Automatic pipe feeding device of sealing machine

A sealing machine and automatic technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems that the filament cannot be guaranteed to enter the hole, the manipulator has a large range of motion, and the success rate of clamping the stem is low, and the loading and unloading time is short. , fewer mechanical actions, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

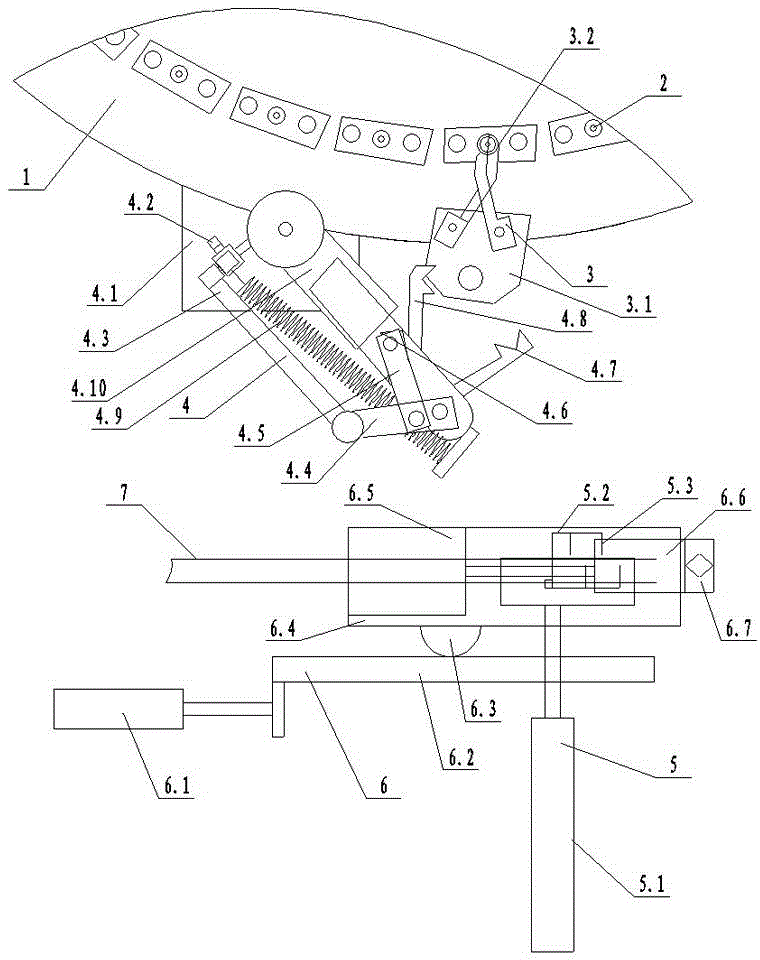

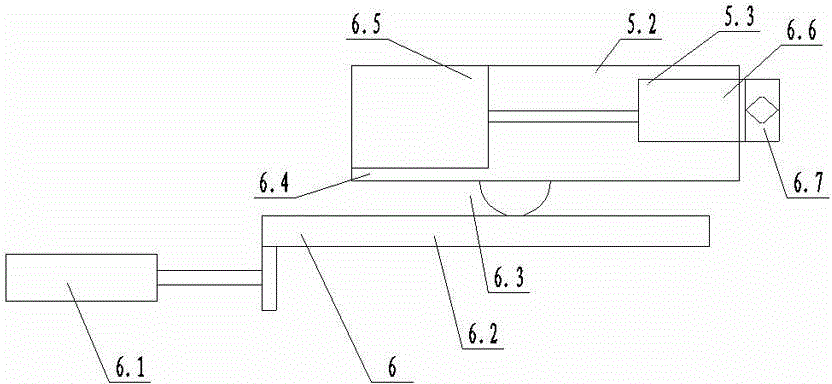

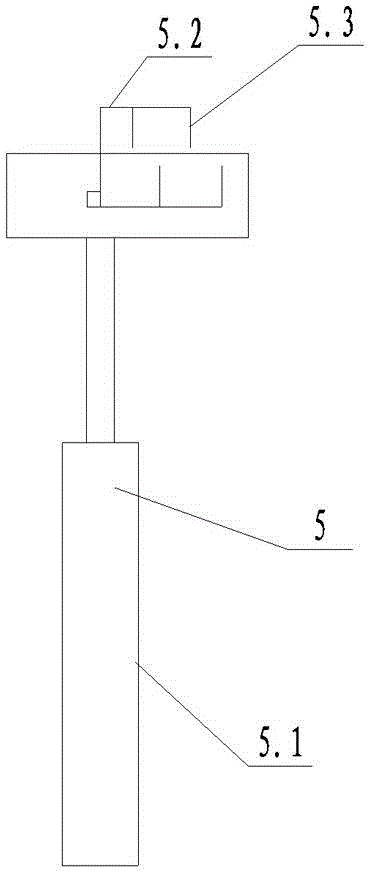

[0015] The automatic tube loading device of the sealing machine includes a stem separating device 5, a first transferring device 6, a second transferring device 4 and a stem guiding device 3, the stem separating device 5 includes a first telescopic device 5.1, and the first telescopic device 5.1 The piston rod is connected to the blocking rod, and the blocking rod is divided into two vertical rods 5.4. The top of the vertical rod 5.4 is connected to the cross rod 5.2. The gear teeth 5.3 are relatively staggered, and there is a gap between the front ends of the gear teeth 5.3 on the two crossbars 5.2. When the gear teeth 5.3 move forward and backward, only one stem moves forward through the gap, thereby separating the stem The effect of opening a certain interval.

[0016] The stem guide device 3 includes a guide base 3.1, and a guide fixture 3.2 is arranged on the guide base 3.1. When the guide fixture 3.2 is clamped, it is funnel-shaped. The guide fixture 3.2 can be driven me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com