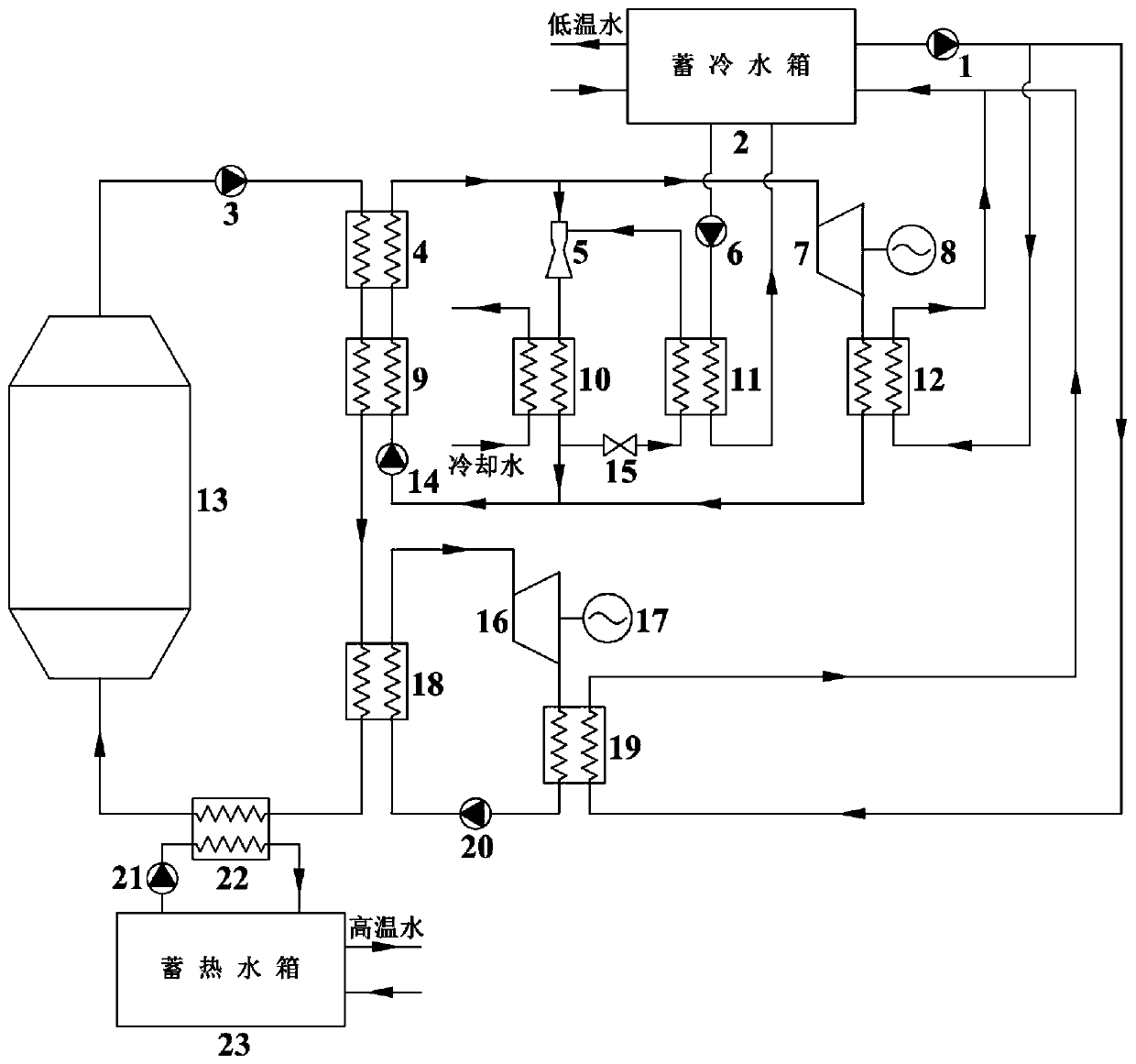

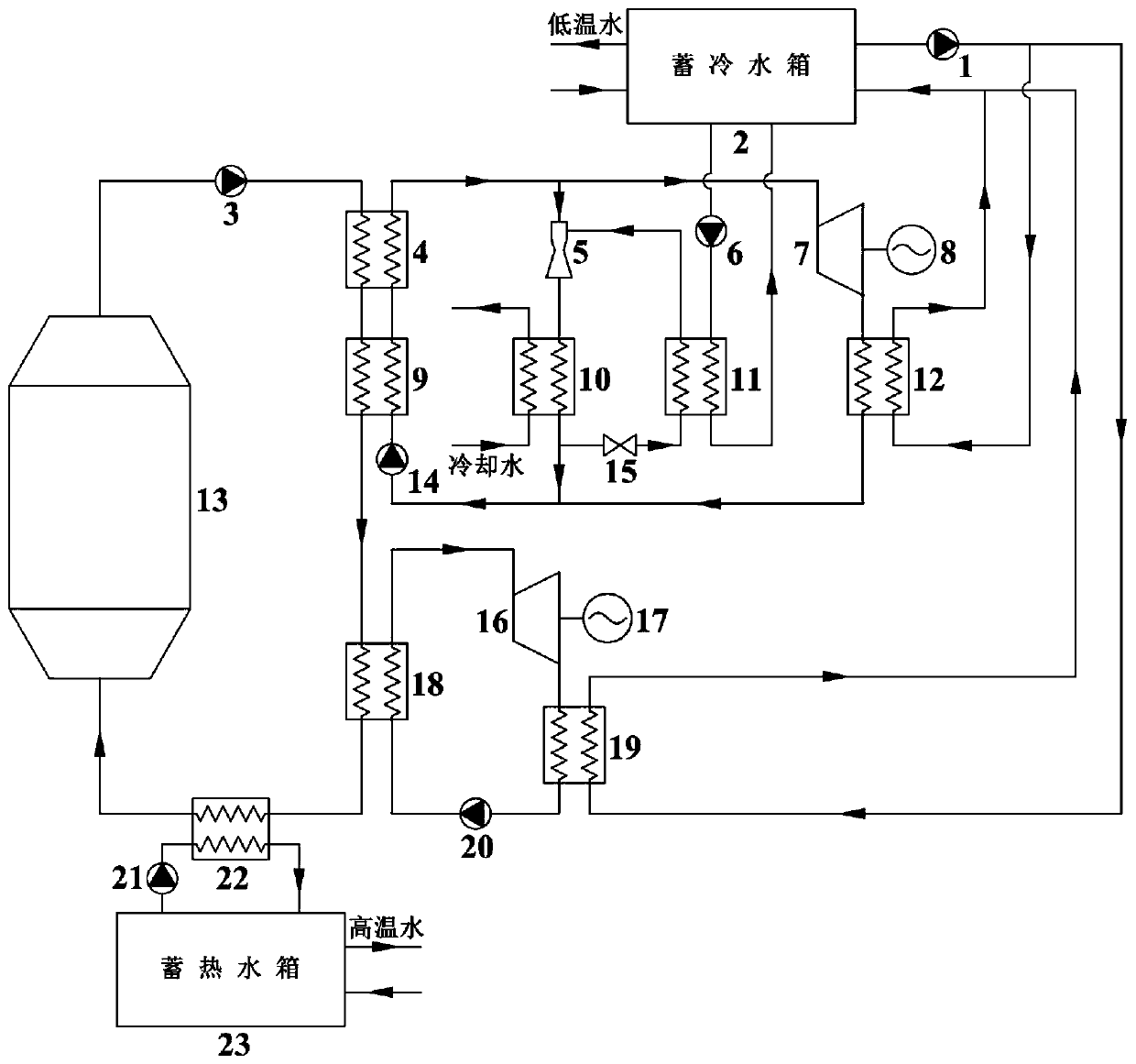

[0025] Such as figure 1 As shown, the present invention is a distributed energy system utilizing CDQ waste heat, including a waste heat recovery subsystem, a water vapor cooling power generation sub-system, an organic working medium power generation The steam cooling power generation sub-systems are connected through the steam superheater 4 and the first condensed water evaporator 9, the waste heat recovery sub-system and the organic working fluid power generation sub-system are connected through the organic working fluid evaporator 18, and the waste heat recovery sub-system The system is connected with the heat supply subsystem through a circulating gas-hot water heat exchanger 22 .

[0026] The waste heat recovery subsystem consists of CDQ furnace 13, circulating gas fan 3, steam superheater 4 circulating gas side, first condensed water evaporato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com